-

Posts

585 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by niwotwill

-

-

Spent the morning fairing the bulkheads getting ready to plank. Nice to have the marks so the gross sanding was completed prior to bulkhead mounting to false keel.

One note to anyone wishing to build Erycina THE TRANSOM BULWARKS ARE VERY FRAGILE ESPECIALLY THE OUTSIDE. The outside bulwarks were doubled and a 3mm filler added and all this must be faired for planking to flow. When complete the outside bulwarks are almost half their size at the tips. A trick I use to make the bulwarks less prone to breakage is using upholstery foam cut to fit in-between the bulwarks.

Its not pretty but does an amazing job of protecting the protruding bulwarks. I buy the foam from a fabric shop near me in 2" thick pieces. When I dry fit the pear wood keel pieces they fit perfectly and I went ahead to glue the bottom piece.

I use elastic bands to hold the keel snug while the glue sets and you can see how the foam supports the bulwarks especially the transom bulwarks.

Many Regards

Will

- GrandpaPhil, Andyrew, chris watton and 6 others

-

9

9

-

Finished Christmas shopping so now back to Erycina.

Started the fairing the forward support pieces and kept putting them on the keel section wondering how is this going to work? Being basically noisy I removed the locating tabs from the 3mm sheet and placed the pieces in place. The more I work with Chris's kit the more impressed I become. Holding the filler pieces to the keel all 3 tabs slipped into place. Amazing.

I had done a little fairing on the forward frames prior to attaching the fillers. But still wondering how to fair fullers. So now the stern fillers using the same method.

These fillers flow into a nice bearding line for a rabbit. And as stated the lower deck fell into place with a little frame jiggling. Each time laser cut parts fall into place amazes me.

Put the + shaped parts in place and glued into position. It is so foreign to me that the frames are just left in a dry fit position. I've always used squares, levels and glue to insure the frames are square to the frame and level athwartship. Now putting in the longitudinal pieces squaring the frames along with the lower deck the boat is becoming rigid.

Had a small problem with the longitudinal pieces aligning with the + pieces. A NOTE TO OTHERS MAKE SURE THE + PIECES ARE FLUSH WITH THEIR ADJOINING FRAMES OR THE LONGITUDINAL PIECES WONT SLIDE INTO PLACE. I fixed my problem with a slight amount of sanding and then the parts sled together. Snapped the after pieces with no issues.The last thing was to snap the false deck into place. Once again the parts alignment is amazing. I slide the deck into the starboard side making sure it was fully seated and the with a slight amount of bowing slipped the port side into the frame notches. Diluted some white glue and painted all the joints. After setting awhile the structure is very secure with no bending or flexing.

Thats enough for today must let all the glue set and begin tomorrow.

Many Regards

Will

- yvesvidal, chris watton, Charter33 and 9 others

-

12

12

-

I want to thank everyone for the looks, like and nice comments.

Allan

I like your idea of how to make strips it definitely would make life easier. I think I just need to get over being frugal with wood. Make a bunch use what you need and feed the barrel with the rest should be my motto.

Kind Regards

Will

-

Welcome everybody plenty of room to join the party. Lets get started.

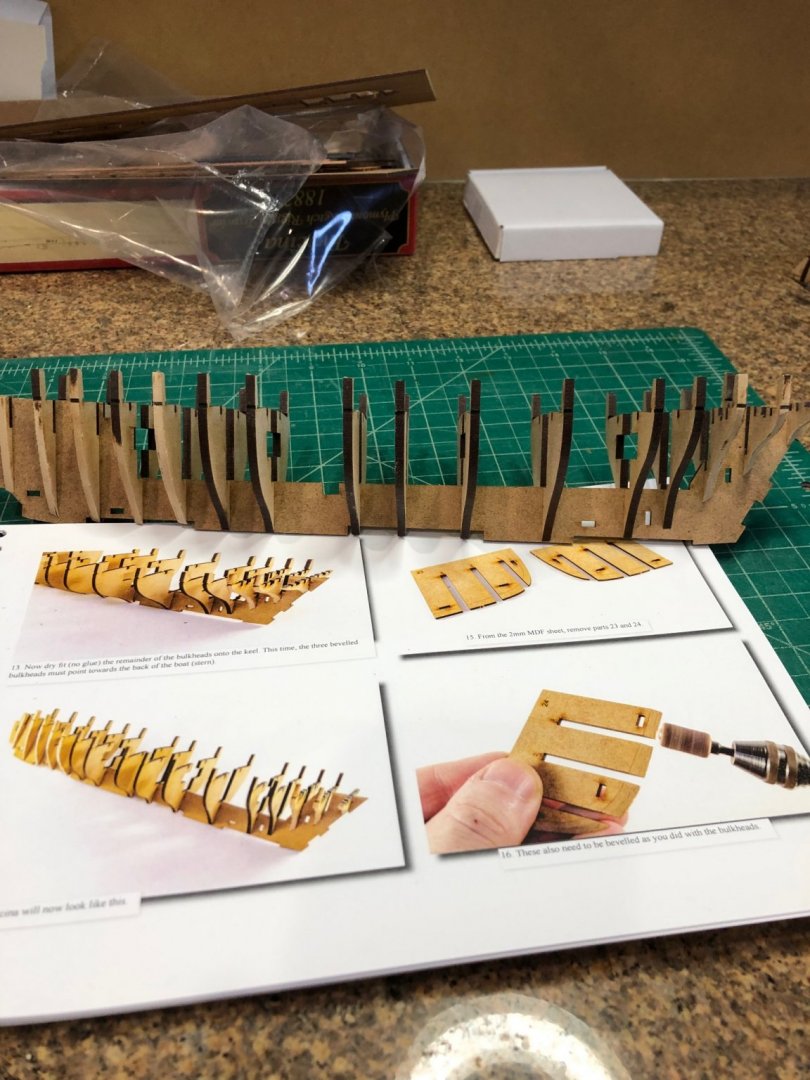

First I carefully cut the 16 bulkhead frames from the 3mm MDH using a #11 blade. When not being sure if the laser char should be removed I removed the keel from the 2mm MDF and dry fit each bulkhead. The fit is so tight, not too tight and not a sliding fit, so I'm leaving the laser char. I did remove the little attaching tabs from each piece.

16 bulkhead frames on such a small ship will make planking easier keeping a clean smooth sweep.

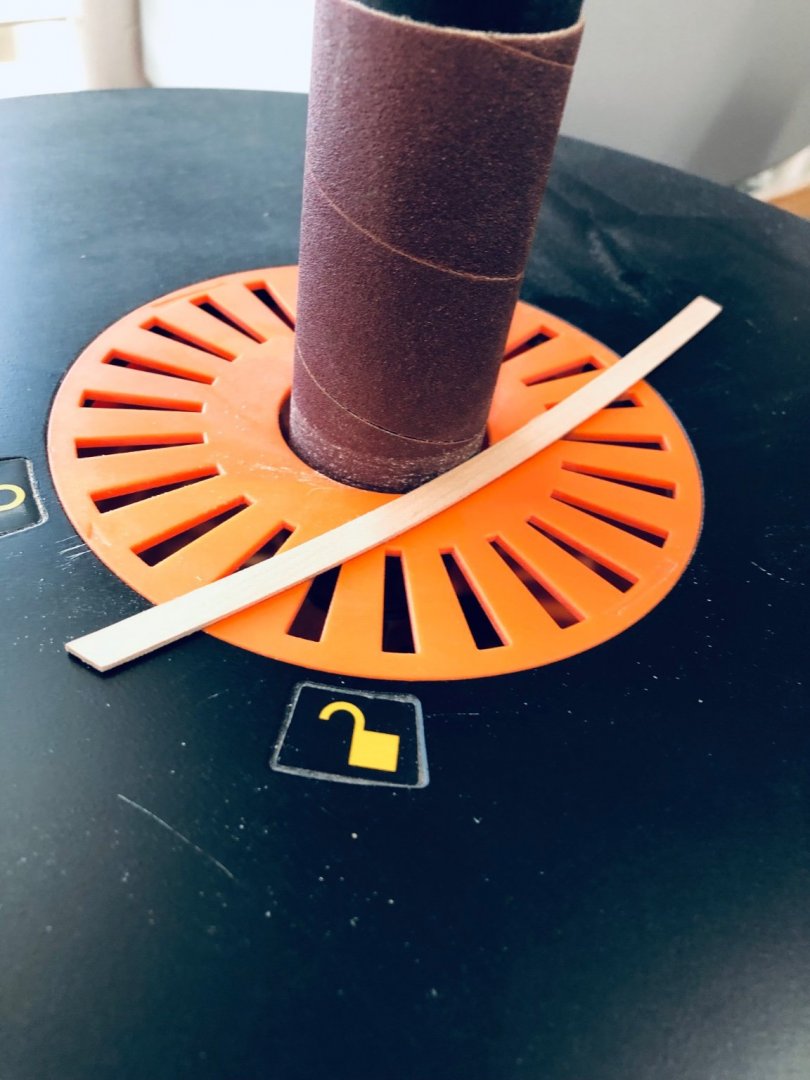

I used my Proxxon rotary too to fair bulkheads 1, 2, 3, 4, 15 & 16 to the laser scored line. It was a little nerve wracking on the first and last frames as the line was so far from the edge. I put the frame back into the keel to check and went ahead fairing to the line. Proxxon has a great clam shell clamp to put in a vise. With it secured it was easy to hold the frames along the drum and up to the line.

All the fairing done and the frames back on the keel as the manual suggested. So I'm now back working in the correct order

Doesn't seem like a lot of work but after spending so much time checking, checking, and rechecking I feel better that it is correct. On previous kits I learned that small mistakes always seem to come back to haunt the design later. So my neurotic checking continues.

More tomorrow now its time to do some Christmas shopping.

Many Regards

Will

- JpR62, Charter33, chris watton and 4 others

-

7

7

-

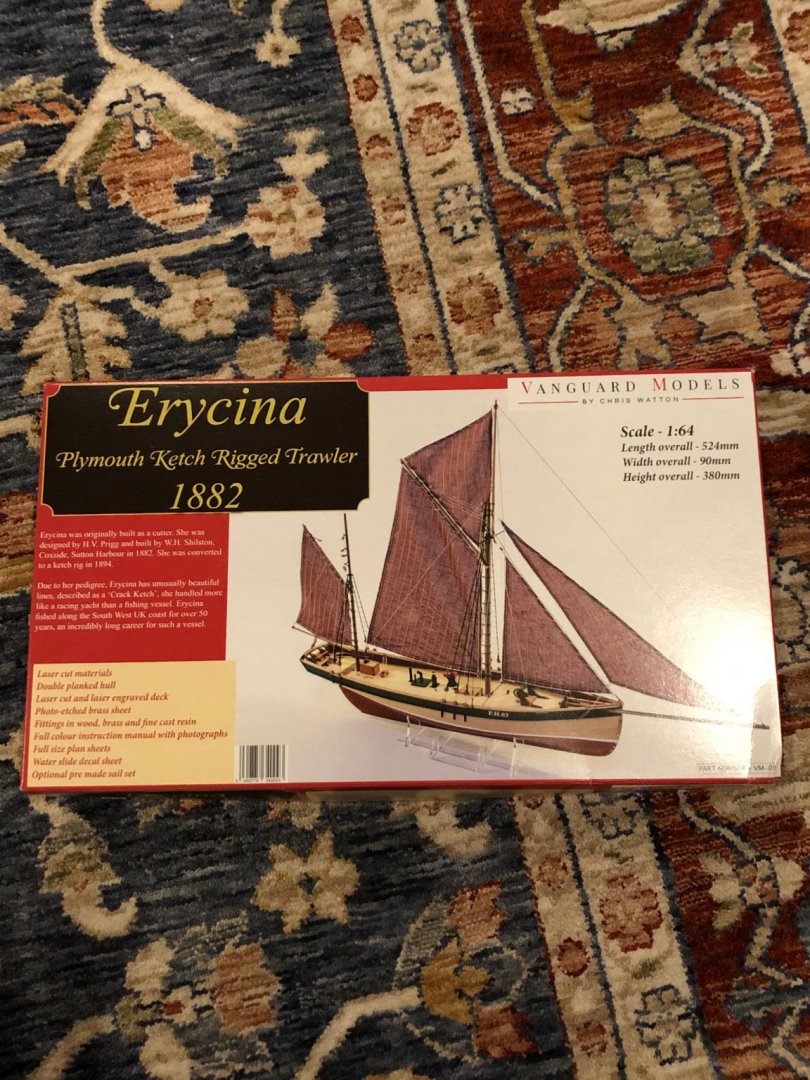

Been following Vanguard Models by Chris Watton for some time and when I saw this kit I jumped. Got the box a couple day ago and had planned to put it on the shelf until other project were finished and when it was time to wait additional supplies I figured I'd start. What the heck 😬 Opened the box and did the usual inventory of parts along with a photo.

Kit contents

I couldn't wait and put the working stand together. When Chris said it should not require glue, he was spot on. The parts fitting was very snug with not wiggle. The laser cutting of the 3mm MDF was very fine and a #11 blade did not fit between the edges. Looking at the parts I am very impressed with apparent quality of the material. THE BEST KIT I HAVE SEEN. Can't wait until tomorrow.

Best Regards

Will

- chris watton, BenD, BobG and 3 others

-

6

6

-

I started the Syren 2 years ago and lost my way. Inbetween I've finished several small boats and started others now I realize that I can't work on 2 models concurrently and have put the other models on hold to finish Syren. I finished up with the lashing to sheer poles and now on to the futtock shrouds and catharpins.

More to come

Regards

Will

- abelson, Overworked724 and JesseLee

-

3

3

-

Ok, as I said I had not ordered sufficient grating strips and since the Syren Model ship company is closed I've decided that I'll put the Cheerful on hold until I finish another project that has been in the works. I have not given up on Cheerful just need to finish something else I started.

All deck furniture completed waiting for more material.

Until I start again

Regards

Will

- Nunnehi (Don), JpR62 and GrandpaPhil

-

3

3

-

Very nice Patrick. Can't wait to see the completed rudder with the P&G's you've done so masterfully. Couple things I like help on 1. Earlier on you detailed how you sandwiched brass to cut when its so thin I could go back and read the log but I'm lazy. Could you explain? 2. How thin is the brass for the P&G's?

Regards

Will

-

Chuck

Somehow I failed to order sufficient grating slats to make the gratings on my Cheerful and your store is closed, when do you expect it to be open for orders? In the mean time I make coaming for the large grate and chimney.

Will

-

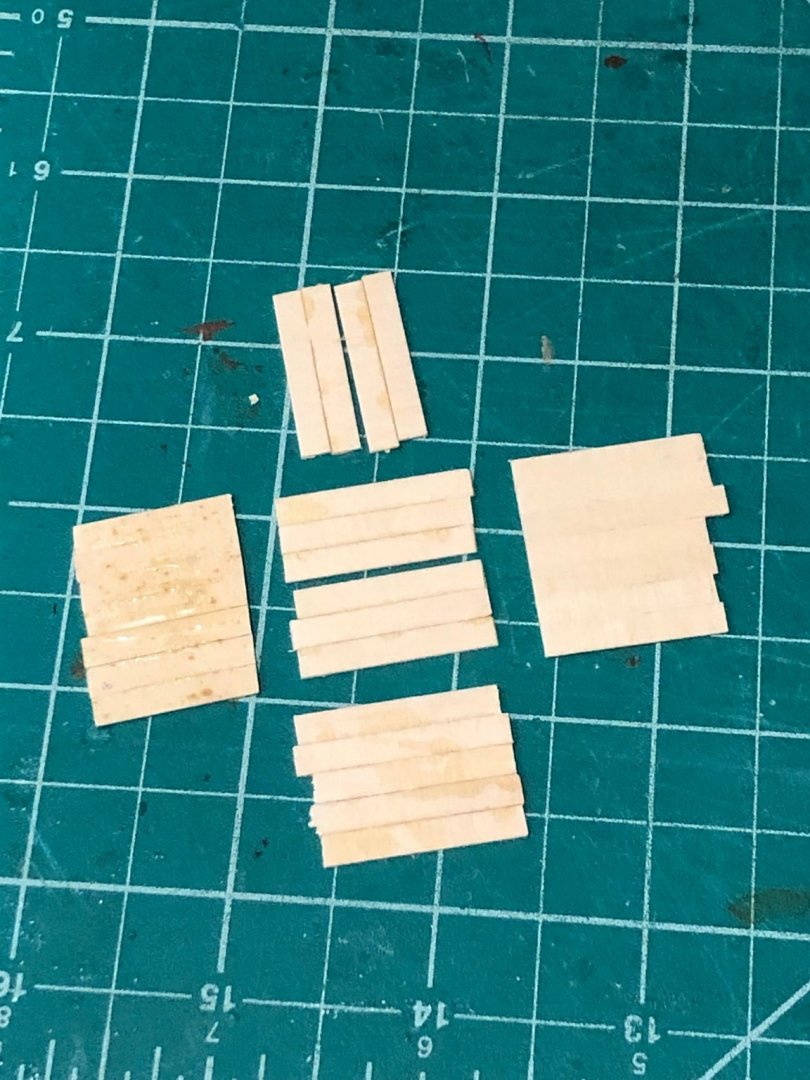

Started the companionway this afternoon. Using the plans for the sizes and started with a 5/32" board and ripped .03 strips and sanded them to .025 thick. Not sure how to build this without any frame so I glued 1" long steps together laying them on my granite work surface with weights on top to keep them flat.

Parts laid out to dry

Door Pieces

Roof in the middle

Rear Side

I'll make the roof and doors in two pieces so its very obvious that they should open with the hinges in position. When glue dries I use the disk sander to square the edges and then sand in the sloping sides. The sides need to angle to make them perpendicular to the keel and match the slope of the deck.

Regards

Will

- GrandpaPhil, Ryland Craze, JpR62 and 2 others

-

5

5

-

Thanks everyone for comments and likes

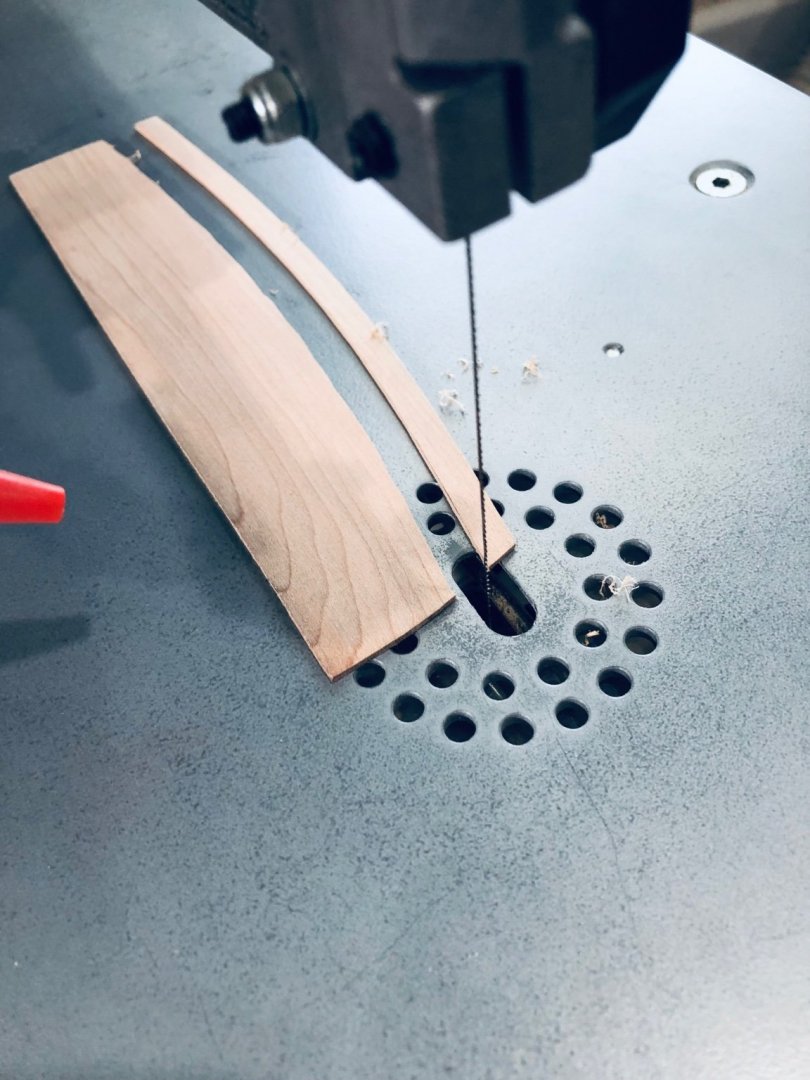

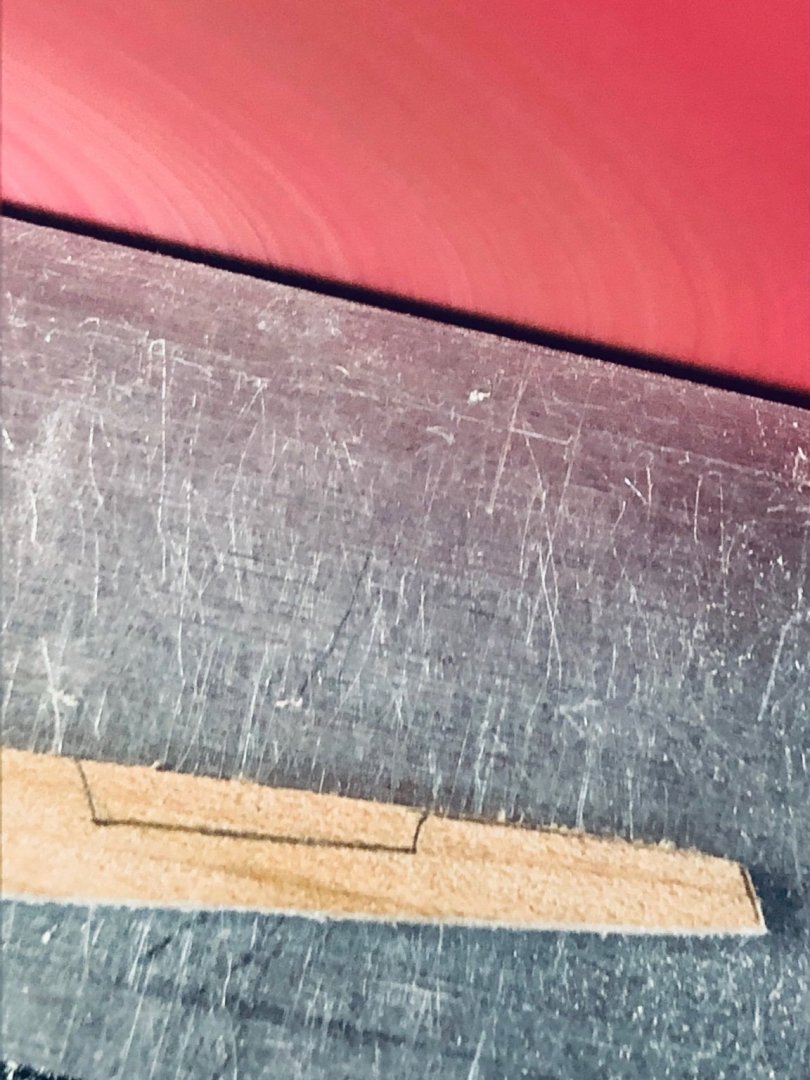

The margin planks and waterways are now complete so I'll try to document the process. In the above post it shows a piece shaped to the bulwarks which was used to cut the forward margin planks. I used a drafting compass to mark the 1/4" width of the plank. Cut the piece close to the line on the scroll saw.

After cutting the inner shape it was sanded to the line a spindle sander.

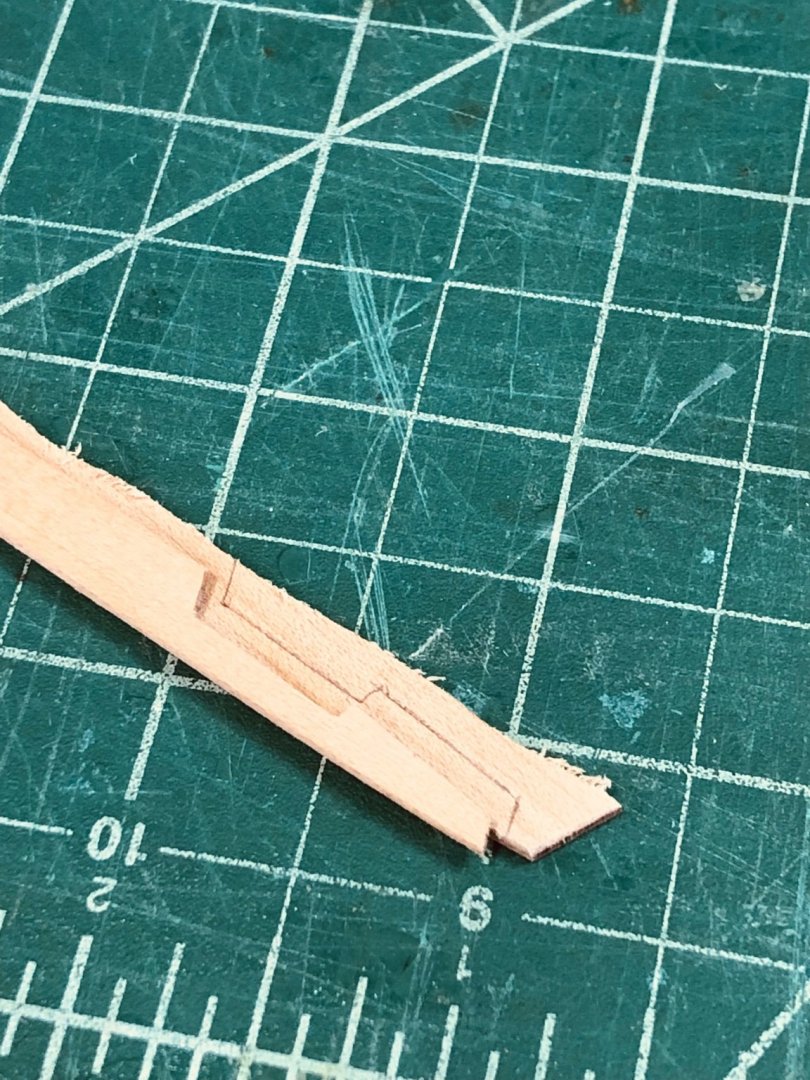

Now I marked the first scarf on the piece after fitting to the stem. Using a #11 blade the scarf was cut, but two problems arose from the cutting. The first was cutting across the grain of the maple required many passes and the result was the cut was too wide with edge angles and the second was the small portion broke off when the blade finished the cut. Many attempts resulted with one or both results so another process needed to be developed. Looking at the traced pattern of the scarf maybe it would be easier to saw the cuts and then finish with the flats.

The traced scarf shape

Next I sanded the flat portion of the scarf

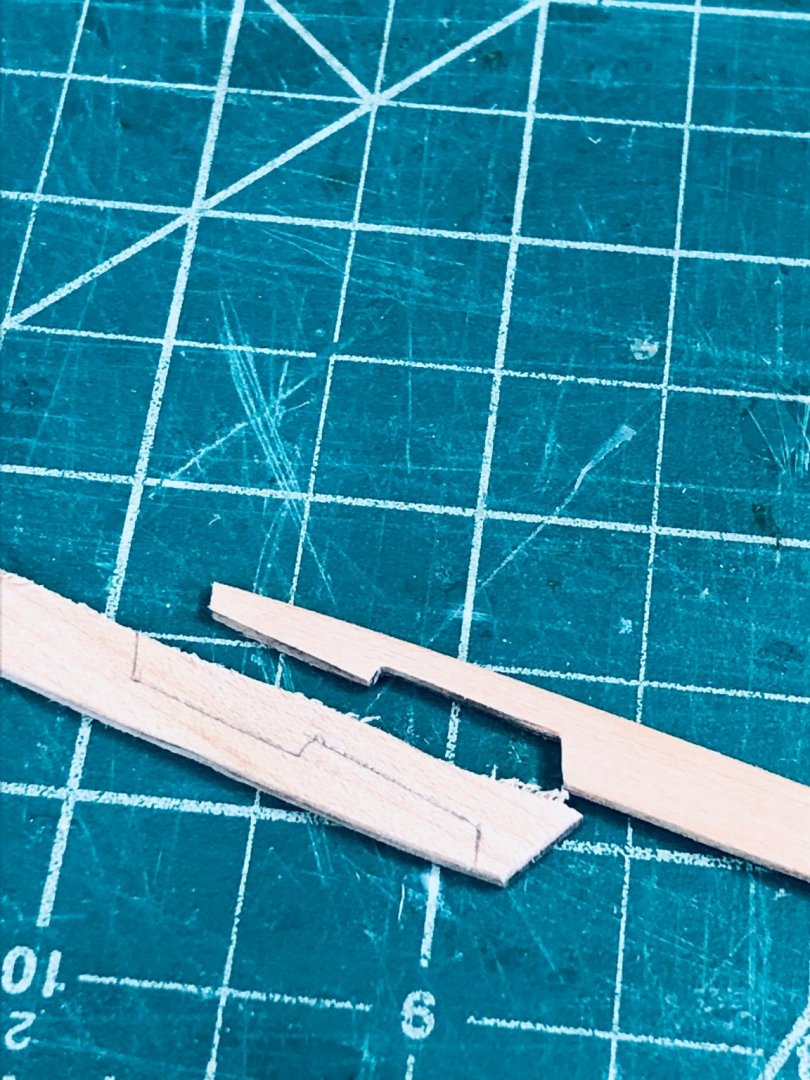

The tab protruding from the recessed portion is what kept breaking while cutting with the #11 blade. After sanding I put the piece in a small vise so the recessed line was level with the top of the vise jaws and used a razor saw to make the cuts.

Then it was a simply paring down to the level of vise jaws. A little filing and I had a joint. Made the balance of the margin pieces the same a the fore section. Still had several joints/pieces that had to be remade but a lot easier with this method. Once the margins were glued down I made 1/32" strips for the waterway. In doing this I realized that there had been no mention of scuppers. I see them in the photos and drawings so I guess that's my next step.

Margin Planks and Waterways

On to scuppers

Regards

Will

- GrandpaPhil, Ryland Craze, JpR62 and 5 others

-

8

8

-

Very nice Patrick. If I take mine off will you make me some? HA HA HA

Regards

Will

-

Andrew

My heartfelt condolences for your loss of Kelly. I lost my companion Arthur last month to a long battle with cancer. Arthur died in bed with me while I was petting him, I can not begin to feel what it is to put them down. So sorry

Best Regards

Will

-

patrick

Sorry for the late response. I use hard silver solder on everything but when its time to solder it all together I use the soft silver solder so the hard does not melt using a butane torch. Hope this helps.

Regards

Will

-

Patrick :

Love that ships wheel from Chuck. I had a lot of fun making it as you stated you had fun. Its really cool how the stuff from Syren Model Ship works so well making wonderful pieces.

How's the shoulder doing?

Regards

Will

-

Where would we be with Amazon Prime? But I do hate to see local business getting hurt.

Regards

Will

-

Hi Glenn

As they say I brought up a chair for your next build. Couldn't stay away from the scratch builds. HA HA HA It is looking good so many frames. You go Glenn

Regards

Will

- FrankWouts and AlleyCat

-

2

2

-

-

-

Patrick

She's coming along nicely very nicely. You might check with Model Shipways that multiple size cannon balls.

Regards

Will

-

Thanks Maury. I'll file that away for future use.

Regard

Will

- mtaylor and thibaultron

-

2

2

-

Just started following your build but still need to go to the beginning and really study your posts. A comment on paper patterns which I also use for cutting is try using the glue sticks that are used for school work, photo albums, etc. It holds very tightly to the wood when cut and washes off with water leaving no residue.

Amazing work i'm looking forward to reading your log from the start.

Regards

Will

- mtaylor, Kevin Kenny and KentM

-

3

3

-

Very nice Maury. I like the sliced brass tubing. Did you also use the tubing to score the rudder post? Overall she's looking fantastic.

Regards

Will

- mtaylor and thibaultron

-

2

2

-

Thanks for nice comment John. I spent my working days as a electrical design engineer and many nights brought the answers for previous days problem.

And thanks all for the looks and likes it keeps me motivated.

Regards

Will

Erycina 1882 by niwotwill - FINISHED - Vanguard Models - scale 1/64 - Plymouth Fishing Trawler

in - Kit build logs for subjects built from 1851 - 1900

Posted

Wanna take time to thank everybody for the likes, looks and comments I'm having fun building this little trawler.

Having worked on my first Vanguard model I have become spoiled by how the laser cut parts fits, but now it time to do a little free flying. The keel fit onto the false keel perfectly and the cut water stem fit perfectly as well after the little sanding as described. The stern post fit the same with not modifications required.

Again elastic bands held everything in place while the glue sets. A couple of clips holding the pieces square and they really weren't necessary since the frames had extensions below the false keel that kept the keel in alignment.

All glued up and ready for the bulwarks. The pear wood really shows its color and seems a real shame to paint. Oh well!

No locating tabs for bulwark mounting just the same old method of fit and glue. One thing that is very important about this part of the build is to read and understand the instructions. Two things jumped out to me that I'll speak to when there. The forward section fits into the slot on the cut water and just a little sanding on the lower section that sits below the slot. It becomes obvious when you hold the part up to place. This is where the two cautions come into play. The first is align the part on the lower deck etched into the bulwark. This is very important as you get the transom extensions you can see that reference for the little deck to be built. The second one struck me with a wham boy did I almost goof up. DO NOT GLUE THE BULWARK ABOVE THE DECK. The extensions above the deck will be cut off and stanchions will be added in the locations etched on the bulwark. I alway use medium viscosity CA glue when I'm planking and the bulwarks seemed like planking so I used CA. So what I did was set the bulwark in place and use clips to ensure it stays in place and turn the boat upside down and apply the CA at the joint of the deck, frame and bulwark.

The last thing today was the counter. I put the counter in a bowl of water and boiled it in the microwave until is sank. Then it was just a process to set it in place and clamp for 12 hours. One thing that I should mentions is the counter extensions have a small notch as the turn up to the transom. When you set the counter against this notch on mine the forward edge of the counter rested the last frame by about 1/32"

Glue the inner counter on tomorrow.

Many Regards

Will