-

Posts

1,780 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by hamilton

-

HMS Granado 1742 Kit - CAF Model - 1:48 Scale

hamilton replied to cafmodel's topic in Wood ship model kits

Just ordered session 1 of this kit.....lots on the shelf, but happy to add this to the pile! hamilton -

That is a cool device - at first I thought it was a drill balanced on a set of miniature parallel bars. In any case your Unicorn is shaping up nicely! hamilton

-

Hello Tim: Thanks for coming bye - great to hear from you! And great also to hear you're coming back to the shipyard - I took a long hiatus too - at least from regular modelling and active participation here (though constantly a "lurker" in 90s internet parlance). I hope that, if you get going on CS that you'll start a build log here - I'm meditating on what to do when Bluenose is done (even though at my current slow pace this won't be for some time) and I think it will either be the Corel Bellona or the Model Shipways Flying Fish. If it ends up being the latter maybe we'll be building in parallel once again! Still very thankful for the extra parts you sent for my America and hope to be able to return the favour one day! Bye for now hamilton

-

Looks great, despite product quality! It's been a while since I made a Corel kit (the last was Greyhound, you'll recall!), but Bellona is up next and I well remember how ginger you need to be with things like the chain plates and other metal parts - sometimes they're just unrefined looking, sometimes, they're just so fragile that they break while they're still in the little containers they come in! Anyways, poor parts in good hands still produce fine results, as your Unicorn shows! hamilton

-

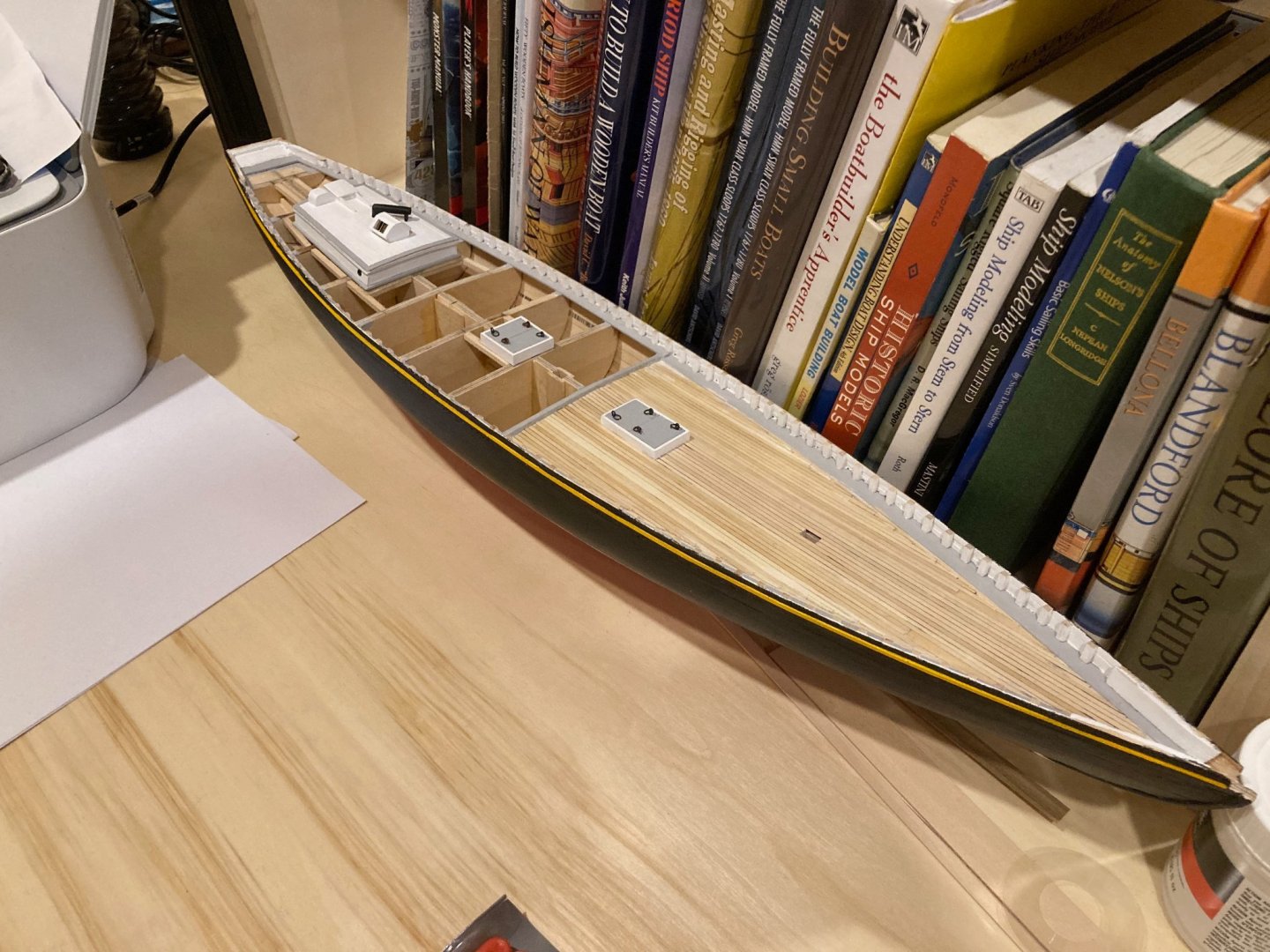

Hello there: Work on Bluenose has slowed as I've had to reduce my modelling hours to Saturday mornings - October-December is a very busy time at work and home so I'm feeling like a very dull boy indeed with all work and no play.... In spite of this I've managed over the last couple of weeks to plank the main deck. The joggling of the deck planks adds a significant amount of time to the process, and I'm not sure about the results - from a distance they're adequate and (judging by the photos below) my camera lens is extremely forgiving. But like everything in modelling it's about practice and getting a better feel for things with each attempt. And once all the deck furniture and fittings are added later things will blend in. The quarterdeck planking is not laid parallel to the centre line like the main deck planking - it curves more or less in line with the tapering of the deck towards the stern. This will no doubt take longer even than the main deck, but I won't have a chance to start on this until next weekend, unless by some chance I can carve out some modelling time tomorrow. In any case, slow and steady..... Enjoy hamilton

-

looking back through your log, I wish I had stumbled on it earlier, as I might have been able to provide some assistance with the odd stern bulkheads. on my Greyhound kit, bulkheads 9 and 10 were WAY off - I had to add 3/16" x 1/32" to the edges of those bulkheads. I used a test batten across all the bulkheads to gauge how thick these extra shimming strips needed to be and to gauge the area of the bulkhead edge they had to cover. It was a very time consuming and frustrating process as i recall....anyway, this is definitely a manufacturer issue! And a big stumbling block for the modeller...despite many criticisms of them that can be found on this forum, I actually quite like Corel kits and have made a few - this one, though, had some problems! hamilton

- 82 replies

-

look how it improves with elbow grease!! The planking looks great! - Nice solid foundation for the next layer. Keep on! hamilton

- 82 replies

-

Looking through your build log is giving me flashbacks! This was initially a frustrating kit to work with for me, but ended up being very enjoyable and one of the models I'm proudest of. I also agree completely with Harlequin (with whom I've exchanged notes on this model and who was a great help to me when I was working on it). Each model is a learning experience and each time you can apply what you learned from the last one and improve. It's difficult when (as is almost always the case with my builds) things don't look exactly as pristine and clean and perfect as they do on the box or in more experienced modeller's hands. If you enjoy the process, then you will enjoy watching the results improve as you go. And to the list of things Harlequin mentions above - knife marks, scratches I'll add - the modeller's own blood, which I've spilled on every model I've ever built! hamilton

- 82 replies

-

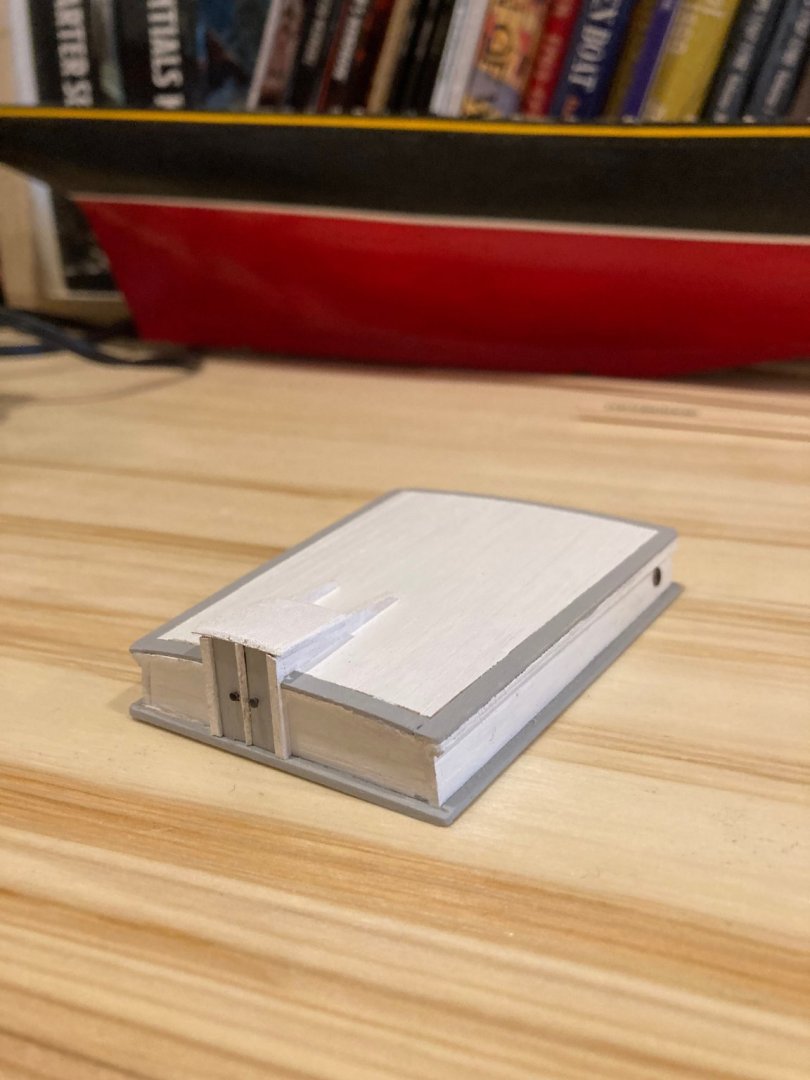

Thanks Mark - I'm contemplating redoing the cabin as it is a little off plumb and the skylight looks like a half-baked cake to me...not in any rush to complete this build, so probably worthwhile to try a re-do while version 1 is still not fixed to the model.....we'll see....bye for now! hamilton

-

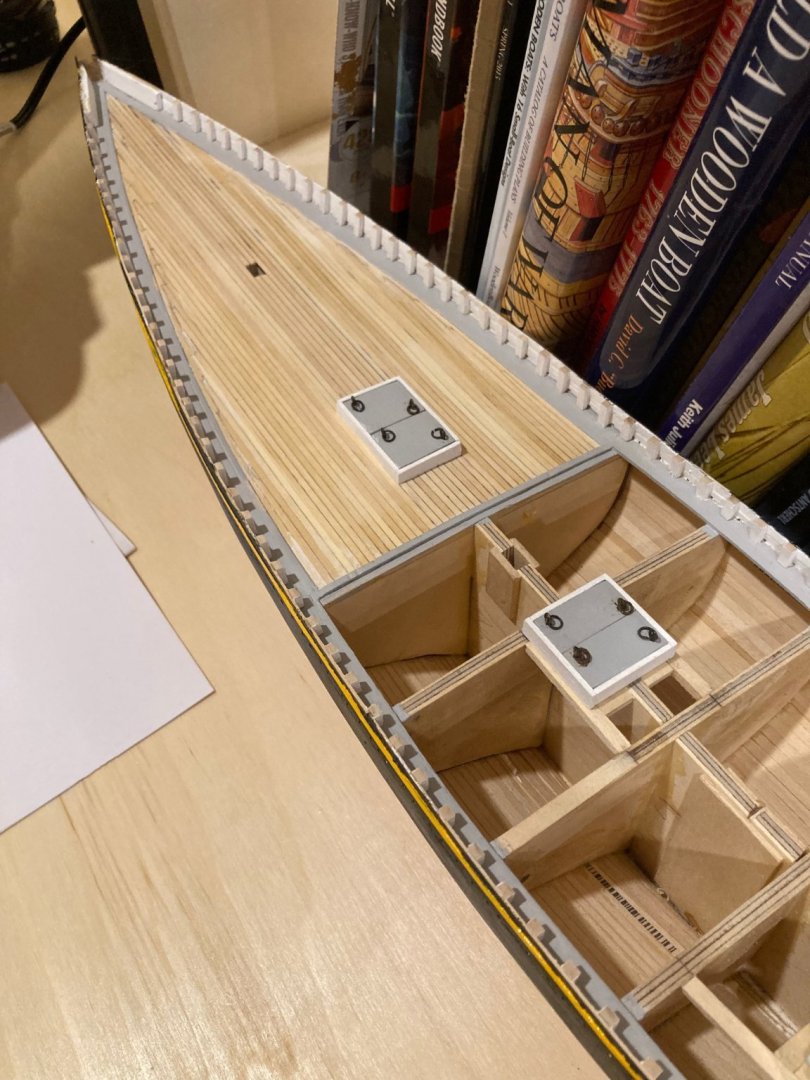

Another quick update on Bluenose. At this point, I've completed the cabin, adding binnacle, skylight and stove pipe - the latter made from some old dowelling I had lying around. I had thought to integrate the cabin, hatches and skylight/companionway into the deck planking, but in the end, I decided only to do this with the hatches and fit the other deck superstructures on top of the deck planking - planking around the cabin aft would have been pretty tricky given that the planking does not run parallel to the centre line on the quarterdeck, which the forward companionway and skylight are so small and close together, that (again) the finickiness of the planking was a deterrent. So I put together the hatches, fixed them loosely to the deck to begin the planking process and will fit them permanently once the deck planking has been finished fore and aft of them (this is to ensure that the planking runs evenly around them. I still have not found a good replace for the now unavailable blacken-it product, with which I always had decent results. With the product I'm using now I feel like parts either don't really blacken at all (likely there is a lacquer or some other coating on the brass that needs to be chemically removed first) or they get really flakey, indicating a very loose chemical bond.....I've read through a couple of threads on blackening and will try some experiments with different ideas/products I've read about here....but I miss blacken-it! So simple..... Anyways, After getting the hatches together I began on the main deck planking. The photos below show only the two centre strips but at this point I've laid down eight strakes of deck planking, which pushes the planks to the outside edges of the hatches. Now the hatches can be more permanently fixed and the deck planking will continue with the winch pads up in the bows, the nibbing strake run agains the waterways and the remainder of the forward deck planking. It looks a little rough (some bleeding of the simulated caulking seams through the action of the CA...Sanding has minimised this effect and the volume of forward deck features will likely make a lot of the little blemishes fade into the background as building continues.... Enjoy!

-

PS - I haven't built (or got) the Caldercraft Victory, but I usually locate gunports by taking a vertical measurement from the plans at midships, then at fore and aft, then at a couple of spots in between. Then run a batten across the marks to check for fairness and adjust as necessary to achieve a good fair run. You can do this for top or bottom of the gunports and then mark the other edge by measuring the height of the gunports and then marking this line across the bulkhead edges.....There may be other techniques used by other modellers and you may get other suggestions here, but this is one that worked for me. Hope this helps! hamilton

-

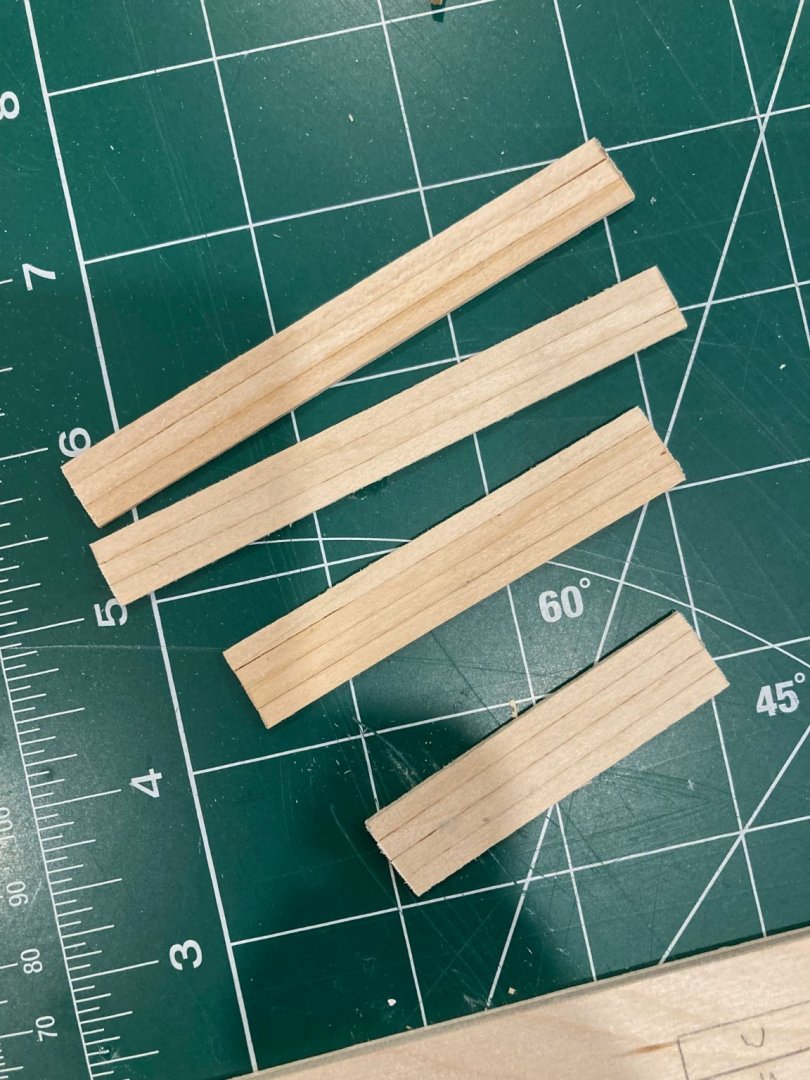

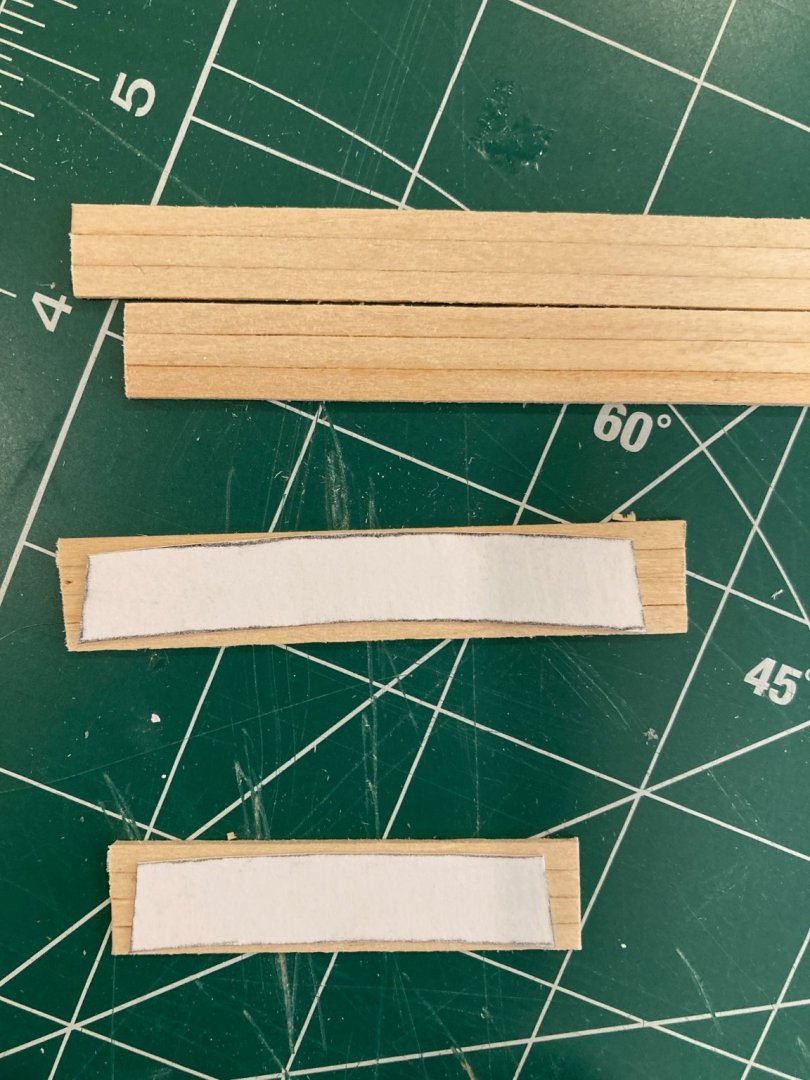

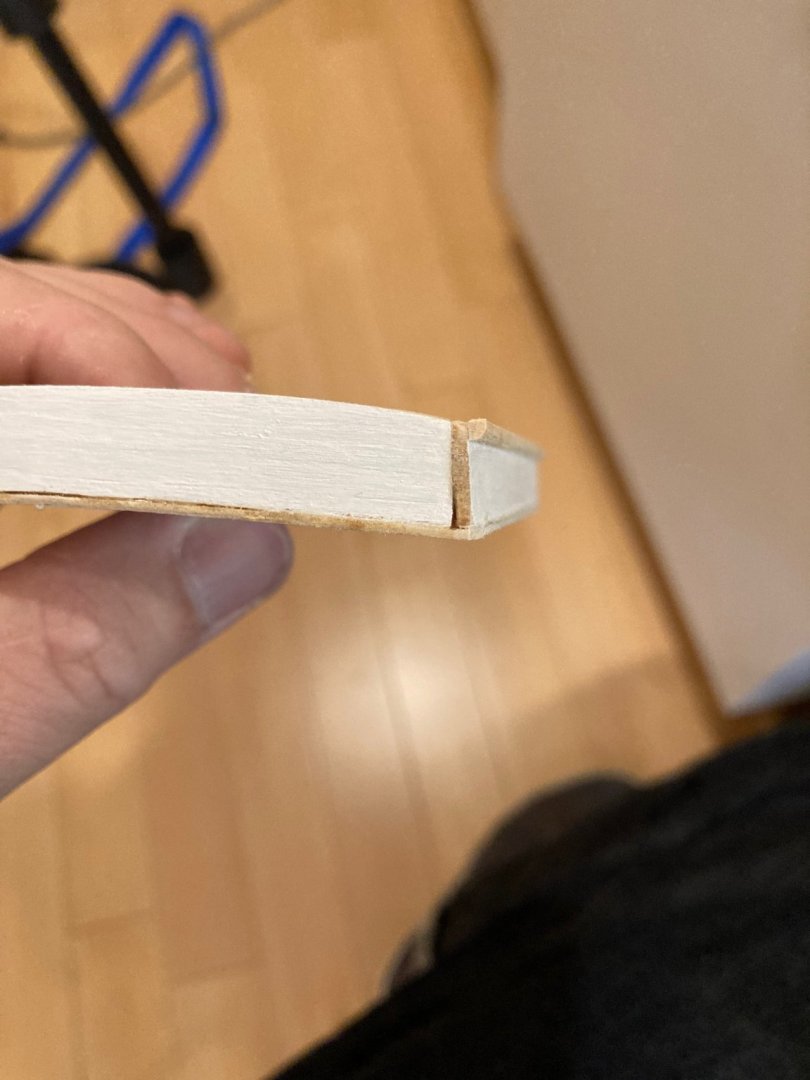

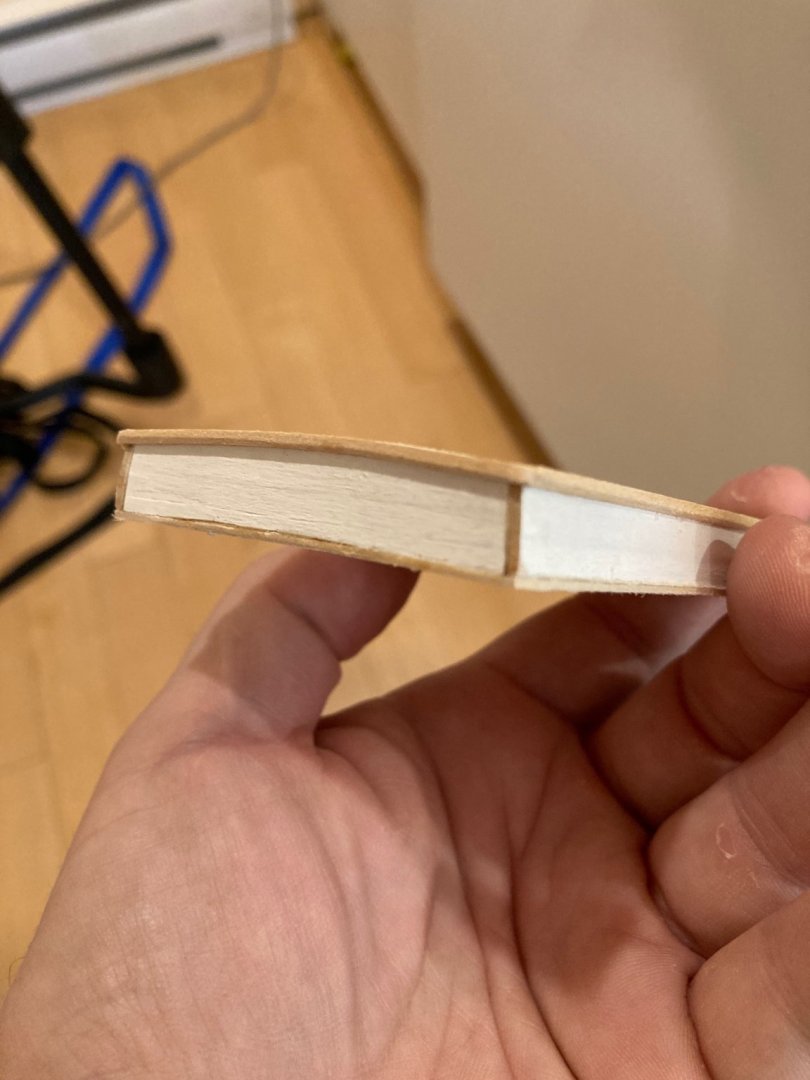

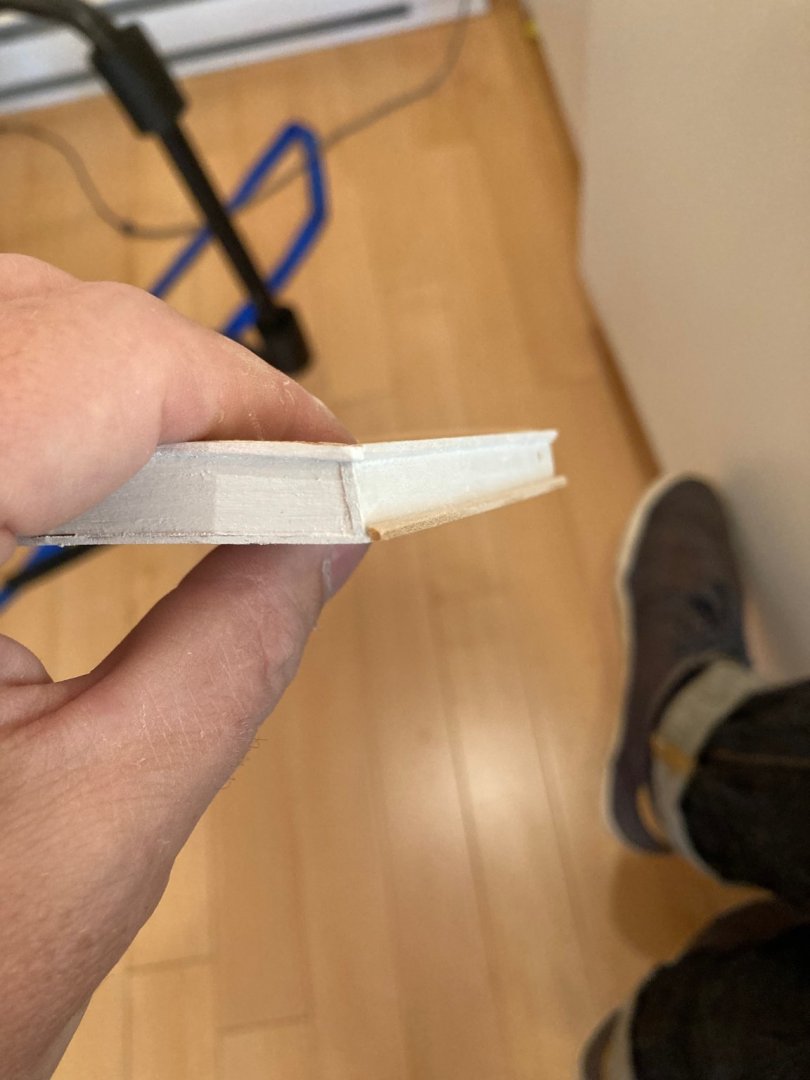

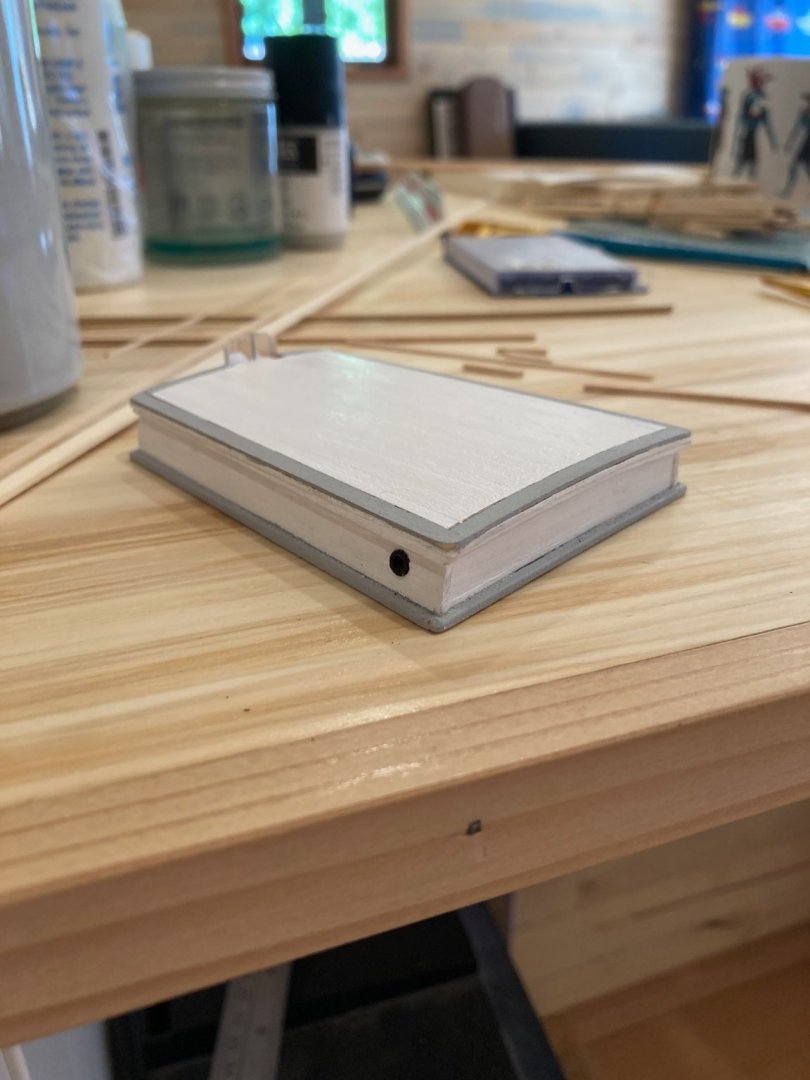

Spent Labour Day working on Bluenose - specifically the cabin construction. I've not yet completed it - with the skylight, binnacle and stovepipe still to add - but so far this has been a fun little mini-build. It's a lot of fun to put these deck features together - one of my favourite parts of ship modelling (other than tying ratlines, obviously)! I took patterns from the deck framing drawings for the general outline of all the superstructural elements on deck, then transferred these to card stock and made templates for the general "footprint" of these elements as well as for the fore and aft panels of the cabin, which curve in line with the deck camber. I started by edge gluing some 1/16" x 1/8" strips together, then trimming these built up panels to the correct size and shape. I then added internal reinforcements (1/8" square pieces) and also reinforced the whole assembly by adding a base cut from a sheet of 1/32" lime and some 1/8" square battens on this. After that it was pretty straightforward - I used some leftover parts for the portholes and went with a different colour scheme than the one suggested on the plans - neutral grey (like the waterways) in place of burnt umber. I made the companionway frames a bit too wide for the 3/16" door panels, but I had a 1/32" x 1/32" strip that worked perfectly as a divider...some brass nails serve as door handles. Anyway, it's a little rustic looking, but I'm decently happy with the results. Now that a new working year has begun, I'm going to have to restrict my modelling to weekend mornings for a while....in the meantime....enjoy the photos! hamilton

-

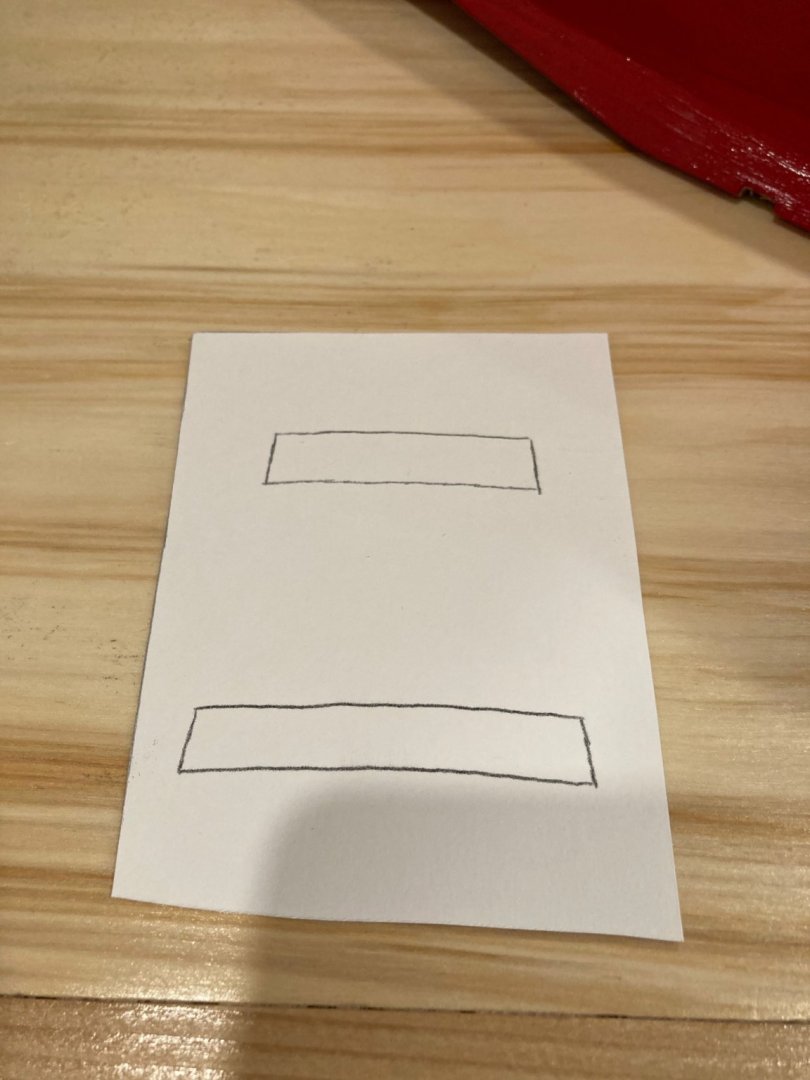

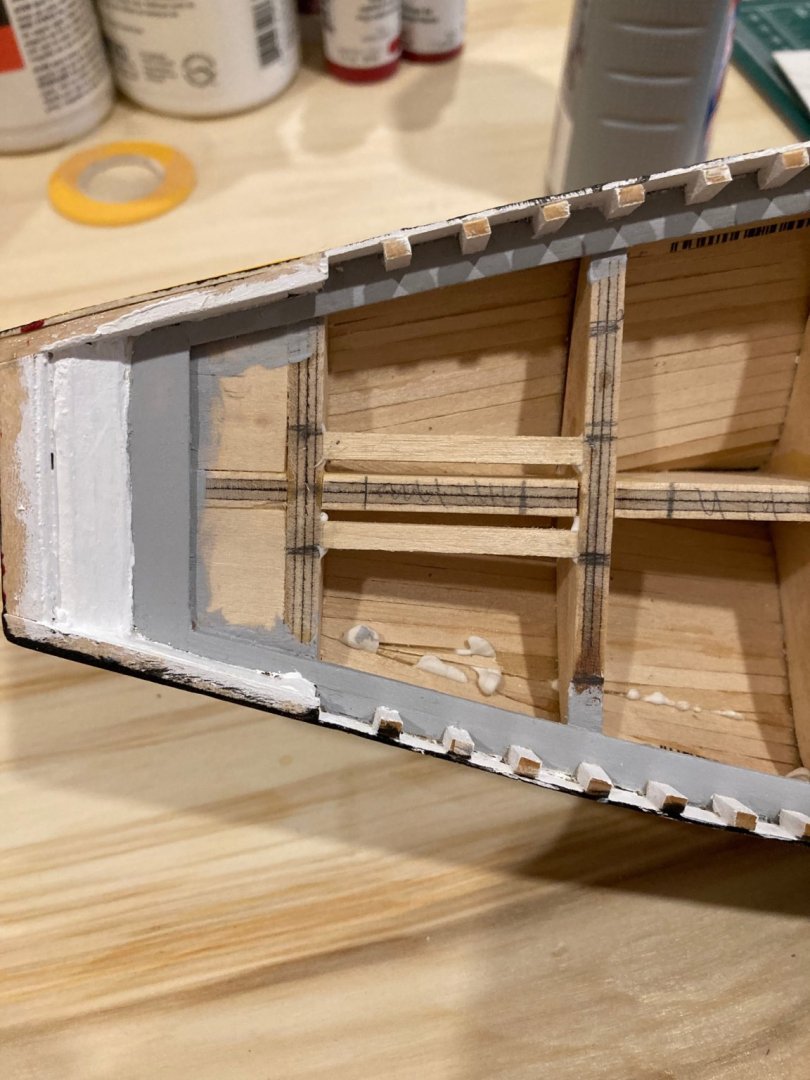

Hello all and happy Saturday Quick update on Bluenose. Over the last couple of days, I've touched up the outboard hull painting, focusing specifically on the cove (yellow) and the waterline strip (white) to clean them up as much as possible - I only have a photo of the preparation of this and don't seem to have any right now of the cleaned up paint job....sorry! I also made templates of the deck superstructures from card paper, fixing them temporarily to the top of the bulkhead frames to mark out their positions and identify where framing strips need to be added between the bulkheads. I added this framing this morning after completing the finishing of the inboard bulwarks and stanchions. There are a couple of little clean-up tasks to complete before starting to build up the deck superstructures. First I need to sand down the stanchions to the level of the sheer - a tedious process, but unavoidable. Then I need to epoxy the forward mounting nut to the bottom of the keel. Then it's on to more fun stuff with the superstructures and deck planking! Enjoy the photos hamilton

-

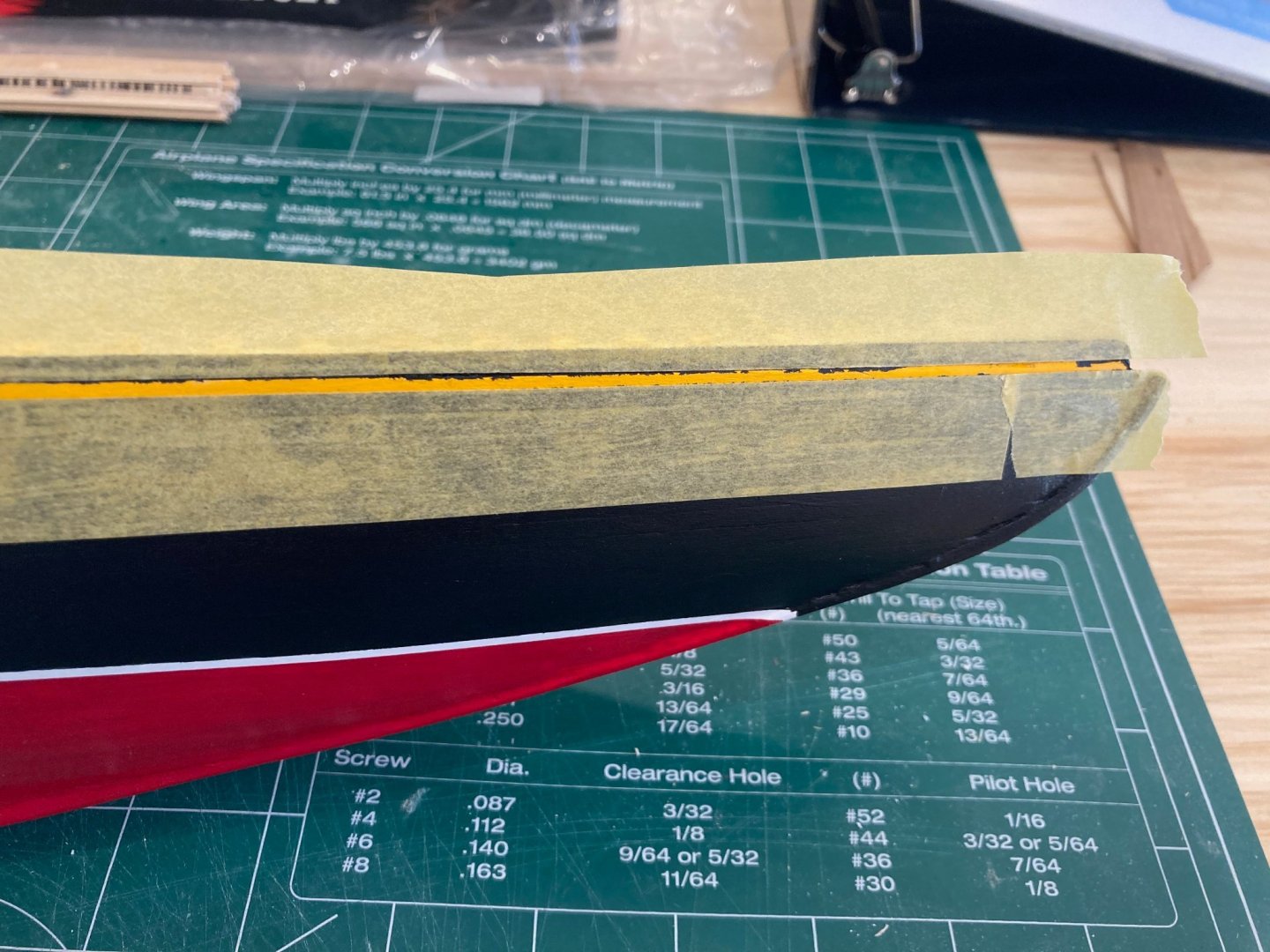

Thanks Steve - definitely some clean up to do - the sheer strake is 1/32" thick while the remaining bulwark planking is 1/16". The cove runs along the top edge of the uppermost 1/16" plank so the bleeding of the black hull paint onto the yellow cove paint was a result of some uneven masking along the "step" between the thicker and thinner planks....a bit of sraping and filing and sanding and careful touch-ups will hopefully correct for the bleeding. hamilton

-

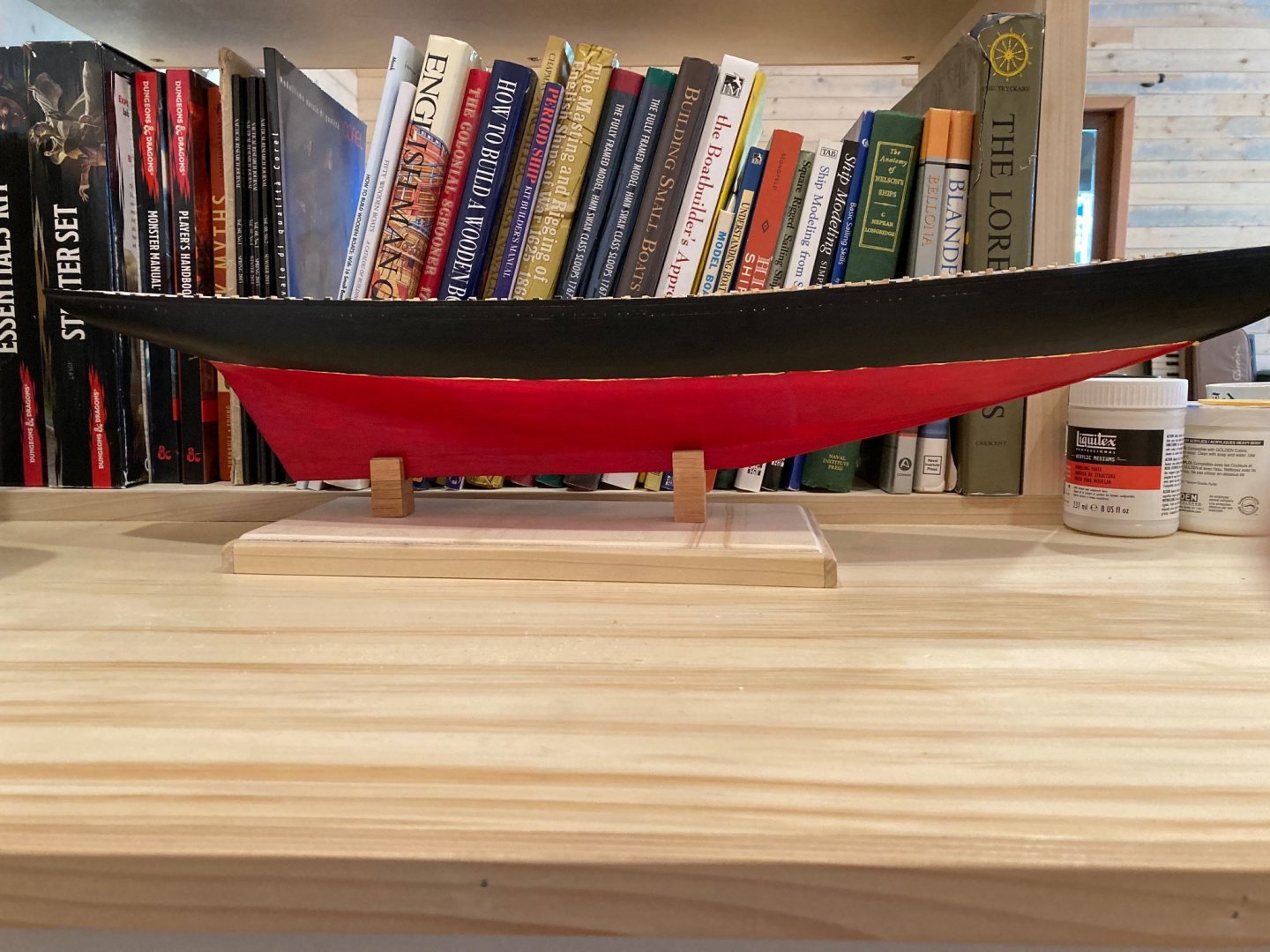

Another update on Bluenose - finished the hull. I first applied a few coats of yellow paint to the bulwarks for the cove and a few coats of white along the hull's waterline region, then masked off where the white waterline stripe and the cove (yellow) are located using 1/16" masking tape. The 1/16" strip is too wide for the cove, but.... I then used a mix of two slightly different shades of red applied one after the other in four coats to get a slightly weathered look to the hull below the waterline and used Bone Black (a slightly bluish black) on the hull above the waterline (three coats here were sufficient). The test for me is always having the patience to wait to remove the masking and reveal the full finished effect. The waterline stripe worked out very well, but the cove needs touching up here and there - the port side is a bit better than starboard and I think a bit of fine knife work will help to clean this up to a decent standard. Next steps - finishing the mounting and adding framing strips for cabin and hatches on deck....nice to be moving on to more superstructural work! Bye for now and enjoy! hamilton

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.