-

Posts

2,006 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Trussben

-

And here are both counter timbers installed and reinforced with a cross spall. I will now start building the framing from the DOF plan to fill in the sides. Ben

- 889 replies

-

Thanks Greg, I'm thinking of glueing in a couple of temporary spalls across them for a little bit of security. Ben

- 889 replies

-

Thanks Druxey, I haven't sanded the bevel into the aft outside of the timbers, I thought I'd wait until all of the counter timbers were installed before I do that to make sure they all fair together. Ben

- 889 replies

-

The side counter timbers are being installed in the next picture, the wooden square you see was made to be exactly 12"3' wide and the same height as the toptimber height from the plan, this was then taped down to the build board exactly 5"3' back from the aft perpendicular as per TFFM. I am hoping that doing it this way will ensure the these counter timbers are in the exact right place. Ben

- 889 replies

-

Good Grief, even using 80 grit paper and course blocks this really is taking some time. I'm am going to go to a final grit of 220 below the Wales which won't be planked but I'm thinking of leaving the framing at the Wales and above at 150 grit so the glue to hold the planking on will have a bit of a tooth to grip to - anybody else do this?? Ben

- 889 replies

-

I'm sure your stove will turn out superb. Ben

- 1,449 replies

-

That's a beautiful figurehead Danny, Janos did you proud. I think I will be getting a commission done for my Pegasus figurehead as I'm not a carver either. Ben

-

My Arm is getting sore from the sanding but one side is pretty much faired, now to start on the other side ben

- 889 replies

-

Thanks Chris! Greg - I find I can " hear " it better than I can feel it! The sanding block ( 80 grit ) makes a note when I'm there! Anybody else do this by ear?? Maybe I'm just weird! Not the first time this has been true, as an engineer I've worked on a lot of equipment that I know more about the way the equipment is running from its sounds and the vibration I can feel through my feet and hands. Ben

- 889 replies

-

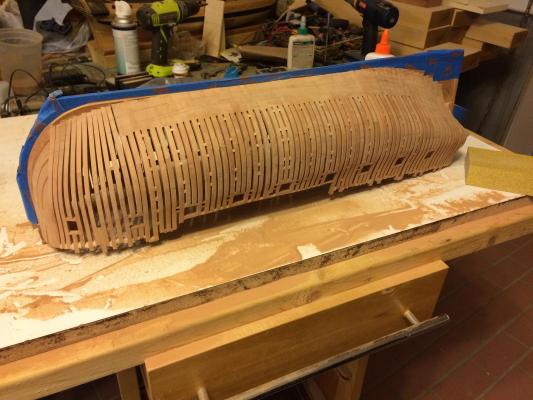

Hull fairing well under way, if you look close you may be able to see the pencil marks that I am using to look for high/low spots. Ben

- 889 replies

-

Thanks Augie, Greg - I have noticed some movement over the last two weeks since we rapidly went from hard winter to spring in a short space of time! Hopefully it will normalize. Ben

- 889 replies

-

She really does look great Augie, you must be proud! Ben

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks Everyone for the likes. Druxey - Yep the fillers were added at the same time as the square frames, I do see some small gaps here and there which will need to be filled. Greg - the pencil method is what I used for internal fairing and it worked well so I will use it for doing the external. Ben

- 889 replies

-

Hey all, Well the internal fairing is pretty much completed so I released the hull from the build board, so I can start external fairing and will also help to complete the internal as I can hold the hull in my lap and be able to access parts that the buildboard made difficult. I see a lot of sanding in my future! Ben

- 889 replies

-

Another addition to the wood stock pile, a couple of billets of nice white Holly stacked on top of my boxwood, Holly is getting really difficult to obtain here in US, So I get whatever I can when the chances arise. I may have some updates to show on Pegasus next week - Ive been working away a lot lately and the sanding and fairing of the inside hull is taking quite a bit of time to get really good. ben

- 889 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.