-

Posts

257 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by AlexBaranov

-

-

-

-

Beautiful execution and excellent workmanship !

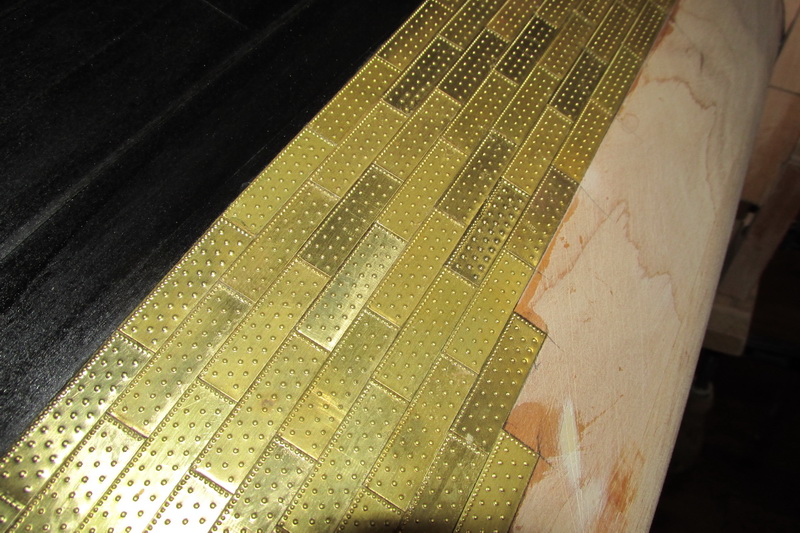

However ... the Muntz-metal sheathing would not have had raised nail-heads I think. Not sure how the plates were fixed to the isolating wood layer, but assume they would have been nailed like in the older days. It was important to achieve a galvanic separation between the Muntz-metal and the iron/steel plating underneath. When the plates are nailed down on the wood (with a layer of felt in between), the pattern looks a bit like on a deep-buttoned Chesterfield sofa. One can see this on the copper sheathing of HMS GANNET (1878) in Chatham:

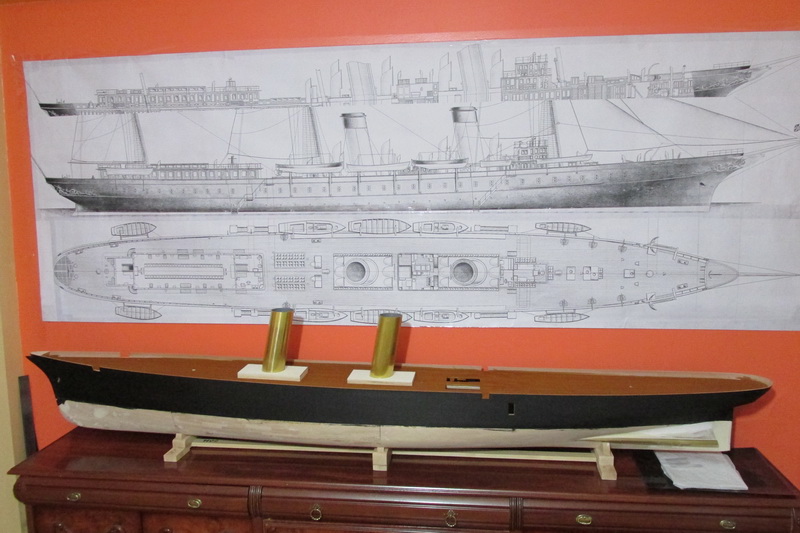

Hello wefalckOf course, you're absolutely right in terms of the historical reality in terms of engineering performance copies of this ship. However, at such a small scale to try to do so as the present, the real ship is not possible. In addition, it should not be done. I do not make a real ship. I'm trying to create a model of the ship and it is above all the image of a real ship. The model is first and foremost a work of applied art. My task is to convey accurately the artistic image, the spirit of a real ship. Therefore (after the experiment), I chose the most successful variant (close to reality), which would correspond to the artistic concept model.Special thanks for the excellent photos. I already took this photo in my archive. Very useful for creating a model in 1:24 scale (at least !!!)

Hello wefalckOf course, you're absolutely right in terms of the historical reality in terms of engineering performance copies of this ship. However, at such a small scale to try to do so as the present, the real ship is not possible. In addition, it should not be done. I do not make a real ship. I'm trying to create a model of the ship and it is above all the image of a real ship. The model is first and foremost a work of applied art. My task is to convey accurately the artistic image, the spirit of a real ship. Therefore (after the experiment), I chose the most successful variant (close to reality), which would correspond to the artistic concept model.Special thanks for the excellent photos. I already took this photo in my archive. Very useful for creating a model in 1:24 scale (at least !!!)- Landlubber Mike, Dubz, PeteB and 7 others

-

10

10

-

Alex! What width planks topside of the Board? Does it scale?

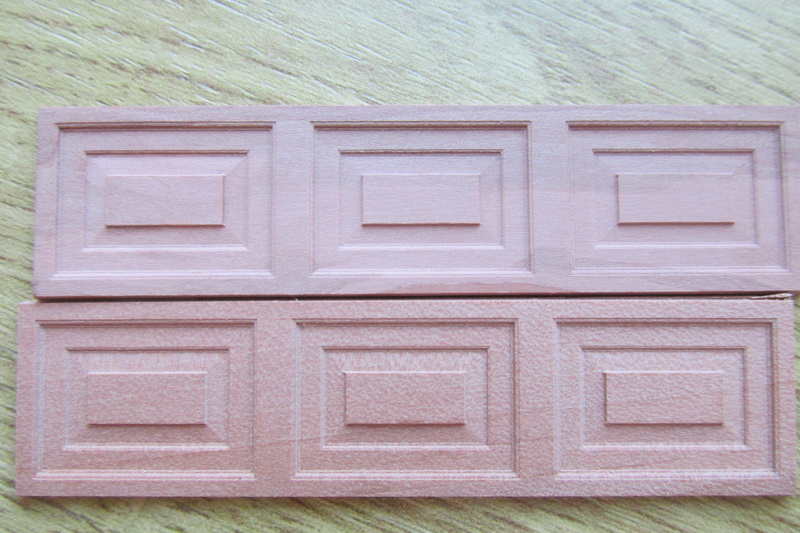

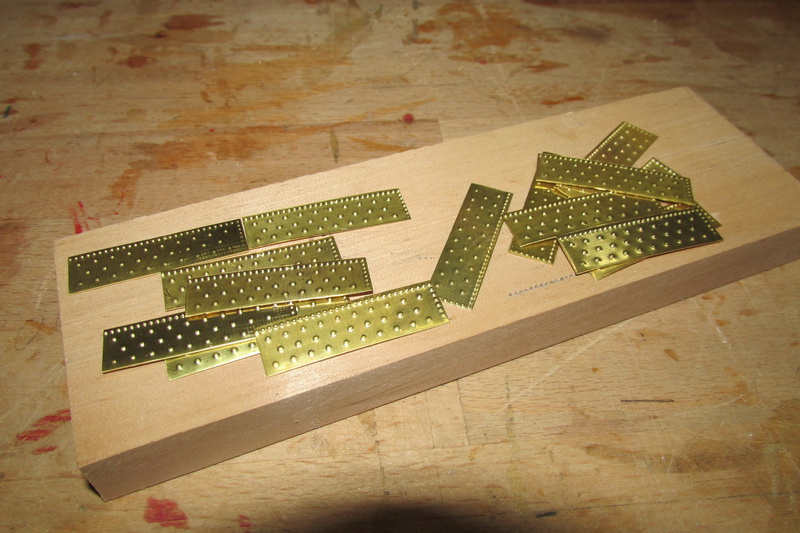

This is not the width of the board. This is the width of the metal sheet. Between the metal strip (pad) is added to belts sheets. The case will be processed in such a way to mimic the smooth metal.

-

Good morning Alex,

beauitiful work

your plating looks very neat, what kind of glue are you using, is it a contact type glue, or CA ?

Is there a certain reason that you are plating from bow in direction stern instead of opposite direction, so the vertical overlapping is not exposed to the onstreaming water ?

Nils

Hello NilsI stuck to the sheets of adhesive cyanoacrylate.Layouts corresponds to the project. -

- KeithAug, IgorSky, Mirabell61 and 25 others

-

28

28

-

- albert, Beef Wellington, Dubz and 19 others

-

22

22

-

Alex I went looking for the brass that you specified, because it looked like it stretched very nicely I did fine one supplier in the Ukraine, did you use a strip of rolled brass or was it a sheet that you cut into the plates? Fantastic work on the die.

Michael

Hi Michael.I bought a brass rolling here: -

Secret technology is very interesting

I like !

I like !Technology is no longer a secret. I did not strain your brain. Our dear great friend Dr. Michael long ago came up with the technology. Dr. Michael kindly told me all the details of the technology. However, it was always just the improvement in my repertoire. I added a digital technology and better materials. So my merit is not great.

-

Could one make one die and simply back it up with a piece of lead, rather than having to machine two matching dies perfectly?

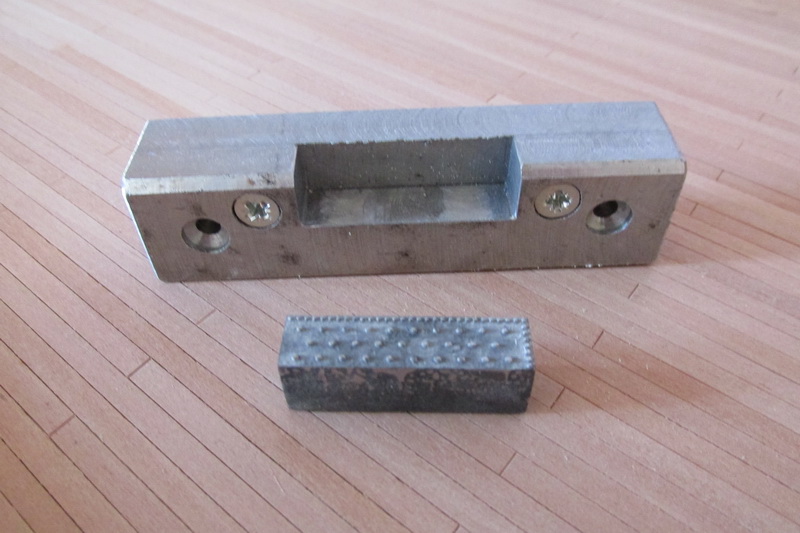

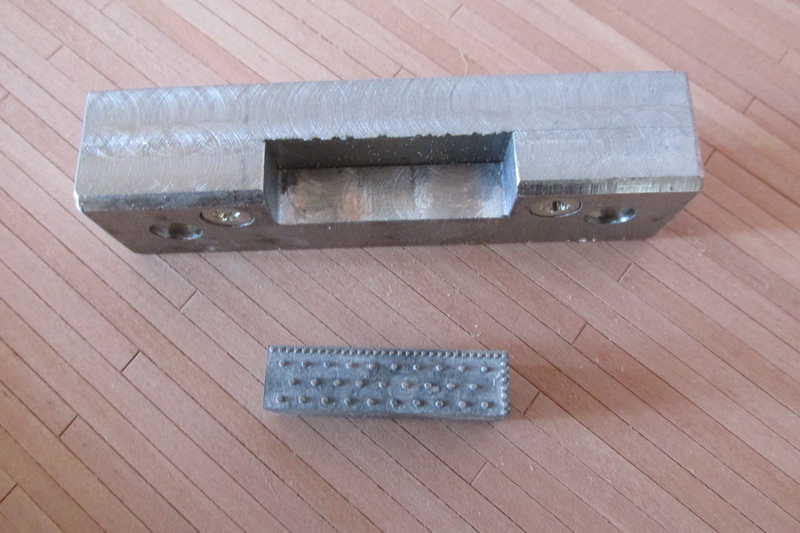

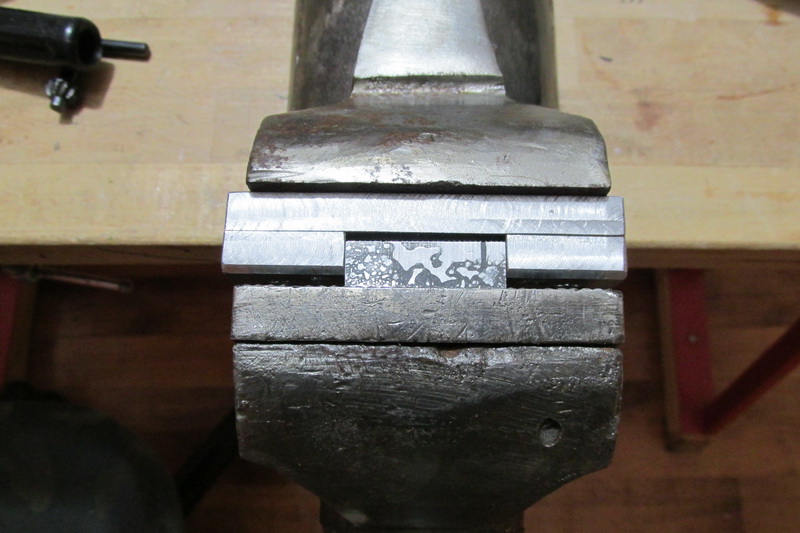

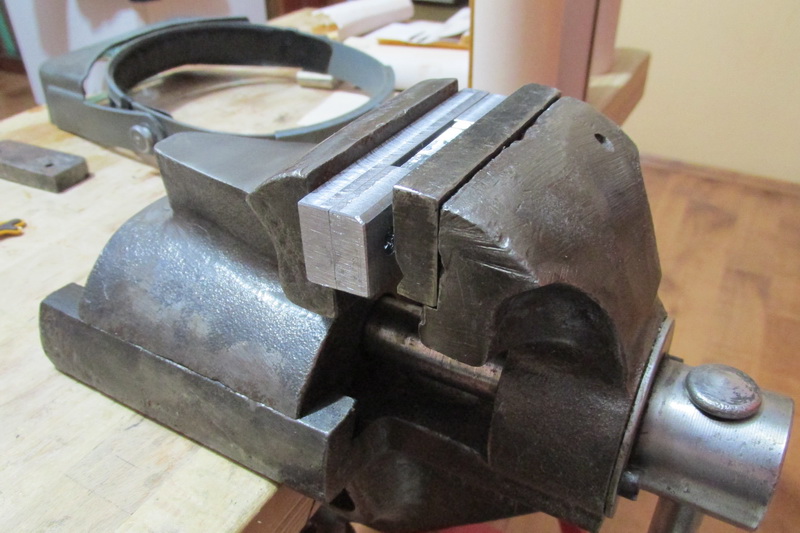

No. Lead use is not desirable. I tried to get bad. For the "mom" is better to use a solid metal. I tried the aluminum but it quickly wears out. So I began to use steel 45.

-

-

Hi Alex,

great work with the metal stamp and it`s heattreatment process, looks like it will have a long stand time. What thickness are your brass plates, and do you have to aneal those for stamping ?

Nils

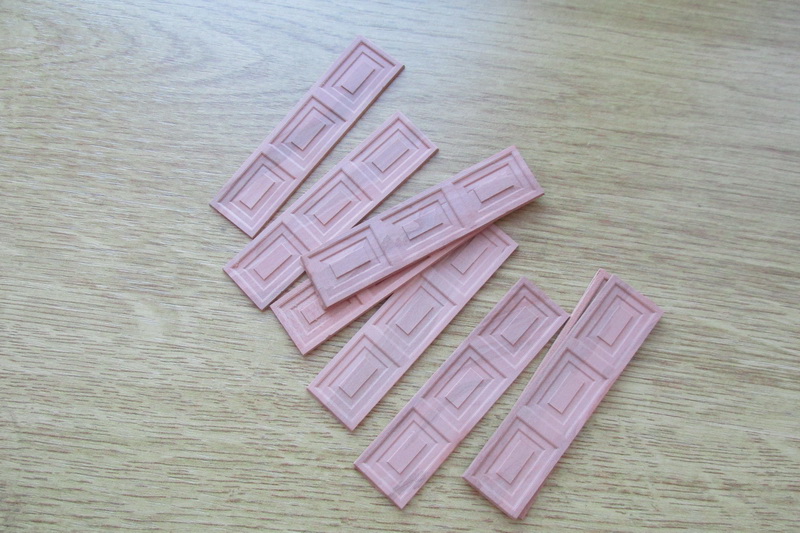

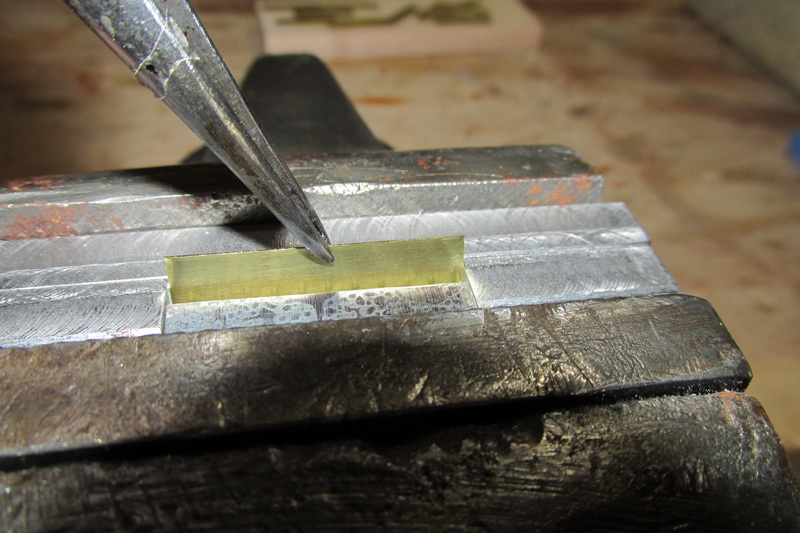

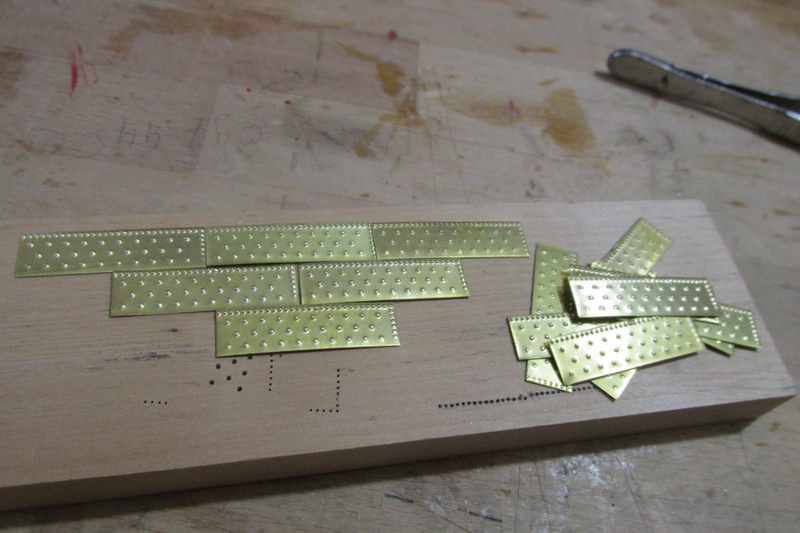

Hello Nils.I use a sheet of brass rolled thickness of 0.3 mm.Dlya smaller models is convenient to use a sheet thickness of 0.2 - 0.25 mm.- mtaylor, igorcap and Mirabell61

-

3

3

-

I used brass rolled 0.3 mm. Brand PM 63

-

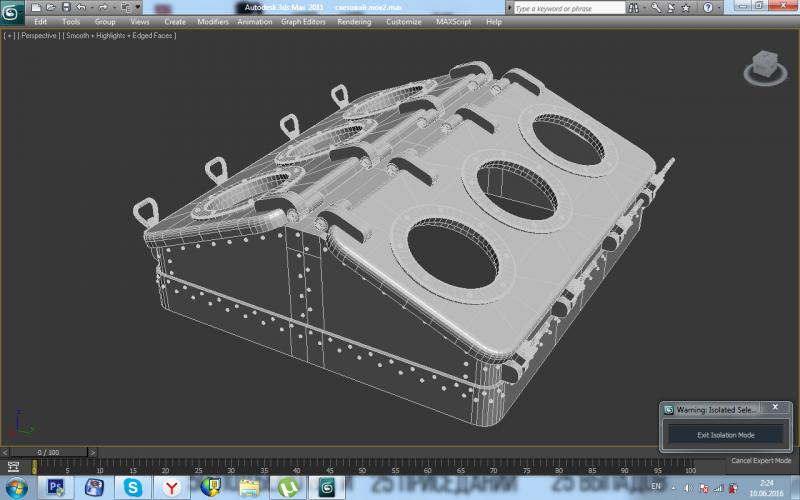

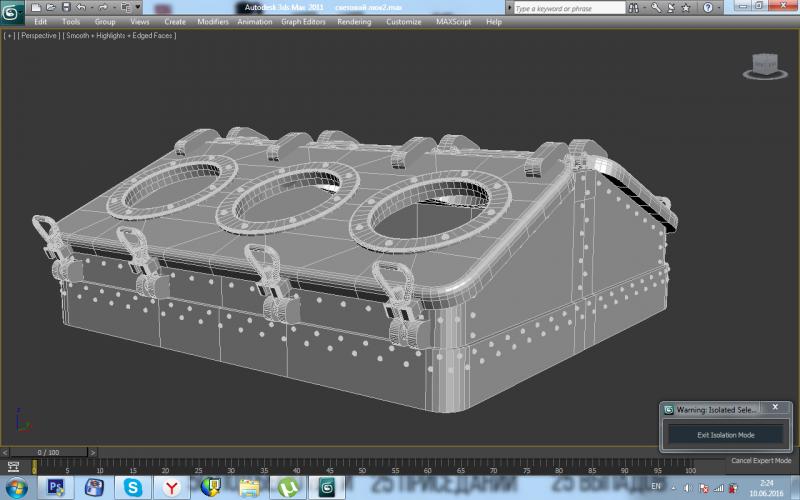

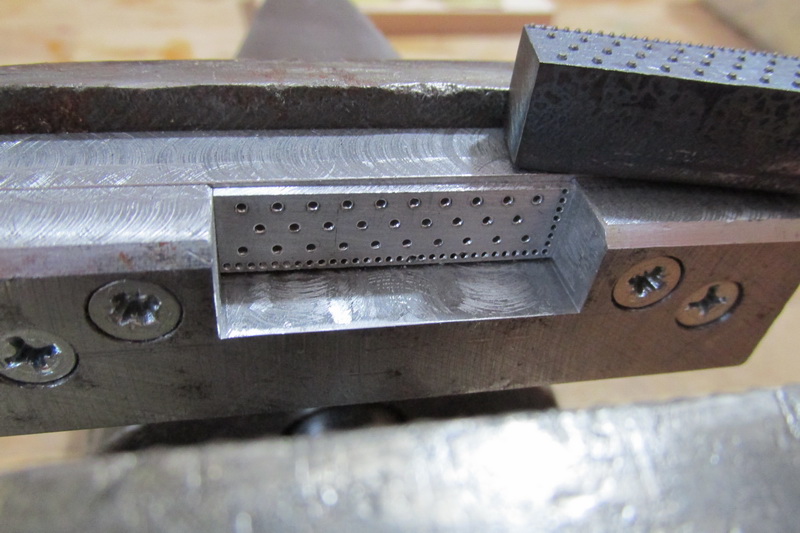

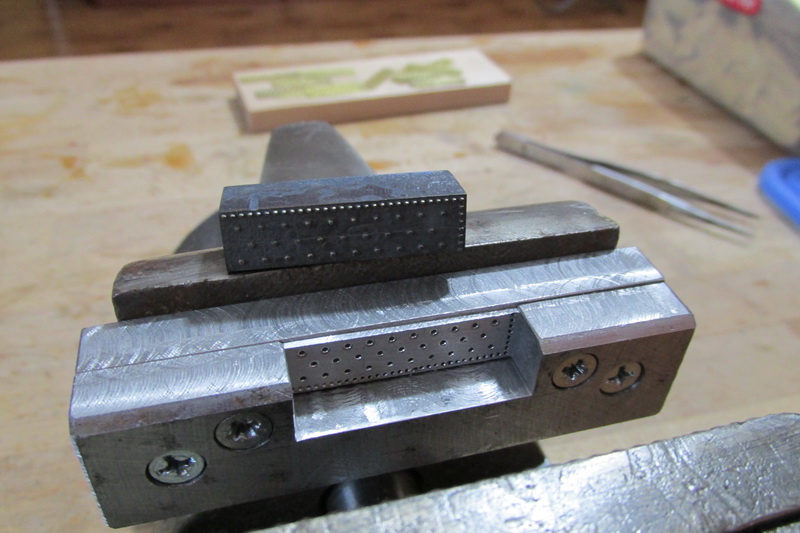

I made stamps from solid high carbon steel with heat treatment. It was the most difficult process of work.

- igorcap, mtaylor, michael mott and 2 others

-

5

5

-

- archjofo, Mirabell61, John Allen and 24 others

-

27

27

-

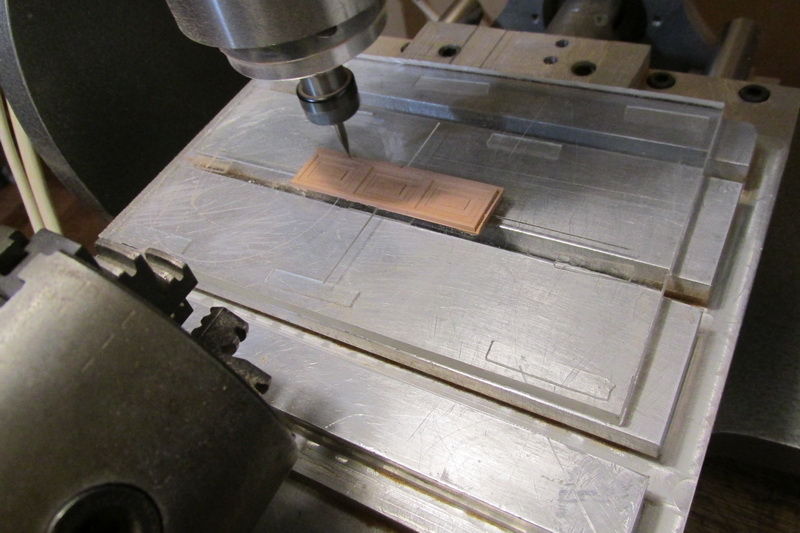

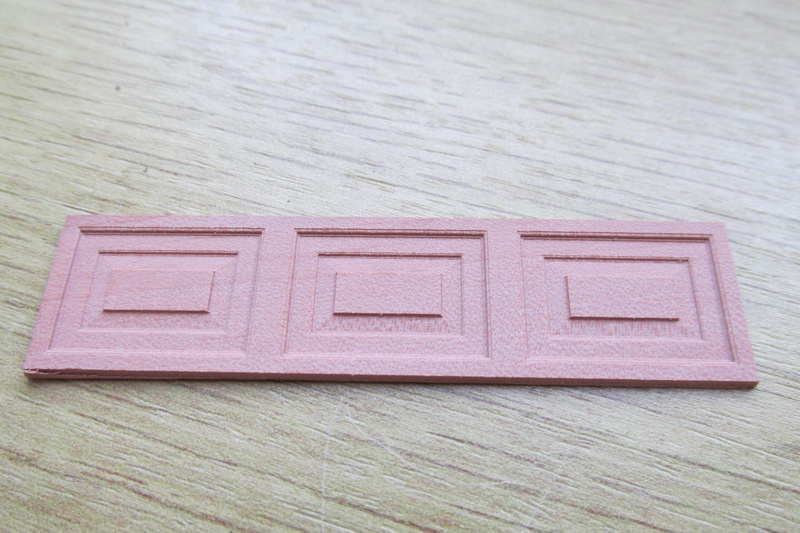

Hello.Sorry for the mistake ... I had in mind the production of finishing surfaces.It always turns out in a hurry. when they speak directly .... Haste needed when catching fleas and diarrhea.The stamp is made on CNC milling machine. I used the high-carbon steel. Then I stamped tempered at a temperature of 800 degrees. After stopping the reaction is released at a temperature of 250 - 300 degrees. The press turned out of the rut and special molds. The mold is made of steel 45.I will show the manufacturing process (stamping brass sheets). The sheets already cut to size. 0.3 mm thick sheet.

-

- Tadeusz43, michael mott, hexnut and 16 others

-

19

19

-

- Klaas, aviaamator, -Dallen and 20 others

-

23

23

-

- -Dallen, cog, aviaamator and 14 others

-

17

17

-

-

-

- egen, thomaslambo, aviaamator and 19 others

-

22

22

-

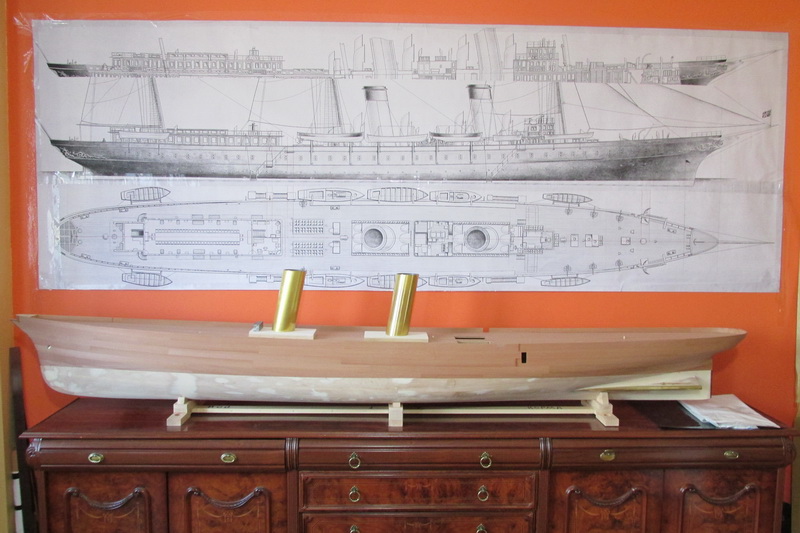

NilsI found a very good brass pipes in the network. different diameters, good brass (LS 63) of the pipe body thickness of 1 mm. These pipes will be very necessary for the manufacture of ventilation ducts and other parts. He spent almost 200 euros. However, I had to buy three times more than necessary. Diller sells pipe only 3 meters long! I had to buy more than is necessary.

-

- aviaamator, coxswain, Dubz and 20 others

-

23

23

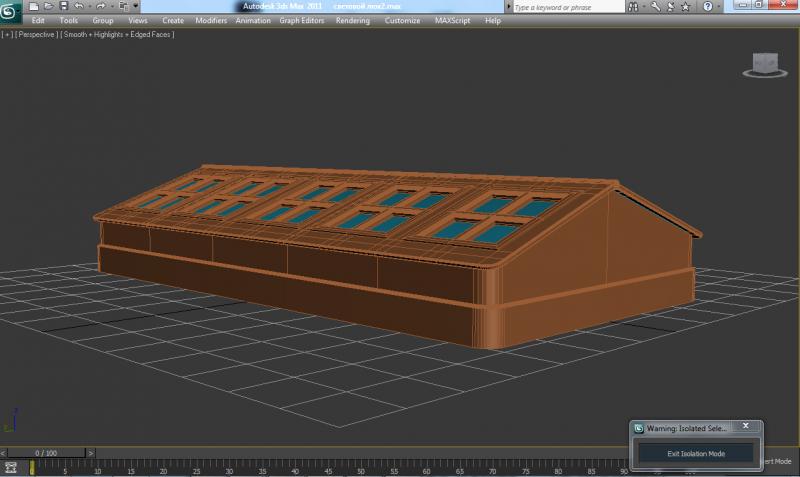

Standart 1893 by AlexBaranov - FINISHED - scale 1:48 - Imperial yacht

in - Build logs for subjects built 1851 - 1900

Posted · Edited by AlexBaranov

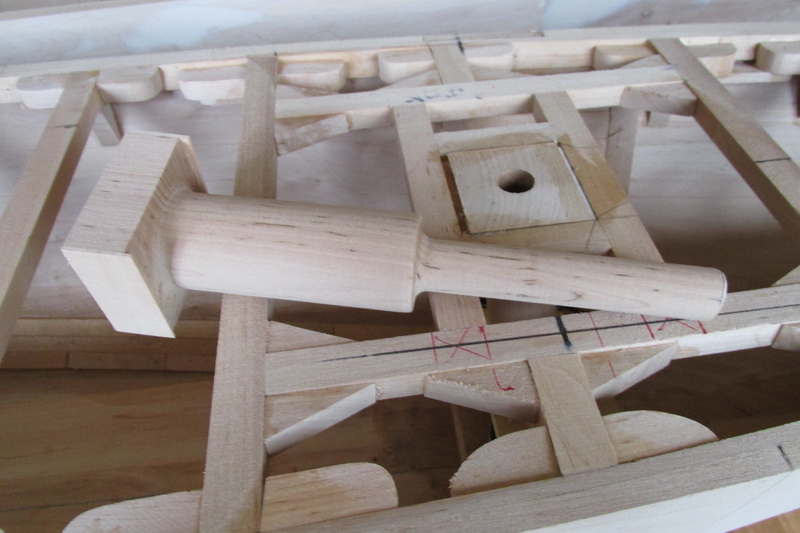

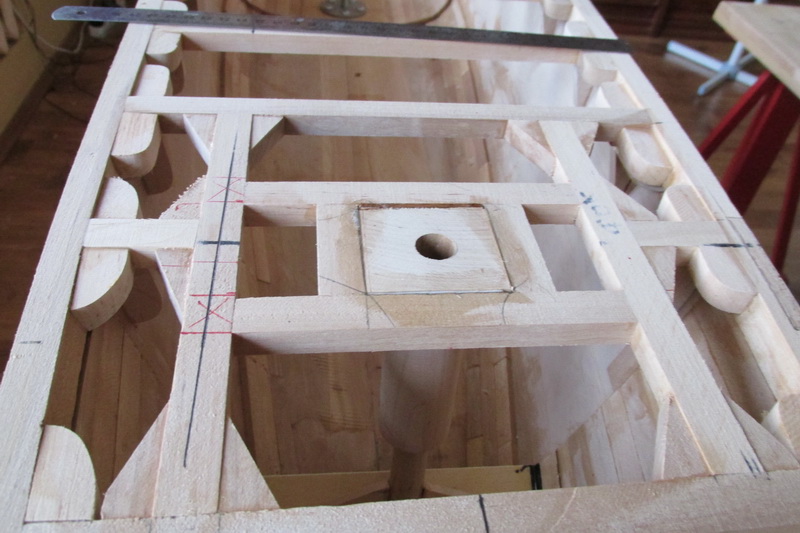

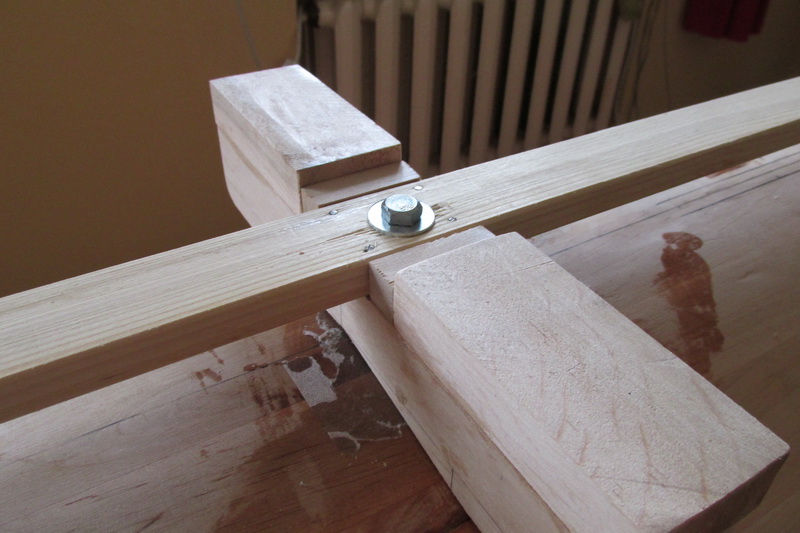

I started to manufacture and assemble parts. Probably, this work takes a lot of time (several months)