-

Posts

2,007 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Trussben

-

Mike, I'm going to follow Druxeys advice and only glue one side of the floor filler, that way if movement does occur it may make a gap but shouldn't cause the twisting that destroyed my original build. Ben

- 889 replies

-

Very glad to hear you will be making new progress and showing us your results. Ben

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Looks great Toni, and a happy new year. Ben

- 1,449 replies

-

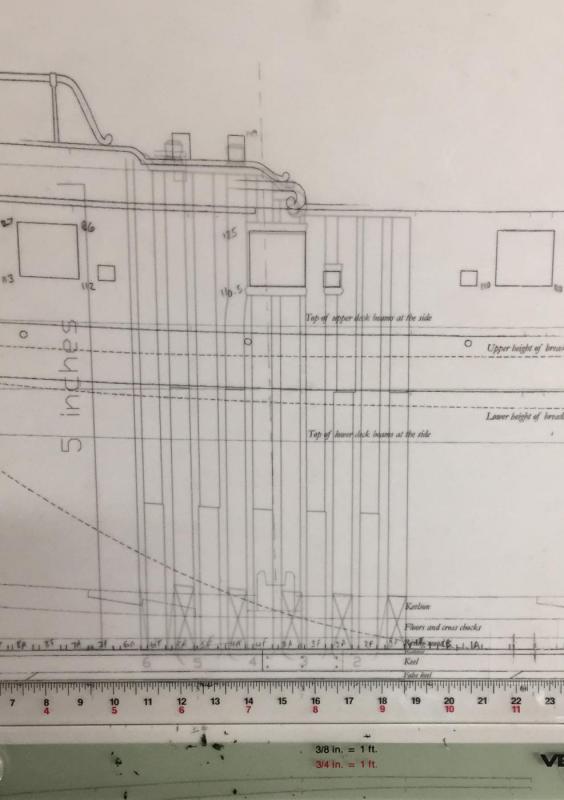

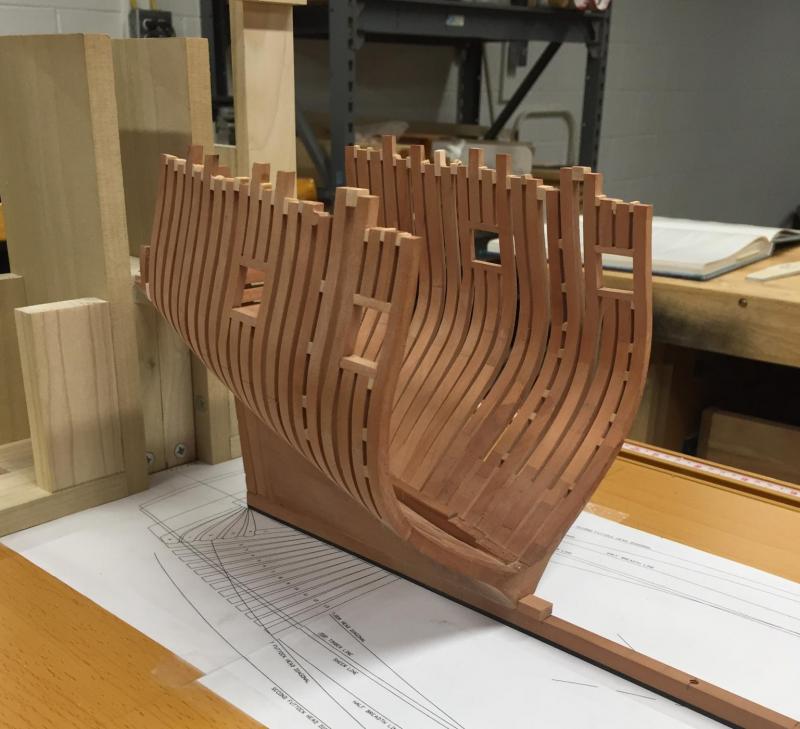

I decided to double check my DOF drawing against the Mylar plan for the next set of frames, everything lines up well except the aftmost timberhead and the top of the rail line is slightly higher on the Mylar. Im also cross checking on the actual NMM Pegasus side draft. Ben

- 889 replies

-

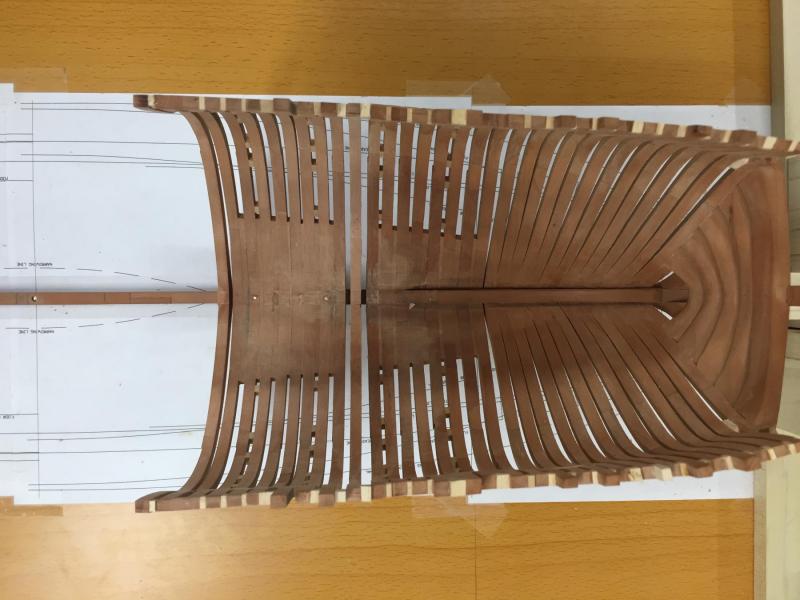

Hey Greg, Yeh, the more I think about druxeys idea the more I like it, if only one side of the filler is glued then it allows for some movement, and if a gap appears it could be filled with a very thin sliver of wood maybe. I'm still going to leave a full frame gap every 8 frames as well just in case. Ben

- 889 replies

-

Thanks David, Everything that could be saved from the old hull is on now, everything to fill the gap has to be made new going forward. I really don't want to take the chance of using parts of the framing that were subjected to the warping that I encountered. Ben

- 889 replies

-

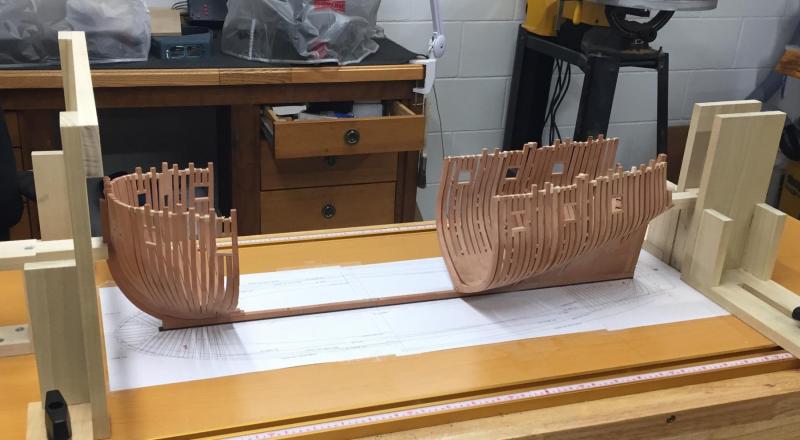

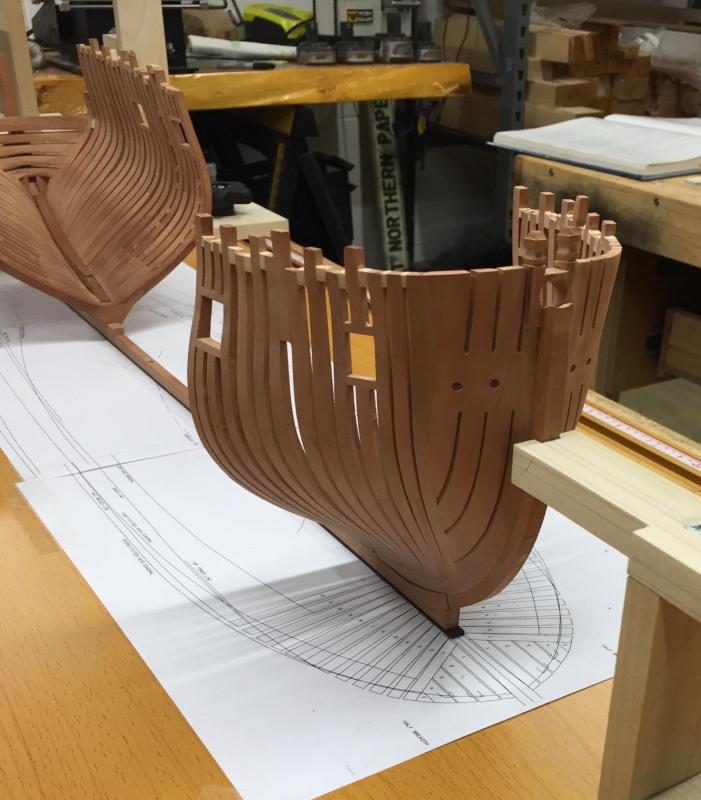

So here is the last remaining saved section from the old hull installed along with a frame fore and aft which have no floor fillers. Ben

- 889 replies

-

Very Sweet Chuck, u are a master! Ben

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That's another idea David, I guess there are a few ways to skin this cat, I'm just gonna try this way and hope to hell it works as I cannot see myself recovering if it goes bad on me again! Ben

- 889 replies

-

So a small piece of rising wood has been added before the aft section for frame 10 fore to be mounted to, then the next surviving section of 8 frames will be installed. Now I'm thinking of leaving the floor fillers around 10 fore out, this will give room for the wood to move and hopefully help avoid the issues I had on the original build. I shall repeat this every 8 frames so it will look consistent and it works out to be the correct amount for the amount frames left to complete the framing. Ben

- 889 replies

-

Thanks Albert and AP, I will reveal how I'm going to continue this build tomorrow after all the saved sections from the old ship are installed. Ben

- 889 replies

-

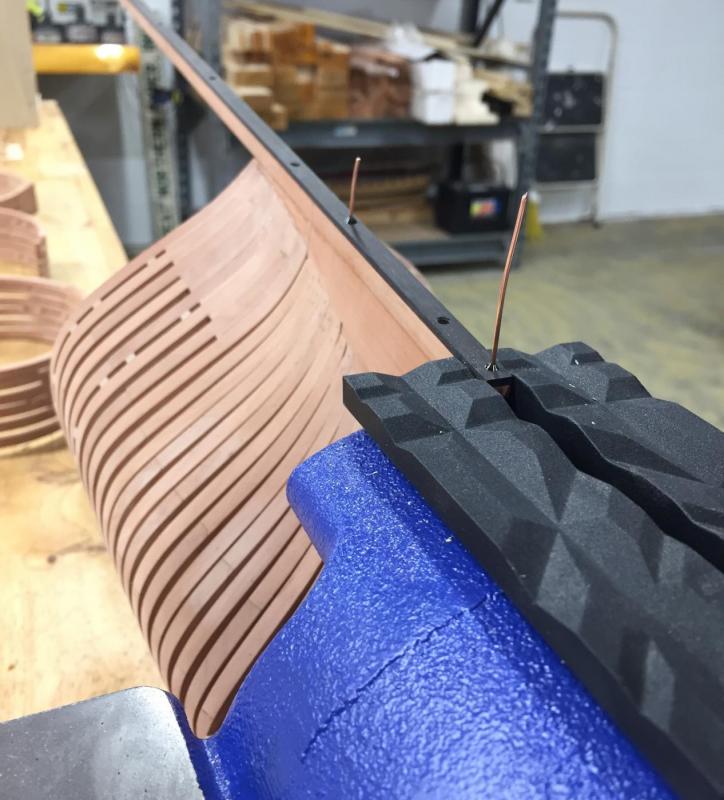

Old forward section has been installed and reinforced with copper wire and epoxy the same as the aft section. Ben

- 889 replies

-

Thanks for all the likes. Old stern section has been installed, and reinforced with 18ga copper wire epoxied through into the keel. Next up will be installing the old stem section in the same fashion. Ben

- 889 replies

-

So before attaching the original stern section onto the new keel I made and installed the filler pieces under the transoms, three on each side had to be made. This was completed and checked for symmetry on both sides, tricky little pieces. Ben

- 889 replies

-

Thanks Mark, The reason for no sawdust in view is that I now have proper dust collection systems, a dust devil and big shop vac to connect to the tools and a big Jet ceiling mounted air filter for the fine stuff, there has been some dust produced - trust me! Ben

- 889 replies

-

HMS Naiad 1797 by albert - FINISHED - 1/48

Trussben replied to albert's topic in - Build logs for subjects built 1751 - 1800

Awesome build Albert. Ben -

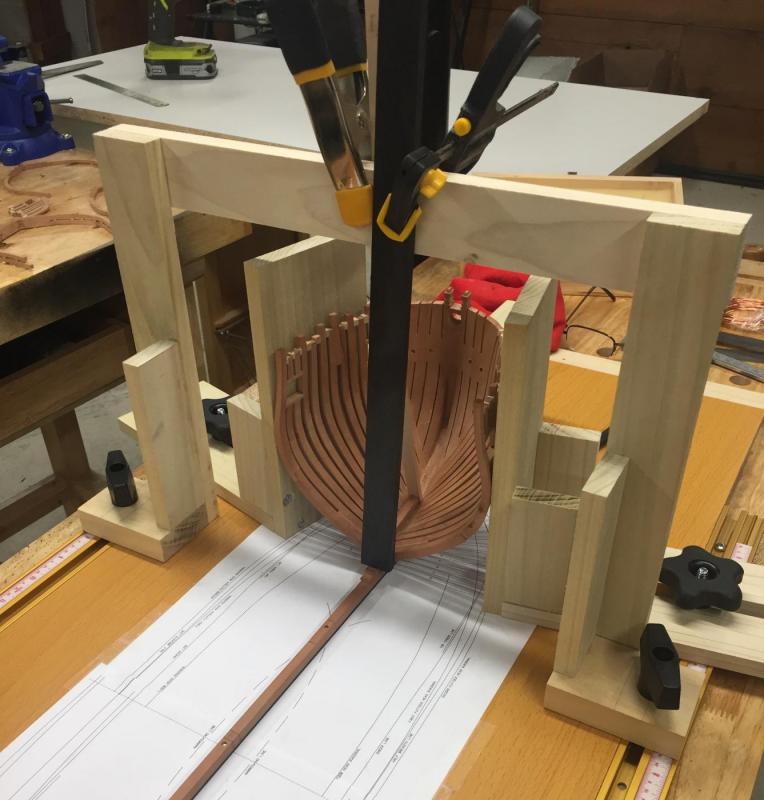

Thanks David. So the new framing squares and overhead gantry are completed. Next job will be to do some work on the old stern section before mounting it to the new keel. Ben

- 889 replies

-

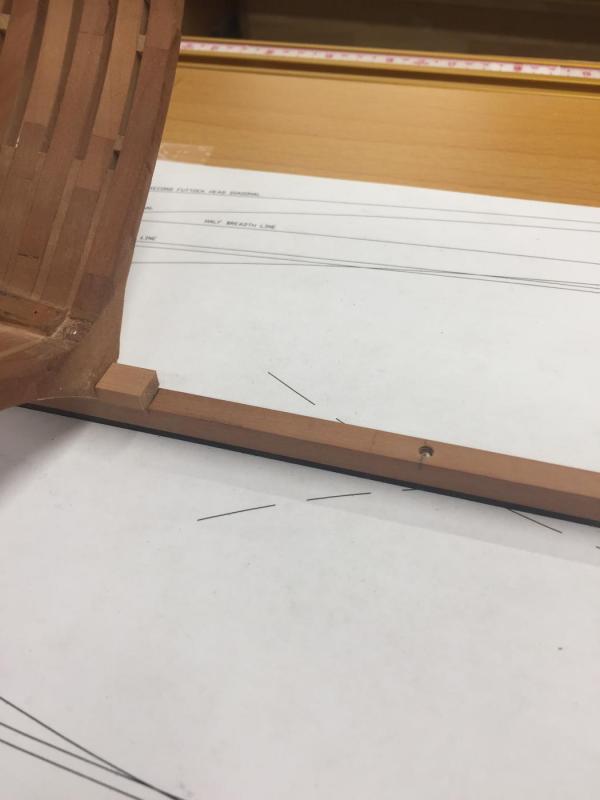

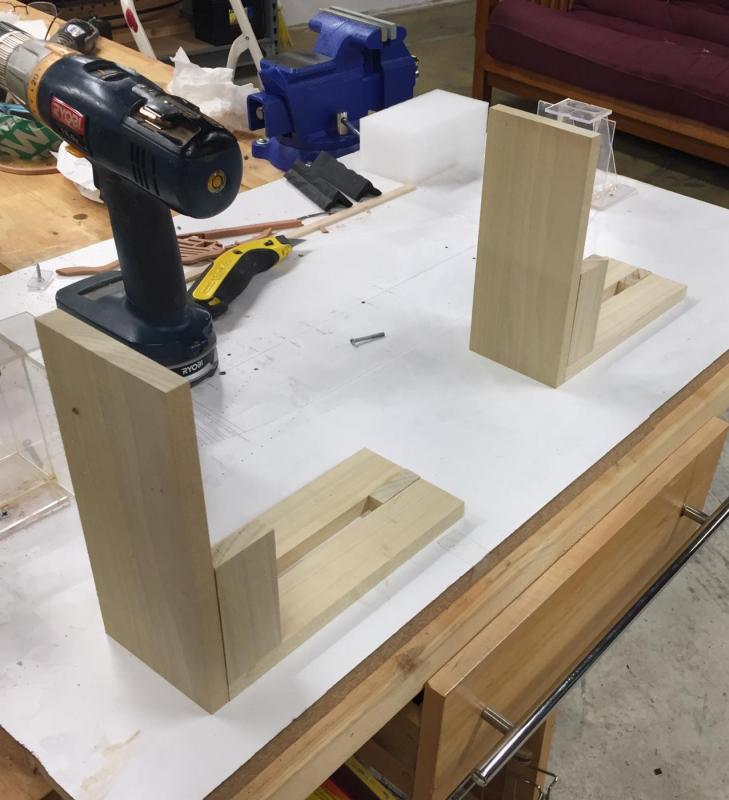

So some new frame squares are in the process of being made so as to be able to utilize the t-tracks for securing them in position, Also new fore/aft holders were constructed out of Poplar just like the squares. While doing these small jobs the build board layout drawings were split into 3 using autocad so as be able to be printed on regular printer paper, great pains were made for accuracy and alignment of these. Now I'm making the overhead gantry which I hope to have done in the next few days. Happy Holidays to all on MSW. Ben

- 889 replies

-

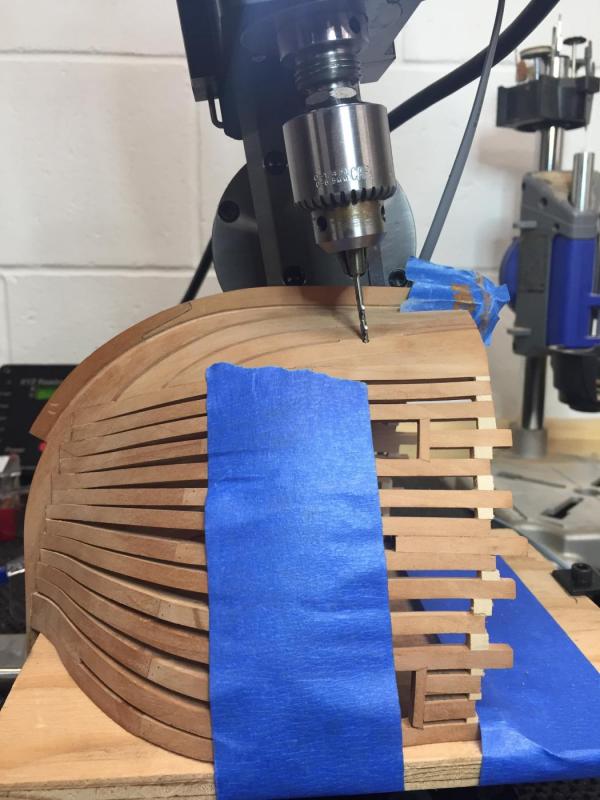

Thanks Druxey, Funny but I got up to a drill bit equivalent to 4" at scale and it started to cut a little noisy with some vibration with the angle and wood grain, so I decided to quit there and will finish with pin taper reamers by hand, I really don't want to tear out the timbers and have to remake them!! Ben

- 889 replies

-

Hey Greg, Yep, it's a 2000 DRO 8 axis. Learning it as I go. Ben

- 889 replies

-

Thanks for the likes. Fun was had today setting up the mill and drilling the hawse holes at the correct 10 degree angle as measured off the plans. They were only drilled out to 4" at the moment, the rest of the way will be done with a tapered reamer, but this has given the correct position and angle of the holes.

- 889 replies

-

New Keel is being drilled for its bolts on the Sherline mill using the sensitive drill attachment. Gives nice accurate placement. 7/8" Bolts will be simulated using 24ga copper wire that will be blackened later with LOS. Ben

- 889 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.