-

Posts

1,379 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Snug Harbor Johnny

-

-

My next step was to remove the original eyelets to lightly sand the hull. The eyelets have varying degrees of flatness to them, so I may make a small die to planish them uniformly prior to re-installation with a little glue. I used flush cutters to get under opposing edges, and they pried out without much trouble.

Now I had a good look at the paint, which is uniformly flat, and appears to be an interior casein paint that used to be common, and is consistent with the age estimate for the model. I was the set painter for two High School musicals in 1971, and used this type of paint - specifically, Iddings Deep Colors. They still are popular for theatrical work and interior murals, and has some similarity with artist's gouache.

Casein paint goes back hundreds of years, but had to be mixed fresh to avoid spoilage - but was stable once dry ... an historic home in our area still has the original pastel hued paint on much of the woodwork. If re-wet, it could re-activate - so overpainting with a similar paint 'welded' the layers. A method of making an oil-water emulsion during manufacture made the surface less prone to reconstitution, and by the late 19th century methylcellulose additives further improved the product. Preservatives were also developed to increase the unopened shelf life to about a year, and 3 months once opened.

Cans of the stuff I used to use were VERY heavy (especially white), because of the lead oxide base ... banned in 1980. So my conclusion is to assume at least some lead content on the hull paint - something to think about on an old model. A test with a moistened water swab and a certain amount of rubbing on the green area did start to pull color from the surface, which began to soften a bit - confirming the paint type. So was there anything else to worry about, given the shade of green?

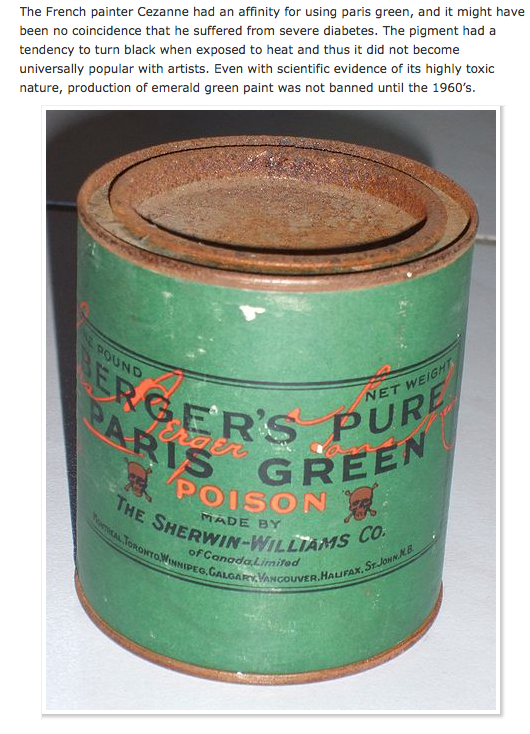

Copper arsenate pigment was widely used from the late 1700s through the mid 1800s for wall paint and wall paper- especially after a more stable form call 'emerald' or 'Paris' green was developed, but died out by 1900 due to the awareness of toxicity and the availability of new and safe(er) green colorants. Yet the use in art colors continued ...

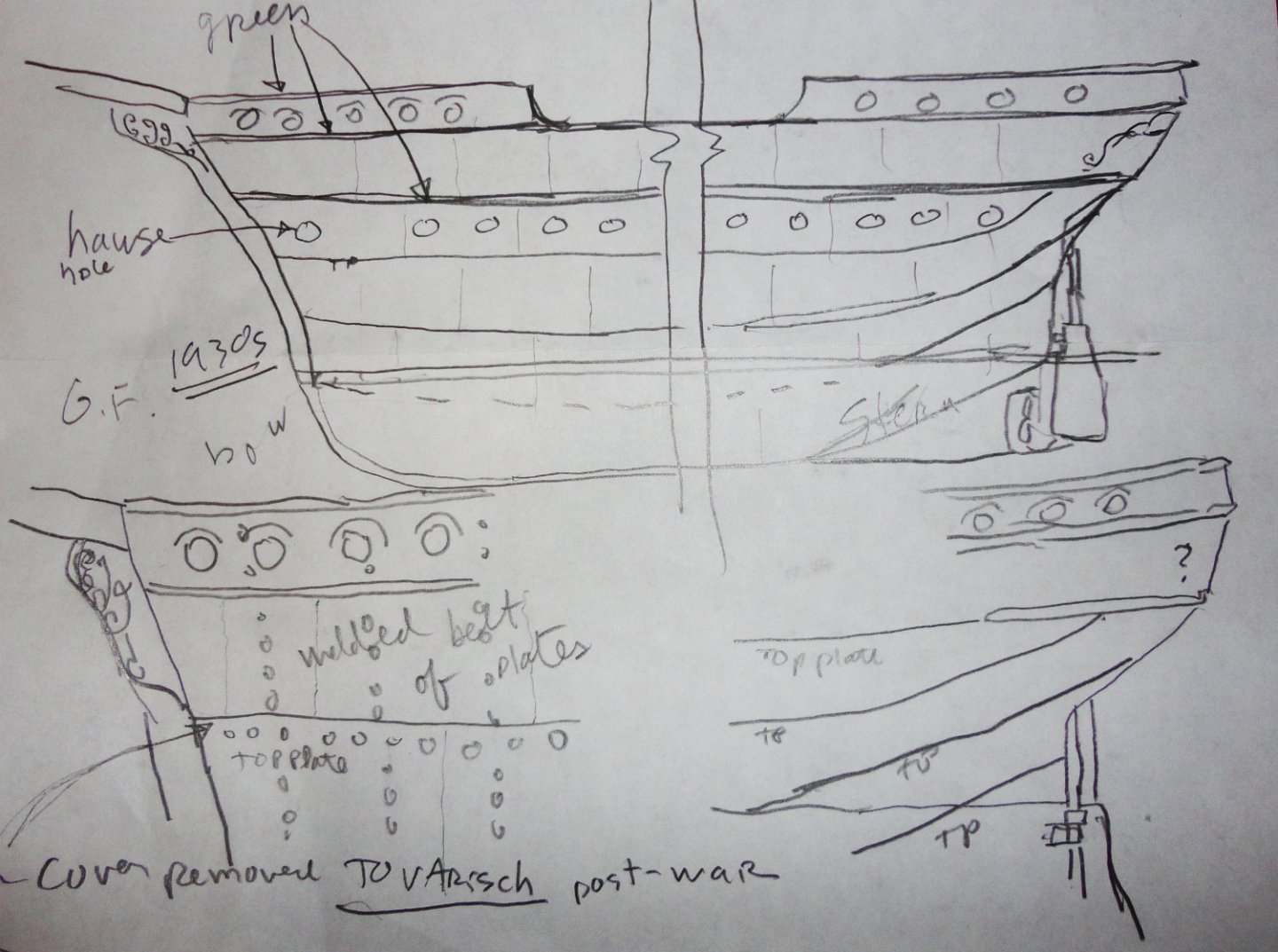

Copper arsenate is reported to have been used in early 20th century anti fouling paint, although the most common agents were red lead, cupric oxide and red mercuric oxides. These were mixed with additives in a shellac/linseed type of paint for the U.S. Navy between 1908 and 1926. From 1926, the Navy switched to a coal tar rosin type of paint. Anti fouling paints in the 20th century were generally red or russet brown, but green was occasionally used, perhaps when copper arsenate was in the mix. The Gorch Fock 1 had the green color, but the constituent ingredients are not known to me. Anti fouling paints changed quite a bit after WW2, and have continually been reformulated as there are now World bans on many substances and chemicals considered dangerous to the marine environment.

But more to my concern, I found this bit of information:

So out of an abundance of caution, I decided to treat the old paint 'as if' there was some arsenic in it. After all, copper arsenate in pressure treated wood was used until 1986 - when a 'safer' inorganic form called 'chromated copper arsenic' was used ... until a voluntary ban in the U.S. and Canada in 2003 !

My sanding was very light, done over a waste can - and mostly to 'skim' off the grime that had accumulated over the painted surface. Then the surfaces were gone over with moist paper towel to remove all dust. Duh, Johnny should have used nitrile gloves ... so washed his hands when done quite thoroughly.

- _SalD_, Glen McGuire, hollowneck and 4 others

-

7

7

-

-

-

On 10/8/2023 at 12:45 AM, Louie da fly said:

Makes a lot of sense. That stuff can be SHARP!

Steven

Electron microscopy shows freshly knapped flint or obsidian goes down to just a couple of molecules wide at the edge ... effectively the sharpest edge for any material to have - as sharp or sharper than a surgeon's scalpel, or Sweeney Todd's razor. This was important for early humans to butcher the mega-fauna they hunted - just getting through thick hides was an achievement.

-

On 9/28/2023 at 6:18 AM, Louie da fly said:

Yep. There are certain fungi that work as well as char cloth, too - the ones that grow on the trunks of trees. Apparently you grind it up when it's dry and then (and I forget what comes next).

I've done it with char cloth and tow. When the spark hits the char cloth it forms a small glowing point which you then wrap the tow around and blow like the blazes (sorry!). Dry grass works as a replacement for tow, too. I was once in a mediaeval gathering over the Easter weekend and we had to douse our fires when we'd finished with them (it was in a pine forest!). I decided to get some practice lighting with flint and steel every time we re-lit the fire- got fairly good with it, too. But hard on the knuckles - you lose skin either from the steel slamming against them while you hold the flint, or (worse still - it's sharp) from the flint itself. This video is very enlightening - I wish I'd seen it before

Steven

In Scouts, after learning how to use flint and steel, we had to master the bow and drill to make fire. The bow and drill was definitely more difficult, and the carved wooden 'base' was key to accumulating embers to nurture the same way as char-cloth. Once mastered, a Scout was awarded the "Smokey Eyeballs" certificate.

- mtaylor, Bob Cleek and Louie da fly

-

2

2

-

1

1

-

8 hours ago, Keith Black said:

Johnny, if you get in that pickle again I have a few of the old style flat eyelets and I may have the size you requite. The type of eyelets used on a model help determine the age. The flat eyelets are generally much older than round face eyelets.

Eyelet types

https://www.iqsdirectory.com/articles/metal-stamping/eyelets.html

These kinda look flat.....maybe??

https://www.leffler.com.au/eyelet-shoe-45mm-antique-pkt-of-100-/

Thanks, Keith. I'll keep that in mind. The flat eyelets used are consistent with the estimate of 70 years on the original, as are other observations. The toothed wheel (unmodified) made somewhat triangular indentations into the wood, so I used a tiny square file to reduce this effect - making the wheel more like 'nubs' - still not sharp. This made for better indentations ( aprox. 0.020" dia. intended to simulate rivets at 1:100) - negative, yes - but just an indication. Burrs from filing wanted to make micro tears in the wood, so burnishing solved that. Light repeated passes (easy does it) were used. More testing is on order before making any decisions.

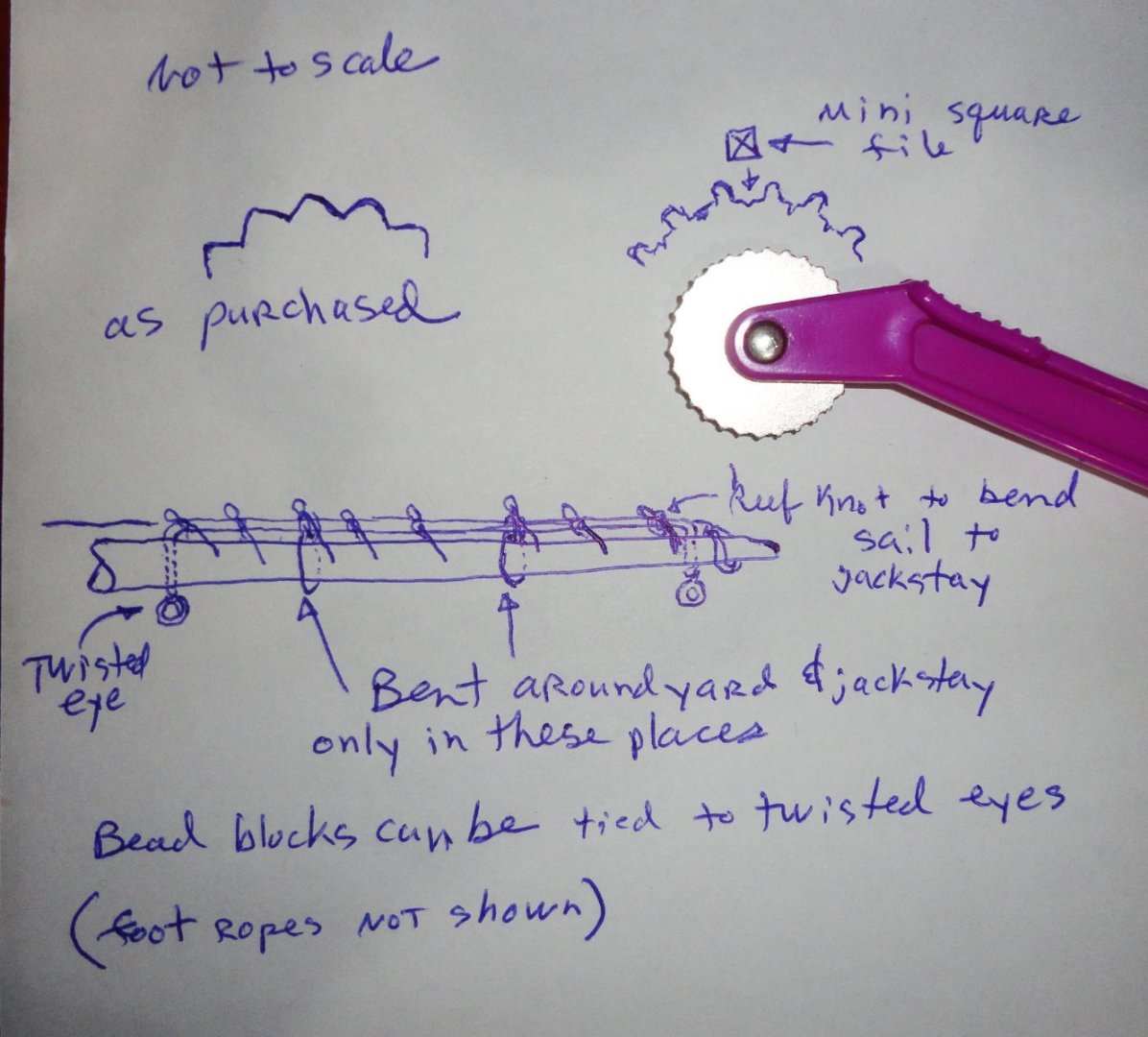

'Still thinking ahead on some other things - like bending the sails on the yards. Option 1 is to repeat what was found - a single thread spirally wrapped around the yard (going through the sail each revolution). Option 2 would be to used individual ties through the sail and around the yard using a reef knot (just a 'square' knot, but with a bight of line so it can be undone with a tug on the loose end of the bight - otherwise the knot is solid and will stay under tension). Option 3 is in the lower part of the sketch - a piece of wire serving aa a jackstay (not on top of the yard, but slightly on the forward side) where only the ends go through the yard, and are twisted into eyes on the bottom. The sail is bent to the jackstay, but also around the yard at intervals. Some try-outs will be done as tests.

As there are no instructions, I'm having to make them as I go ... lots of hours (on and off) thinking about things and how they might work out. Many years ago when building model kits, I was totally reliant on the "instructions" ... assuming that everything was accurate. Hmmmm, a good reason to read and think about everything before hand - including NOT to make assumptions one way or the other on engineering, scale or accuracy. Obviously, most modelers must make compromises - especially at smaller scales - but its good to choose them for a reason. The project at hand isn't even a kit, but if building one, checking out any build of that kit on MSW is a SUPER idea, as there are lots of tips about pitfalls, fixes, and enhancements to pick from.

- _SalD_, mtaylor, Keith Black and 2 others

-

5

5

-

This is a cool way to make a plexiglass case ... as plexiglass cement 'welds' the pieces together, and they can just be lifted off. This gives me an idea - to make a case where there is a solid back with a thin mirrored surface attached. Then the clear panels are the front , sides and top - the mirror enabling one to see the OTHER side of the model.

-

The replacement eyelet was tried in the empty spot ... first, it was a little loose in the hole, and would require pushing a drill bit through to 'right size' it. Second, it just doesn't look right at all, having a more prominent flare and is super-bright - as the photo below shows. That had me thinking of what else I'd have to do to disguise it.

One picture is worth a thousand words ... So I resolved to try and find the lost eyelet, and searched all around the shop floor on my hand and knees (the other hand holding a flashlight). 'Thought I'd looked everywhere already (several times) when, at last, I saw something way underneath that looked like it ... and it WAS. I'm resolved to be careful going forward, and perhaps use a little glue when re-installing after hull painting.

The well-organized (and neat) builder may never know the sheer joy of finding something that was thought to be forever lost !

- Keith Black, Knocklouder and mtaylor

-

3

3

-

'Bought some walnut veneer at Woodworker's Supply (there are a couple in our area, so I went to one store to SEE what they had on hand). There was also mahogany and lighter woods in 0.028" thick veneer, sold several pieces per plastic sleeve. The idea is to make my own "plywood" by stacking 3 or 4 pieces together, varying the grain angle and painting a thinned wood glue between the the layers ... then clamping between boards (or weighing them down good) and allowing to cure. This will make thin stock much less likely to break.

As for seeing pencil marks on a dark substrate, I use white pencil (comes in other colors) the Admiral uses for marking cloth from patterns prior to cutting. 'Guess its a form of tailor's chalk in pencil form.

- clearway and theoracle09

-

1

1

-

1

1

-

I thought that one of the eyelets might go astray ... and that's what happened to one of them - and dang if I can find it now. I've order some on line, and as there are 200 to a packet there will be plenty as replacements. And if the difference between a replacement and the originals is too pronounced, then new might be substituted for old. The railings will be new brass as well.

I told both the lazy imp and the Hatter to stop kibitzing and get lost. It turns out that the paint on the heads of the pins (fake rivets) on my test piece previously posted, flakes off easily due to the smoothness of the metal surface. To get paint to stick, I'd likely have to use bent pliers to grip each pin shank and roughen the surface of the smooth head on fine sandpaper to give it some "tooth" for the some primer to grip. This really makes the idea impractical, and has been suggested is inappropriate for this project.

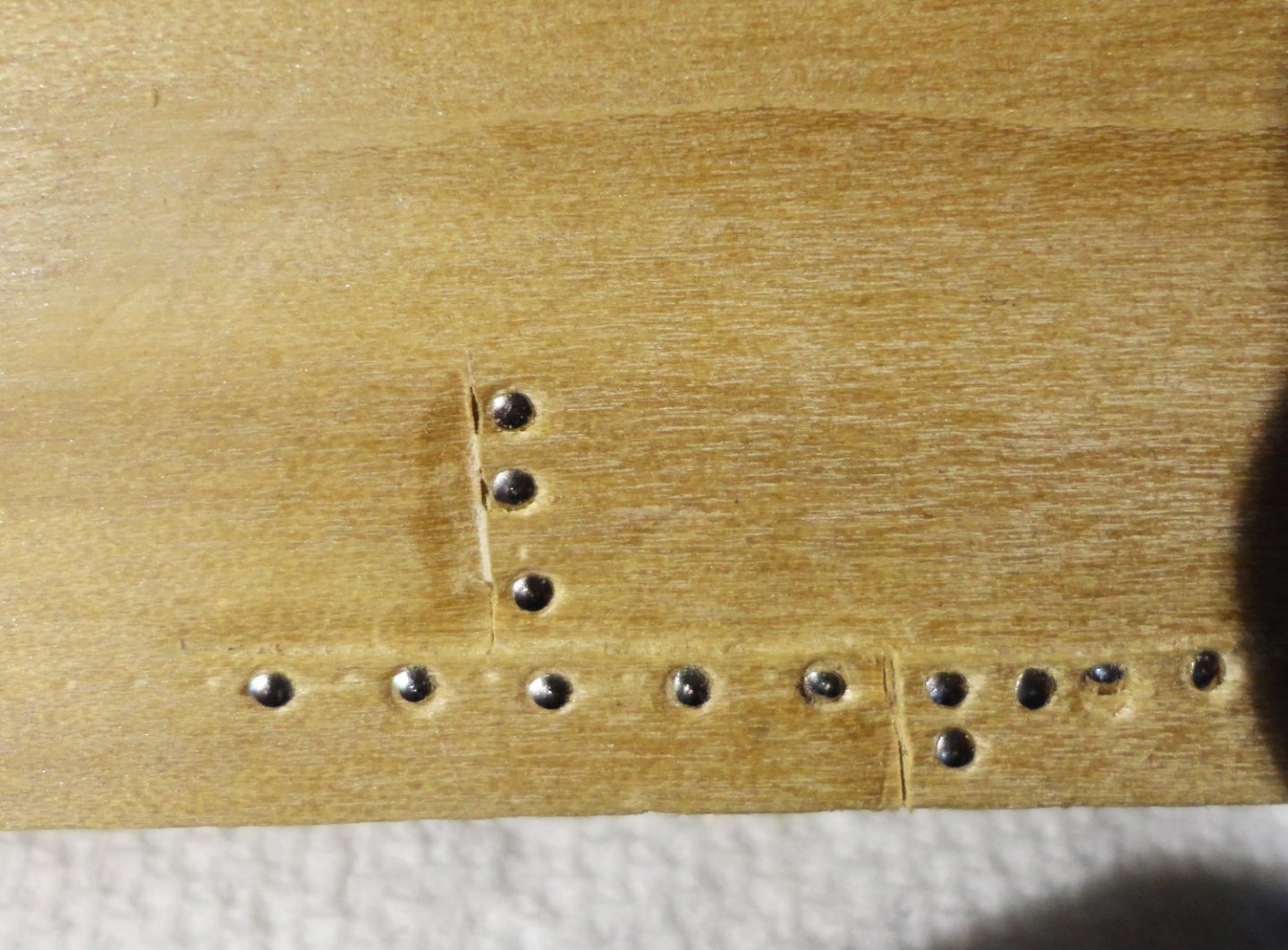

I do like the look of riveted plating as seen on the build of the Ergenstrasse elsewhere on MSW. A test was done in an inconspicuous place near the keel with a 'dull' sewer's pattern marker (there are 'sharp' versions as well), and there are slight depressions that look interesting. When painted over they'll partially fill, but still give a slight impression of rivets. At a distance they'll hardly be noticeable.

There is the stand to build, as the present one is rather crude. I like the ides of making cradles so the hull can be picked up and replaced while working on it. Later for display, screws from below (or simple pins, perhaps) can fix the hull to the stand so it does not shift if the case (to be built last) is moved. I need to drill a hole for a new bowsprit if joining the original with a steel pin does not work out - replacement being 'plan B'.

- Rick310, Keith Black, Glen McGuire and 2 others

-

5

5

-

Ded reckoning: A means of finding rocks and shoals.

- Bill Morrison and John Ott

-

2

2

-

-

I found that a dab of Tarnex (liquid silver polish) applied with a cotton swab (Hmmmm, could also swab the barrel of a miniature brass gun with a suitably sized bore) was the first step in neutralizing excessive tarnish on the eyelets. this was done in situ for convenience. Then a light rubbing with Nevr-Dull shined the flange exteriors. I wore a nitrile glove so not to blacken the finger tips.

Step 2

Step 3 was to lightly work the rounded surface of the eyelets formed inwards with a soft rubber bit for the rotary tool.

The eyelets will be carefully removed to permit light sanding and repainting (plus some blackening inside the hole into the wood). The railings will be new brass, so the eyelets and railing will then acquire a natural patina over the years at roughly the same rate.

- mtaylor, Glen McGuire, Keith Black and 4 others

-

6

6

-

1

1

-

On 9/28/2023 at 12:29 AM, Keith Black said:

Johnny, whatever choice you make is the right one. Just remember, you're restoring a model, not building a new one.

A good re-direct, Keith. So often I'm overthinking various aspects of whatever project I'm on at the time - in part because there is almost never a re-do. Past projects of various kinds represent closed chapters, yet sometimes there are thoughts like, 'What if I'd done it a little differently?' So imagining all sorts of ways to progress on a present work still means that I have to choose a certain way to go. Having discarded other paths not taken, there will be no 'what ifs' concerning them since they were consciously set aside.

Only if I later think of something NOT mulled-over prior to acting will I muse over it. But there has been progress in doing less of that, in part by doing more thinking beforehand ... which may drag something out - but maybe its better than rushing in. In the present case, I'll keep the original eyelet-ports in the spirit of restoration. The upgraded deck railings are brass, and I don't care to paint them - so they'll go with the eyelet ports. I'd like to use many of the deck fittings from the original model, such as they are, where possible. The fife rails will have to be re-done, in light of the improved rigging (simplified, though, as previously planned) - a main interest in doing this project. Every line has to have a purpose and means of operation.

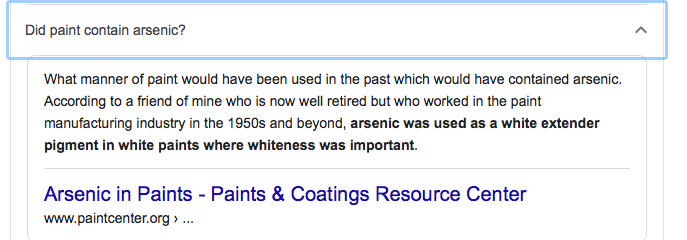

While the hull is stripped bare, I may still do a little on it, in that photos of the original (as modified) still show some obvious horizontal join lines. The present incarnation has them welded over for strengthening - which only emphasizes them more than when they were just riveted as she existed in the 1930s. The lower green belt is discontinuous today, but was continuous as built. Each horizontal 'belt' of steel was composed of neighboring plates welded together pretty flush, so those joins are not obvious. The belts follow the lines of the ship and are not unattractive - rather , they provide interest.

Another 'thumbnail sketch' was made to think about these belt lines for consideration.

I'm also seeing some advantage to a solid hull - at least for ships that have painted hulls (with or without copper bottoms). There is always something solid to 'pin into', whether eyes, chainplate or whatever. And solid hulls are 'old school' carving projects. I'd likely use a drill press to make mast holes while the wood is still a block, setting a mast angle (if any) by shimming one end of the wood block to suit.

Obviously 'Age of Sail' men-of-war with multiple gun decks can benefit from planked construction, and any ship that was largely unpainted. And most kits have laser-cut frames to plank. Yet the time saved by not carving is taken up by everything involved with Plank-On-Bulkhead. One may want to add additional intermediate frames, wood filler blocks (hmmm, so it starts to resemble a solid hull), then fairing like hell, then first planking - filling - sanding - putzing, before ... second planking.

- mtaylor, Glen McGuire and Keith Black

-

3

3

-

These are points well worth noting. Do I want to save myself trouble (the imp on one shoulder), or do I want to go down a 'rabbit hole' (the Mad Hatter on the other shoulder)? A long winter looms ahead soon enough, so I'm not sure. Now there is the GF 1 riveted plate (as built, which is the model being restored) - renamed Tovarich post war, prior to some modifications - and the GF 2 of welded construction (although the weld lines show in photos of her).

Below is a close shot of the Tovaricsh (English spelling) showing the lapped, riveted plates - and the rivet do indeed stand slightly proud. They are not 'domed' as seen on locomotives and other steam equipment of the 1930s, but still have a convex shape above the surface of the plate. The air ports (port holes) are nothing like the eyelets used on the model as previously advised ... no flanges are on the outer surface. If the eyelets are omitted, small 'eyebrows' could be put over the holes as seen in the photo.

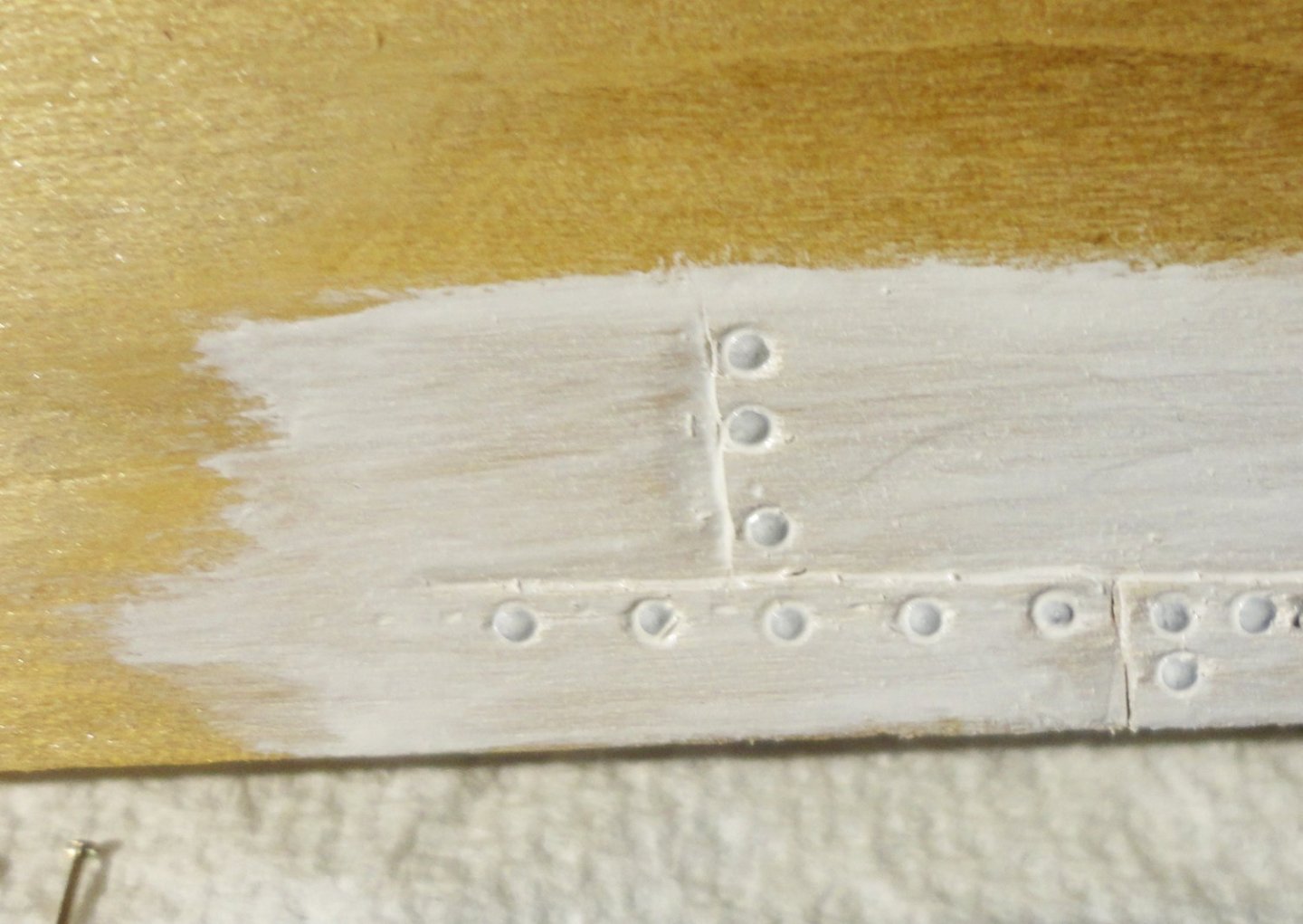

So to fool around with the idea of mimicking lapped plates, a piece of poplar was manipulated with the tools in the photo below. 1.) A shallow horizontal line was cut with an X-Acto, with a couple short lines at 90 degrees to the first. 2.) Small and medium leather working bevels were tapped on one side of the cut line to try and mimic lapped plates. I used to tool leather, so a light touch is needed. There is no groove, as the wood fibers are compressed on only one side of the initial cut. 3.) The smallest pins I could find at JoAnn Fabrics were 1/2" long with about .050" heads, so the length was trimmed with a cutter (could have used dikes) - but the thin soft wire shank can be cut with a beader's flush cutter. 4.) The pins were pushed part way with bent pliers (I should get a pin pusher), then tapped (not too hard) before setting with a nail-set (again, I buggers a couple learning the right amount of force to use). The sample stick is also in the picture.

The test of concept was 'freehand' - no measuring or guides, so I can do better. The nail-set pictures below show the convenient concave center that nests well on the concave pin head. Now the heads are not to scale (what 5" at 1:100, versus something like 1 1/2" or so on the original), but the idea is to suggest riveted plates.

Below is a close-up of the test piece.

Now paint will 'fill in' some of the defects, as the first coat of some Testor's paint indicates. After drying, bit of dust and wood fibers can be smoothed away before using a tack cloth and applying a second coat of paint (not done on the sample yet).

The concept looks promising, so the question is which of the 'nudges' on my shoulders will sway me ... the imp (devil) or the Mad Hatter?

- Glen McGuire, davyboy and Keith Black

-

3

3

-

The small eyelets the builder used for the port holes can be lifted out, as they were not glued - just held in by pressure from a properly sized hole drilled for them ... and none are missing after all these years. The first picture shows one removed. A bit of grain shows through the now 'chalky' paint - I might lessen that a tad with a careful sanding rather than trying to fill. The ship was riveted steel, and would show no grain, yet the solid wood hull on the model was made as-is. 'Guess its a balance between restoration and enhancement, and I don't want to overdo anything.

The eyelets have dulled over the years, but with a couple swipes of 'Nevr-Dull' treated cotton (still available) a satin brass (soft shine ?) They have a 2mm through hole, a 5 mm flange width and a 4mm height. I saw new ones available, but they'd look "too shiny", and might not have the same 'fit'.

The eyelet was replaced after touching up, and it seems OK. The picture is a little out of focus.

Under consideration prior to a light repainting is to scribe some plate lines on the hull, and make some small divots to suggest rivets. The next picture shows three as a test ... 'Not sure if indents will do as they can on copper plates or strips applied to coppered hull bottoms, as the small nails used on original copper plates do indent - versus the domed shape of a rivets holding plate hull together. (Welding later made riveting obsolete.) Perhaps tiny dots of dried glue could be experimented with - or tiny pin heads if they can be found. OR I can just sand and repaint.

Suggestions are always welcome.

- Glen McGuire, mtaylor, _SalD_ and 1 other

-

4

4

-

4 hours ago, Keith Black said:

Using hot water as you did I'm surprised the sails didn't shrink but all's well that ends well. Do you plan on ironing the sails to help eliminate some of the puckering? A build log by Burma (see below) on his Cutty Sark, his sails are some of the best I've seen. If I were to ever build a model with sails I'd sure try to copy his techniques.

You're right that Bruma has an outstanding build of the CS - one I could never come close to. 'Hidden' in my earlier post today, I do mention that ironing with a medium iron (no steam) will be the next step to de-wrinkle. The Admiral assured me that the sails are made of linen gauze - something hard to come by today. Cotton would have had a much higher risk of shrinking, but with either fabric, most shrinkage can occur if one 'tumble drys' (especially with heat) - just as woolen knit-wear will also do. That's where the 'blocking' comes in.

Also, if one makes clothes 9as the Admiral does), both cotton and wool from the bolt can be pre-washed to remove any sizing AND pre-shrink by tumble drying with heat. With wool, this process was known as 'fulling'. Further shrinkage of garment made with pre- shrunk fabric is unlikely. Therefore, if I make sails on a future project, I'll pre-shrink the raw material first before cutting.

- Glen McGuire, mtaylor and Keith Black

-

3

3

-

Ahoy, Tony ! I used to like the 'Minwax of Old' for general woodworking, but it has been significantly re-formulated to comply with VOC reduction ... likely a good thing. Now, as then, it really takes 3 or 4 days to dry - and in the interim it gives off a distinctive odor - a litttle less each day. Its still good as a colorant, as I had to match some unfinished red oak stair 'bull-nose' to pre-finished 3/4" tongue and groove red oak flooring. I started with Minwax that was a little lighter (and a slightly different chroma) than the flooring, then added small amounts of artists' oil colors (thinned with a little Minwax clear). Just a little at a time to the container used for mixing enough for the need, as it is hard to 'lighten' if one goes to far. A test piece of oak was used and compared to the finished flooring (which had some color variations inherent due to variations in grade. Also I was using #2 common, less expensive than pricy #1 - yet still much better than the next lower grade.).

'Seems that Minwax is fully compatible with artist oils, and to be sure of my color (after 'force drying' the test piece with a blow dryer) a little clear varnish was applied over to get the sheen of the pre-finished flooring - and the color would be 'flat' without the top coat of varnish. It looked good, so I went ahead and treated all the bull-nose needed. One day later I applied the clear Varnish (Varathane clear - a different brand name, but also compatible with Minwax) and the next day was able to go ahead doing the landing into our sunken family room ... We can't tell that anything was matched, it looks that good.

Right now, I'm restoring a very old Gorch Fock model that had the deck and masting coated in varnish 'back in the day'. The varnish prevented any dirt and grime from getting into the surface of the wood. I was able to use slightly soapy water, isopropanol and acetone (on that order) to get off all the gunk - which may have had 70 years of tobacco smoke, dust, aerosols and grime built up (especially on the decks). In fact, I used a low-angle carpenter's chisel to 'holy stone' the deck (gently, as to not compromise the original protective layer of varnish) - and I'm amazed how much stiff came off to reveal the beauty concealed below. This raises my opinion of varnish as a protectant (especially is a model will not be cased, as was the case with the one I found neglected in an antique shop).

If wood is conditioned with 'boiled' linseed oil (and unless it says 'raw' linseed oil on the container, it will have a 'dryer' in it), it is advisable to mix it 50-50 with ordinary turpentine. Some woods will darken with this application, such as walnut or mahogany ... mush less so with lighter woods. If a few days go by, the turpentine (which assisted penetration of the linseed oil) will have 'out-gassed', leaving the linseed oil to cross-link by the action of the dryer. I have a tin of 'Japan dryer' (enough to last a lifetime), and am in the habit of adding a drop per half pint of linseed oil or any oil-based paint to insure good drying.

Once oiled wood has out-gassed, it will accept either varnish or shellac as a top coat. I happen to like shellac (amber or clear, depending on the wood), but caution to use product no much beyond the expiration stamped on the can of pre-mixed shellac (e.g. Zinnser) - much easier than making ones own from shellac flakes. If shellac is used, it can be removed by alcohol (if needed), so future cleaning cannot be done with alcohol.

-

11 hours ago, Keith Black said:

You may want to make sure the sails didn't shrink, they cleaned up nicely.

Good thought, Keith - and I had considered that as a possibility (just never said that in a post). The Admiral previously showed me how to block a knitted sweater on a towel to prevent shrinkage. By 'blocking' the sails on paper towel (with the scale being small for the sails) I figured that the roughness of Scott towel and the sailcloth were a fair match. I had to pull the edges carefully to lay them out straight and nearly taught, because that is how I got into trouble on one of the sails I did earlier (and the repair was documented). The moist material 'gripped' the paper towel and the sails dried without appreciable shrinkage.

There is some puckering within the sail area, but (as done before) they get a light pressing with medium iron (no steam) - and that removes wrinkling. BTW, I thought the sails were slightly oversized to begin with, so a little shrinkage might make them fit the masts better ... but they are nearly the size they started at. And then (as before), I'll straighten and tint the reefing lines.

Its amazing how much grungy yellowing came out of the sailcloth - and Beth is using the same method on her antique Galleon sails.

- mtaylor, druxey, Glen McGuire and 1 other

-

4

4

-

Thanks, Keith. I think its just fine as far as I went ... no use overdoing anything. So today (after more garden stuff ... this ideal weather PA is having will only last so long) the remaining sails were treated with Restoration. With confidence (and careful handling) I did the step 1 rinse in hot tap water, then did 3 successive baths with the cleaning product. Ceramic cookware was half filled with hot tap water, then heated to approx. 160 - 180 F on the stove, shifted over to a cool part of the cooktop, some rinsed sails added and a scoop of product - stirring with metal (stainless) tongs.

It really foams up a lot, and if there is too much water to start with there is a danger of the foam going over the top (my first batch threatened to do that, so two pieces of paper towel were put on the foam to 'soak up' and break the bubbles). After 5 minutes (or so) the hot pot was moved with pot holders to the sink, and cold water run in. My gloved hand scooped the sails out and rinsed under cold tap water.

Then I 'blocked' the sails on paper towel, covered with more paper towels and hand pressed.

I have other 'irons in the fire', so rather than get the blow dryer, I took the blocked sails outside to get sun-dried ...

The dirty, old sails (likely starched originally as previously noted) now have a new lease on life. Fragile when wet, they firm-up once dried. I treat the reef points as already pictured, then pick something to do next - probably do work on the hull. There is not enough space to install 'eyebrows' over the top row of portholes, so that, as well as any thought of simulating rivets should just go out the window.

I might consider replacing the eyelets used as portholes - as conceived by the original builder. That will make repainting the hull easier, as it really does need repainting.

-

Super tip, Sal ! I will definitely try this block-sanding jig to make use of some "ordinary" blocks I have lying about. Of course, once Chuck is re-stocked is fabulous array of CNC made blocks I'll likely order some. Yet even those might benefit form just a few seconds in the sanding canister - with very fine paper.

-

'Nice ship's wheels. 'Saw recently that a ten spoked wheel is needed for OcCre's Endurance (another fine build).

-

'Thought I'd start with a gentle cleaning with water plus a little mild dishwashing liquid soap ... hey, if it can be used on ducklings, why not a deck? There was obvious dust & grime picked up on the bunched paper towel used, but left on the deck was a grunge that didn't readily come off. To the touch it was slightly tacky, so I let most of the water evaporate and tried to use a flat, low-angle carpenter's chisel (carefully) with short reciprocal strokes ... and a bunch of stuff started coming off ahead of the blade - revealing more of the underlying inked (or penciled - not sure) and over-lacquered plank pattern.

This might be compared to 'holy stoning', except on a model.

The idea is to skim very lightly without compromising the original surface underneath. No way did I want to cut through the lacquer and expose bare wood. The hull has a nice 'heft' to it, and might be maple (heavier than pine). The next picture is a close up of the process. All the eyes and railing nails were pulled before beginning, and the nail holes are oversized for the nice 3D brass stanchions procured to replace them. The solution will be to glue round toothpick ends into the nail holes flush with the deck, then drill what size is needed for the replacements.

So far, so good. Since it was already determined that lacquer was used (rather than shellac - which alcohol would attack), I decided to try rubbing with denatured alcohol next. Having worked with both finishes, I knew that lacquer would not be dissolved by the methanol.

This time more grime was removed, but not completely, and the methanol flashed-off fairly quickly. The next step was to use acetone (sparingly), and with the right pressure applied in the direction of the wood grain, most of the accumulation or 'whatever' did come off. There was only so much it was safe to do, and the object is to restore - not strip. I thought about it, and don't want to make this model something its not - so enhancements will be limited. The rigging will be done better, as that is something I wanted practice at - but I can still respect the original modeler's intent.

Below is the cleaned deck - the lighter area on the right is where the main cabin went, and fortunately it 'popped' off easily - being glued apparently with wood glue to the previously lacquered deck. The orangey cast is how my cheap camera depicts some areas, but it is not quite that orange in real life - more of a yellow orange.

A close-up is added to better see how it looks. Maybe the plank lines were just penciled.

-

Gorch Fock I 1933 by Snug Harbor Johnny - 1:100 - RESTORATION

in - Build logs for subjects built 1901 - Present Day

Posted · Edited by Snug Harbor Johnny

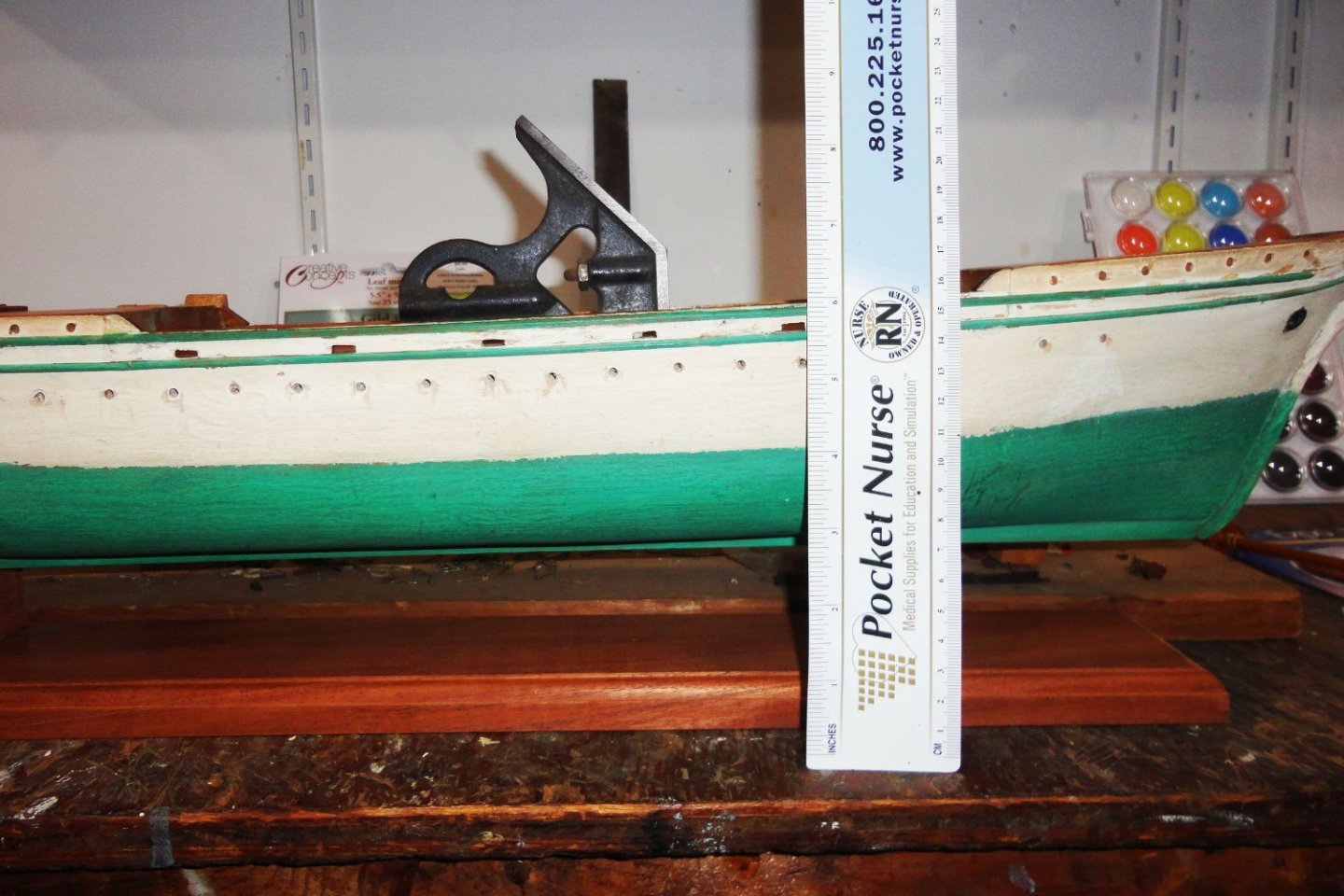

I've always been a 'hammer and chisel' guy, so it was high time I made a better stand for the restoration - the 'as-is' stand being rather crude. A piece of mahogany was scrounged that looked about the right length ... the width ? ... well it seemed OK, and no use 'designing' something that would require buying a new piece. The thickness is 3/4" (standard), and the ends can be trimmed with a table saw, but first the edges needed planing. My favorite low-angle plane set to a light cut (and the blade is kept very sharp) made nice thin curls, once some of the roughness was removed. Its not a proper jointer, but the idea was to remove just a little since the width is on the narrow side - ending up at about 3 1/2".

After the ends were table sawn I thought I'd rout a nice recessed quarter-round - inspired by the nice bases that come in the vintage Scientific clipper kits. The photo below is self-explanatory (having avoided the metal pieces pinching the board), and the piece was simply shifted a little laterally to complete the milling.

The location of the cradles was judged by eye, then the same measurement was made from each end. My old mitre box was used to hand-cut pairs of limiting lines carefully figured so the cradles should drop into rabbits with a snug fit. Yeah, it might be easier (and more contemporary) to get a right-sized router bit, set up a stop and just make a single pass for each rabbit ... but (being an old-school guy - and having an afternoon to putz over something) using hand tools gives one a lot of satisfaction ... until something gets screwed up.

Next up, a small hand router ... given the grain orientation of the base, it seemed wise to set the bit to 1/3 of the needed depth and work 'with the grain' on either side of the margins. The picture below is actually the 2nd pass at 2/3rd the required depth.

Once the edges have been shaved, the orientation of the cutter is made 90 degrees to the grain - which shaves off OK since the sides were done first.

BTW, those checking this project from time to time will realize my pace is quite slow, with lots of 'thinking' in between steps. No sense rushing, as I'm often quite absorbed doing things, then going off to do something else (many time seasonally influenced or otherwise mandated), then coming back and getting lost 'in the weeds' again. 'Suits me just fine. Below is a full-depth rabbit.

'Turns out the width is nice and snug - one can always trim or sand a tiny bit if needed, as opposed to trying to put wood back on. There's one spot on the edge of the base that didn't quite clean up when edge planing, but I didn't want to take off the additional 1/16" just to smooth that spot. A little sanding can help. I also dropped the base and a small chip came off one corner - but no matter.

The truly inspiring scratch build of the Mary Rose gave me the idea to get a profile (contour) gauge. This will transfer the hull shape to the respective cradles before jig-sawing out the waste. I realized that the hull lines constantly change, and that the cradles are about 1/2" thick, so the hull profile of the forward cradle was taken from where the front face of the cradle goes - and the profile on the rear cradle is taken from the stern face. I did mark the pieces lightly in pencil so I'd keep track of how everything needs to go together. Note that the keel is pinned to the solid hull, and the applied trim on the hull is also pinned - a previously noted advantage of a solid-hull model.

After cutting the waste from the cradles, a rotary tool was used (with numerous trial fits) to carve the cradle to fit more closely against the hull on the face opposite the one that the profile gauge marked. Then some sandpaper (gripping reverse side paper would have been batter) was placed on the hull so the final sanding was done on the cradles where they are supposed to go.

So far, so good ... but a trial fit of the assembly had the hull higher at the bow than it should be. I noted that the deck in the raised stern section curves up, and the deck forward of the main mast curves up going forward (dead rise at the bow). The picture below indicates that the bow cradle needs material removed from its base, and (after measuring) that cradle was removed and pieces of wood stacked to support the bow - adjusted so that the level was level just behind the main mast. I judged how things looked by eye, and was satisfied with how it sat. Re-measuring told me how much to cut from the forward cradle - which was done on a band saw with a guide.

Below are the old and new bases side-by-side, and there is a marked improvement. The cradles will be glued, then a pair of screws will be fitted from below as mechanical strengthening.