-

Posts

431 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rshousha

-

I just hate it when a kit sits there month after month, staring at me because I haven't worked on it. This kit has been doing that to me for a while now and so I need help to reduce my stress level. Would anyone like to help me out? The first person to make a reasonable offer for this kit will get it. Anything over $600 USD, including shipping anywhere in the world is a good offer. A couple of things about the kit: 1 - a few small engine parts are started 2 - interestingly, the person who had the kit before me put the parts in the bigger box from the K75. This means the parts are not as squished in. 3 - I checked the clear plastic parts and nothing is broken 4 - it seems to me that all the parts are there but I think one tire valve stem is missing. I really did not inventory every single other part but these kits are quite plentiful and parts are found quite easily in the UK or the US. I will gladly point people to where they can find the parts. 5 - it's an older kit. Plastic gets brittle after fifty years. The brown plastic tree is now fairly brittle and must be treated carefully. The other colours seem to have weathered the time well. This is typical of this edition; the brown stuff gets brittle before the other colours. No idea why that is. I think this is a pretty good price for the kit. If I had more storage space, I wouldn't mind so much, but it's in the way and my palms sweat whenever I see it. Thanks for the help! Cheers, Rick

-

-

Try piano wire. Comes in bundles. It's amazing stuff; made of hardened steel. It takes a shape easily and is a great colour.

-

Justifying the purchase of a mill

rshousha replied to Captain T's topic in Modeling tools and Workshop Equipment

I think I will wade in here with my own thoughts. There is nothing to justify. The cost of buying the mill is just an entry to a learning process. The learning process itself will consume hundreds of hours of your time and thousands of dollars of materials. The cost of the mill will become irrelevant with time and experience. The details of this mill or that mill, or this part or that part are really secondary. You are buying an education. This is priceless. Cheers, Rick -

How to stain or dye boxwood?

rshousha replied to tkay11's topic in Painting, finishing and weathering products and techniques

Saman; most amazing stuff. A Canadian product. I use it on models, furniture, and a floor I just did. Amazing stuff. https://saman.ca/en/products/ I use their stains and their water-based varnishes in matt and satin. -

You are doing an amazing job with this model! It will be quite a piece when it's finished. Well done, and thank you for sharing this work.

- 150 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

Great kit and parts source

rshousha replied to JohnU's topic in REVIEWS: Model Shipwrighting Tools, Parts and fittings

Thank you all for your thoughts on my friend's passing. And now I have some time to write what I really think of the positive future of our industry: Anyone who has seen my website will see that there is a page that I call "The Virtual Factory". I have been touting this concept for at least twenty years, ever since I built my first website in 1996. In this concept, success will be found in creating unique products and services that will plug into a greater whole. Of course there is room for kits but it is clear that more and more people are spending time and money improving kits they buy. This trend will continue and, taken to extreme, a "kit" will be made up of the sum of its parts, those parts being made by many different businesses all over the world. Just from a financial perspective, this makes sense. It is already a modus operandi in the multi-media model sector where many of the latest 1:8 scale car kits are being produced bit by bit. Why spend $2000 on a kit when you can spend it at the speed you work? As an example, I am receiving plans obtained from this museum on a regular basis and am now designing and cutting frames for very large R/C models continuously. Using advanced software, I am putting out about a kit a week for clients all over the world. One fellow even asked me to design a J-class boat for him that he could steer from the inside! I declined that order. Next, there are already some great suppliers of parts. I have just received a pile of wood to cut from Northeast Lumber, for a client in Norway. The entire transaction, from Zooming with the client, to getting the plans from a museum in the UK, and to getting the wood from Northeast, has been really fun. Now, it's up to me to get another fantastic model out of my digital workshop as soon as possible. Add to that people who are interested in 3D printing, photo-etch, rope-making, block-making, and such, and we have a great future. As someone mentioned the other day, one has to figure out a good business model. Yes, it is harder than just copying the next guy, and lowering prices, but it will be much more rewarding, and more stable, in the long run. My designs are described at length on other websites. The next one I am doing is for a present-day yacht designer, whose boats I have sailed on many times. And then the order book is pretty well full until 2023. So my tiny part of the Virtual Factory is working full-tilt. Best Regards, Rick -

Great kit and parts source

rshousha replied to JohnU's topic in REVIEWS: Model Shipwrighting Tools, Parts and fittings

Thank you, all. I am sure you've all had great difficulties this past year and I am being selfish in making a fuss. I do thank you for your thoughts. -

Great kit and parts source

rshousha replied to JohnU's topic in REVIEWS: Model Shipwrighting Tools, Parts and fittings

The second of my two best friends passed away this morning. Perhaps that is why I lashed out for no good reason. Somehow, it's always easier to lash out at friends. My apologies. -

This is excellent work! The solution I use in Solidworks is to reduce the frames by the offset amount of the planking that the builder is going to use. In the end, the surface is not useful if you are doing a design in order to create laser-cut frames so there is no need to make the thickening function properly in the first place.

-

Can't believe there are two of these in Whitehorse! This must be the highest density of Agamemnon models in the world! Well done!

- 150 replies

-

- agamemnon

- caldercraft

-

(and 1 more)

Tagged with:

-

NEW Vasa kit from Artesania Latina -- looks to be quite good

rshousha replied to md1400cs's topic in Wood ship model kits

From what I understand, the material used in those flags had a magnetic property that used St. Elmo's fire to create a reverse energy that made them flow against the wind. I have never found that fabric, but I know it's out there. -

kit review 1:10 Blériot XI by Amati Model

rshousha replied to James H's topic in Non-ship kit reviews

Absolutely fantastic model! A really enjoyable build. I built mine the way it had been when it flew over Toronto, in 1911. The float was great fun to build but I ended up throwing it out as it was not used on that flight. I gave it to a museum in Toronto in 2011, on the 100th anniversary of that flight. I have pictures, if people are interested, but I don't want to interrupt this excellent thread of a review of the kit. -

Gentlemen, in defence of the company, I buy a lot of kits from Jotika/Caldercraft. They are a great company and their kits are, in my opinion, a great value. It's a small company and can barely keep up with the demand for their current line-up of kits and other products. The weakness of the UK pound is giving them great leverage these days and they are shipping as fast as they can. Compounding the production pressures, issues with Brexit are adding a level of complexity and administrative effort. All this means they are very busy with the kits they already produce. There is enough variety in their line-up to make most builders happy for several lifetimes and I suspect very few people have built all their kits. I don't want to start a big discussion on this point. I just think we should encourage our favourite companies in this fragile industry and give them the benefit of the doubt. It is surprising to me to see that, on the one hand we want traditional companies to thrive, and then on the other we make disparaging remarks about those same companies. If others are developing new kits, that's great news. I just don't see the need to make discouraging remarks about our friends.

-

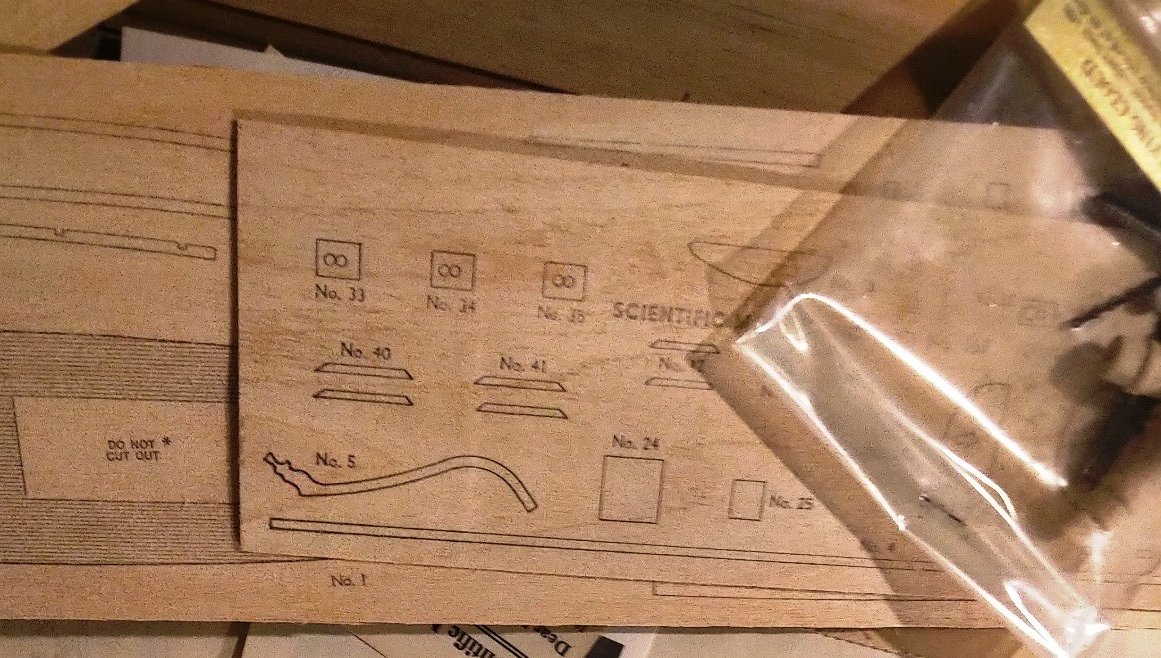

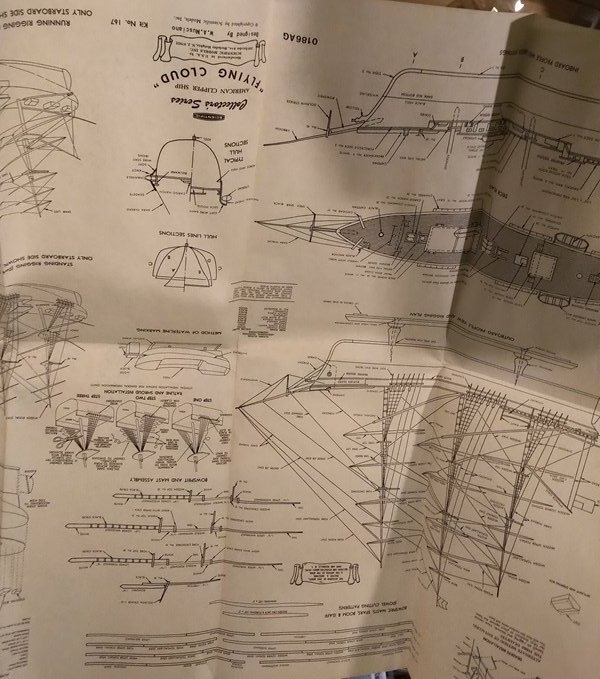

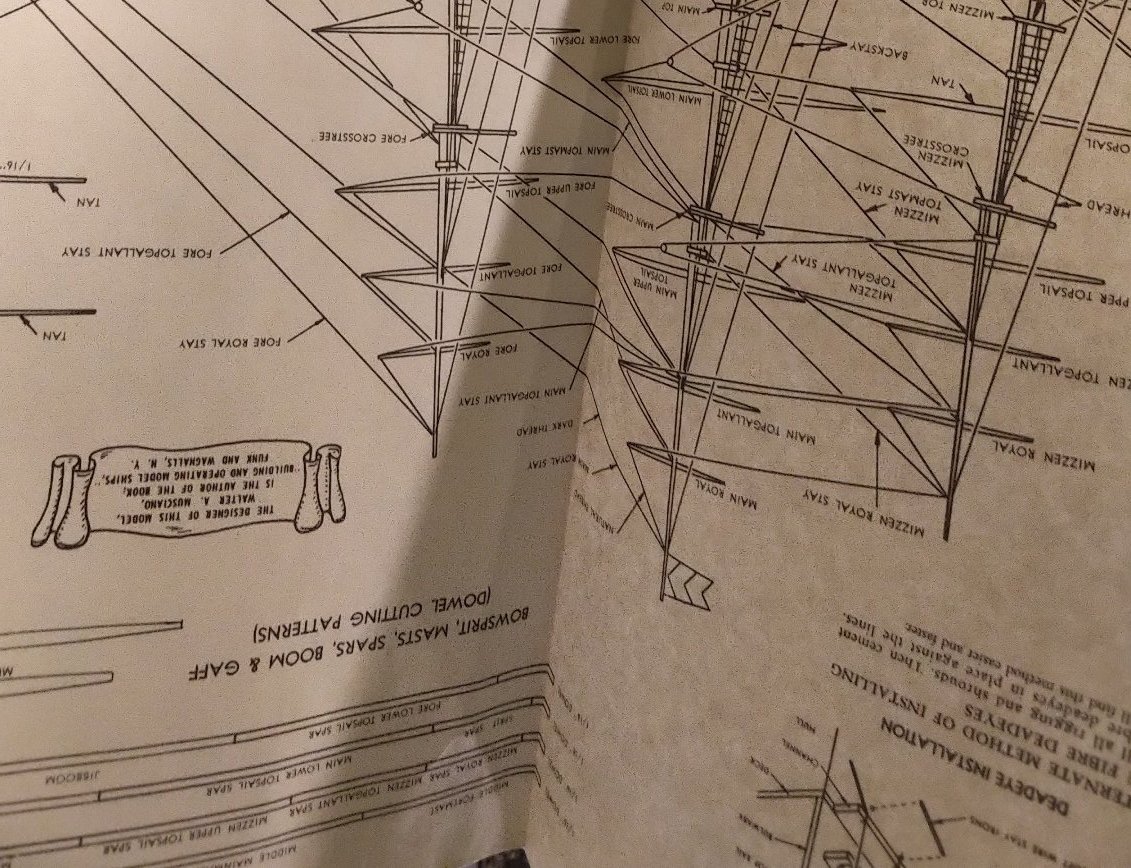

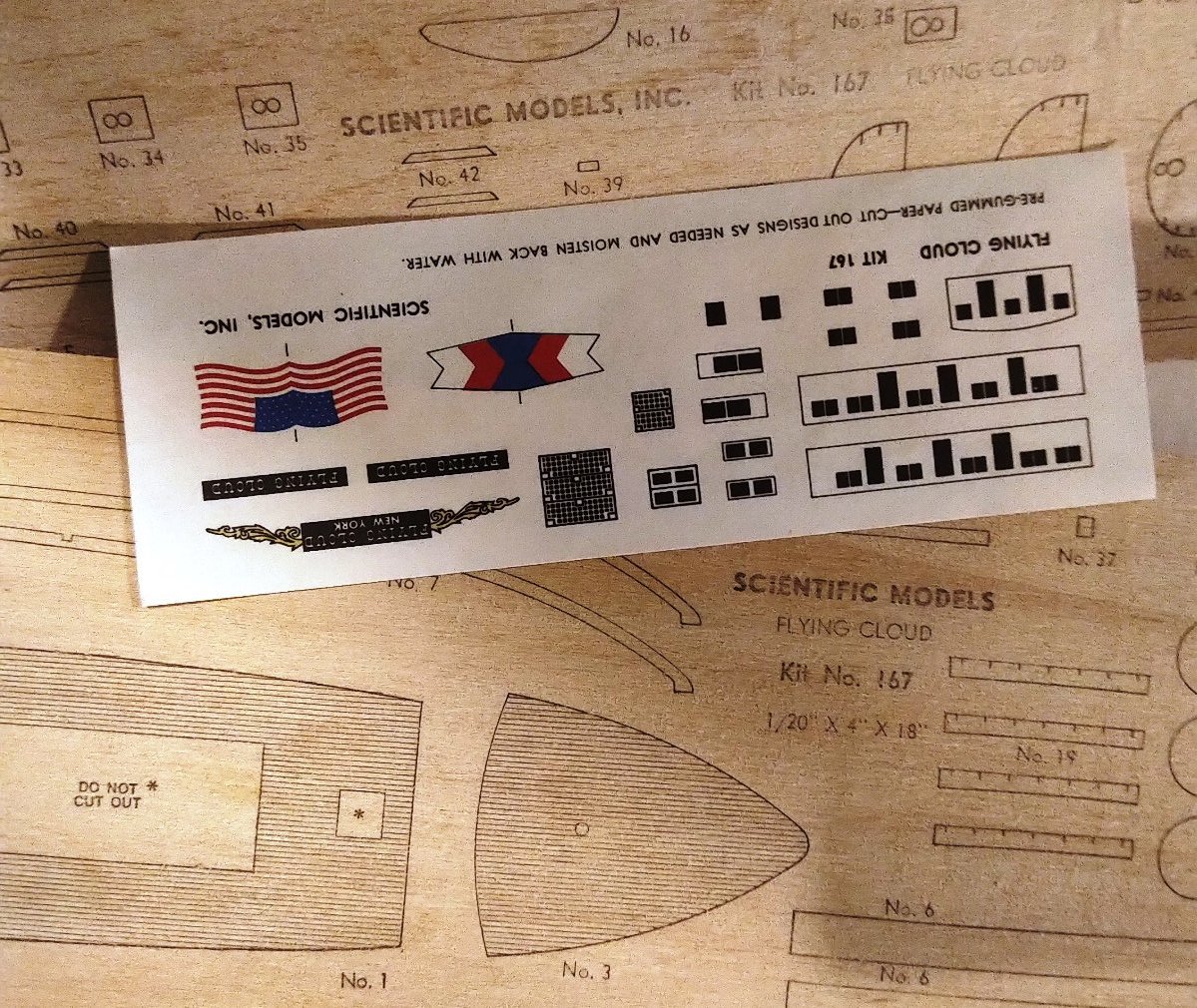

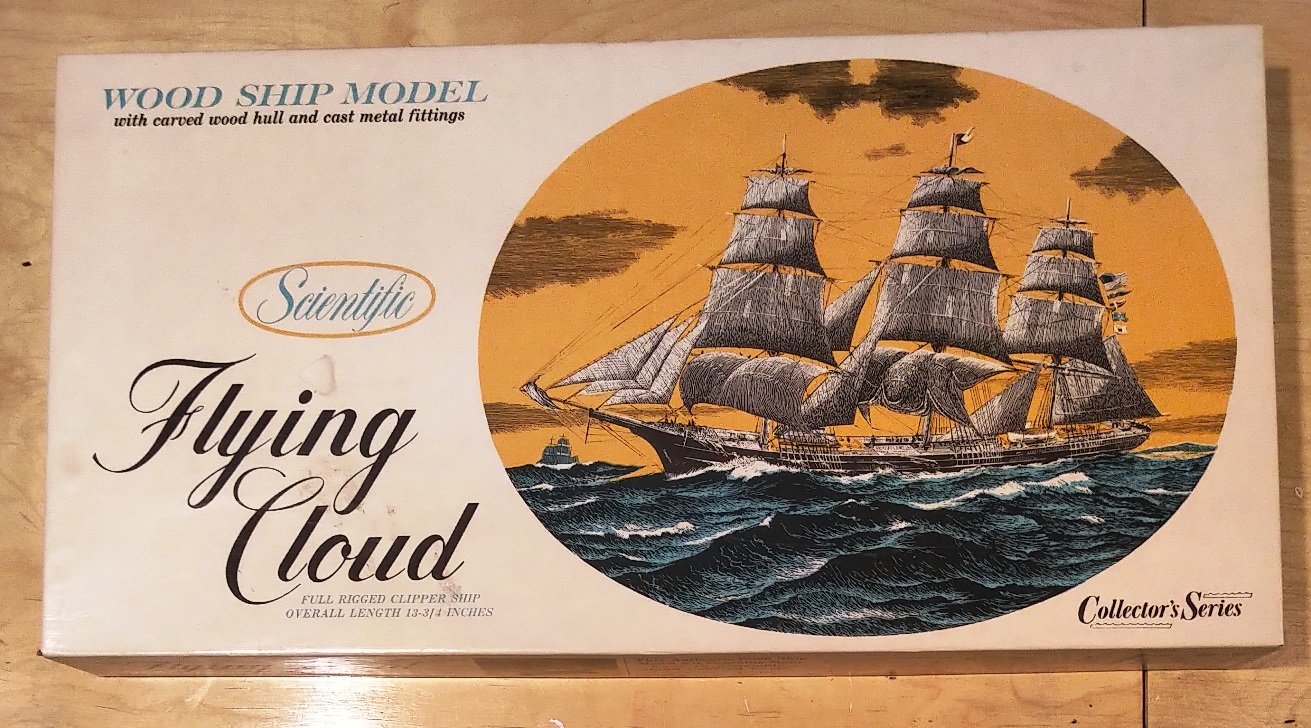

As I was cleaning up some closet space, I found this interesting little model. As I have absolutely no intention of building this, I am putting it up for sale basically for the price of shipping. I would like to get $35 CDN to ship it anywhere in Canada or $40 USD to ship it anywhere in the US. Of course if you are local, I'll take a couple of bucks if you want to drop by and pick it up. It is not going to go on eBay or anything like that. I will hold onto it for a week or so and then the poor little thing will go in the recycling bin. Cheers, Rick

-

For a second there, I thought I had drifted off to a page from Yachtworld, or something, and I was looking at one of my usual searches, "Bristol Cutters for Sale"...and then I saw the end of the pencil.... Really wonderful work. Thank you for sharing. Best Regards, Rick

- 2,214 replies

-

Why do some manufacturers make single plank kits?

rshousha replied to Meriadoc Brandybuck's topic in Wood ship model kits

I sell hundreds of ship kits every year and so have a lot of experience with this. I field this question at least once a week. In my opinion, it is 100% a question of price. I have many clients who absolutely love those single-planked kits because they are much less expensive than the double-planked counter-parts. The flip side of that is that I always warn a new modeller that price and difficulty are most definitely not a measure to go by when buying a kit. Most of the time, a less expensive kit, in the same subject, will be harder to build than the more expensive version. Again, though, I need to emphasize that the story goes both ways. A good modeller may find the cheaper kit most excellent for his interests, and a good bang for the investment. On the other hand, a less-experienced modeller may find the more expensive kit much easier to build and, as Ron mentioned, having more material in a kit allows you to cover up mistakes more easily with what is included in the box. -

Drafting

rshousha replied to mangulator63's topic in CAD and 3D Modelling/Drafting Plans with Software

Drawing in CAD is absolutely amazing! I stumbled upon Solidworks in 2012, when a client I was working for as a consultant installed the software on my computer so I could help him improve the manufacturability of some of his parts and assemblies. It was quite a revelation. I took some preliminary courses in the subject and then I quit my consulting work completely in 2015 and enrolled in a Community College to get a diploma in CAD. Here was a 55 year-old engineer with a degree from McGill going back to school to get a technical diploma. It was wonderful. I now have a great setup, running a high-end laptop computer and the latest version of Solidworks. With my eyesight making it difficult to build scale models, the software allows me to zoom and zoom and zoom. Also, I am allergic to CA glue now. Connecting stuff in 3D is really non-allergic. Finally, everything I can design can be sent to 3D printing or laser-cutting with the press of a button. Going back to the 2D drawings, when I started my learning curve on the subject, I pulled out three of my father-in-laws drafting texts from the 1960s, and drew and drew and drew. I think I must have copied 2,000 exercises from those books. I now have industrial clients that hire me to take those old hand-drawn documents and convert them to digital copies. During the day, I work for industrial clients and, when I get a chance, I "build models" in 3D. The closest thing I can think of to a "one size fits all" package would be Solidworks. I have tried many of the "usual suspects"; Delftship, Autocad, Revit, Solid Edge (for more than a year), Rhino, and Catia. On cost/benefit basis, I have found Solidworks beats them all, hands down. However, it is costly to get a powerful computer and keep the software licenses up-to-date. I have no solution for you "on the cheap" but the pleasure I get out of Solidworks is more than worth it. You may find it's a lot of money to get involved ideally with the digital world of design but, once you're there, you will really enjoy it. Have fun! Rick -

Nic, you are amazing. I actually use some of your jokes around the table!

- 82 replies

-

- spray

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.