-

Posts

3,268 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by realworkingsailor

-

-

A small update for everyone. I was in touch with the company this afternoon, and they have a relief for me. I'll be able to go home when the ship gets back to the Welland Canal in 6 or 7 days or so. Never in my life did I ever think I would actually be looking forward to going to a funeral..................... Andy

- 1,148 replies

-

That looks like the sinking of the General Belgrano....

-

I'm guessing you're glad you went with the prefab strips now, right? Looks great, even without the close ups Andy

- 326 replies

-

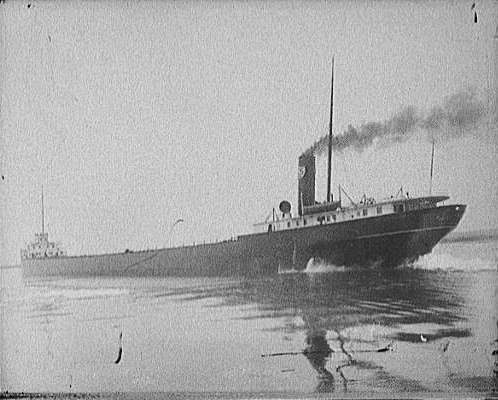

- vinal haven

- steam ship

-

(and 1 more)

Tagged with:

-

Just an idea.. you might find these even better (and less work): http://www.sceneryexpress.com/products.asp?dept=1053 More specifically: http://www.sceneryexpress.com/prodinfo.asp?number=HK1863

- 170 replies

-

- ogallala

- praire schooner

-

(and 2 more)

Tagged with:

-

Naval History On This Day, Any Nation

realworkingsailor replied to Kevin's topic in Nautical/Naval History

1975: Loss of the 730 foot lake freighter SS Edmund Fitzgerald, with all hands. This marks the last large vessel lost on the great lakes. Andy -

Whew... I though for a moment that was the view from your house this morning.... note to self: read captions first....

- 2,215 replies

-

Great work. The colours are excellent. Muted, not garish, but still brilliant. And they compliment your hull nicely. Andy

-

Once again, I can't thank everyone enough. And every time I show up, there are more of you to thank. Such a great community here. Andy

- 1,148 replies

-

Naval History On This Day, Any Nation

realworkingsailor replied to Kevin's topic in Nautical/Naval History

November 9 100th Anniversary of the great storm of 1913. In one afternoon, 12 ships where lost with all hands and another 30 where stranded. Over 250 sailors died in the freezing water. The twelve ships lost are as follows: Lake Superior: Leafield, 1892, 18 crew Henry B Smith, 1906, 25 crew Lake Michigan: Plymouth (barge), 1854, 7 crew Lake Huron: Argus, 1903, 28 crew James Carruthers,1913, 22 crew Hydrus, 1903, 25 crew James A McGean, 1908, 28 crew Charles S Price, 1910, 28 Crew Regina, 1907, 20 crew Isaac M. Scott, 1909, 28 crew Wexford, 1883, 17-24 crew (actual number unknown) Lake Erie: Lightship #82, 1912, 6 Crew For a full description of the storm see here: http://en.wikipedia.org/wiki/Great_Lakes_Storm_of_1913 Andy -

Again, thanks to everyone for your messages of condolences. I had a long chat with my sister earlier today, and we spent a lot of time talking about our fondest memories from when we were kids. There's going to be a celebration of my grandfather's life later this month and I'm trying to figure out something to say. I've started put some ideas together, but nothing concrete yet. I'll figure something out. Andy

- 1,148 replies

-

Now that's a smart idea! Moving canons.... Very cool Andy

- 536 replies

-

- diana

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks everyone for your thoughts and condolences. It's nice to have such a great group of people around here who truly care about each other. To be honest, there are times when I feel very much alone. Being able to see a few ships being built, and the great stories and laughs everyone has here helps a lot to make the distances shorter, and things a little easier. Once again, thank you all so very much. Andy

- 1,148 replies

-

Hello everyone Sorry if I'm not my usual happy fun time self lately. We've had a sudden and unexpected death in the family, and it's hit everyone rather hard. You folks are a pleasant distraction for me just being who you are. Please keep it up, it does help. I'm hoping to get an early relief off the ship and be home by the middle of November. Andy

- 1,148 replies

-

Well... I've been worried for quite some time.... Now I'm on to genuine concern..... Next step is outright paranoia.....

- 1,148 replies

-

Yeah... headrails.... everybody's favourite head-scratching, how-the-he** moment. Nice work you've done. Although... that second canon.... sorry to say.. but...uh.... he seems to be aiming a bit low...... Andy

- 536 replies

-

- diana

- caldercraft

-

(and 1 more)

Tagged with:

-

Popeye.... I'm starting to get concerned about you.....

- 1,148 replies

-

You think you guys are eagerly waiting my return... Just imagine how I feel anticipating my own return..... It's been a long year on the lakes and I can't wait to get home, take it easy and do the things I want to do...... Oh yeah... And actually sleep the whole night for once! Andy

- 1,148 replies

-

If it's not available at your local hobby shop, you can get it from Microscale: http://www.microscale.com/Merchant2/merchant.mvc?Screen=PROD&Product_Code=MI-2 http://www.microscale.com/Merchant2/merchant.mvc?Screen=PROD&Product_Code=MI-1&Category_Code=FINPROD&Product_Count=1 Andy

- 94 replies

-

- santa maria

- revell

-

(and 1 more)

Tagged with:

-

Decals... Ok... First off have you got any microset and microsol? Both of those will go a long way to helping sett decals down on uneven surfaces. The other thing that helps is having a glossy surface on which to apply them. Don't worry, when everything is dry over coat with dullcote to seal them in and hide all the edges. First off, I use tepid water, not hot or cold. Dipping a decal in for about ten seconds is more than adequate. The the decal sit for another minute or so before you try to slide it off the paper backing. While the decal is sitting, apply a dab of microset to the area you want to apply the decal. Bring the decal (still on the paper at this time) to the area a d gently slide the decal off the paper into position. The decal should almost float in the microset (almost!). With a needle nose tweezer, carefully position the decal into place. You can now dab up any excess microset (along the edges). Gently press the decal to the plastic with a damp paper towel. When dry, apply microsol. The decal will wrinkle... It can be startling to see... But don't touch it!! It will settle down before too long as the microsol dries. When it does, take a very sharp #11 exacto knife blade and look for any bubbles that may be trapped underneath. Gently prick them with the knife and dab on some more microsol. Repeat this process until you are satisfied. Give everything a good 24 hours to dry thoroughly and over coat the decal with dullcote. This will seal and protect it from handling and damage. Andy

- 94 replies

-

- santa maria

- revell

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.