-

Posts

2,227 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by EJ_L

-

-

That is what I had till it broke a few weeks ago. Worked great but didn't last long, (I bought it in January). I'm gonna try to get something with adjustable temperature and an on/off switch. Might help prevent burn out on the next one. The end piece on the electric plank bender is just held on with a screw so I can always switch it to the new one.

-

I have not tried steaming yet. The closest I have come to that has been to soak the wood then use a hot air gun when bending. That worked okay but not as good as a hot iron. Of course care must be taken not to burn the wood with the iron so steam may have the advantage there. Might give it a try till I get a new soldiering iron.

-

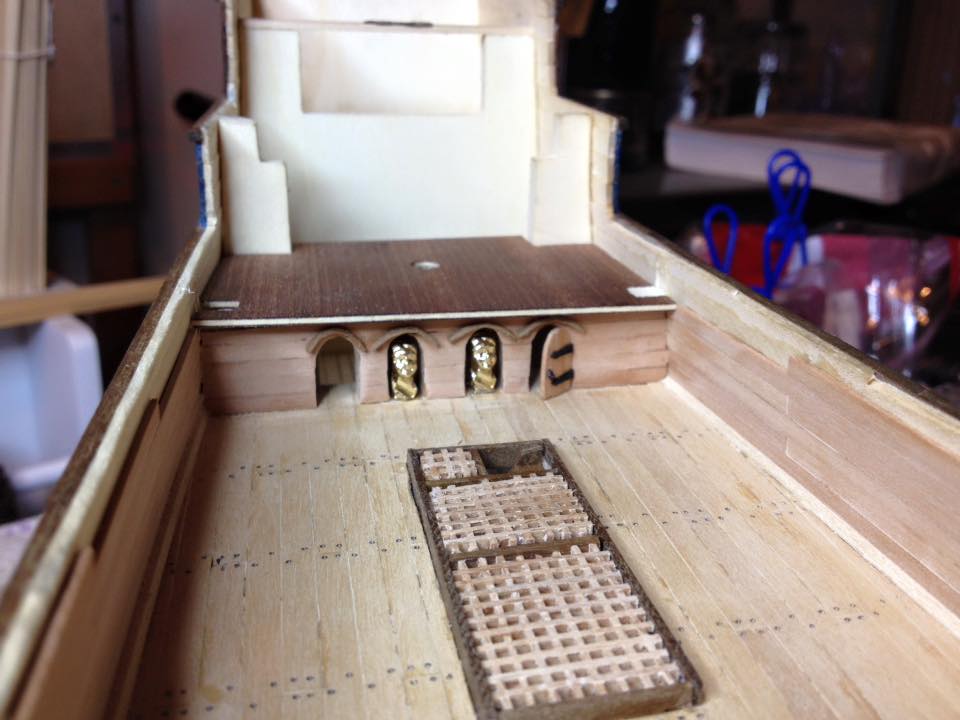

So after spending the last couple of days looking at the results on the cabin bulkhead, I decided that I was not happy with the trim arches over he doors and alcoves and so they are now in the trash. My plank bender crapped out on me a few weeks ago and I have not yet bought a new one so I had tried to bend them without it to less than satisfactory results. Now I am making new ones and carving the arch instead of bending it. So far I am much happier with the results. Pictures soon to follow.

-

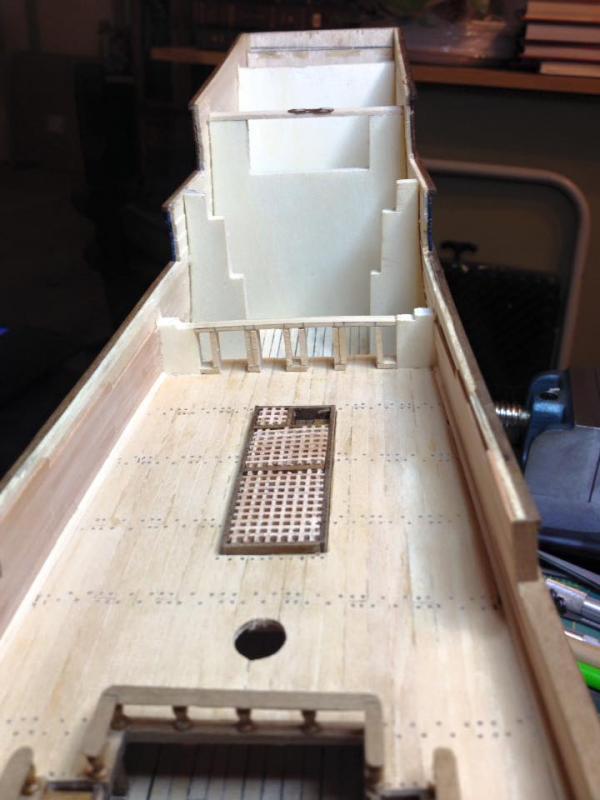

So this week has seen a lot of smaller details come together. I got ladders built and installed from the upper gun deck to the spar deck, railings installed, more cargo hatch gratings built and most of one of the cabin bulkheads built. Still have one more door to build and some clean up to do but overall a lot has changed. She is starting to come alive with these details.

- marktiedens, KenW, WackoWolf and 9 others

-

12

12

-

I second Don in saying real good idea for the anchoring the canons. I have had a few come loose over the years and that is a nightmare trying to put them back in place after decks have been installed and rigging has gone up. That will be great insurance against the glue not holding.

-

-

Planking those areas will make the model look a lot better. Good job on that.

That is rough looking wood. I was curious as to the quality of the lumber provided for the planking. That can be used for framing or areas that won't be seen but I hope the wood for the upper decks and the hull is a lot better.

-

Incredible Johann! Every update continues to amaze me with the level of detail you manage to put into such a small space. Beautiful work!

- paulsutcliffe and mtaylor

-

2

2

-

Sorry to hear about your injury. That has to be frustrating on many levels. Rest up and heal and we will be here ready for your return!

- cog, aydingocer, mtaylor and 1 other

-

4

4

-

I would plank the bottom deck at least where you could see under the grating. I think in the long run you will be happier knowing that it has been planked even if you can just barely see it. I typically only paint black where the space is completely false. All the decks below the upper gun deck on my Couronne build are completely false decks so any openings in the hull or deck are black. Everywhere else has been planked though very little is actually visible.

Also I would use the lighter wood. If you go that route you should be able to see it down through the gratings better than the darker. If you are going to put the effort into doing the extra work you may as well be able to see it and enjoy it.

-

Looking good!

I don't think I could use food as weights as my weights would constantly be getting lighter...

- Canute, marktiedens, Patrick B and 8 others

-

11

11

-

I think I may know what I will be asking for for Christmas....

-

Thanks for that fascinating article. I feel for those tug boat pilots as that has to be a nerve racking job. The canal has been a tight squeeze for a long time and although this new system will probably be better in the long run, like the article states, there will be a steep learning curve and the first few months there will probably be a lot of "white knuckled" pilots.

-

Indeed thanks for sharing the pdf Michael. I'm not building the Vasa...yet,

however the similarities between her and la Couronne in regards to rigging make this a valuable asset for when I start her rigging. Plus it will be good to have in the files for future use.

however the similarities between her and la Couronne in regards to rigging make this a valuable asset for when I start her rigging. Plus it will be good to have in the files for future use.- md1400cs, Salty Sea Dog, WackoWolf and 1 other

-

4

4

-

It is very unfortunate as this would be a fun kit to build alongside another as the down time between package arrivals would allow for the second ship to be built. One can always hope for change in the future.

-

Those parts look like they are of decent quality. Joints look clean and it appears that so far you have not had to do much of anything to get them to fit together. Off to a great start! I am like you in that I hate waiting for stuff to show up in the mail. I think though that as you get further into this project you will appreciate the wait times as the difficulty increases. Right now though I am thinking that this would be a fun kit to work on along with another model further on in it;s build. Every few weeks when the next steps show up would be a nice break from endless planking or rigging.

-

-

Chris,

This is great information and although I find myself chuckling quite a lot while reading it as I used to find myself having to give similar explanations on the value of handcrafted wood work vs mass produced pieces when I was selling my own work at shows.

As you have stated often MSW does get a lot of inquiries about the value of random generic ships and many people don't understand the difference between the cheap one from China that was purchased at a store or a well crafted model by a master craftsman. Or the other big misunderstanding that even if it was handcrafted and has been in the family for generations it still may not be of any value other than sentiment as often the quality of the work is no greater than that cheap decoration ship from China.

It is good that you are taking the time to educate people. Much like Chuck's thread on banned ship kits and the reasons behind the ban, this kind of message can seem mean, cruel and unfair but if understanding can be achieved then appreciation of the true values can be had and the community becomes richer as a result.

- ccoyle, CaptainSteve, mtaylor and 1 other

-

4

4

-

Bill said what I was going to Elijah. You are doing a great job and seem to be finding a comfortable talent in ship modeling. Keep this work ethic up and I predict you will have a very sucessful future both in this hobby and in your daily life.

- Canute, robnbill, Gerhardvienna and 2 others

-

5

5

-

Ulises,

You bring up a good point in saying that the life of a ship was largely dependent upon such a simple thing. It is crazy to think that without this simple item of rope, ships for thousands of years were in a way just floating pile of timber no better than a simple rowboat.

I think that from reading through this thread that the enjoyment of rigging isn't always so much in the actual act of rigging but in both the relief of having completed hundreds of hours of hull planking, carving, and furniture building and can now do something else, as well as the awe factor that a ships rigging inspires. Miles of rope that to the average person looks like a confusing tangle that no one could understand is actually what allowed ships to perform. To ship enthusiasts this is comparable to engines in sports cars. This is the power and control of a ship. I think that is why so may of us enjoy rigging. We are building the engines of our ships and bringing them to life.

-

Sunday has been another very productive day as I now have all of the supports in place and trimmed out. Ended up making 14 of them in total. Time to build a couple of ladders and a capstan to complete the upper gun deck. I will have to build supports for the ships boat but those will wait till I build the actual boat so I can make sure I get the cutouts for the hull correct.

- md1400cs, zoly99sask, MEPering and 7 others

-

10

10

-

I built one of those a long time ago. I think it is in the collection at my dad's house now. Sometimes it is good to take a break a work on something you are more comfortable with. That when I work on my model railroad. Different materials and subject matter as well as difficulty level can like you have said, restore confidence in your own work as well as just simply provide a break.

Good luck to you and I look forward to your return!

-

Thanks Bob!

The planned supports were massive, out of scale arches built into the bulkheads. I have left them in for the primary deck support but only after extensive modifications to make them look a lot better. I'm still not completely happy with them but I moved on. I figure there are more important things to fret over.

I have noticed that one of the downfalls to POB kits is that often the manufacturers make the upper deck supports and frames much thicker and out of scale then they should be. I understand how this happens as they are made from a uniform piece of wood and where it will not be seen it is fine. However, on a ship like this one where parts are exposed or they create the top rail, they will not work. I have removed everything that was preformed on the bulkhead above the spar deck and hindsight being what it is, I wish I would have just cut them off at the upper gun deck and built my own framing from there. Oh well, live and learn for the next one.

- skipper1947, WackoWolf, md1400cs and 4 others

-

7

7

-

Just caught up on your build. She is looking good and you definitely have the saw dust flying! Good plan on saving the dust for filler later. It is always nice to have some laying around especially for small areas. I will follow along with your build and look forward to seeing her come together.

Battle Station by cobra1951 - FINISHED - Panart - 1:23 - Also known as Posto Di Combattimento

in - Kit build logs for subjects built from 1751 - 1800

Posted

Very nice. I'm enjoying seeing the details at this larger scale. Especially the rigging which is nice as with smaller scales it can often be hard to see just what the ropes are doing. This also makes your photos look like they are on an actual ship rather than just a model of a ship. Of course that is also due to the great job you are doing on building these models.