-

Posts

610 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Remcohe

-

I understand why you dreaded this part, yet you executed it beautifully. Remco

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

You have some nerve to cut the margin plank after it's fixed to joggle the ends deck planks. Remco

- 191 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Cutter Cheerful 1806 by rafine - FINISHED

Remcohe replied to rafine's topic in - Build logs for subjects built 1801 - 1850

Very nice planking Bob, Il like the subtle differences in the shades of the holy. Remco- 525 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Piet, given your current scheme the post should be green and not red, as the last band below the post is already red. The caprail yellow and if you can pul it of a thin yellow band below the posts. Or if you are opening the paint cans anyway you can alter the whole scheme to something like the Batavia. Remco

-

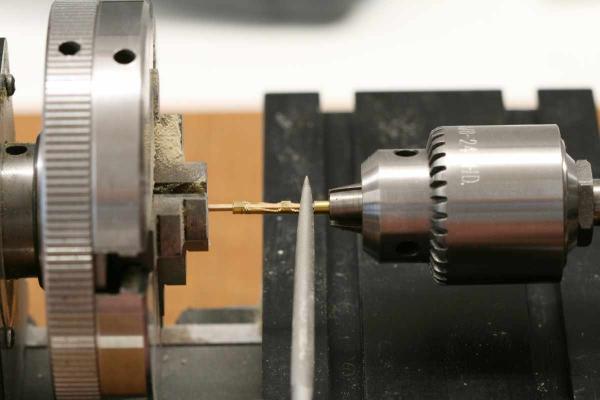

Mark, I think it might work. Although a file would probably fill up very quickly so maybe you want to adapt a regular cutting tool and turn the duplicator 90 degrees and feed the tool from the side as usual. only one way to find out... Remco

- 1,207 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

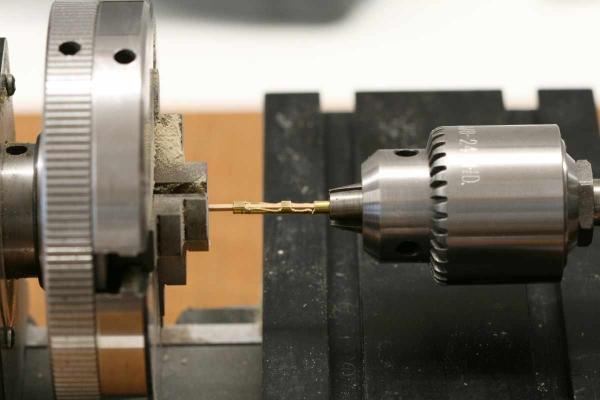

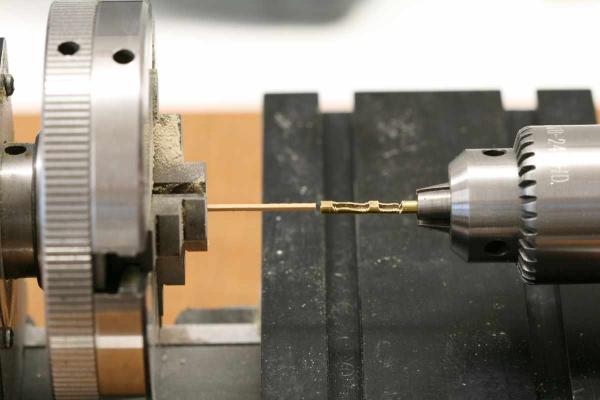

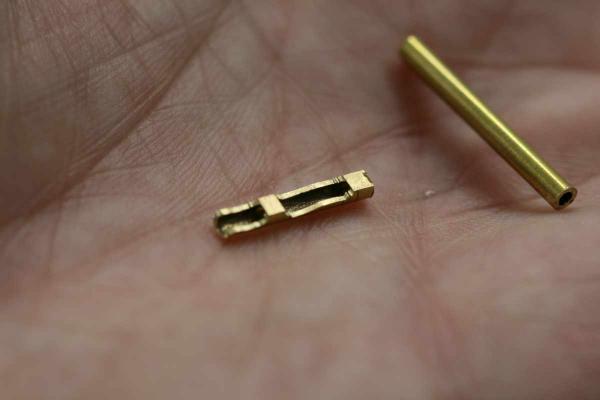

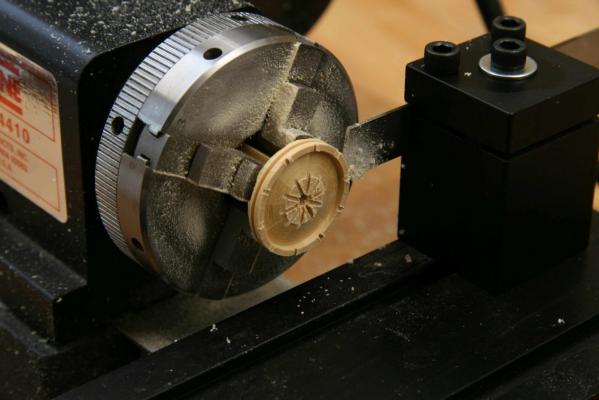

Thanks all for your very generous comments! Mike Y and Pat figured it out, I expected more of you would have Here is the setup on my Sherline It takes some practice to get it right as it is not an exact science. The inner diameter of the tube is a bit bigger than the stock so in the beginning it will flex under the pressure of the file, once the spoke gets thinner it will push against the file due to the centrifugal force. Practice makes perfect as always. After today no more spokes, I accidentally bumped into the jig and broke it :-( Remco ps TFFM refers to the excellent collection of books The fully framed model vol 1-4 by David Antscherl and Greg Herbert

- 1,207 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

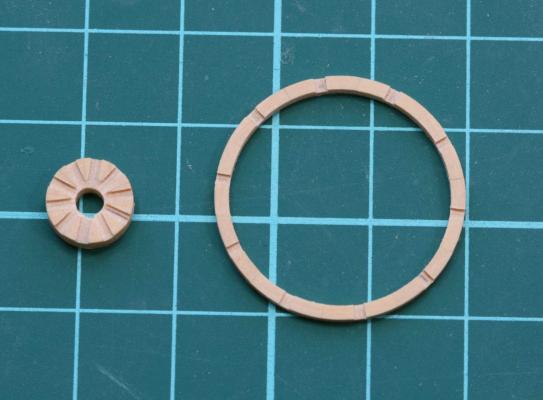

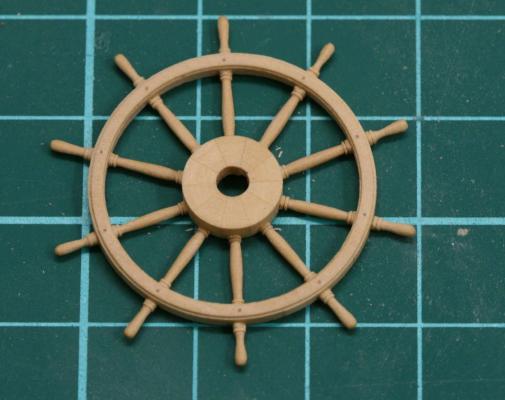

And now for something completely different. I took a break from the tedious deck work, intrigued by Garus' steering wheel on his excellent Victory and especially his duplicating device, I build the steering wheel. Using the technique described in TFFM 2 and 3. Not easy but lots of fun, frustration and multiple redo's later, the results: Remco

- 1,207 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

It all turned out beautiful in the end. Oh yes and "measure twice, cut once" and all the other hard earned lessons we all learned over the years. Still I tend to forget them very quickly and I don't know why. Maybe a shipwright is stubborn, luckily I'm very skilled at redo's ;-) Remco

- 2,207 replies

-

That sure looks great Greg. Do you have a picture of the finished stove, it would be a pity if we couldn't admire the result. Happy Thanksgiving. Remco

-

HMS Naiad 1797 by albert - FINISHED - 1/48

Remcohe replied to albert's topic in - Build logs for subjects built 1751 - 1800

Really great. Not easy to have the beam ends fit snug against the hull, especially where the hull starts to curve in two directions. You did an excellent job. Remco -

Jan, I don't remember where I got it. I probably bit the bullet regarding the shipping costs. I searched for you and if you get it from amazon (uk) the shipping costs are ok: http://www.amazon.co.uk/Extended-Liver-Sulfur-Patina-Oxidation/dp/B004PLZ4SS Remco

- 1,207 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

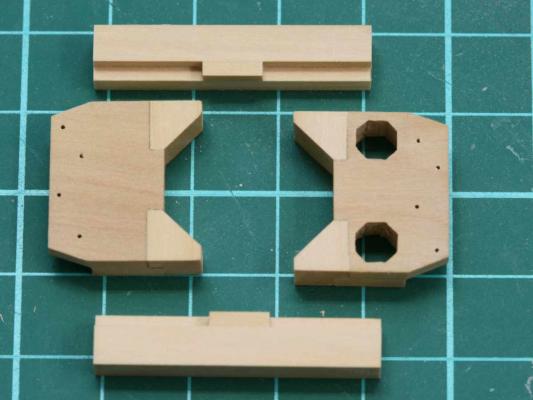

I made an error in the building sequence and I should have installed the main mastpartner earlier. Now I got a bit into trouble getting it in at this stage. I had to take a shortcut and omitted half lapping the carlings under the deck beam. After the gratings are installed this won't be visible, but I'm confessing this error anyway :-) Getting the pump tubes right was a bit of trial and error but after not to much work they were in place without to much hassle, I guess I was lucky today. I added iron bands at the end of the tubes from thin paper. Remco

- 1,207 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Cutter Cheerful 1806 by rafine - FINISHED

Remcohe replied to rafine's topic in - Build logs for subjects built 1801 - 1850

The 3 holes look great Rusty, indeed no easy task. Remco- 525 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Nice port Mike. I don't think there is a silver bullet to do this, maybe the closest thing might be 'patience' Remco

- 967 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Very nice progress Ed! Though I thought the same as Jan, quite a hazardous setup IMHO. I prefer to use a table saw to performs such cuts. Safer and faster if you take the time to set up a simple jig. Remco

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.