-

Posts

1,566 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Vladimir_Wairoa

-

Hello winnies masters, how are your Winnies doing?..cant wait to show off the roof rail of my princess, she is being dressed to point she could go dancing soon dont be too harsh on me please hope you enjoy it. what a miniature, i firstly thought Chuck designed it himself as some kind of revenge to torture us v.

-

lovely work Bruma, I have one revell in the storage shed somewhere , contemplating i could jump on her for the rigging and masting sake. looks great. V.

- 399 replies

-

- cutty sark

- revell

-

(and 2 more)

Tagged with:

-

wow i never seen starboard side view....its far from non erotic postures other greek figures are shown.... One of few most beautiful figureheads in my opinion. (not olny by fact of late figureheads era, but from various aspects. its shockingly erotic for the acceptance of the era, more so in such religion driven or influence absorbed society that america of that time was - ...whatever... v.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Oh my goodness...where to start few days not following and what a read. @Rob, i enjoyed immensely your photos and description of meeting with Mr.Mjelde. by the way, on the table - Fantastic model on its own. ! wow ! @ Dear Arina, please pass to your father a sincere Thank and admiration for his phenomenal talent and effort with writing the books about Glory. The way that it far beyond just ordinary writing. I spent two lovely summers being drown into the books so immensely it was unputdownable. I rejoice those moments with as happy warm feelings still giving me a pleasure with fighting my longterm healthy problems and psychiatric diagnosis. at this point I wish endless speculations about plus minus verticality of bow ends soon and Some plan materialised I can buy of jump into i just want to start assesssing preparations and material so i can start building the glory by autumn this year hopefully if hlealthy....:) looks like i can turn back to my own observations stating bow agressiveness cannot be that radical but from now on I outstep from these discussions. @ Clipperfan , great stuff about figurehead also some great artistic skills. even im in the middle of different boat but you made me unroll my glory plan today to look at :)) I guess we all enjoyed past postings with enormous joy. ! you are doing great effort Rob. Thanks. stay safe V. .....

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

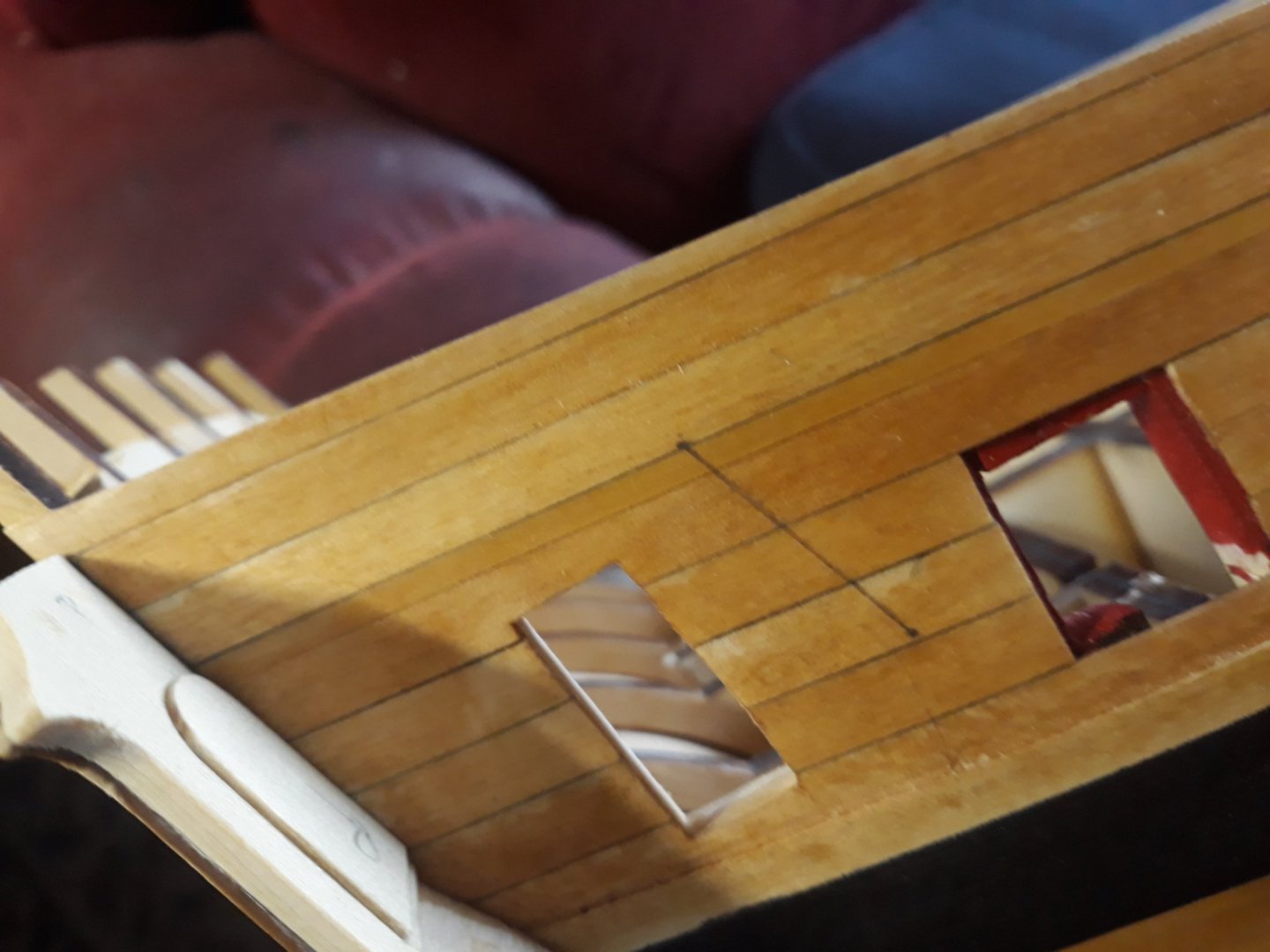

Good moring folks. I halted any progressing on chapter 3, and focused on curing the blotches on hull....they stepped away plain ugly. I spent a week on it... I possibly made few mistakes after 220 sanding mostly not sanding hull perfectly with few places leaving glue so varnish didnt apply evenly and not having proper brush and working with clothes from the start I happen to blotch specially bow part....Lime or basswood does not particularly like staining - and I am not fan of any commercial available stain product also not the shades or outcomes it produces. I was quite satisfied but bow is a critical part that I was not able to run off of blotches. And I cannot live with that awfulness on hull. Unfortunately I dont know product that would even out blotches if someone has experiences I would be happy if you can share those...the point of multiplying darker and darker coats will result in just darkening blotches and at the end mess will multiply. So i had to sand off....completely. here is the outcome Im defintiely more happy / . It alsways goes like this. Eye forgives a lot. Than take camera and pic and look. if it looks OK just be sure its not OK and try harder and third time you take pics ....it will be OK. There is no blotch I can see by eyes, but camera can see it. I consider coloring wood one of a hardest part of woodcraft, but i always listen to urge to experiment. according to slogan - best learn mistake = own one. I m sure you would agree that was necessary to correct those. These are pics before and after correction. v.

-

Thanks a lot Ron, appreciated. Im glad you like the color and curious about it. Its asphaltum, https://thefinishingstore.com/blogs/news/asphaltum-a-forgotten-finishing-gem i know many dont like it as its possibly never dries completely, but I use it extensively for detailing work. It covers all warm excellent shades of wood and its transparent. Glazing with it is pretty much used in woodworking still as much as in painting. I use simple artistic color like https://www.royaltalens.com/en/catalog/rembrandt-oil-colour/oil-colour-paint-asphaltum-414-40ml-tube/ You can pretty much mimic Chucks laser black lines in molding to the point you wont recognize which is which if you scrape it to same size scraper. I always wipe off content with cloth so it leaves nonblotching surface. Boxwood is literally painless...I would not use it on blotchy woods like boxwood but its possible. and take my condolences that you had to replank. hope it pays off. ...

-

I would humbly inexperiencely think coppering would ruin beauty and philosophy behind it for me. and cover palnking . im with Greg. elegant with simplicity. its same logic applied as going with treenails. posibilities are endless. - fully ? partially with framing ? one side? I would for sure not put scuppers on mine. Im eager to see how top deck would look like apart of cannons. Would there be those crossbeams like on greenwich model we see? only Chuck knows im looking forward to explore it as it goes....

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

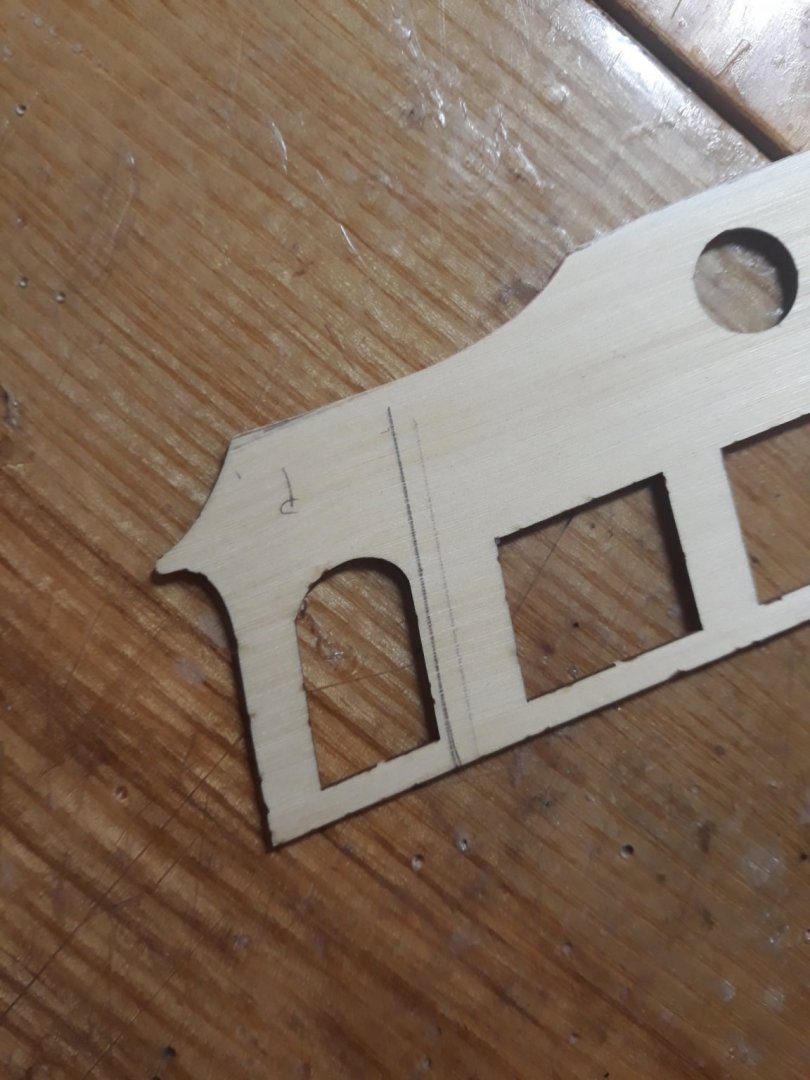

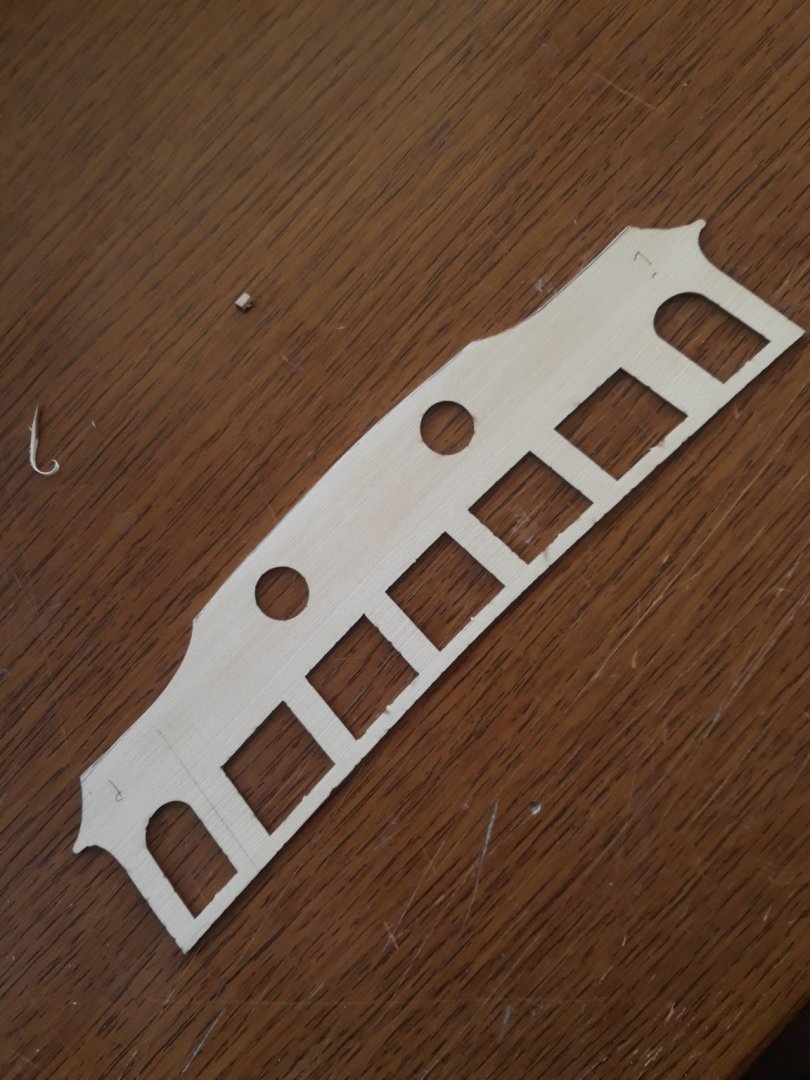

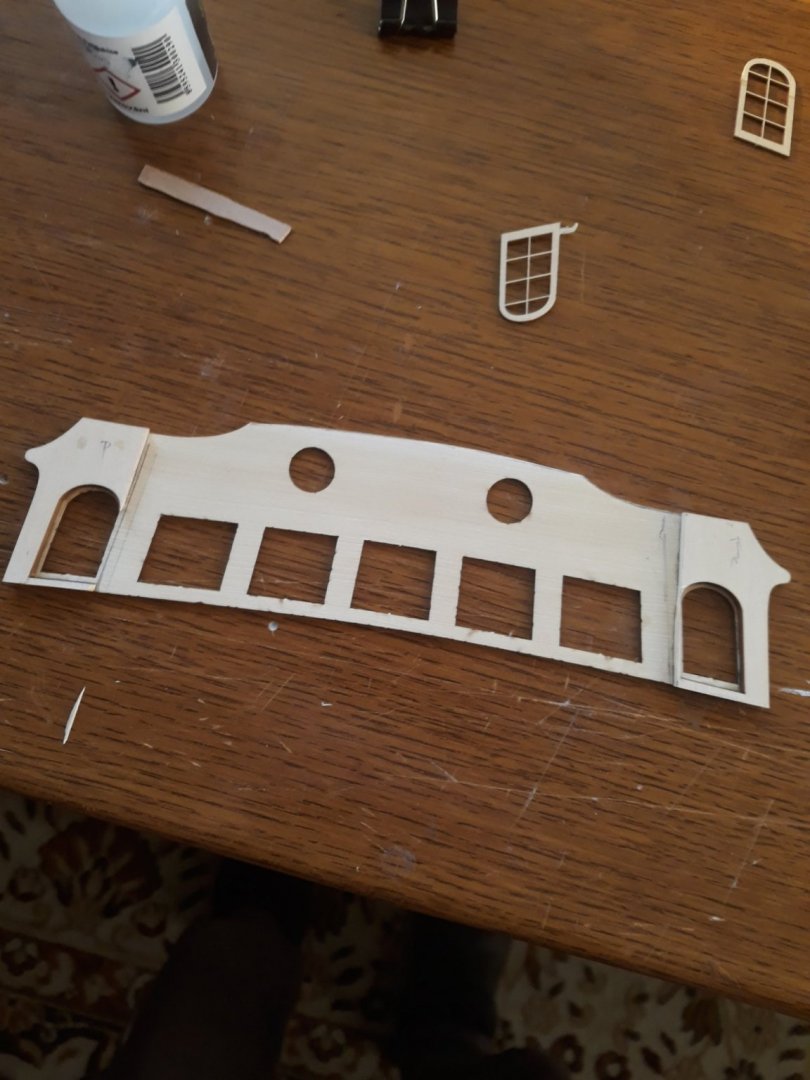

Good health everoyne. I was just about to ask whats the news but reading thru Robs news a Im like kids getting christmass and what a company we have here. Cannot wait for those outocmes i myself little abandoned plan to continue as realized there still would be somenthing i am not really up to. nice start of year just hope everyone stay healthy safe, to update myself i started to build rigless model of hms winchelsea under Chucks group project ( sou can chcek if youre interested) meanwhile, which got me in touch with nice fellow around here who is cutting laser stuff and made me fantastic bulkheads for very fair price. So I cant wait to see some proper glorys lines. I would jump on wagon in 1:65 scale even it would be hell of a big beast. cheers everyone.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Ron If i had to adopt such critical thinking of milimeter here and there in places where it wont affect anything and will not be visible I would have to grab axe and my winnie would heat the room in fireplace ! i call it third mastering dirty rule of modeling- to charmingly cover imperfections to the point noone ever notice there was any

-

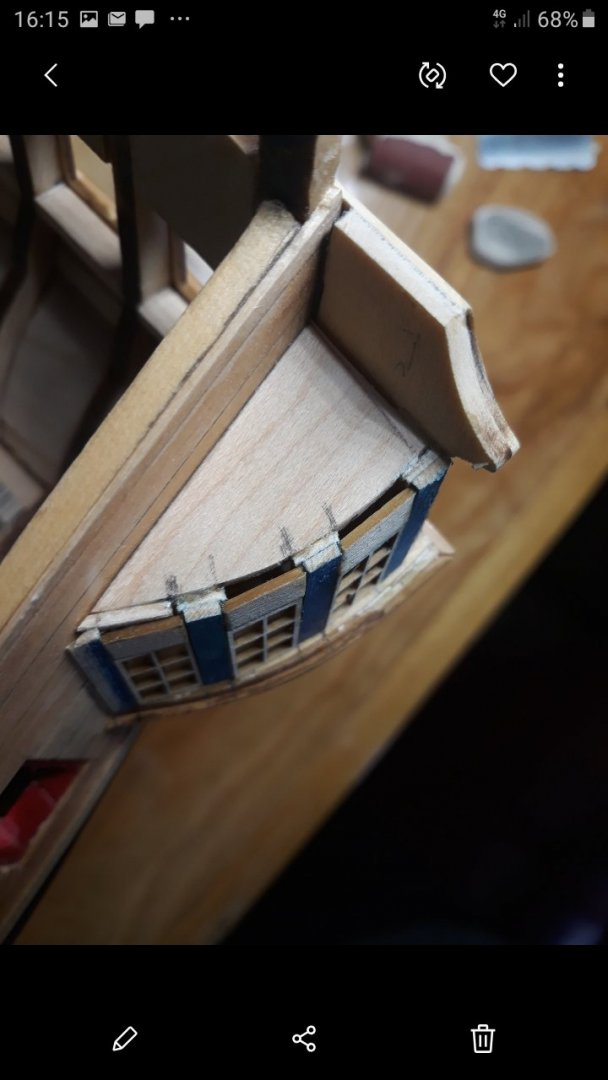

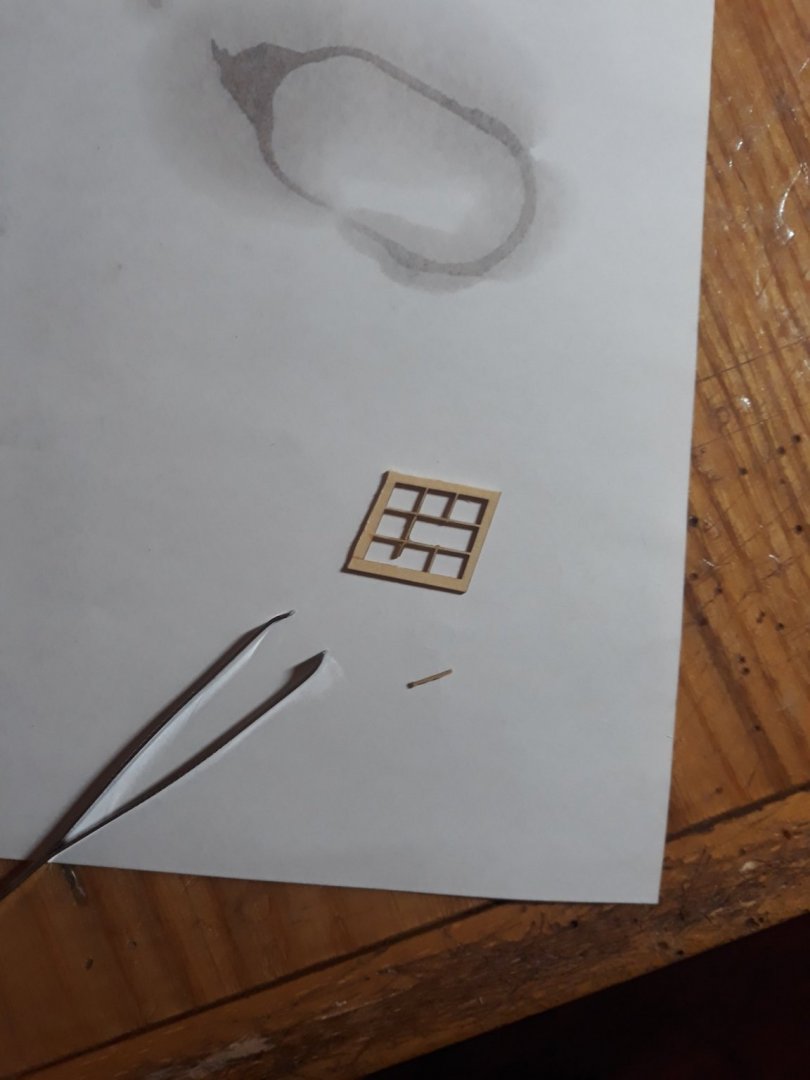

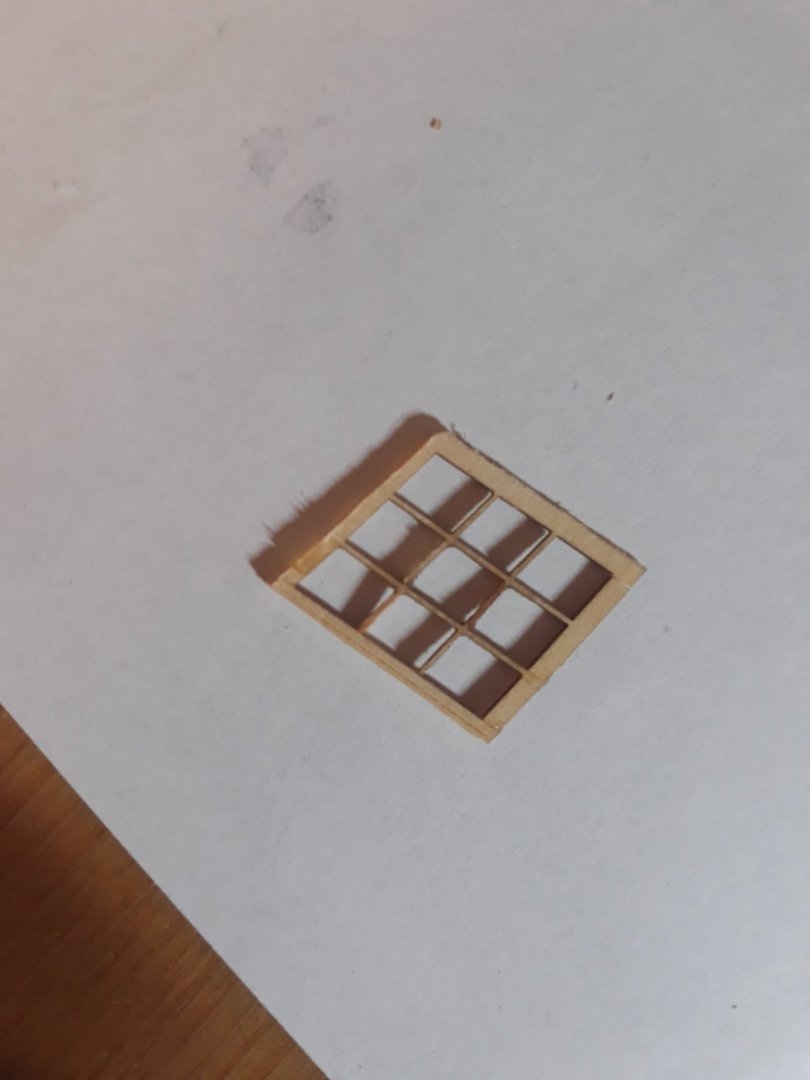

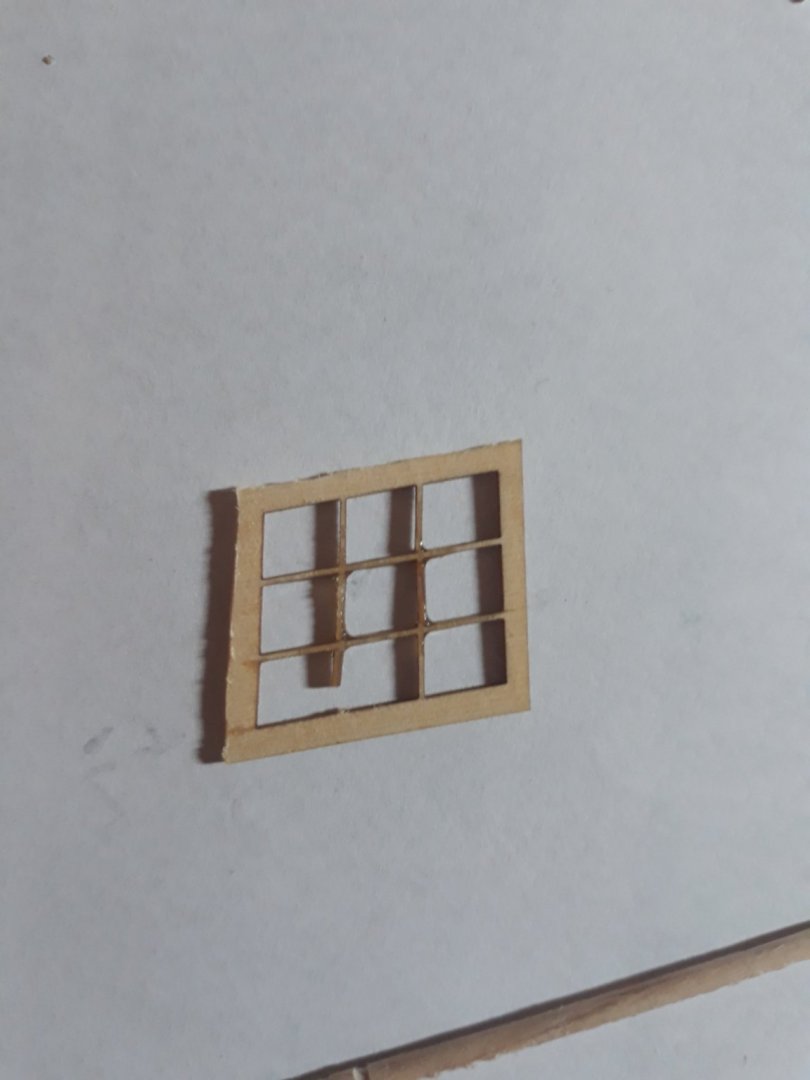

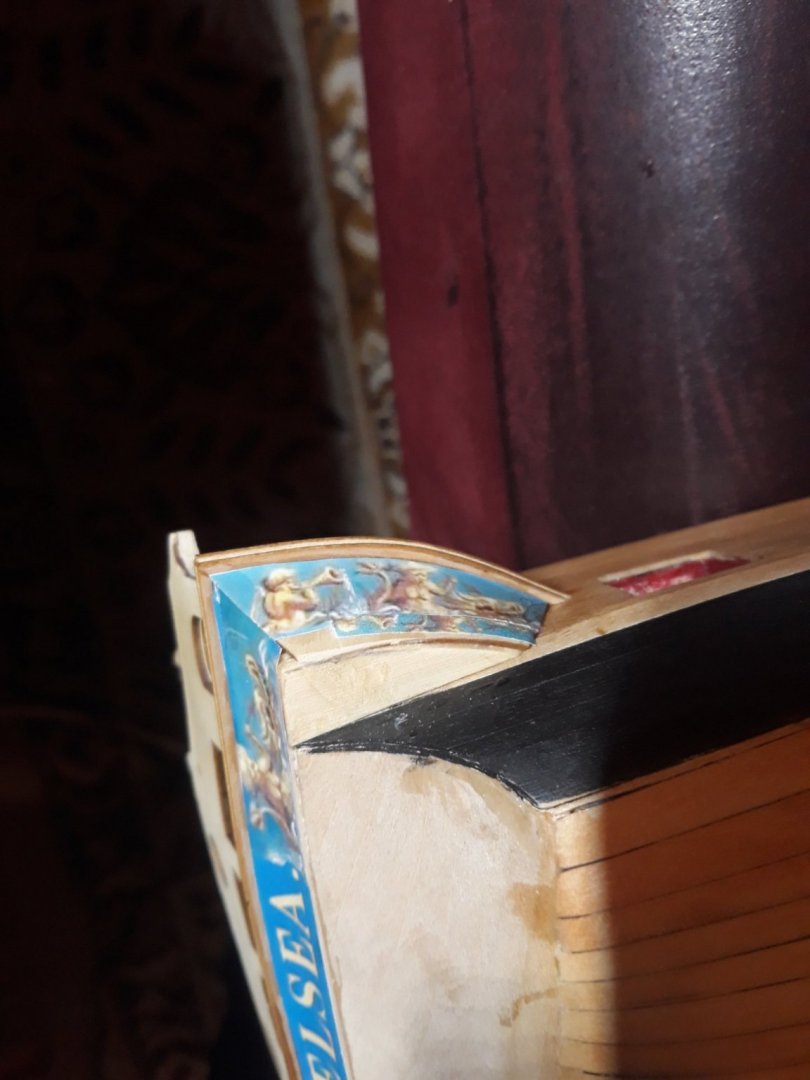

Good weekend everyone. I took a lean way this week and made only one gallery. It is tough! I only now understand why Chuck left almost entire chapter to it. Unless measurements match of course. otherwise windows would not match...I had to improvise a little as roof was not aligned properly. At the beginnig i was thinking of painting window frames white but i changed mind as along with darker hull and fluted statues i think now it makes nice contrast...I also changed main stern underwingows molding and as i got used to scraping more i made classic 90 degrees one one that its top reaches more outwards ...finally i painted columns underroofs filling blocks that sit on windows with diluted asphaltum to unify the look. .next week i am about to sand down few blotches from hull and put another coat up. And second gallery. Thank you for look, any comment, etc.

-

Ron I should take writing slow as well as my inexperience with scraping - i realized Chuck provided boxwood for scraping. which is definitely tougher than even cedar. Well I had to elarn how to scrape along the grain. key is to have sharp one. even touching scraper firmly and pulling timber works flawlessly. there is no ugly fuzziness on that wood. so i stand corrected folks. therefore cedar must be easier than boxwood by definition

-

Where can I get such horse Ben? id prefet to have it on winnie instead of that angelic musician:) . thank you, Vlad

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

How i worked transom... I must say it is like a price for me after planking, but it is not easy even it may look like. Chuck carefuly mentions all tricky parts and dangers in monograph. I never read better written guide for modeling. He mentions more ways and i opted intuitively for gluing outer windows frame to transom outside the boat not when transom is glued. Im glad i did because i made one important mistake ij chapter one and put windows little bit lower than should be or my boat is wide whatever. You cam see i had to remove inner side of window frame so i could stick windows in . Thabkfully no broken bones. I carefully tried windows and finally managed to glue ttansom firmly to the boat. Than i despite of Chucks waring dared cutting on windows here along the grain and even sanded with grinder. But never do that, its like feather. I crushed one window and managed to repair it, but I wound not like to again :). So after satisfied i left them aside - untill finally firmly glued. Than I mounted round side windows - easy task and i protected them by tape so tape is not touching it. With work around aft, there is really dust coming and visible oj black window- yes those windows are just so georgous. ... than i started most difucult part. Gallery base. Main complex beam is godsend to us from Chuck ! And i want to thank for all parts. It so rewarding working them. Beam must be sanded so it touches flush all parts it touches to. Plank is grear But most dufficult part was attaching plank and bottom of the base - each boat us skightly different and those parts are perfectly oversized to accomodate that. I went with different approach. I first glued plank to too base and than gradually cut bottom side to match the curve. But i again cyt counter a little bit more than i should so i pushed plank a but too much towards the boat to touch counter. I funally managed to glue it together satisfactorily but it is not without flaws even those are hidden now. So again no pain. With moldings - i first attached frezie to see how big and where is the border so there is no gap between molding and paper. And for the finish I onky regret i dont have mire complex scraper to make more complex underwindows molding. But i wont try to make scraper so i go safe route. I managed ky way to combine them with paints and i like the outcome so even if not complex i think they are pretty. What you think? I observe other so i can see how to proceed further so I hope my pics could be of some value to someone. Hope you enjoy it and thsnk you. V.

-

Chuck, it only looks like rush. I have possibly week or max two to finish 3d. than I will have to leave it until end of summer so there will be no waiting for parts soon. I am at home in quarantine next 14 days cannot go anywhere as i dont have covid test . so I worked in relaxed pace thru it last two days up to the bits i like finished. no disaster so far I follow the chapter it is so completely and helpfuly written.

-

Enough for today. If you look closely - Yesterday disaster happened. I smashed one glorious round window to 5 pieces ! .And - impossible task for 2 hours and surgical instruments - i managed to restore it ! I used asphaltum color for moldings - just from the tube on t- shirt and wipe out -or with tiny brush into bigger hole - it will leave color inside the lines...and leave awesome boxwood beautifuly golden.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.