-

Posts

612 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Remcohe

-

That is a lovely base for such a great model. Remco

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

I can imagine your frustration getting the moulding right. Making cuts with a scraper on such small piece is hard or even almost impossible. Unfortunately the moulding itself is hardly visible on the pictures. It's a joy to follow your progress on this little gem. Remco

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

I really love your miniature boats Remco

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Your carriages came out really well!! Remco

- 1,449 replies

-

I love all the details you're cramming into this little model. Makes me want to try something like this as well... Maybe I will allow myself a side project to get away from the planking I'm currently struggling with... But I shouldn't. Remco

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

HMS Naiad 1797 by albert - FINISHED - 1/48

Remcohe replied to albert's topic in - Build logs for subjects built 1751 - 1800

Lovely progress Albert Remco -

Wonderfull display of craftsmanship, I can only imagine how challenging it is to get the shapes of the planks just right to get an excellent fit. Remco

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Looking great Danny, the tennons are a nice detail on the stanchions. Remco

- 268 replies

-

Sorry to hear about your humidity issues. But that will sort out with the 'right equipment' I love your workshop, lots of space and light. Remco

- 889 replies

-

I totally missed the start of this beautiful build. On the upside I had a lot of catching up to do so Druxey you you made my day extra special Your choice of subject is great and your execution out of this world. I will stick to workboats as this barge is out of my league Remco

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

HMS Naiad 1797 by albert - FINISHED - 1/48

Remcohe replied to albert's topic in - Build logs for subjects built 1751 - 1800

Absolutely beautiful Remco -

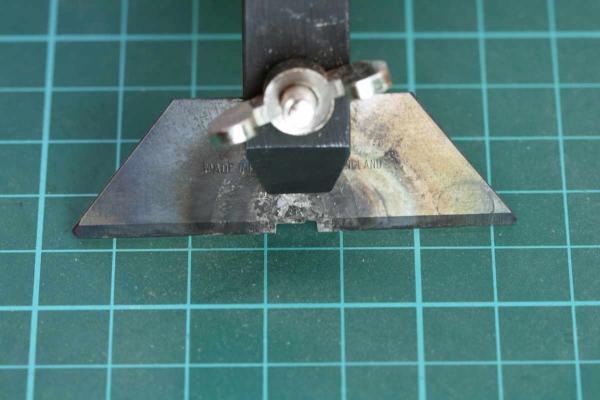

Nope, stupid questions don't exist, stupid answers do exist... Jan, first the blade is annealed, I use a small blow torch to heat the metal till it's bright red and then let it cool slowly back to room temperature. Now the blade is soft enough to use files and saws to make the shape of the waterway. Then the blade is heated till its red/orange and immediately dropped in a jar with oil, this is quenching. I used peanut oil as this was the only one I had in at hand. Then The blade is heat treated in a regular oven at 400F/205C Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Thanks all! I lost count Piet Greg the scraper worked fine at the curved sections. I just had to go slow and take very thin shavings. The vertical edges1 of my scraper are smooth so they hardly take any wood off, the horizontal side is sharp and does all the cutting. The scraper was made from a blade of a Stanley knife. The steel was treated to soften it for shaping and then hardened again to keep the edge sharp. It's clamped in a small hand vice to make the scraping easier. Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

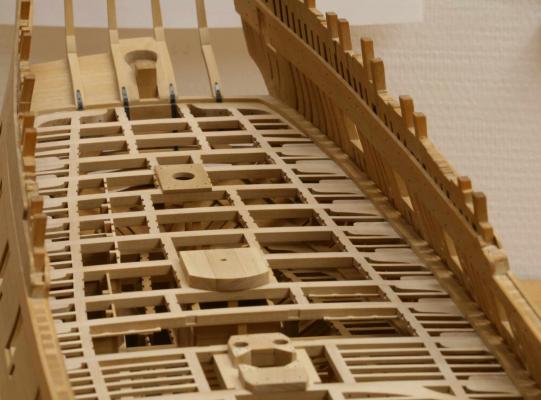

Between a side project to add more store capacity to my workshop (lots of extra drawers, can't have enough of them it seems) I installed the waterway. Using card templates to determine the shapes and home build scraper to get the typical profile of the plank (see last pic). The hook and scarf joints were extra tricky as the position of the waterway it self was fixed due to their shapes relative to the hull. So I had to get them right the first time. They all were ok, although sometimes I had to fill a minor gap with a small sliver of wood. The small piece at the bow connecting the port an starboard waterway was challenging. Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

That is a clever trick to cut the flanges! The overall result of your metalwork is great (again...) Remco

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Grant, Great project. To defog the instrument panel 'glasses' you can dip them in Future Floor Polish or an equivalent. Aircraft modellers use(d) this to make the canopy's clear. Remco

- 339 replies

-

- dumas

- Chris-Craft

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.