-

Posts

1,566 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Vladimir_Wairoa

-

Ron, thank you for encouragement. your is impressive . im set on european limetree , ( or baswood if you wish) ( by the way a national tree of my country :)) but it is a bit stronger i guess. for simple reason, i have one big batch of it spared. so i ordered blonde version of stem from Chuck. i dont know how much that cedar differ colorwise but that is to observe later on...:)

-

Good day, continued today. Happily took winnie to my room upstairs. I observed few of folks winnies and must say they are all being worked beautifuly. Day two chapter one. I did few small but important revisions and repairments from yesterday. Firstly i built swiftly temporary stand out of styren so i could turn skeleton back to repair unglued rabbet linem. I cut, cleaned and glued up small piece of rabbet that unglued, attached sgernpost rabbet, and faired hull here and there. Than i started with fastening bulwarks extentions. Took it slow. First two three are a bit scoopy though..:/ Like that work anyway it is pretty relaxing doing it while listening to music. I plan to continue tomorrow tith bottom starboard side and than building up upper line. Using only handsaw and sandpaper and pencil so far. Enjoy. As far as I didnt fair all middle extentions being dark brown still they are absolutely flat so i think they are ok like this. . V.

-

oh yes thats proper workshop:) grandpa worked there father snd son now:) there is no heating though. but good excercise with hand planer and i end up wearing tshirt :)) well, sanding dust cannot go to room. i feel for you but ahe will go to my room as well as i like working on the desk. and i made 1:24 cutty sark last year halfly in my room sitting on carpet. there was swearing around but they got used to it. this time they asked why i am going downstairs with her - i just answered - sanding:D

-

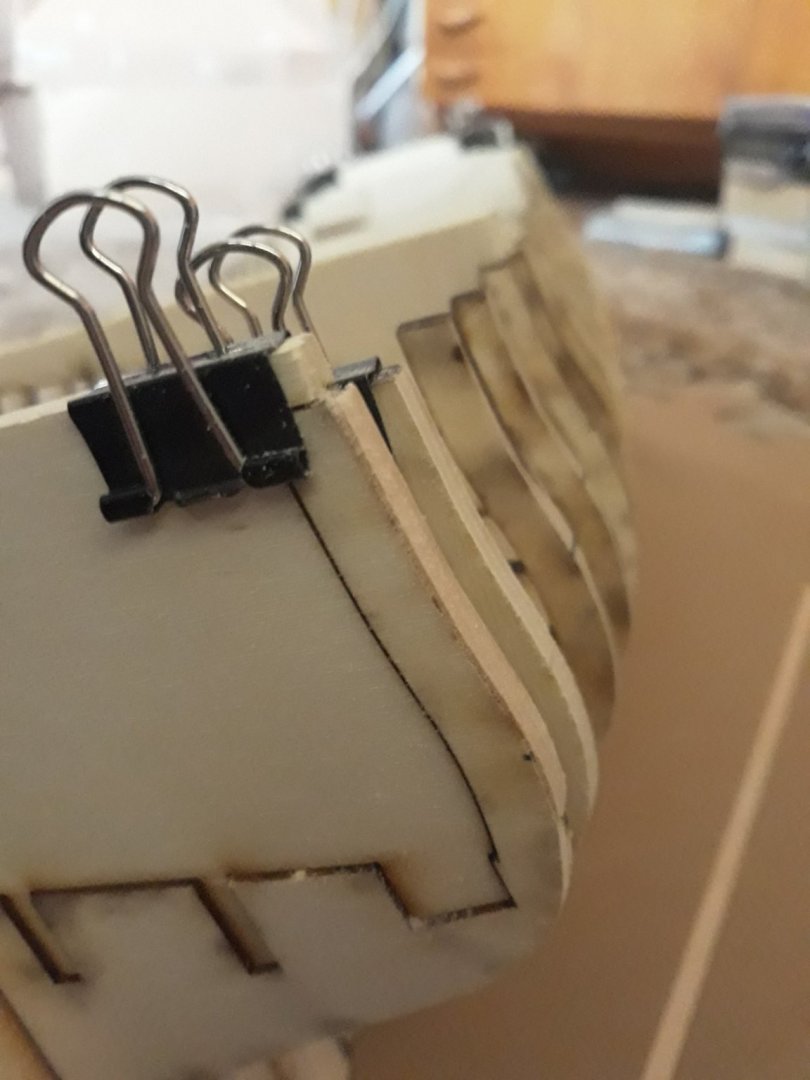

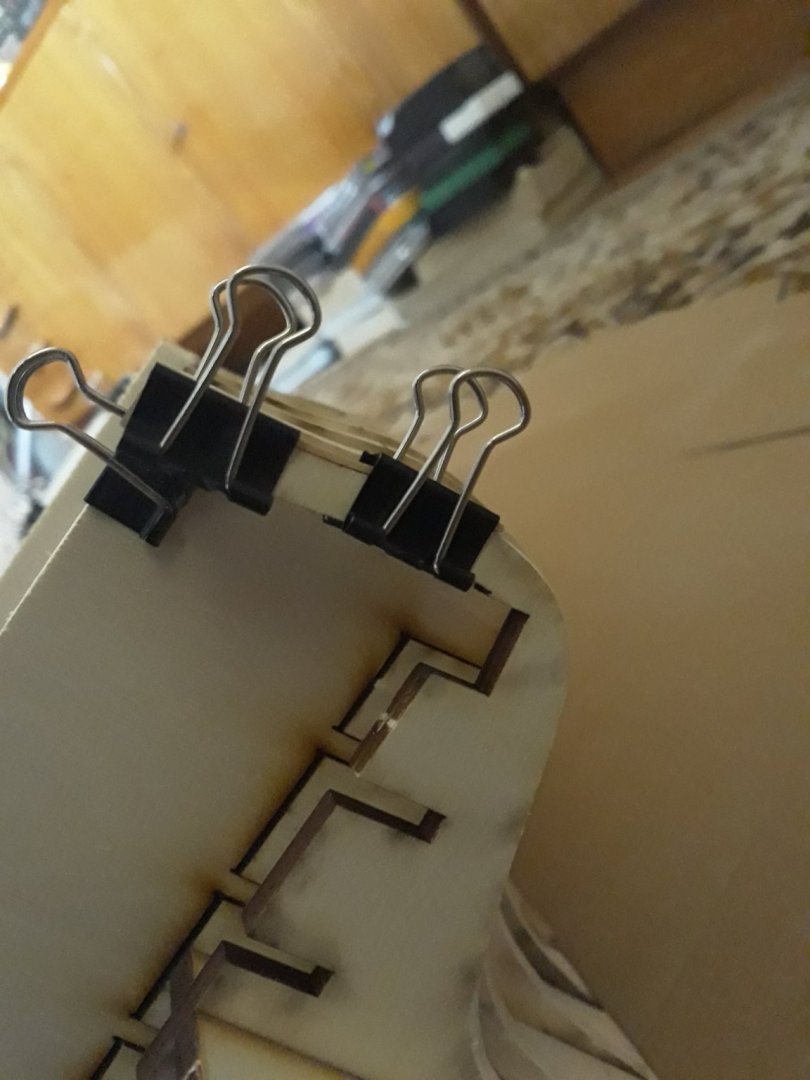

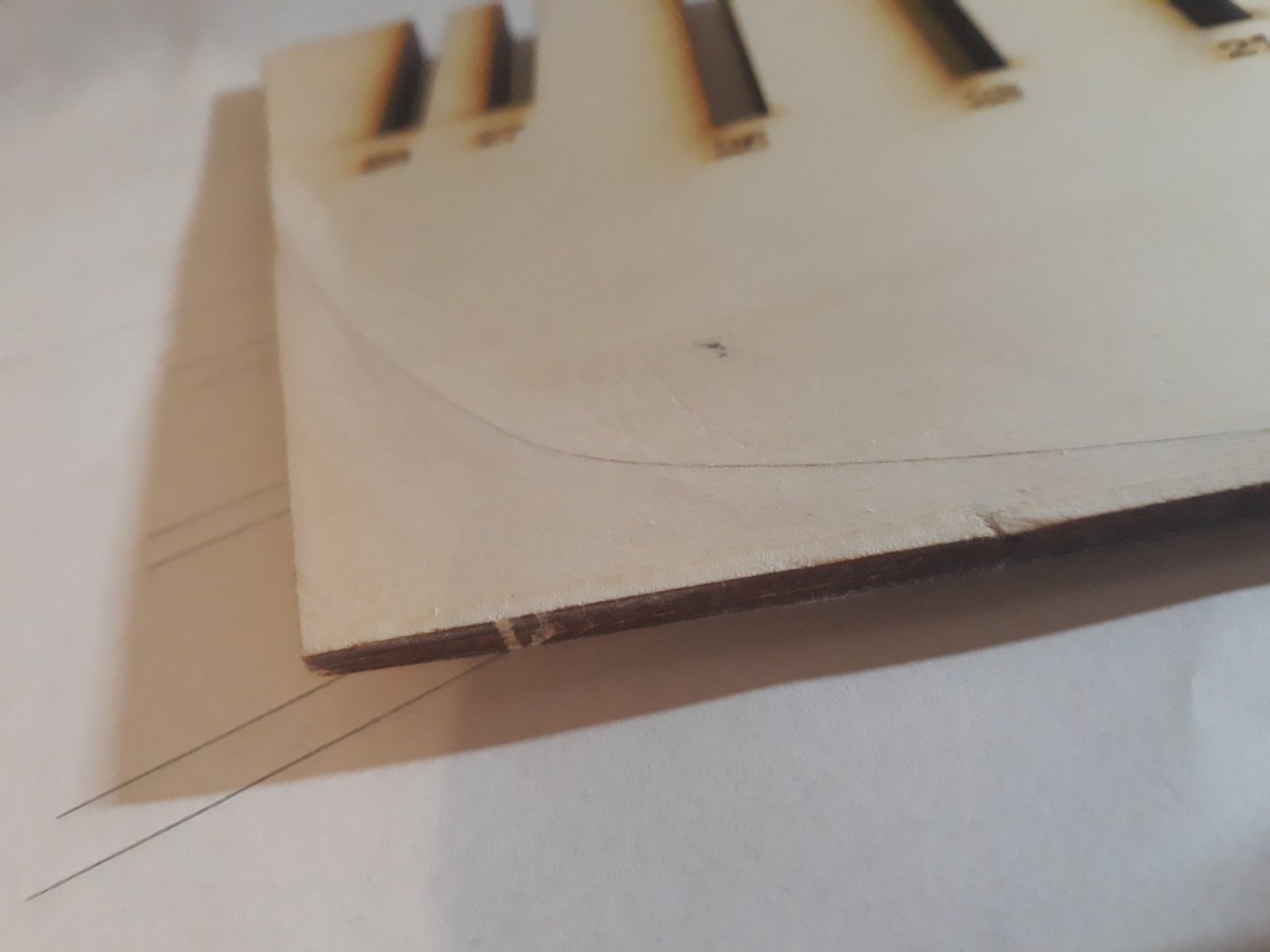

Hi guys, sanding hull in one go. As I feared those sticks or upper walls quite a lot, to find out a way not to break them. I found my way apparently as i used mirroring gap between them - leftovers from laser cut wastage. Just clipped them up, viola. I would not have dared to sand them without that support. i was able to put some pressure on sanding blocks without any fear. just to move sandpaper vertically, no horizontally. used no60 and no 120.... and you were right poplar worked like a charm. i thanked for it massively. Im worn out like a... but happy i hate this tedious work. I went skowly and checked sandings properly with strip of wood. Tomorrow making proper standing board and gluing together those beasts so they wont be so fragile hopefully anymore. Point is? Not one broken bone so far! from there I am on track... just waiting for the parts to arrive so i can continue look at my horrible instalments to fix her so she didnt wobble.:)) those squareholes worked - vice, some wooden block...:))

-

I started guys. So happy back in modeling, missed it. Decided to attach keel later when arrives. Doesnt bother me at this point i can fair hull and insert those pieces of wood between upper walls. I think i cut off a bit more around stern post than it should so i will check it when sternpost arrived. Plenty to work meanwhile. Plan and lasercut is so precise. If i struggle wuth something ill ask. Thank you vlad.

-

Ron thank you ! much appreciated. it seems OK. anyway even if not, game is on! already started. Chucks plan is so precise i never come across such skeleton, as bulkheads are so close its faboulous. i admire folks who make own bulkheads as i made few myself but this was piece of cake so precise. i had to push them down by hammer. ...

-

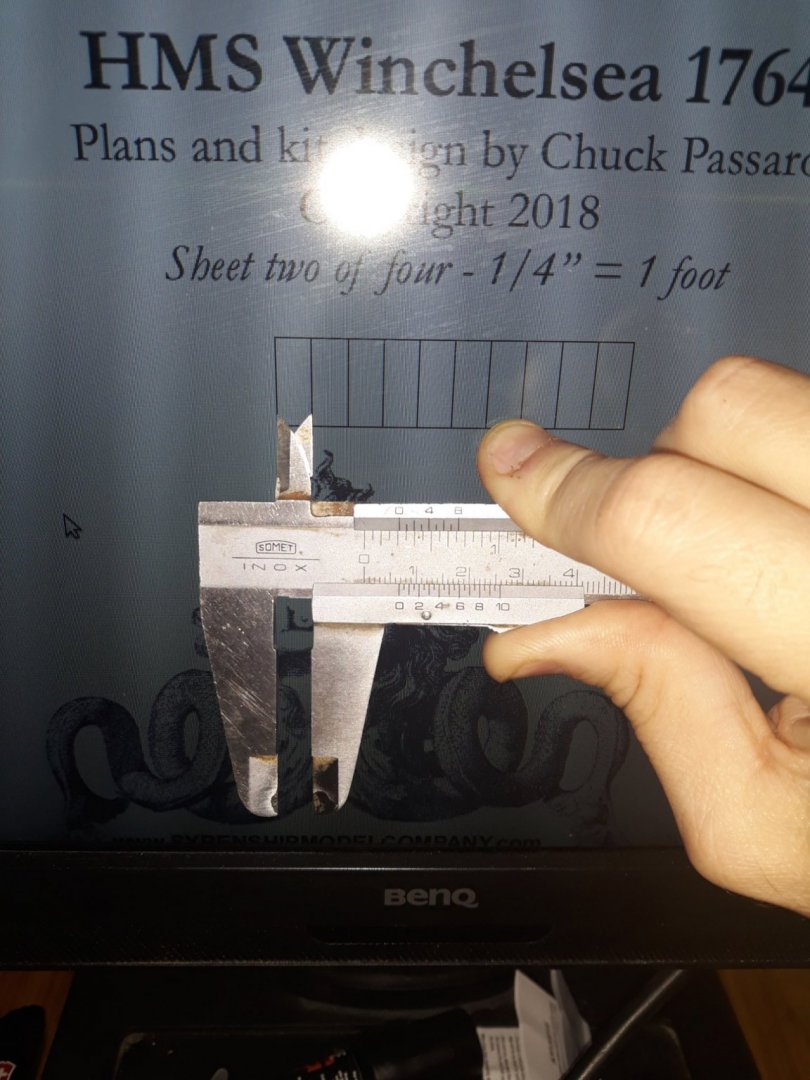

...to add to confusion ---- im definitely not drawing any conclusion. using linux so i installed adobe acrobat there to compare ubuntu simple reader there and measures at 100per cent were even more off some 17 cm ?.? :/// woohoo. I just hope i am not making some trivial mistake omg... I think i will wait for Chuck to provide center block sternpost measure as i pictured...shoul i watch it in some vector program as corel or... im not that engineering able though... so I know what program is ok LOL.... i think i figured it out though its not usual to get 6.3 or 6.5 mm ply here so i settled on 6 mm thickness ( which they are) and i guess he set up measures exactly for 6 mm so it shrinked the plan ratio accordingly littel bit which resulted those 96 percent. makes sense to me cant imagine how else it could have happened...im on verge to continue anyway with the hope windows will fit and with sigh i will have to extra rasp off the parts here and there. i will have dificulty to find out even 6.5 ply which can be on other hand even bigger which is trouble. at the point of skeleton the crucial part is gallery and stern side so well...i cant imagine making mine bulkheads after cutty in 1.24 its auch relief to follow nice guidance anyway...

-

Well I cooled down a bit i remember there is stuff with enlargening of plans in softwares etc... I measured quarter inch on not sure it might be calibration staff or what, but 1/4" looks 0.68 in 100 % not 0.63 as should so im a bit relieved i can have it ok. . Stem length as on picture is 14.4 cm = 5.7 inch. So if that measure is correct is all good.:) If should be longer than i know i am off... so far hope lasts

-

Hello all, alreadyvRun into first deadlock folks. :(((seems i enjoyed it prematurely, as i measured center board and bulkhears and all is cut smaller than original exactly 96 % of 100 size:( . im in despair as i see no window here than just to get it cut again , ican manage part 1 ( but curvature of stern would be problem i guess) and i ordered onl part one and three i intend to make part 2 and 4 myself. but that would be always struggle and i am affraid windows would not fit there , maybe ornametation wouldnt be a problem. as boat progresses I guess there wont be much hassle as its few per cent so it makes 3 mm on 15 mm lenght which is quite a lot i guess...i would have to rub down even laster parts which does not make a sense to me to star this wrong...what do you think?

-

Hi very nice start looking fwd as it goes along .Vlad

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

beautiful job. congratulations!

- 103 replies

-

- new bedford whaleboat

- model shipways

-

(and 1 more)

Tagged with:

-

congratulations. you should be proud for this accomplishment as first build. well done! beautiful . v.

-

congratulations Mike. fabulous indeed. this boat is my desire in future build and i will look for this one and to your meticulous craftsmaship for inspiration.

- 128 replies

-

- model shipways

- new bedford whaleboat

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.