-

Posts

3,076 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Gregory

-

-

If you decide to glue them, just some white glue in the hole should keep them in place, but allow for easy removal if you need to later..

Meanwhile your cutter is really looking great!

- Old Collingwood and VTHokiEE

-

2

2

-

-

36 minutes ago, WalrusGuy said:

...should the coils be oriented in a clockwise direction?

What sources could we check in this regard?

-

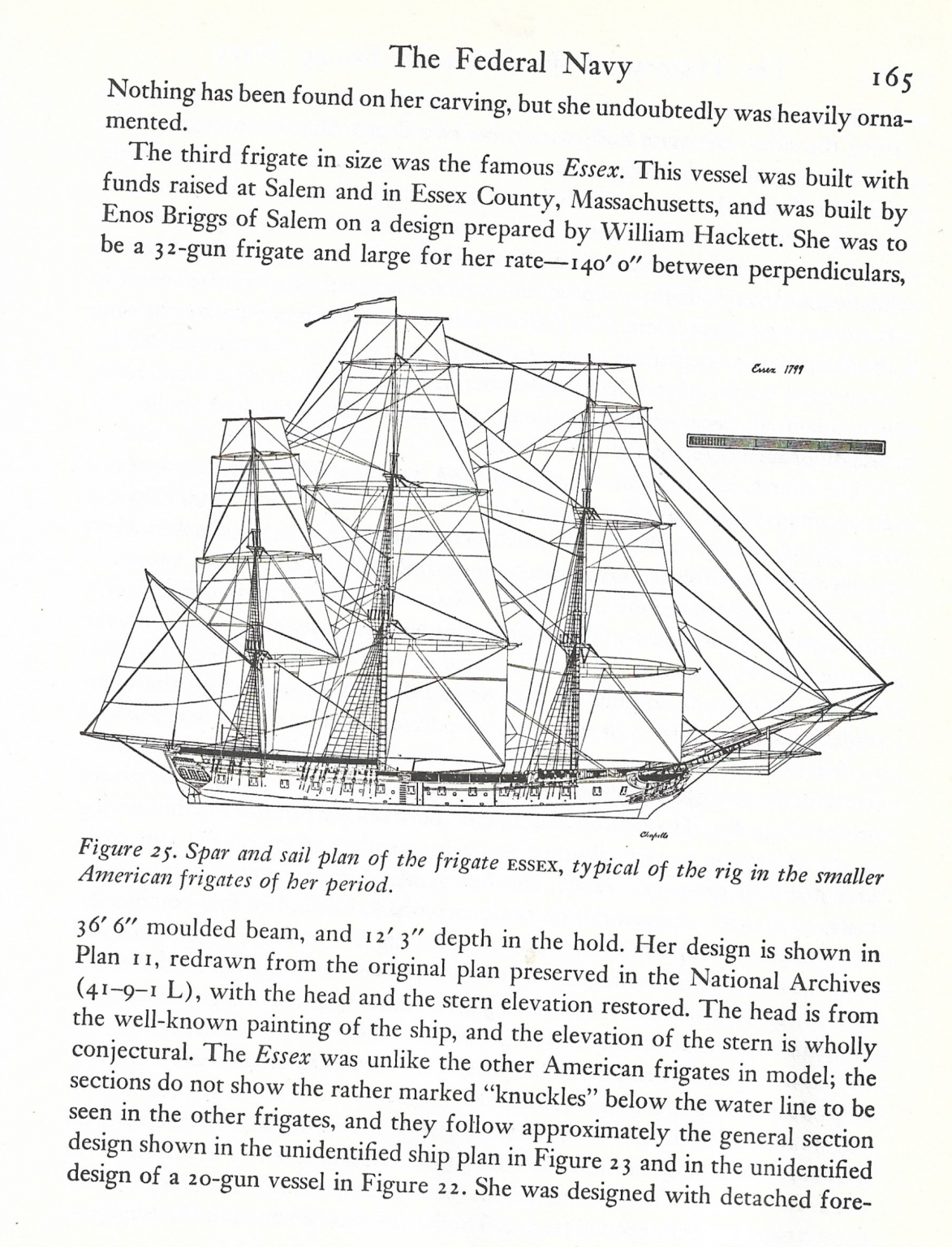

Someone mentioned AOTS, which is 32-Gun Frigate Essex (Anatomy of the Ship, which would be the best source, depending on your budget.

Not cheap, but Googling shows copies for less than $50..

While there are those who would argue the details, the general arrangement of the Constitution might be an option.

There are lots of resources for Constitution rigging plans.

-

21 minutes ago, VTHokiEE said:

Really? I didn’t think CA needed a porous material as it is often used for metal bonds (I understand epoxy is another choice). Now PVA on the other hand I’ve always heard needed a porous surface.

It may not always be the case, but I have never found CA to work well on, say, two varnished surfaces unless they were roughed up.

I have had success with laser char as long as the loose stuff was removed.

-

-

Have you checked out the pricing at Cornwall Model Boats ?

Even after shipping costs, the price can be very competitive..

-

I've been told the flat coils might have been used for inspection, but not on a working ship.

I have never seen a contemporary model or illustration with the coils.

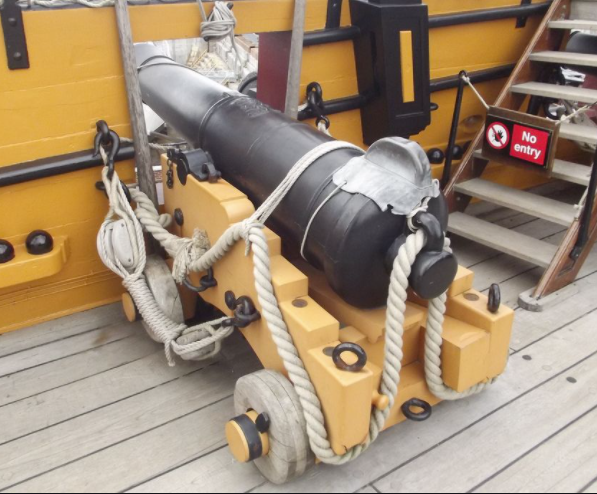

Here is what you see on brig Niagra

Another method is called frapping, as seen here on Victory.

I think the coils are a modeling convention from who knows where.

In the end, it is how you choose to present your work.

-

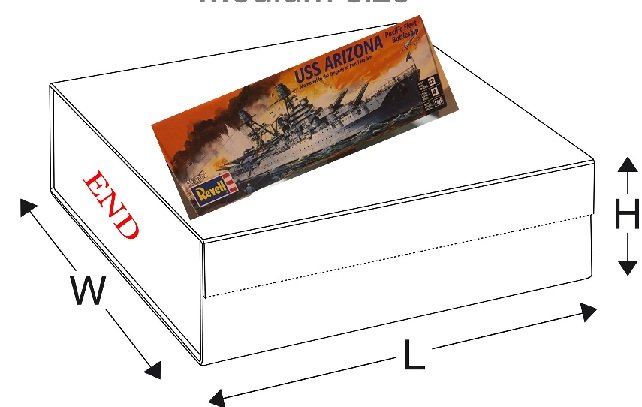

1 hour ago, mtdoramike said:

Where are you going to put the already together hull? It ain't going to in a 30x8x4 box, the original kit box maybe.

I was just putting that out as an example of what it cost to ship USPS. Did you see the part about:

QuoteWhile your actual numbers may be different,

But thanks anyway, for your help...

-

-

Have you considered US postal service.

I have shipped large packages with them Often. ModelExpo uses USPS and Chuck at Syren does also..

While your actual numbers may be different, I calculated a 30x8x4 inch package at 5 pounds from VA to CA would cost $26.70. 2-day Priority..

-

-

Can someone have pity on a landlubber and tell me what the " hair bracket " is?

You can imagine what Google came up with.

- FrankWouts and bdgiantman2

-

2

2

-

I apologize if I'm being too much trouble, but I'm thinking of the end like this:

Once I see the end of the box, i can tell you what I have in mind..

Thanks

- Old Collingwood and mtaylor

-

2

2

-

-

-

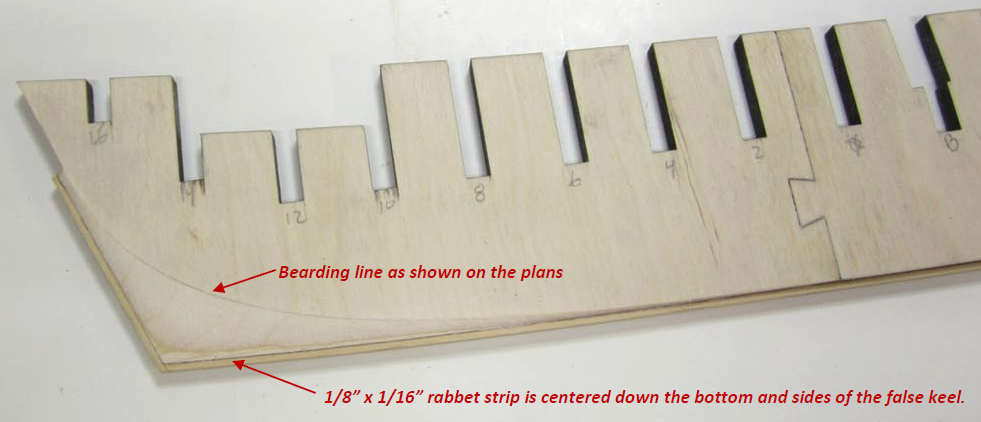

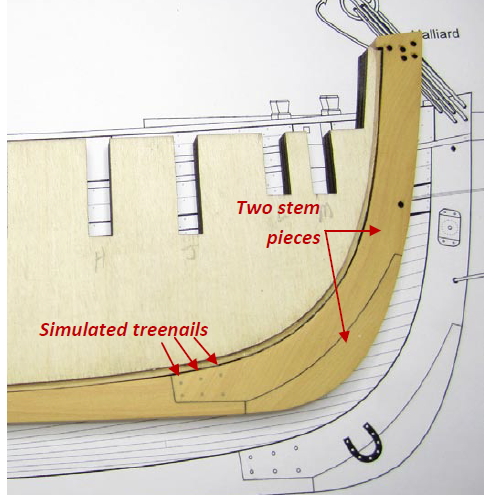

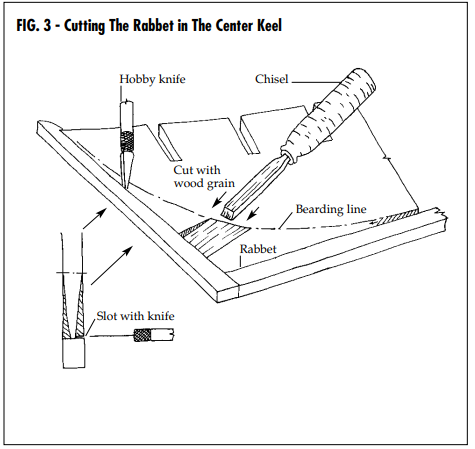

There is also the option when building a POB kit, of using an offset strip a'la Chuck, down the center of the backbone ..

Image from Chuck's Cheerful instructions.

Notice the groove created by the rabbet strip, that serves as the rabbet at the stem.

Of course, kits that haven't provided separate parts for the stem, keel and sternpost, would not lend itself to this method.

-

This is far above anything available in a kit. Beautiful work..

I don't think it would be unreasonable to try to recover some of your development cost in your pricing structure before the cheap knock-offs show up.

I know there is already a lot on your plate, but perhaps sometime in the future you could offer headrail upgrade kits for kits like Syren and Confederacy.

-

Here is a basic drawing from some of the ModelShipways kits.

The idea, is that the final planking fits flush with the keel and stern post. So the depth depends on the thickness of your planking material and whether or not you will be

doing single or double planking..

For instance, if the keel piece is 3/16 and your total planking material is 1/16, you would want the bearding line and rabbet to be recessed 1/16 on each side of the keel piece.

Regardless of the thickness of the keel piece, the depth of the bearding line and rabbet needs to be the thickness of your planking.

There is tapering to be done, but you have to refine that as you go along.

-

-

-

-

I see you answered your question, but keep in mind, you can do as much or little as you see fit.

While my decking would not survive a test of realistic accuracy, I got everything as close as I could within a mm or so, then used the waterway to fill any gap.

P.S.

Let me add one more thing.

When I glued my off the deck planking onto the false deck, I used yellow glue. I had to take few minutes of smoothing and pressure with my fingers until the glue started setting up,

which it did pretty fast - 5-10 minutes

-

You mentioned you have a kit.. Which kit?

Does it have a rigging plan?

Byrnes Table Saw making a 1mm by 1mm strip

in Modeling tools and Workshop Equipment

Posted

Has anyone mentioned blade height?

I wouldn't have the blade height much higher than the final thickness, and also at low RPM..