-

Posts

7,417 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

great looking Cutter under sail Tony ! congrats to this fine model good idea with the sealevel, in all well done Nils

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

-

Thank you very much for your nice compliments and comments Mick and Piet and for all the "likes" Mick, thanks for your words, much appreciated.... Piet, yes, thanks a lot Piet, the challenge alone is the drive.... Nils

- 2,625 replies

-

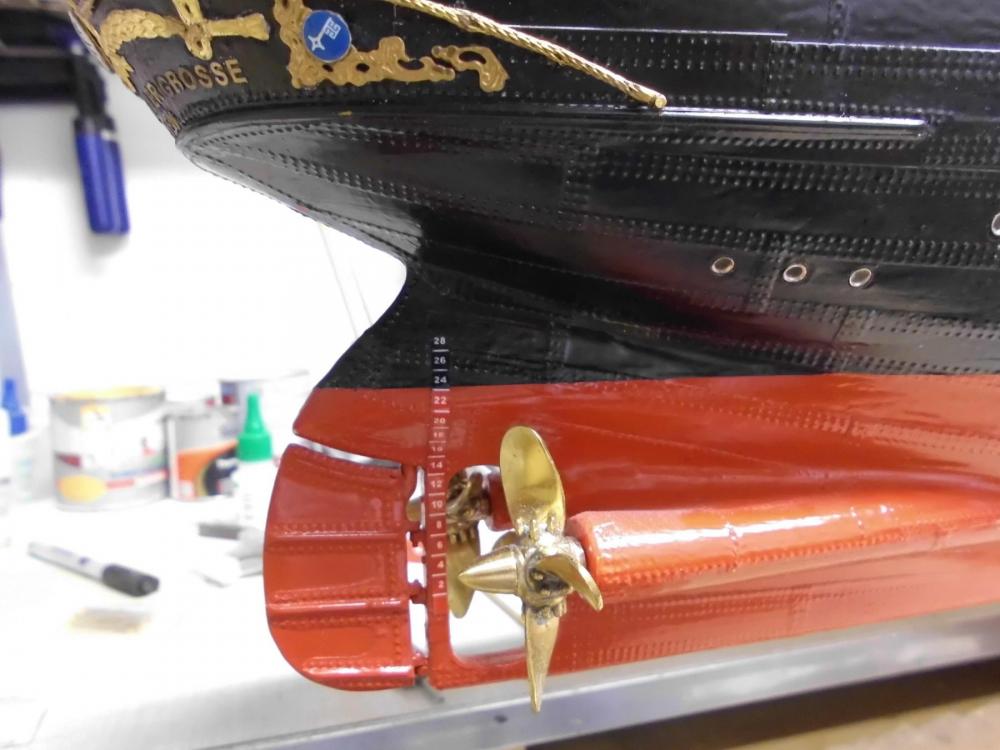

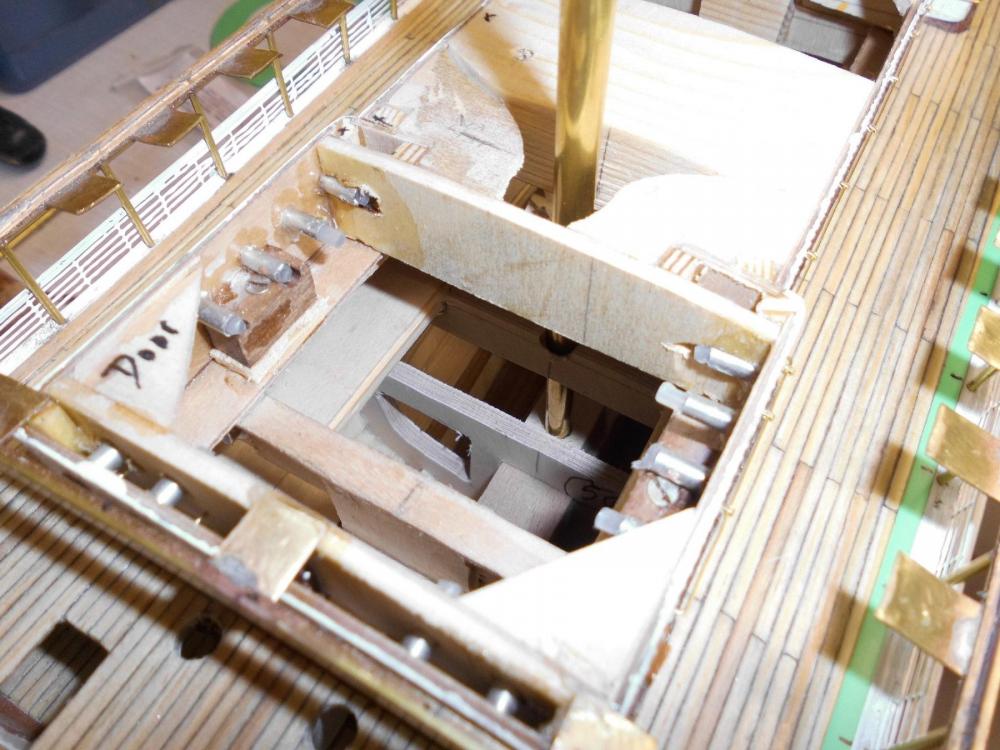

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi John, thanks for your compliment and your extensive look into the build log, your interest in the KWdG build is much appreciated.... You have an open reservation for the port side promenade deck "Comodore Suite" on the backtrip NY-Bremen Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Jparsley, welcome to the build, thanks for your kind comment. Have booked a nice 1. Cl. doublebed cabin for you on virgin trip... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Patrick, many thanks for your nice and greatly appreciated compliment. Competitions....., no, that was`nt my aim in any way, also no thoughts about that, just building for pleasure and a bit of challenge if I can do it. Cheers, Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Nice work on the Granado Bob, and very sorry to hear of the damage suffered by Cheerful, I very much hope you will get her set together well again to former blossom Nils

-

Update soldering the upper davit bearings in place, beginning with starboard side Nils 10 boat stations = 8 davit pairs and 2 single ones per side the still unpainted wooden chunks, will later on be the nav-light cabinets, access from the deck side, per door

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Chuck, your last pics on the Royal Barge says it all...... Wow ! Nils

- 269 replies

-

- Queen Anne Barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Alex, you`re right, thats a very costy solution, Are there no Hobby shops in the near surroundings where you live ? Are you able to buy from German web-shops for receiving through the postway ? If you wish I can give you some links for the web-shops I use..... Nils

-

Alex, good metal work on fitting of prop tubes, anchorchain tubes and sleeves for stand spindles.... Nils

-

Nice work on the boats job Bob, they certainly will look super on your Pequot..... Nils

- 348 replies

-

- pequot

- cable ship

-

(and 1 more)

Tagged with:

-

Thank you very much for your interest Kevin, I wish you much pleasure by looking in..... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Kevin, thanks very much for looking in and for your nice compliment.... In answer to your questions : in June this year it was 1 year work from keellaying onwards, presume one more year to completion as an estimate yes, I intend to give her the weathering of 1 or 2 Atlantic crossings have`nt decided yet what will hapen to her when completed, probably in a large glass case on a shelf in my hobby room, until final decision... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Many thanks to Oystein, Kees, Piet and B.E. for all your comments and compliments...... Oystein, for bending I hold the profile with a firm grip in the plyers and then gently bend only tiny angles, step by step every 10 mm. When narrower bendings are to be done, the profile is anealed and quenched down quickly, in order to make it softer. Keees, I liked that arrangement of the actual ship, and did my best to reflect a bit of it with this model.... Piet, I have the same attitude in thinking, when I see technical solutions (in model), sometimes it can be seen how it was done, by careful studying the objects... B.E., I always wonder how the professional builders manage to get those awsome tiny details done, (museum models) the clean and well painted surfaces, and no signs of anybody hushing something together. I would like to look over the shoulder of a professional builder. I presume they work with very skilled people and probably unlimited resources for toolpark and appropriate equipment Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Bob, thats a little model of my pal "Ronny" ( fox terrier ), he goes everywhere where I am all over the house like a shadow, but walking the dog outsides keeps me in motion at least 2 - 3 times a day.... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Rob and Denis, thanks very much for your nice comments Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Many thanks to Patrick, Bob, Dirk, and the "Likes" very much appreciated Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Update... am still building the profiled edge of the boats deck, am pleased with the way the stanchions fit for soldering, it provides a strong hold... Nils the profile is done in 3 sections, each about 250 mm long the small brass brackets will get a drop of CA later on to fasten and hold the boat deck edge here the lower portion ( 6,5 mm tube ) aft mast is set in, considering its correct rake angle, it rests in the ships "spine" square bar down, just above the keel. Also some of the porthole sleeves and their "glassing" in one of the deck housings can be seen... status overall view drilling the 0,8 mm stanchion holes into the edge profile. A simple little jig (slotted wooden chunk) holds the T-shaped profile for drilling

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.