-

Posts

1,566 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Vladimir_Wairoa

-

one of the most beautiful work i ever seen ! following .

- 121 replies

-

- la jacinthe

- schooner

-

(and 2 more)

Tagged with:

-

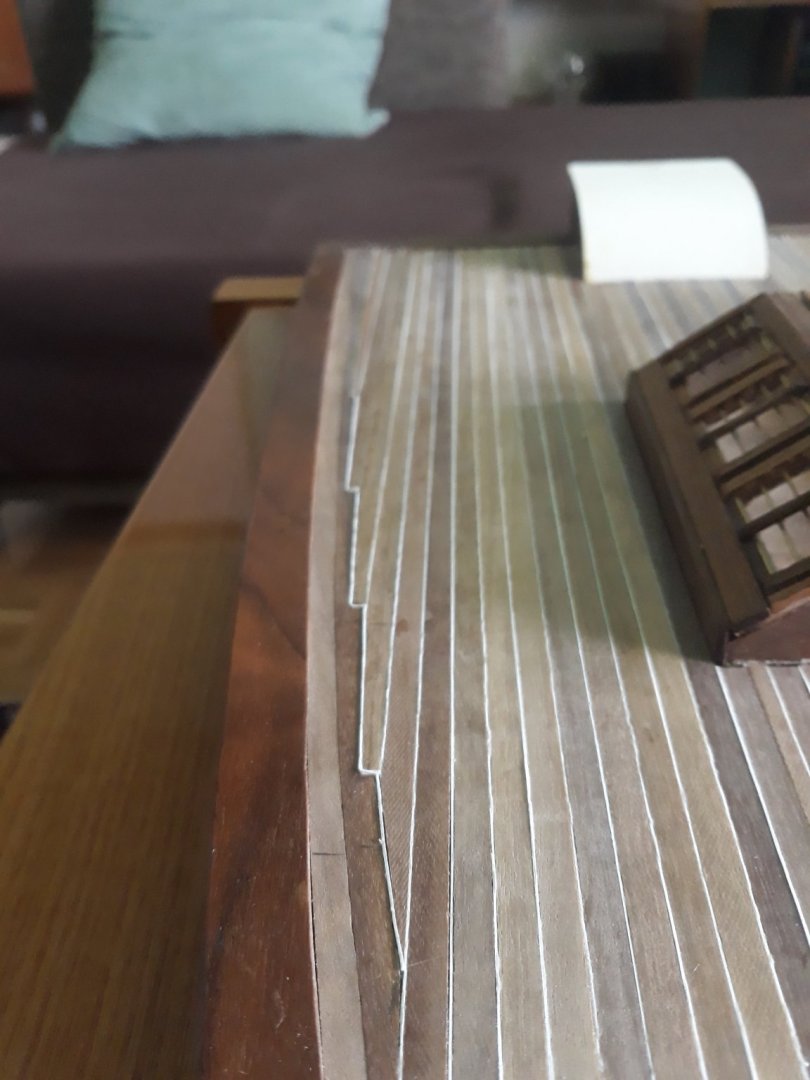

Hello everyone, Always thanks fof comments likes in advance etc...as weekend went on following up on progress... V. Im rather more than satisfied so far, measuring was spot on as both sides met graciously. I had to overrun foremast as i didnt want to take it out so i hoped both sides will meet at kingplank. They did. I had to check constantly if lines of planks are as straight as possible, otherwise havoc ....Already started nibbing , pretty shaky first but think i figured it out by now...there will be break i guess i have to manufacture new stock if timbers for forecastle deck so i will post once finished. .thanks. V.

- 200 replies

-

- cutty sark

- clipper

-

(and 1 more)

Tagged with:

-

Thank you! oh my fantastic build even underroof decorations there, top notch sheathing, congratulations! there is ongoing debate on Robs W. glory of the seas log about her body and more it goes more I am scared if there is a point to build on unproofed plan or vaguely criticized for appearance. even i think myself that glory has to be built more to be brought to wider public....maybe i will jump on fish meanwhile. thatforecastle gangs of anerican clippers are pretty darn complicated to me i would not like to spoil the effort... ok back to cutty sark though

- 200 replies

-

- cutty sark

- clipper

-

(and 1 more)

Tagged with:

-

Hi Brian post here for sure. i obtained plan from model snhipways for the reason i am bugeer scaler...but i gravitate towards glory of the seas so the plan will probably lay idle for a bit hovewer it is very useful for masting rigging and overall techniques as model shipways is great at that. feel free to post here she looks very fine thanks. i hope moderators wont concur either. im into american clippers now after i finish cutty. but still to work on her for sure. glad to hear you think of building cutty. cheers

- 200 replies

-

- cutty sark

- clipper

-

(and 1 more)

Tagged with:

-

wow flying fish, beautiful work.Thanks Brian for explanation, soon im at planksheer so i can show how it materialize and we can possibly suggest how it goes. finger crossed V. do you have album of flying fish so i can see her?

- 200 replies

-

- cutty sark

- clipper

-

(and 1 more)

Tagged with:

-

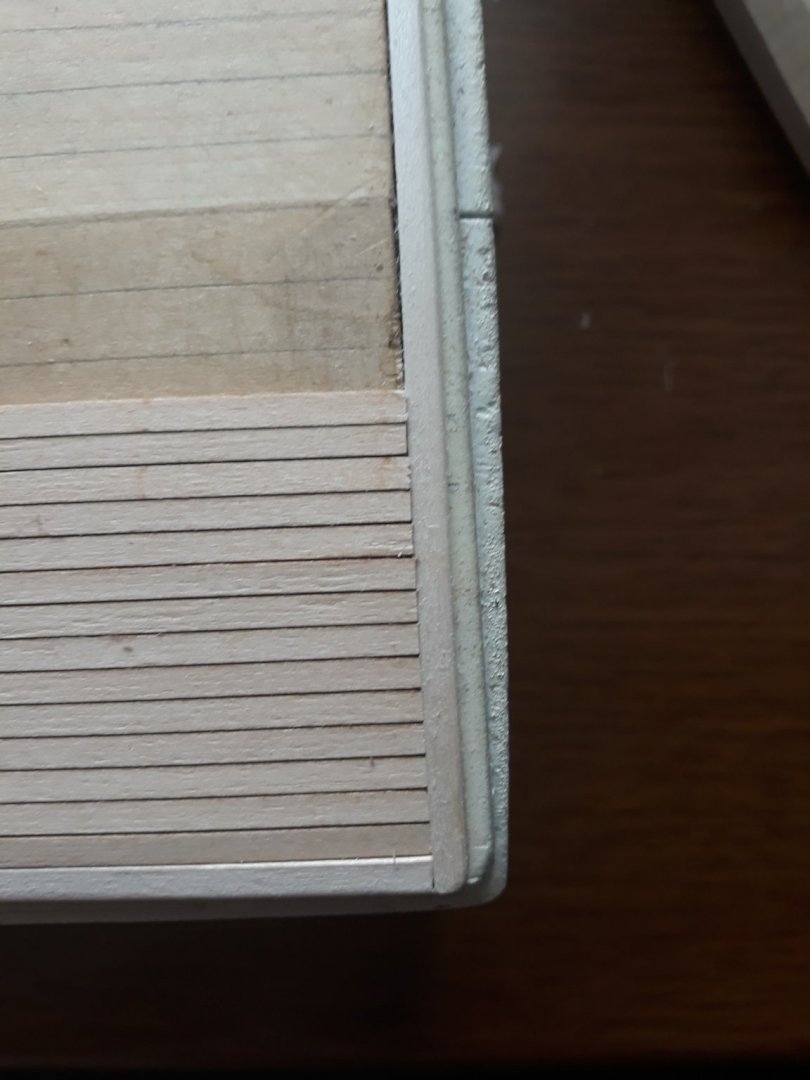

Many thanks for comment Brian. I should better not complain probably because it is enormous scale...but doing it 1 time really, this was training before i reach sheer on deck..do you maybe have some hint ? I first cut straight plank, attached plank and redraw lije with pencil on share but i did not dare glie the heerline because of wallnut. On deck i have baswood sheer firmly glued so i will have to draw lulijlne cut probably carefully little smaller ..to prevent large gap...will see though. V .

- 200 replies

-

- cutty sark

- clipper

-

(and 1 more)

Tagged with:

-

I wholeagree Rob ....that Clipperfan turned it to the right direction. Im happy myself and eagerly following, anyway my opinion is to be taken very lightly only more like observation... as you know i am not that experienced and rather say totally inexperienced as far as american period ships. I must dvelve myself more into mckays package ships etc...

-

....planking ongoing. Everywhere for unpatient as i am this is tough. But patience is the key i guess. Disc sand would be beneficial i guess...definitely like subtle shades of colors of timber.

- 200 replies

-

- cutty sark

- clipper

-

(and 1 more)

Tagged with:

-

Gddday Vaddoc, some days are bleak for sure but you still do wonders with those difficult bow angles parts. sanding discs are tools with capital T. enjoying the progress with comment and learning from it. V.

-

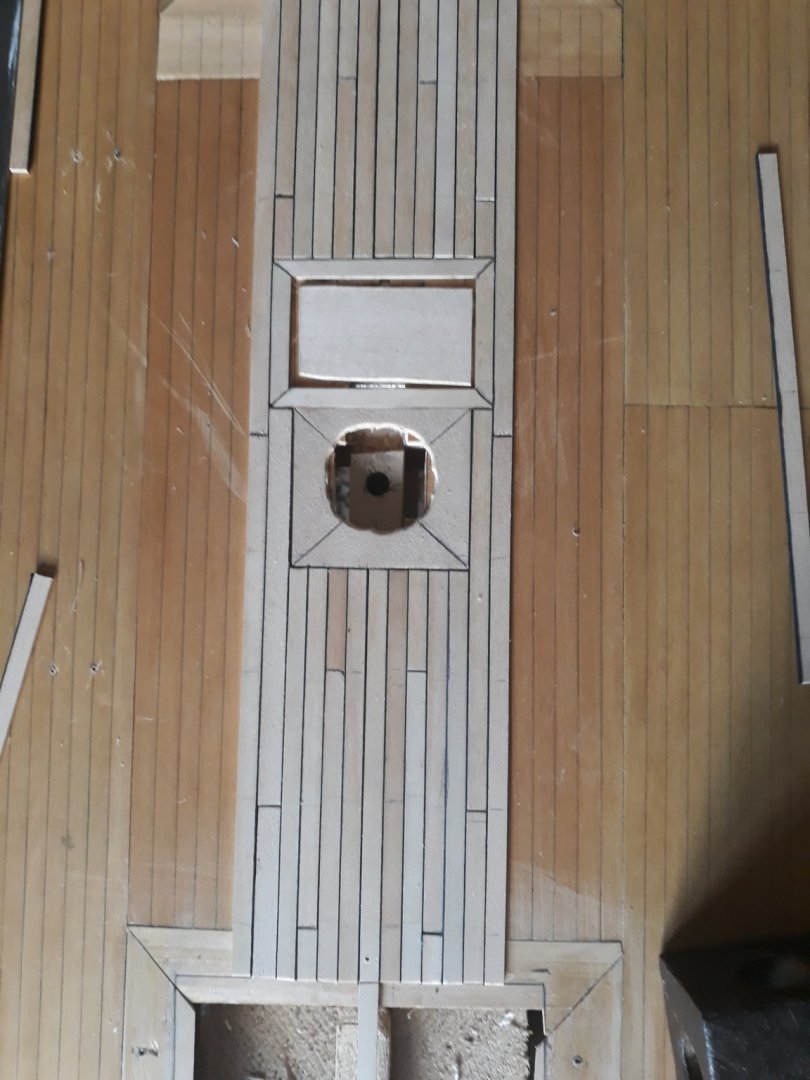

And so it has started.... Great planking of 2020. Started offv yesterday , had to use paper as caulk because no pencil would be wide enough to be realistic un my scale. I worked in batches of 13 timbers - cutting, gluing with wood glue to furm paper of 1/3 mm, i was nervous but once lfigured out that it went smooth cutting with surgical scalpel, ut went quite fast. When glued up i sanded rough ends to the line in once... fingers crossed as im doing this first time, but i rembmber from real floor laying that many can go awfully wrong easily. measured it throughout twice and so far satisfied....will see how it goes on if the kung plank is straight...im less nervous now but sheer will be it....ow . Done roofing on decjs as well. Poop will be dark with white seams..thx

- 200 replies

-

- cutty sark

- clipper

-

(and 1 more)

Tagged with:

-

Material for keel

Vladimir_Wairoa replied to mikegr's topic in Building, Framing, Planking and plating a ships hull and deck

Hello Mike, thickness pf the keel is according to the plan/ scale. i can imagine dense grain wood like cherry pear probably best suited in regard of comfort of eork etc...stay far away from hardwoods like oak etc...frames if you mean bulkheads choose something you can later push pin into etc...and if you are going to fill reat of skeleton woth balsa etc..you can have fine base fo gluing and wood wont work if future... -

You are a treasure Martin , thank you very very much ! looks like less work though:) in 1:24 scale it means 1.6 mm in center of plank approx 5 mm from end. plank width 5 or 6 mm. makes sense seems to me there were probably iron bolts to hold planks just covered with dowels. i will show the progress, starting tomorrow, i have deck roofs already finished, so there will be probably same approach just adjusted to smaller timbers. 3 mm on my case . ..but i would not bother for roof probably... is he mentioning that as well please? gosh i sould have bought that book really. but i am affraid i would rework that ship 3rd time so better not have fine weekend Vlad

-

Good moorning folks, i have question to ask pelase .im about to plank deck of cutty sark i have log on this forum....have most of it fugured out but what I did not run to is what pattern would possibly be treenail on deck planks. i dont have books about cutty but it would help immensely if someone knows what pattern 1850 english vessels made at joint butt and in sections. if two nails parallel-even like this : or off / angled. like this l:l vs l. 'l l. 'l l. 'l thanks a lot in advance. Vladimir

-

Silverman , i just made knees for lifeboat and found quite easy way toovercome grain direction. i would definitely go for 4 way. im not sure how small your knees are be it miniature i just draw knees on 3 mm cherry pannel wood, and drilled holes along curvy sides . them i easily cut outer straight sides out. then i start gently removing wood towards holes on unparallel leg of the knee up to the 2/3 towards knee center and when done just cut alongside holes on other leg of knee. as grain runs there alongside holes it cuts quickly. probably not celarly explained i should add pics later. happy build. Vlad

-

enjoyable to see breathing a new life to someones past work. it is very beautiful in its own way Phil. Vlad

- 22 replies

-

- kate cory

- restoration

-

(and 1 more)

Tagged with:

-

beautiful work Sceatha, thank you for sharing it! congratulations.

- 81 replies

-

- egyptian

- byblos ship

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.