Paul Le Wol

-

Posts

843 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Paul Le Wol

-

-

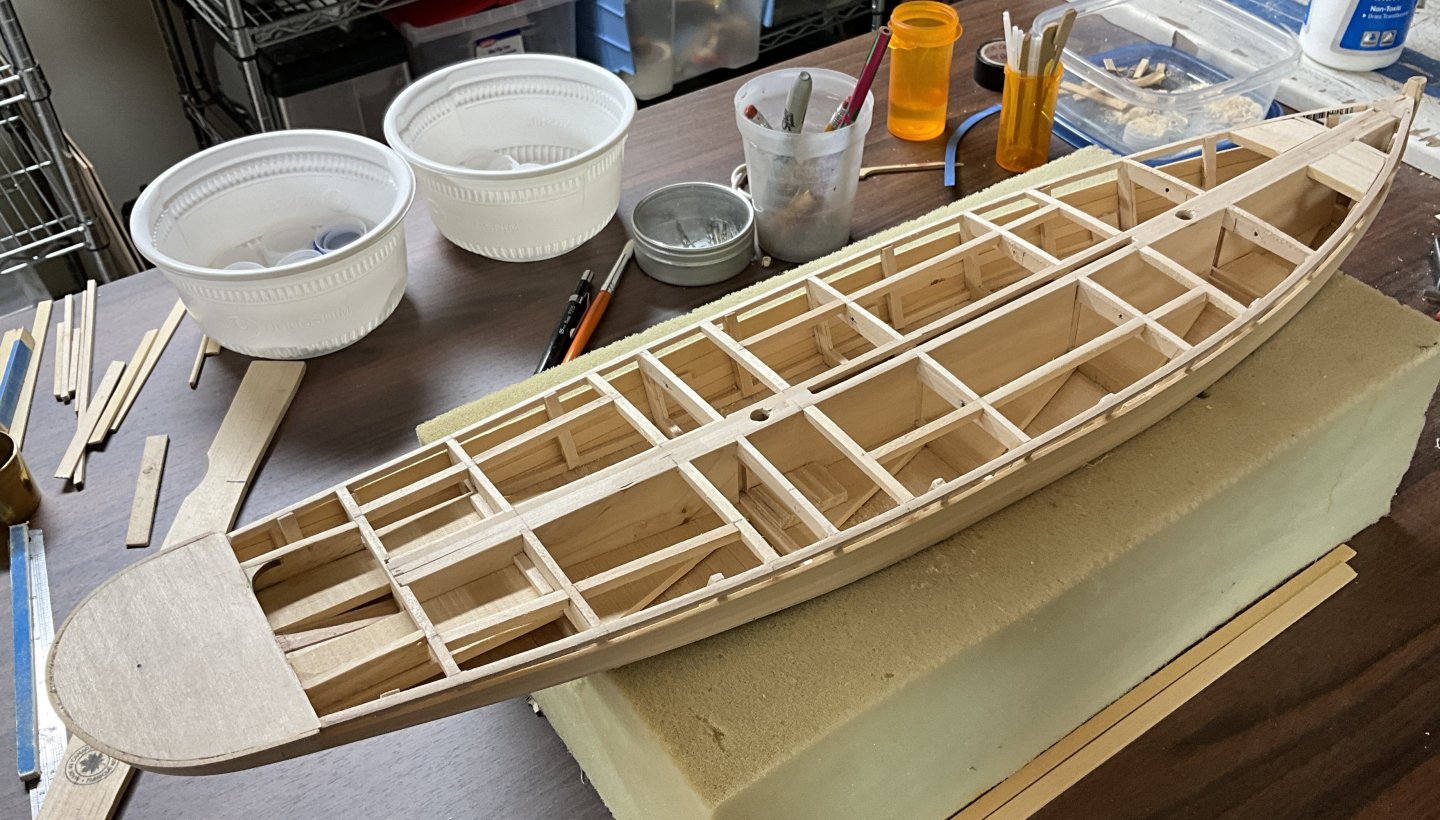

Hi Everyone, thank you for the Comments, Likes, and for dropping by. The deck beams have been completed and then the king plank was removed where it crosses the cockpit.

The cockpit was framed using material from a carrier sheet that had the correct radius for the aft two corners.

For a change of pace I made the cockpit floor and then gave it a dry fit.

Support was added for the deck furnishings and the holes for the masts were opened up

The inner stem was cut flush with the deck beams.

This week the hull planking will be worked on. Hope to see you next time. -

Jacques, that came out so nice. I think that you have just written the book on thatching!👍

- Glen McGuire, JacquesCousteau, mtaylor and 1 other

-

3

3

-

1

1

-

Gary, thank you for explaining your technique. Definitely going to give it a try. The results you’ve achieved are amazing.

-

Jacques, very nice find on all of these details!

- mtaylor, FriedClams, JacquesCousteau and 1 other

-

3

3

-

1

1

-

Gary, beautifully amazing work. When you stain the wood with the chalk/ alcohol do you apply it to the raw wood and have you had any problems with blotching?

- Keith Black, vaddoc, Glen McGuire and 1 other

-

2

2

-

2

2

-

Hi Micha,if you are good with the overall shape of the hull, perhaps you could make your own ribs by building up 1/8 x 1/16” strips of basswood. If you can make some wedges to fill the gaps you could then build up the ribs with as many layers of wood as you need to make it look the way you want it to. If that makes sense. Lots of work 😀

- Scottish Guy, Keith Black, mtaylor and 1 other

-

3

3

-

1

1

-

-

Gary,thank you very much. I was at the hobby store the other day to pick up some basswood sheets and it has been on backorder for quite some time. Don’t know if that is the case in other areas but I’ve started looking at stir sticks in a different light. Some of them I’ve gotten lately have been very nice quality. They could be good framing material in the future.😀

- JacquesCousteau, FriedClams, Canute and 1 other

-

4

4

-

-

Hi Everyone, I have a bit of progress to show. The stern’s staves have been sanded

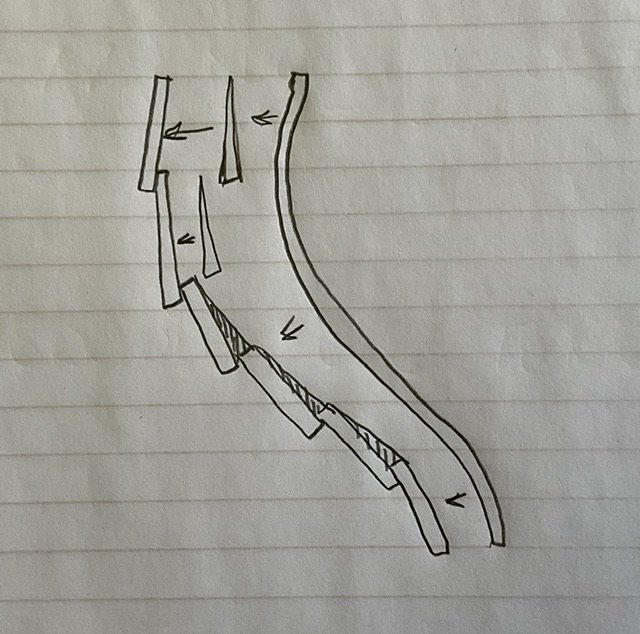

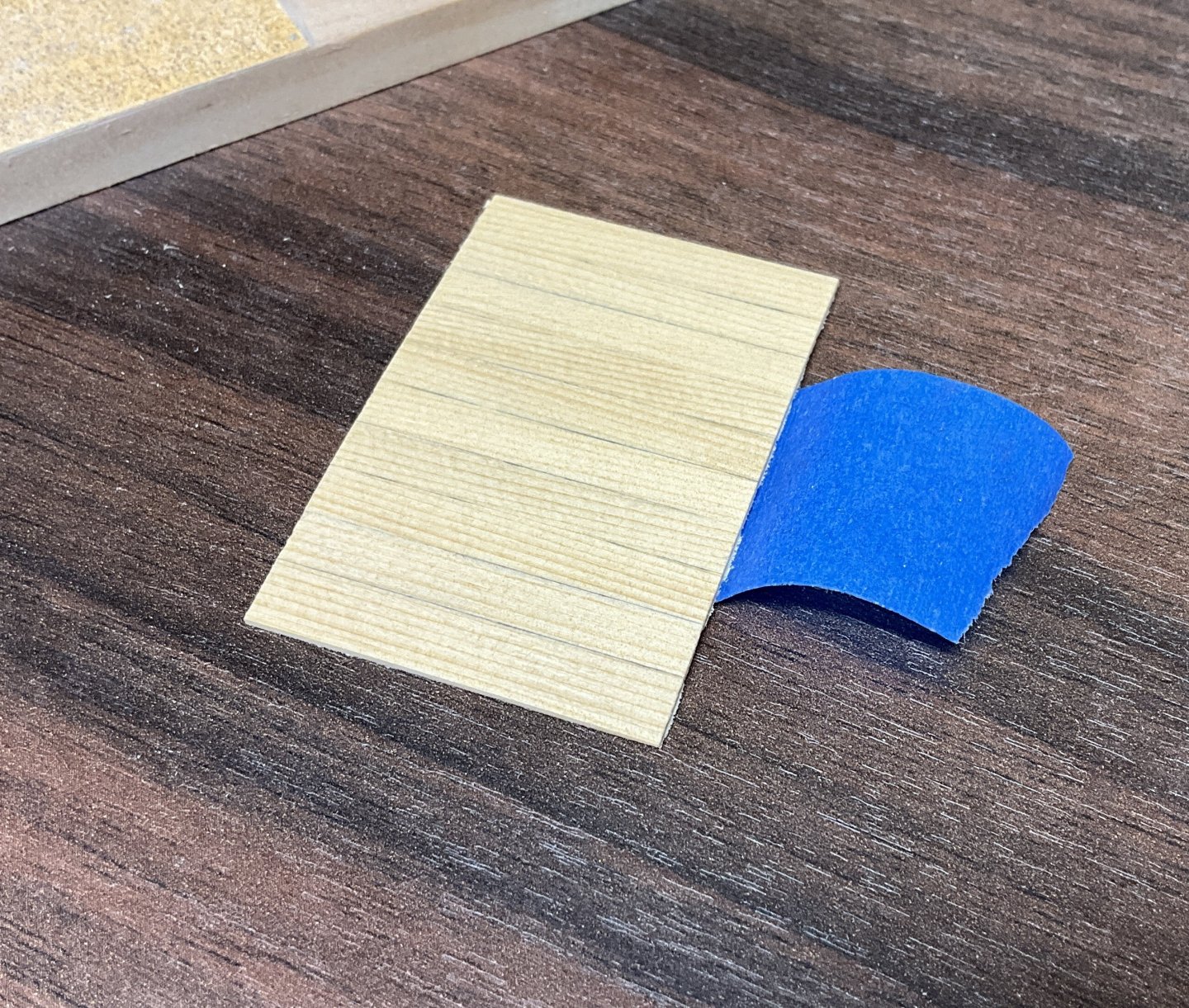

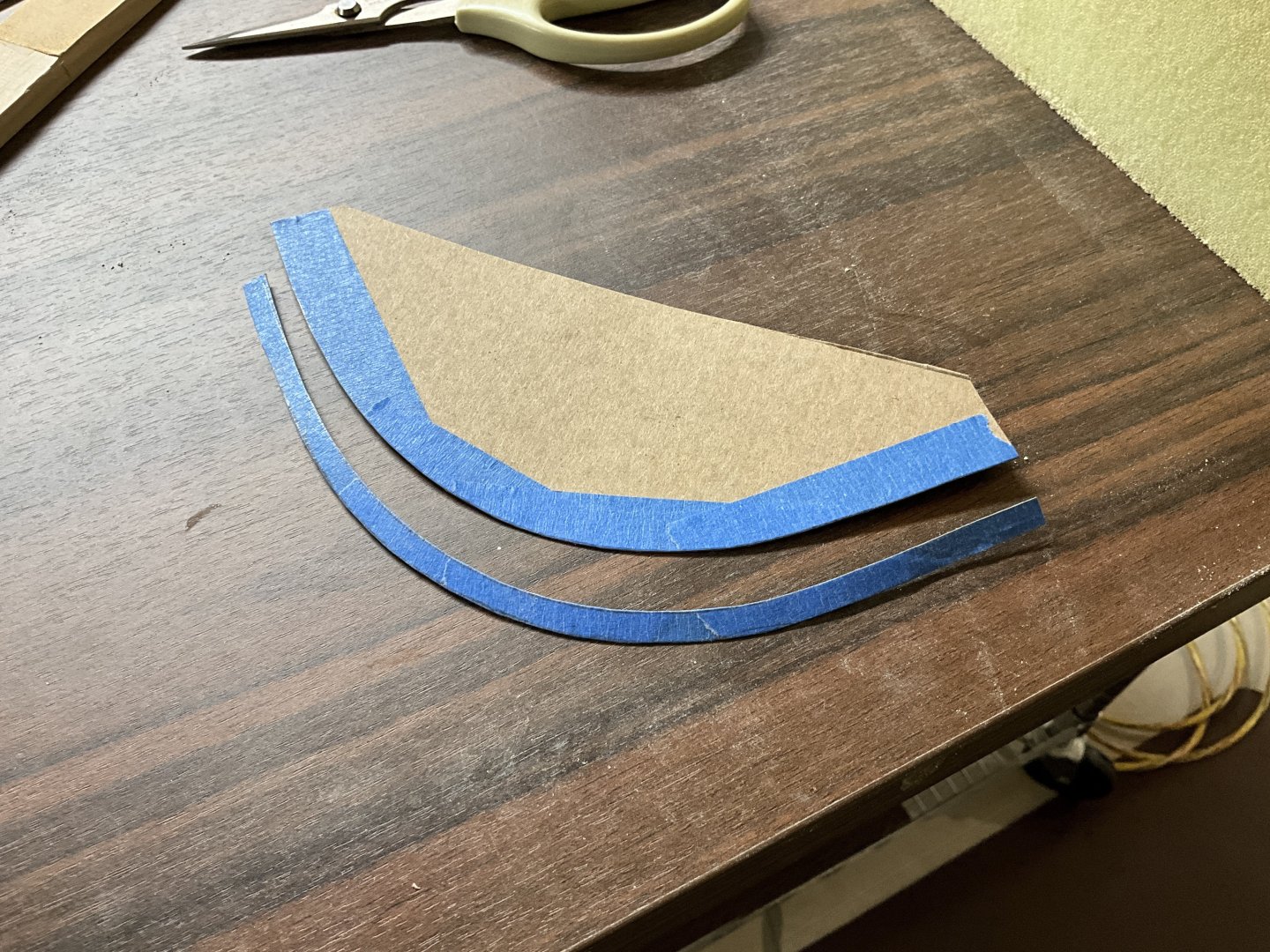

A pattern was then made to create the section of the false wale that runs around the stern. That section was cut out of a 1/16” basswood sheet.

The basswood section was soaked in a pot of water for a few minutes and then clamped to a pot with the appropriate diameter.

Before that can be attached the crown in the deck had to be addressed. I used a construction article from the “usvmyg.org” website to make a deck beam pattern. I ended up with the pattern cut/sanded into a paint stirring stick. Tapered pieces of 1/8 x 1/8” basswood were glued to the top of the frames and finish sanded to shape using the deck beam pattern.

Once they are finished the hull planking will be started. Hope to see you soon.

- CiscoH, Canute, Seventynet and 7 others

-

10

10

-

Chris, congratulations on completing your Grand Banks Dory. Excellent! And thank you for the tips when building the bucket. Much appreciated.

-

-

Glen, congratulations on completing your Ghost Ship Jenny. Such a wonderful subject and presentation!

- Ian_Grant, FriedClams, Keith Black and 4 others

-

6

6

-

1

1

-

Beautifully done Dave. I’m always amazed when I see how colorful some of these planes were.

- Egilman, Old Collingwood, mtaylor and 3 others

-

6

6

-

Bob! Congratulations on finishing your beautiful Mayflower. Excellent!

- Scottish Guy, Keith Black, Gabek and 2 others

-

5

5

-

Hey Micha, looking good. If you haven’t already, now that you have a few planks attached on each side maybe you could flip it over and check to see how the notched frames sit against them. Perhaps even attach them. These plywood planks seem to have a mind of their own.😀

- Keith Black, Glen McGuire, Cathead and 1 other

-

3

3

-

1

1

-

Hi Micha, the only experience that I have with this type of Billing construction is with their Nordland Boat. It wasn’t built in two halves but rather the molds were one piece and mounted upside down on a build board. Since you have glued the two halves of your molds together, maybe you could consider converting your build to an upside down one. By the looks of it you will have to remove everything from the build board to attach the planking. You might have to add some plywood to the molds to extend them so that the stem and the stern clear the base. The molds are just etched to guide you where the planks will sit and will be removed later so should not be glued to anything. I wired my keel ( ? ) to the molds to keep it secure. The link to my Nordland is below. It may give you some ideas although it is a totally different type of boat.

- Keith Black and Scottish Guy

-

2

2

-

Jerry, happy to see you working on the Pinky again. Looking forward to your posts.

-

Thank you Jacques. When I started planking the bottom I started in the middle and worked in both directions using the basswood that came with the Glad Tidings kit. When I ran out of 3/16” x 1/16” basswood I changed to the 3/16” x 1/16” leftover Alaskan Yellow Cedar that I had bought to plank the Glad Tidings. So the bottom has a few inches of AYC at the bow and the stern. The sides of the hull are AYC. Started with 3/16” x 1/16” until it ran out. The rest of the hull will be finished with 1/4” AYC. She will be painted white so it should be okay. That was kind of long-winded wasn’t it 😀

- robert952, Canute, FriedClams and 1 other

-

4

4

-

3 hours ago, FriedClams said:

Hey Paul, good to see some movement on this model!

Easy to do - I know. I think model building should always be about enjoyment and just doing the best you can, rather than the rate of progress. And your sharpie is coming along very nicely.

Gary

Hi Gary, thank you for your nice comment and for checking in on the sharpie. I’ve been slowly planking her. Been using two planks in each strake so usually I glue the end of the plank at either the stem or the stern and then the next day finish gluing the rest of the plank. So it’s been taking four days to complete a strake. A couple of months ago I picked up an Ultimation disk sander and started using it to taper the planks. I like using it a lot. And it’s so quiet!

That’s it for the planking for now. Going to do some sanding and then work on giving the deck beams some camber before laying down the sub deck.

- FriedClams, robert952, GrandpaPhil and 6 others

-

9

9

-

Hi Micha, I am glad that you have accepted the Billing challenge. It will turn out great!

- Glen McGuire and Keith Black

-

2

2

-

Congratulations on completing your Yakatabune. Fine looking boat and great pics!

- Canute and SighingDutchman

-

1

1

-

1

1

-

Hi DuckDetective, what a great yacht and model. Such a shame that Billings would discontinue her. Everything is looking super!

-

Roar Ege by Scottish Guy - Billing Boats - 1:25

in - Kit subjects built Up to and including 1500 AD

Posted

Hi Micha, I’ll appreciate and enjoy seeing your second Roar Ege build log.