-

Posts

6,644 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith Black

-

Very good, Scott. It's great to see you are continuing work on the restoration.

- 44 replies

-

- Thermopylae

- Revell

-

(and 3 more)

Tagged with:

-

Putting them on eBay is your best chance but unfortunately eBay is currently awash in model ships. Or you could put them up for sale in Facebook Market Place, neither model is going to bring real money. Your friends memory would be best served by either keeping them both and displaying or offering them to mutual friends where they can display to honor his memory.

-

Pocojo, welcome to MSW. Glad to have you aboard.

-

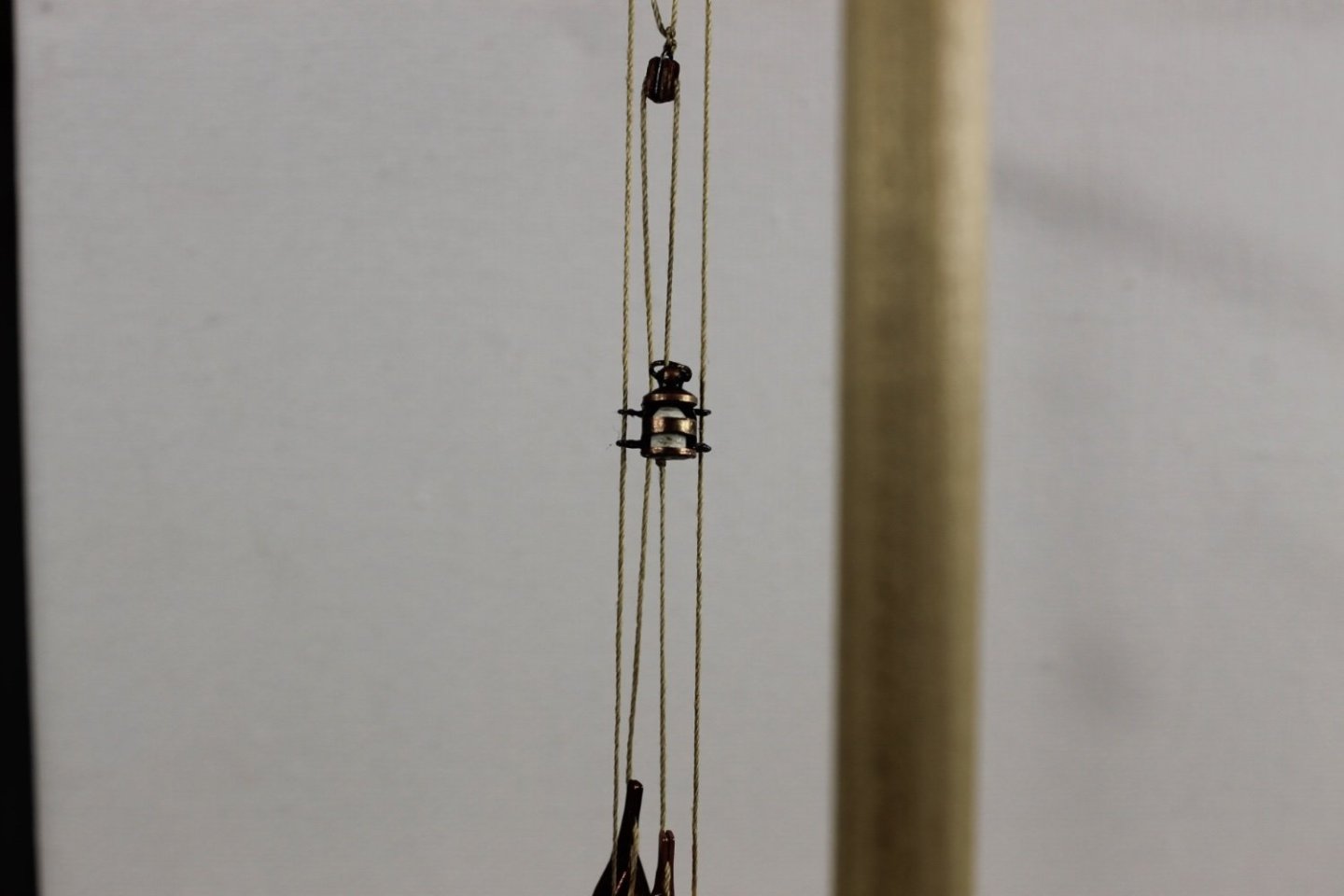

Rob, thank you for the compliment. I considered gravity as the only means for the lantern's trip back to the deck but then I thought of those winter nights when the block and lines would have iced, maybe even froze and would have required a pull from a downhaul line to bring the lantern back down to the deck. If you note in Eberhard's first photo in post #787, at the base of the carrier there is an extended plate with a hole where a clevis would attach for the downhaul.......me thinks.

-

Pete, welcome to MSW. Glad to have you aboard.

-

I was transferring my experience with kerosene lamps with glass chimneys and Coleman lanterns to ship's lanterns with which I have no experience. My apologies for being wrong to do so. Okay, the middle eyes are there for the halyard adding another line of stability to keep lines and lantern from twisting.

-

Pat, if you don't mind me adding my two cents worth. In Bob's post #778, I basically copied that lantern. the rings at top and bottom are for the guide lines, we can't see the back but it's not hard to imagine it being something similar to what I've done less the the eyes for the halyard to the deck. I added those to keep all lines separated and to insure the no line came in close contact with a hot lantern.

-

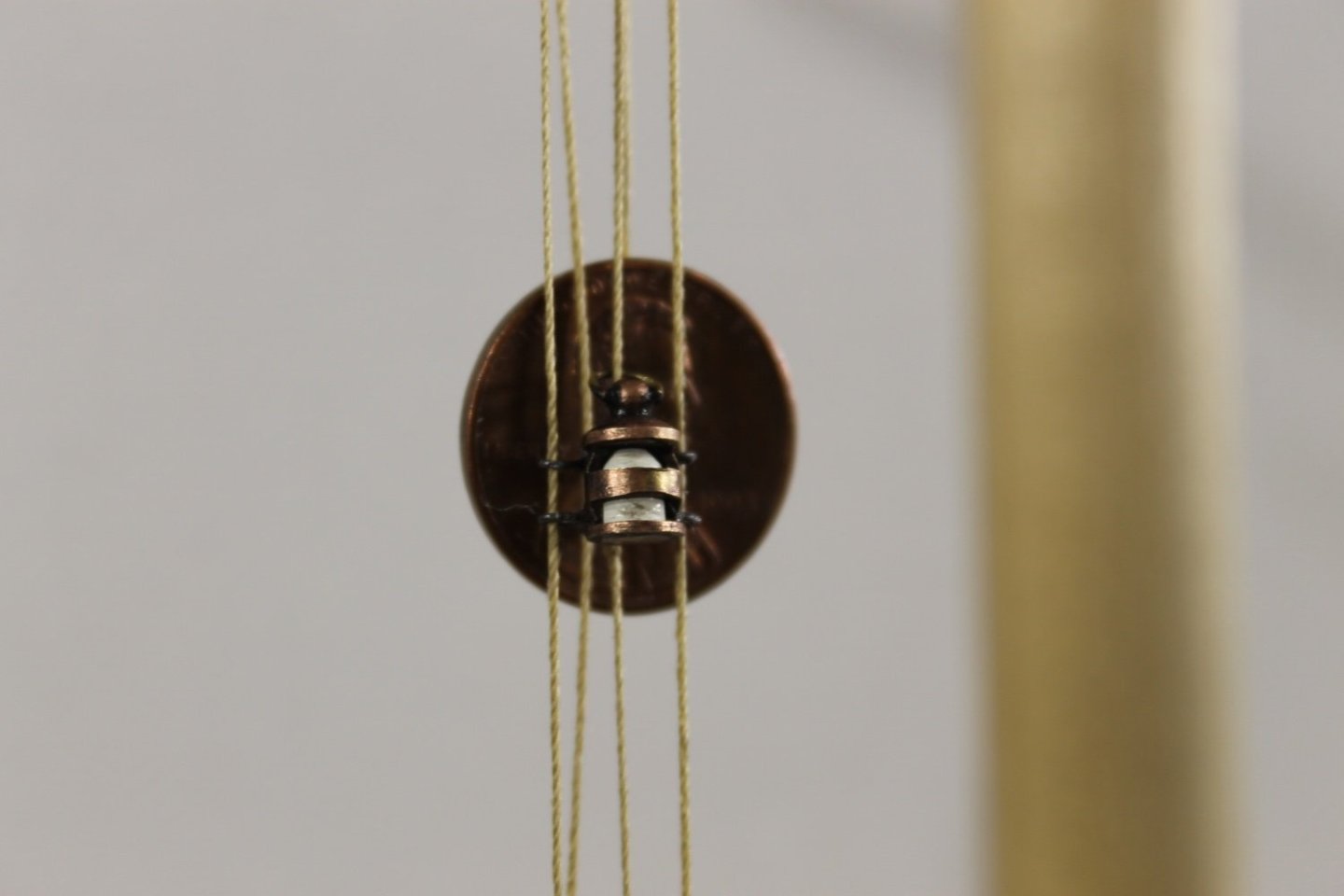

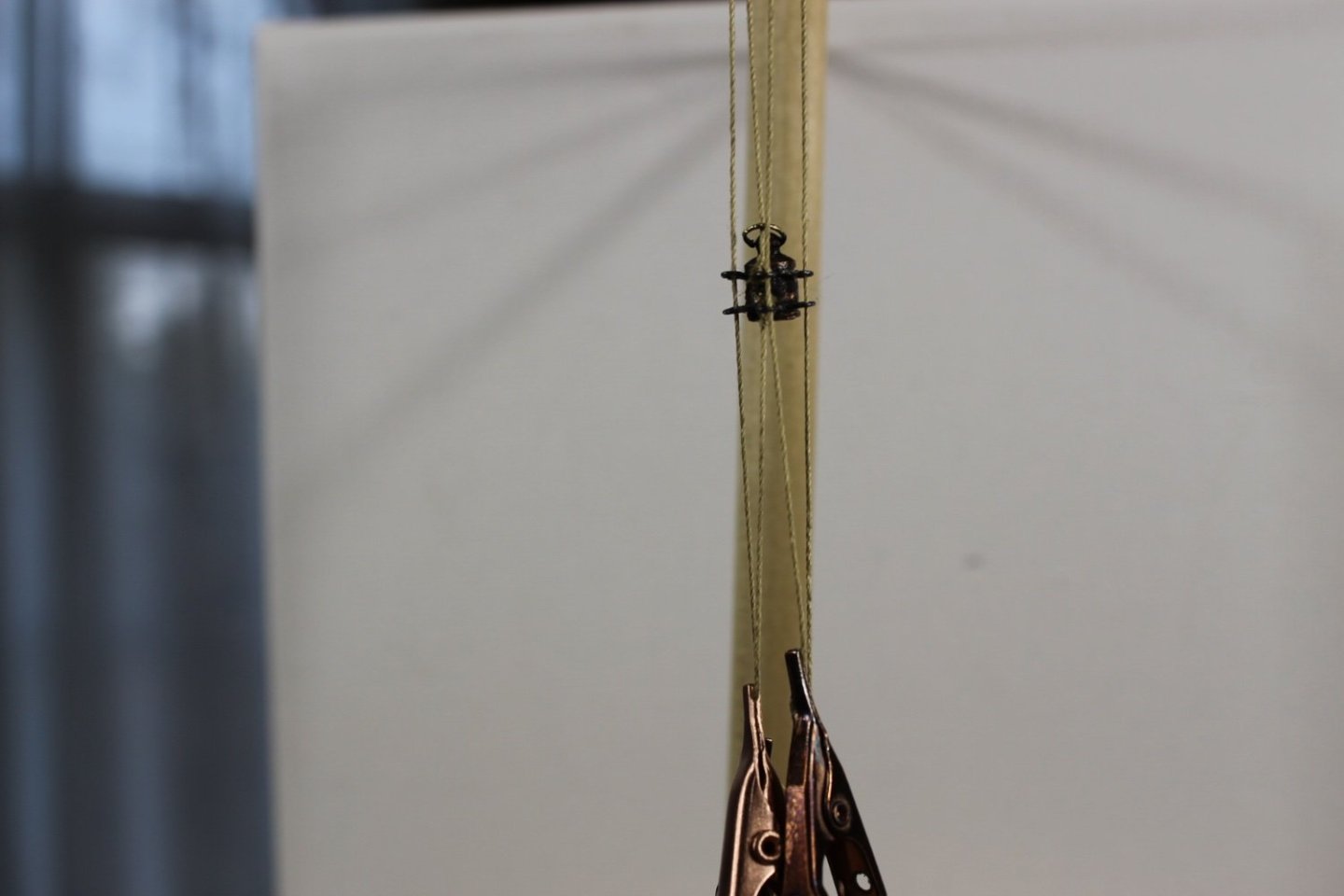

I tried making a lantern carrier as is pictured in Eberhard's post #787, first and second photos. It turned out looking like the dog's lunch so I moved on the masthead lantern 2.0. I was going to attach wire eyes to the carrier but it looked so nasty I said to myself, "self, just add the wires directly to the lantern", so that's what i did. The top eyes are made from a continuous piece of 28 ga annealed wire. The middle eye is made with single twist around a jewelers round nose pliers and then the eyes one either side are a inside loop made with the jewelers pliers. The bottom eyes are made the same. The wired eyes are attached to the lantern with CA. The outside loops are for the guide/stabilizing lines. The middle top and bottom eyes are for the halyard to run through to the deck. The halyard and downhaul line are tied at the base of the middle eyes. The viewer must use their imagination as to how the lines were removed from the lantern via clips and clevis where it could be taken below and serviced, those are just too small to try and replicate. After viewing the photos I need to adjust the eyes to level. This temporary lash up has too much slack so the lantern appears a bit wonky but once permanently added to the model with lines under tension the looks will hopefully improve. Once again, thank you to all who made this lantern project possible. Thank you to all for your kind comments and the likes and thank you to all for having the patience to follow along.

-

And I pondered that object for years always wondering but never knowing till now. Thank you, Eberhard. I would have great, if not impossible, difficulty in replicating the sailcloth ventilator. Even more difficult is determining what is being ventilated. The third set of photos in my post #802 is the only photo showing the forecastle deck. I've never known what was shown just forward of the 60 pound Parrott rifle. being so blurred I ignored it but now I'm thinking that's a companionway which would make sense and be reason for the sailcloth ventilator. Edit.....Impossible means giving it your best shot and if you fail, then the task maybe impossible. It's not a companionway forward of the 60 pounder, it's a hatch which fed ammunition to the Parrott. I wondered how they got shell and powder up ladders to the forecastle deck, they didn't, it was via a hatch. I looked for companionway stanchions and couldn't see any so it has to be a hatch. I'll have to move the bitts forward a tad but I'll get a hatch in there. Then I'll give it my best shot to model the sailcloth ventilator. It must be rare as nothing comes up when sailcloth ventilator or canvas ventilator is Googled. I owe it to Eberhard for the discovery and knowing what he was looking at and to the Tennessee for having one deployed to make an honest effort The hatch coaming is higher than the hatches on the main deck which makes sense because of waves breaking over the bow. The hatch cover will need to be partially open for the ventilator.

-

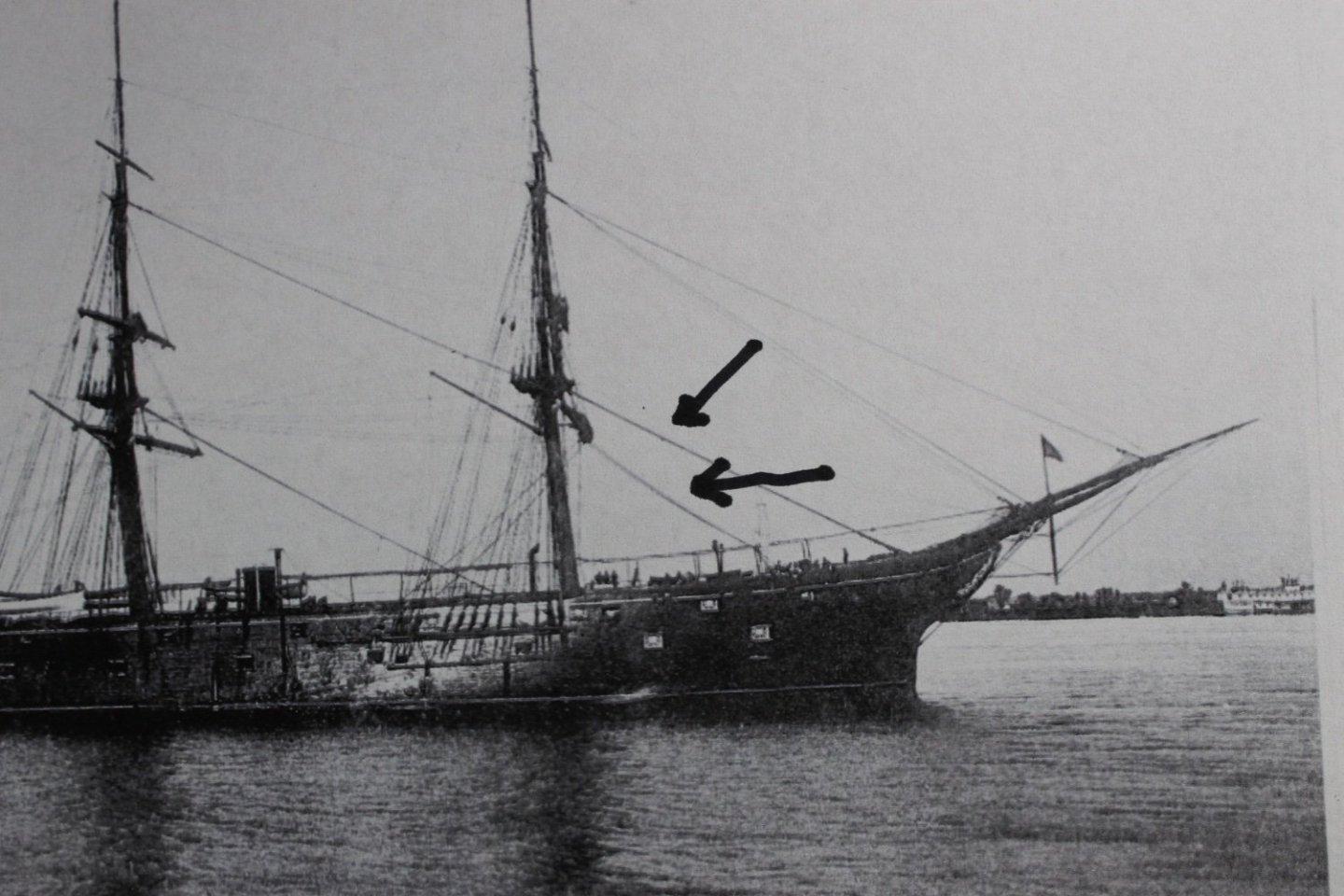

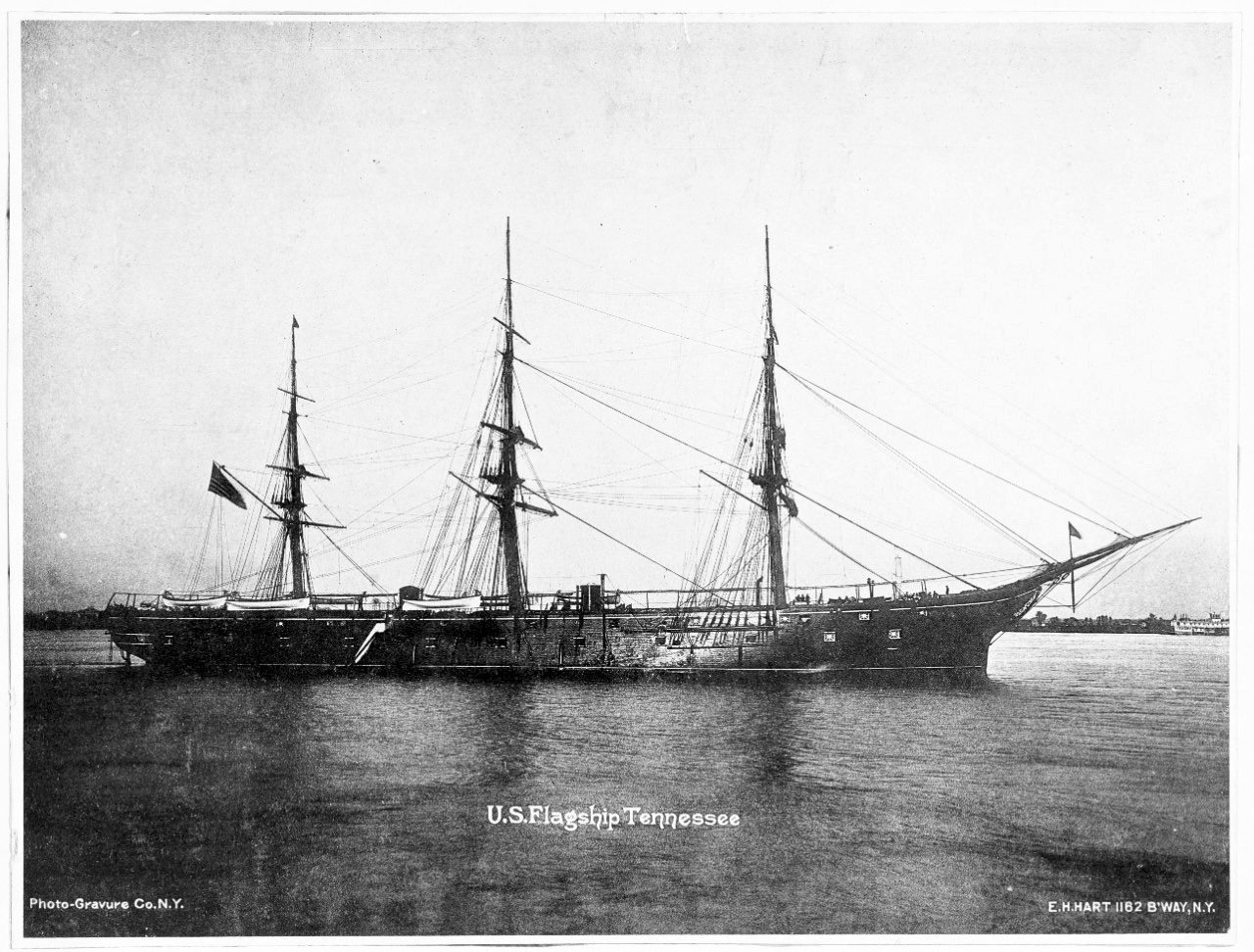

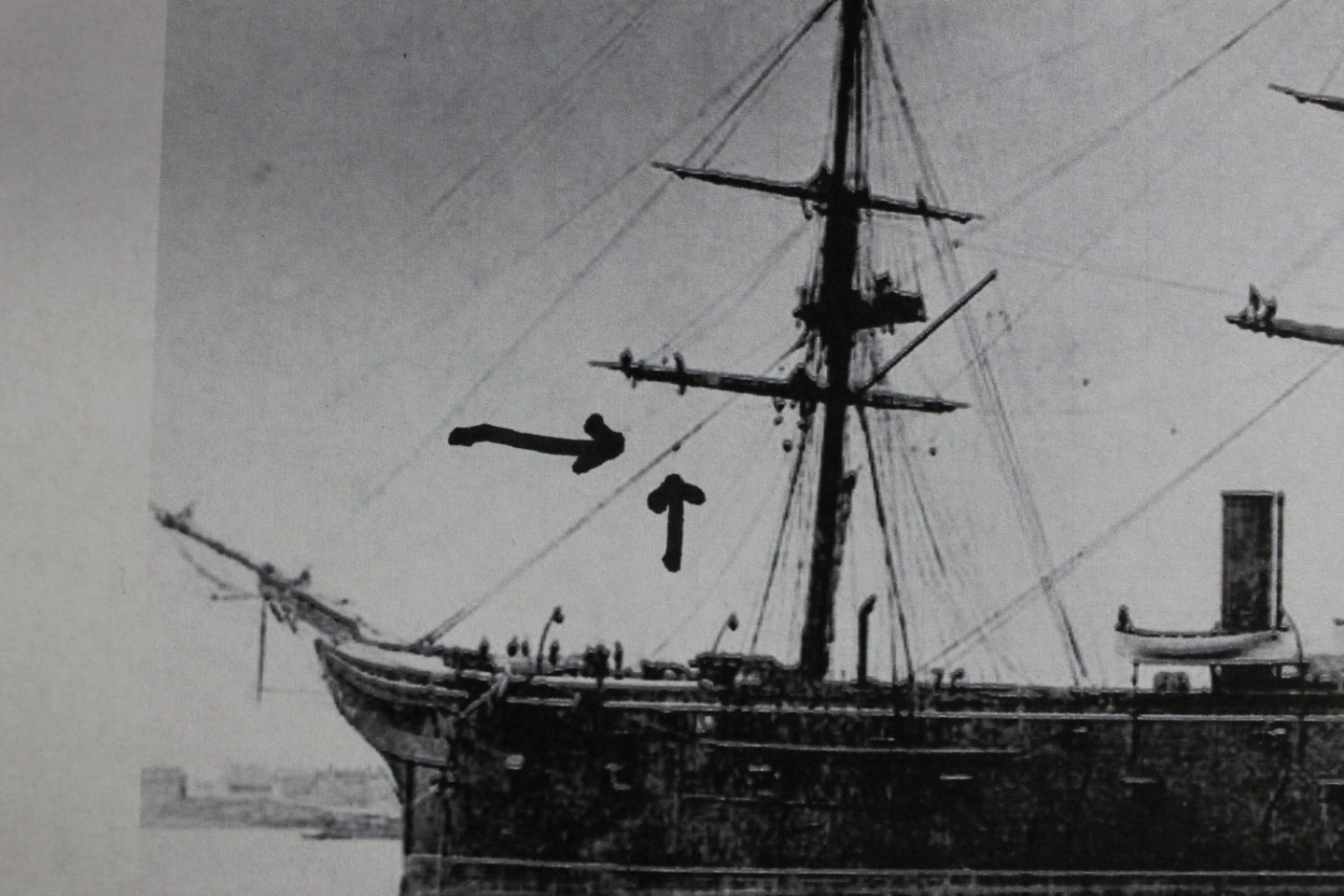

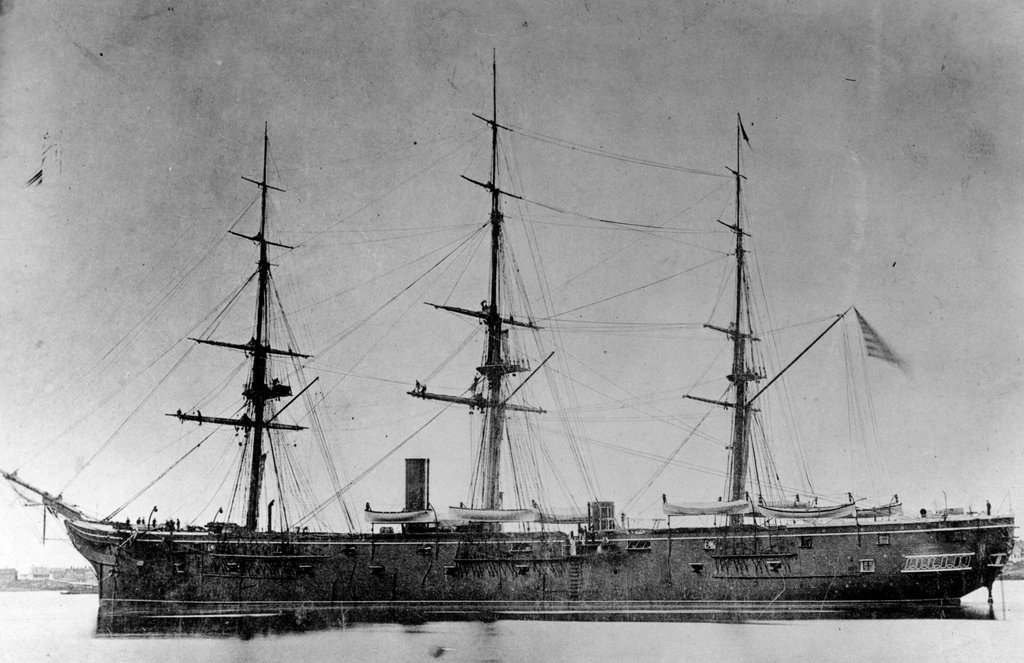

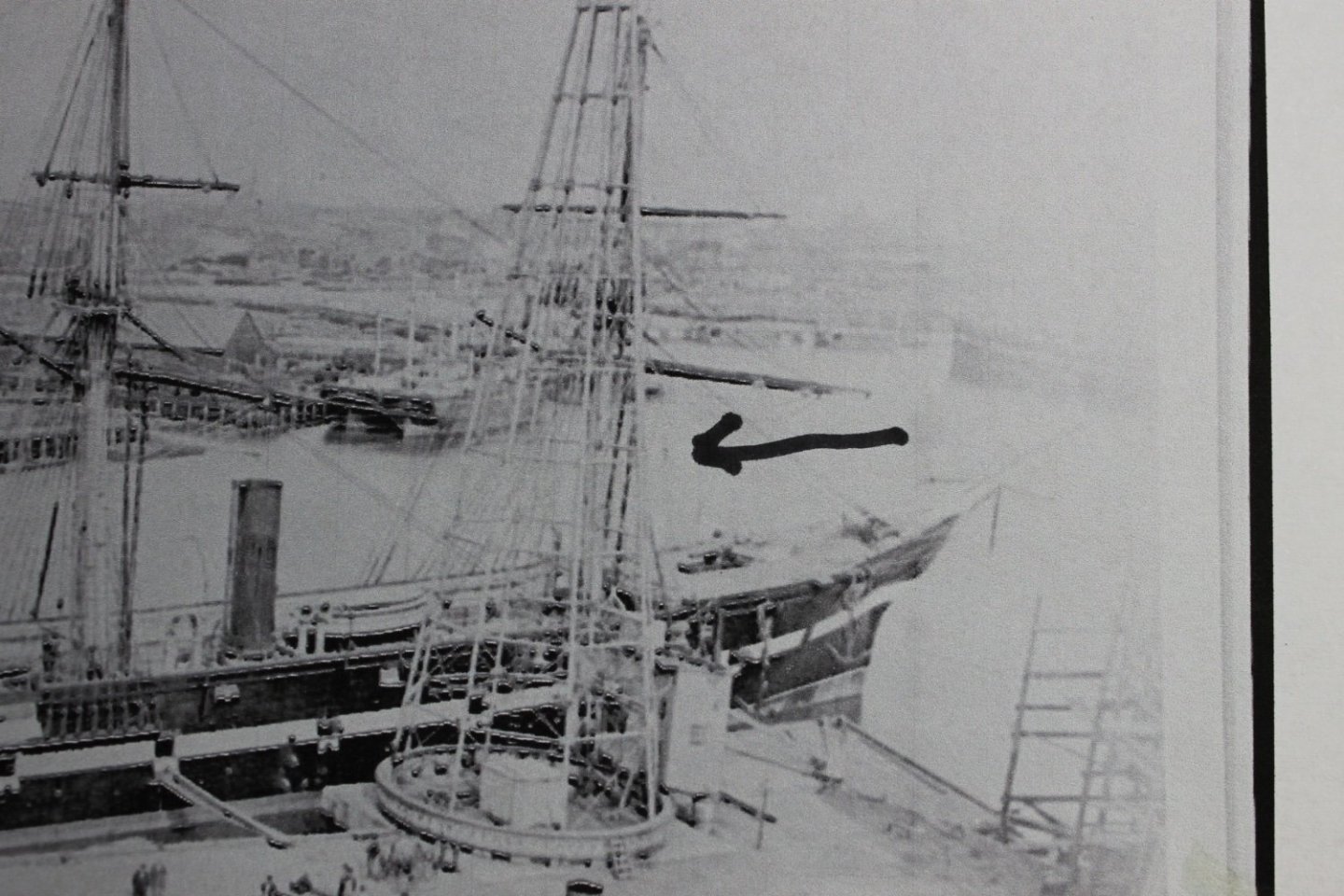

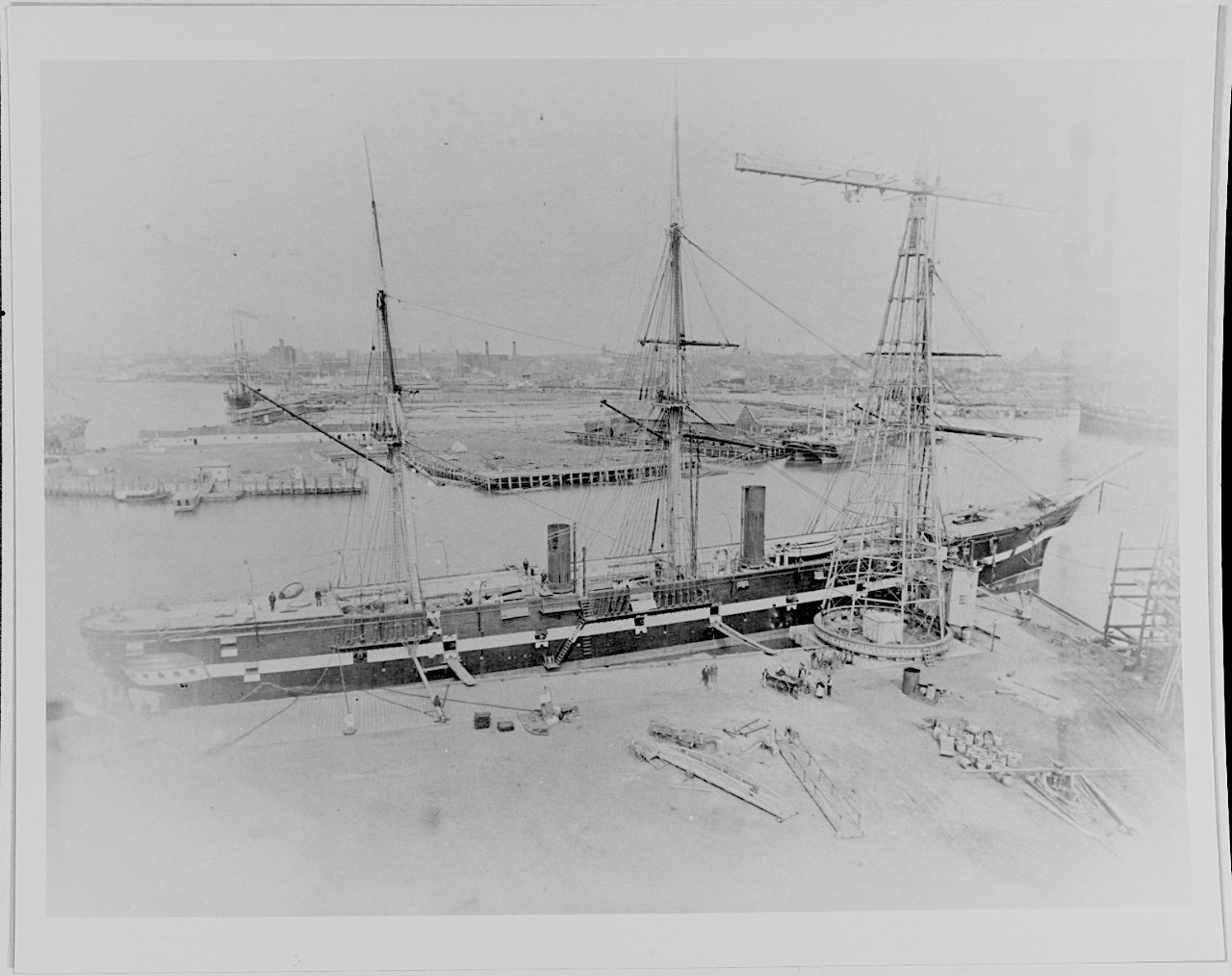

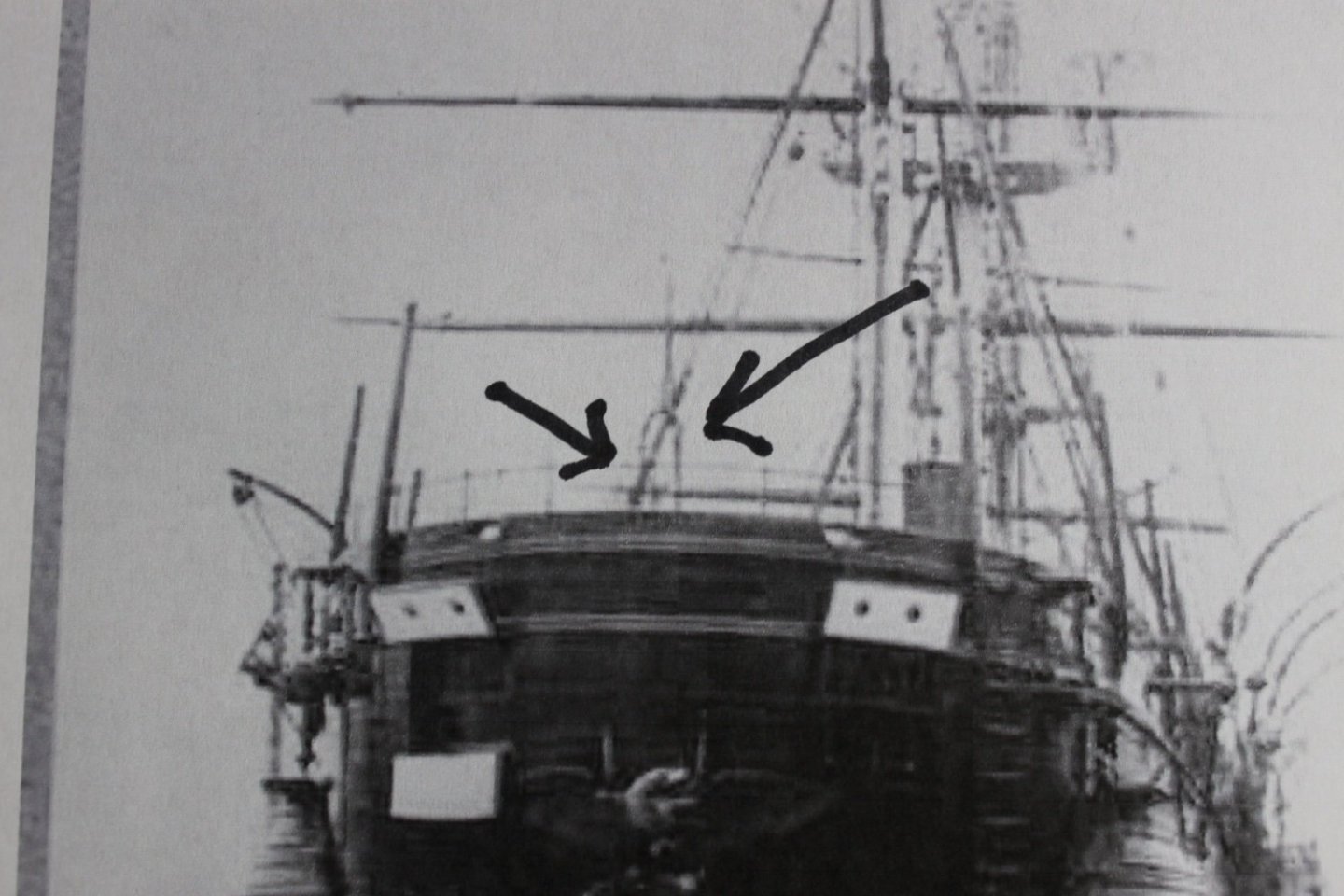

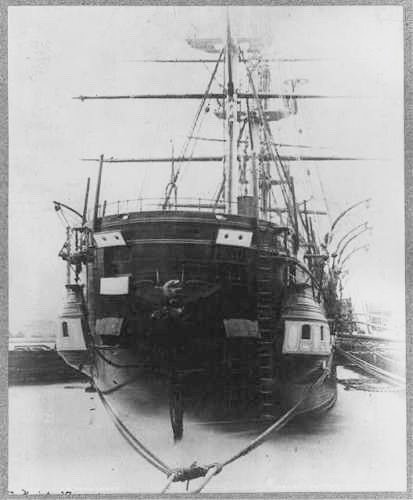

Once I was provided with all the useful information during the lantern discussion I went back over all the Tennessee photos and I'm pretty sure I've located the block for the masthead lantern. When I noticed it I slapped my forehead, smiled, and thought of and thanked each of you. In the below photo I'm pretty sure the top arrow is pointing to the masthead lantern block spliced into the stay. Also, zero to 180 degree vertical lines can be seen leading from the block to the stern castle stanchion railing area which I take to be the lantern guide, lift, and downhaul lines. Maybe the lift and downhaul lines were tied off to the stanchion railing? I can see no reason for a block to be spliced into the stay at that point and for dang sure not the vertical lines for anything other than for the masthead lantern. In the photo below the block is visible but not the lantern guide, lift, or downhaul lines. The below photo may and I say may show the actual lantern? It's in the right location but the photo quality make it a guess. The following photos show??? For years I've looked at this stern view photo and mused as to what the object was between the arrows. Is it possible that it was for the stern lantern? It's the right shape at the top and the lantern could be tied on each side to keep the lantern from twisting. Thoughts please. To find something new after looking at these photos all these years is exciting to say the least. Thank you!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.