-

Posts

8,111 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by allanyed

-

-

-

7 hours ago, Jorge Hedges said:

1:72 scale; construction paper should work well, or black tissue paper... will give it a try then

The construction paper I have is 0.007" thick so would be about a half inch seam which would be OK, but you may find the appearance to be a little too thick. If you can. experiment with both to see which looks best to you.

After you make your planks to the breadth and thickness that you want, glue a few planks on edge on the sheet of paper and let it dry. I usually lay down several strips on edge at a time with a little space between. (You will only need to glue the paper on one edge.) Once the glue is cured use a scalpel or other sharp razor cutter and cut the strips apart then shave off the excess. Just be careful not to gouge the edge of the wood of the plank.

Allan

-

Jorge,

What scale are you working on? If you are not happy with a pencil or marker, black tissue paper that you can find in most any craft store works very well for smaller scales. There is no seepage so the line is constant. It is visible but subtle. If you are working at 1:48 or larger black construction paper works very well. Both can be glued with white or yellow PVA or even matte medium. PVA (wood) glue for wood to plastic does not work well. If you do go with the plastic, epoxy or polyurethane glue should work well. I am guessing trimming plastic would be difficult. If you are working very small scales 1:96 or so it may be better not to use anything as it could look overdone.

Allan

- Jorge Hedges, Bob Cleek and mtaylor

-

3

3

-

For the future you might want to check out the string of posts in https://modelshipworld.com/topic/34577-taper-of-the-keel-stem-knee-of-the-head-and-stern-post/#comment-985522 Some find it of some importance, others not so much.

Allan

- VitusBering, Dave_E, Glen McGuire and 1 other

-

4

4

-

Thank you Craig,

This study has been a fun topic for me, and I hope for those that have tuned in as well

Allan

- Keith Black, cotrecerf, thibaultron and 1 other

-

4

4

-

On 8/12/2023 at 10:31 PM, Knocklouder said:

This is a cannon from the kit on a carriage, it does look to big, the bottom one is from an Astrolabe model that I have but can't tell you what size it is. More research lol.

Sorry for the late reply. If you have not already gotten the information that you need do you know what the designated length or actual length of the 6 pounders were in full size? I can send you the appropriate drawings and dimensions at your scale of the Armstrong Frederick pattern in a high resolution, but in the meantime, the below may help. The designated length was usually as measured from the breech ring to the muzzle, but for these small vessels, they were sometime shorter than the common length. See David Antscherl's TFFM Volume II page 129. Also, from The History of English Sea Ordnance, Volume II by Caruana, page 217, while lengths were generally expressed in whole feet and half feet, in reality the actual variation was as much as plus/minus 2 inches (or for 1:64, +/- 0.03" (+/-0.8mm)) There are a number of sources for turned and cast barrels, but I have had very high quality barrels printed in black resin, including the cypher and trunnions for well under $1US each including postage.

Allan

- Glen McGuire, VitusBering, Dave_E and 5 others

-

7

7

-

1

1

-

Hi Darius

I have found that the four books you show are some of the most useful to be had.

One comment, hope you don't mind. The strakes near the keelson would normally be about a foot away from the keelson. There would be limber boards between the keelson and the first limber strake which is rabbeted to accept the limber boards. From both Steel's Elements and Practice of Naval Architecture 1805 and The Shipbuilder's Repository 1788 the limber boards were small pieces not to exceed three feet long and on a first rate were 3.5" thick. They typically had two holes in which fingers could grab hold to lift them. They rested as shown in the drawing below without fastenings. On a 100 gun ship the first limber strake was 8 inches thick and 15" broad. The second strake was 6 inches thick and 14 inches broad.

Allan

-

Thanks Craig. While this is a bit later than the era I am working on for now, it is very informative. I see sandwiched trucks at this point in time as well.

Regarding the straps, most models don't show these and at our common scales, probably not worth the extra work as they will be barely noticeable at the most. For larger scales such as 1:24 or larger, they could be a nice added touch.

Allan

- iMustBeCrazy, Keith Black, mtaylor and 1 other

-

4

4

-

Picture of USS Constitution copper plate says it all regarding color. I realize many folks won't like the look of weathered copper, but it is another choice. Note the number and size of the nail holes rather than the over scale rivet-like bumps seen on some model plating. Can the plates with bumps be reversed so as to look more realistic with nail dents versus the look of rivets which were never used? Some manufacturers have gone to laser marks that etch small dents so there are no bumps and look much more realistic.

Allan

- mtaylor, Ryland Craze and Bob Cleek

-

3

3

-

Thanks Pat and Craig. You Melbourne guys are tops in my book!

Allan

5 hours ago, iMustBeCrazy said:The British ones would be more like this:

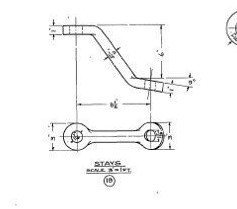

This is what I would have gone with had I need seen the drawings above. Do you have a source that shows the rectangular stay rather than the US version? The rectangular version would have been much easier to make full size, but if there was to be a rabbet cut into the axletree, the reduced arm width on that found on the Constitution would use a smaller cut into the axletree and thus less weakening.

Thanks again!

Allan

- mtaylor and thibaultron

-

2

2

-

A very warm welcome to MSW Ian. Enjoy the ride!!!

Allan

- mtaylor and Swordfish073

-

1

1

-

1

1

-

47 minutes ago, bobandlucy said:

this is a new process for me.

Even 40 plus years in this hobby does not alleviate the opportunity for me to learn. Seems I find new and useful information on this site nearly every day.

Allan

-

-

-

I just received some additional information from Chris Watton who was kind enough to send me the following references which cover from 1720 into the 19th century. He let me know that AOS books on the Alert, Blandford, Victory and Pandora and Alan McGowan's 'HMS Victory, her construction, career and restoration, show carriage details.

I looked at a couple of these that I happened to have and noted that Blandford 1720, which would likely have carried Borgard pattern guns when launched, shows no straps on the carriage drawings. She may have been re-outfitted after 1724 with Armstrong pattern guns and different style carriages but I am not sure when the use of the straps was introduced.

Allan

- mtaylor, thibaultron and Keith Black

-

3

3

-

Bob/Lucy

Have you looked at any planking expansion drawings? The strakes widen at the stern towards the keel and in the following cases they narrow closer to the wales. https://www.rmg.co.uk/collections/objects/rmgc-object-83709 and https://www.rmg.co.uk/collections/objects/rmgc-object-83495 show two examples. They show outboard planking as well as inboard planking.

Allan

-

Thank you Pat. Can you post or PM me a higher res version or maybe give the dimensions on the stay as I cannot make them out when downloading and enlarging. Looking at the lower drawing, it appears that the strap is going into a rabbet in the axletree rather than having a rounded bottom. After seeing these various drawings, it is likely another case of multiple solutions to the same problem, none being wrong.

I never realized the American long gun is very similar in appearance to the Armstrong patterns right down to the button ring. The top plan looks like an Armstrong pattern where as the lower looks more like the Armstrong-Frederick pattern. Live and learn!

THANKS AGAIN

Allan

- thibaultron, Keith Black and mtaylor

-

3

3

-

6 hours ago, druxey said:

The metal S-strap - the fore axletree stay - appears on several carriage drawings, so must have been standard at the time. Also see TFFM, Volume II, page141.

Thanks David

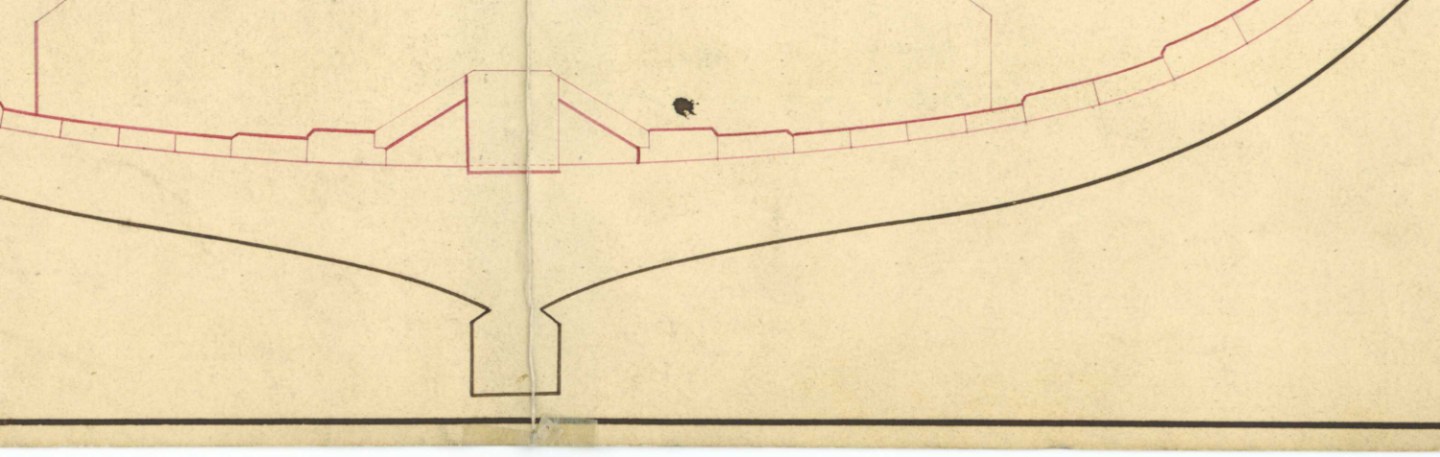

For whatever reason, I completely forgot that the underside of the forward axletree was rounded at least part of the length at some time. The reason I say at least part of the way is that the contemporary drawing I posted above shows part of the forward axletree to be rectangular in cross section. The strap configuration seems to indicate the bottom to be curved for at least a portion. Do you happen to know an approximate time span when this was the norm? Don't know where my head was and forgot to check TFFM. Ron's suggestion makes sense or possibly slightly different as in the below rough sketch

Thank you all!!

Allan

- Keith Black, mtaylor, thibaultron and 1 other

-

4

4

-

There is what appears to be a metal strap under the brackets and forward axle. The contemporary drawing shows it curving such that it would wrap under the round portion of the axle, but it is not round where it crosses the brackets so not possible as far as I can determine. I have drawn a possible solution, but welcome any ideas on alternative solutions. Again, another view would be helpful, in this case from the bottom, but I have never seen one so can only assume the width of these possible straps is about the same as the bracket thickness which is the same as the diameter of the bore.

The carriage in question is for a 24 pounder long gun circa 1775 when Armstrong Frederick patterns were the most common in use.

Allan

- Keith Black and mtaylor

-

2

2

-

Pat and Craig,

Thank you very much!

The rebated description of the drawing seems to be spot on Craig. But while in the stowed position, the carriage can still swing in an arc. It can be secured with lines, but having a pivot point and the rear trucks it would be more prone to rotating than wheeled carriages with their four trucks. Still, this may be the answer.

If nothing else, this topic has opened my eyes to possible solutions to a number of problems. Next post is another conundrum I have run into.

Allan

- Keith Black, mtaylor, iMustBeCrazy and 1 other

-

4

4

-

This is great Gary. I see a horseshoe bracket as well than I had never noticed before. This is a huge help, thank you!

Allan

- Keith Black, mtaylor and thibaultron

-

3

3

-

On 8/17/2023 at 2:33 PM, Andrewj said:

I,m in the process of building Billings HMS Victory and your build log is most useful. I woder if you could tell me where you got the safety netting support brackets.

Welcome to MSW Andrew.

This topic has not had an entry in 8 months do you may not get a response. You can PM the builder and ask him directly, or if you want to have more members give input on the netting brackets, do a post in the Ship's Deck Furniture forum.

Again, welcome aboard. It would be really nice if you would post a little introduction about yourself in the new member forum here at MSW.

Allan

-

I thought that might the case as well Pat, but how is the fighting head secured to the spirketting (or deck if that was the case) I drew in a horizontal bolt as if this was how it was secured to the bulwark but that is only my best guess. If the shorter pin penetrated down into a deck frame that would indicate to me this was how it was all secured, but it ends on top of the deck planking. In the end, unless someone is building this at 1:24 or larger, it would be barely be noticeable.

Allan

- thibaultron, Keith Black and mtaylor

-

3

3

-

2 hours ago, Martes said:

I ran into a plan suggesting a very early (~1728) Danish use of gradually increasing width of the planking towards the lower wale:

This is a great drawing confirming this is how it was done. Exceptions there may be, but the majority of evidence points out this feature. Be it scratch or kit, it really is easy to accomplish the thinning of the wales strakes. This is also a great example for showing how all the strakes end at the rabbet, not coming to a point short of the rabbet,

Thanks for posting this Martes.

Allan

- mtaylor and hollowneck

-

2

2

HMS Diana by DavidEN - Caldercraft - 1:64

in - Kit build logs for subjects built from 1751 - 1800

Posted

That sentence would work well in the Them Old Jokes forum here at MSW. I think I speak for all who have tuned in, to use an old maritime phrase, we have every confidence you will finish with flying colors.

Allan