-

Posts

8,111 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by allanyed

-

-

-

5 hours ago, NRG Office Manager said:

Allan - Thank you so much for your generous donation!

You'll be getting a CAMM pass from me as well!

My pleasure.🙂 The MSW site has brought me MANY hours of pleasure and the donation is the very least I could do. The Admiral told me that based on the amount of time I spend on the site (and out of her space) that I should not cheap out. Thanks for the CAMM pass. I will do my best to get to at least a couple of the museums, including the one in Bradenton which is on our way to Tampa in October when we are going up to see Aerosmith on their last concert tour. Good times!!!!

Allan

- Rik Thistle, mtaylor, ferretmary1 and 1 other

-

4

4

-

7 minutes ago, TBlack said:

My only comment is that the site won’t let you give more than $100.

You are right. There should be a way of typing in a unique amount like a lot of restaurant machines now have.

Allan

-

It looks similar to the Jim Byrnes sander. I cannot speak for the Vanda Lay unit but my Byrnes unit is about 15 years old and runs like the day I bought it. Thousands of board feet of wood have gone through it. It is a bit more compact than the Vanda Lay unit with the motor built into the frame. No matter which unit you choose, DO NOT use it without a vacuum hose attached. If you do not have a shop vacuum set up, portable or otherwise, you will need one. The amount of fine power sawdust created is immense and will cover everything, including you. Wear a mask!!!!!

Allan

- druxey, Jaager, scrubbyj427 and 4 others

-

7

7

-

14 hours ago, Yorky1 said:

Of course the AL kit had no such thing but I just had to ad them.

Love it!!! Well executed.

Allan

-

Hi Mary,

I clicked on these but it just goes back to this string.

Allan

-

-

10 hours ago, kurtvd19 said:

If you have ever tried to use Steel’s Tables for your masting and rigging,

Hi Kurt,

THANK YOU. If this is only for masting and rigging, the title Steel's Dimensions of a Ship of each Class in the British Navy may be confusing. Are these just for the masting and rigging found in Steel's Elements and Practice of Rigging and Seamanship or does it also include the scantlings in Steel's Elements and Practice of Naval Architecture? If the former maybe he should change the title to Steel's Dimensions of Masting and Rigging of each Class in the British Navy.

Thanks again.

Allan

- thibaultron and hollowneck

-

2

2

-

It will likely take a bit of research but I would start with Meyer Werft. I have been given drawings by shipyards in the past when I told them I was interested in building a model. These were pleasure craft, but it might work for your project as well.

Allan

- Dave Wood, mtaylor and michael mott

-

3

3

-

Allegheny

It would be very nice if you would post an introduction about yourself in the new member forum here at MSW. In the meantime, Welcome Aboard

As you can see this topic went quiet 7 years ago so you might get more responses if you post in the plans forum or even bring it up in the new member forum if you post an intro there.

Do you have the plans of Ingomar from 1904 in Chapelle's book The American Fishing Schooners on page 256 and the other books listed by Giorgio in the first post or have you researched the Smithsonian and LOC to see what they might have that would help you?

Allan

-

I am not sure this would be any help but RMG Collections has a contract of the Albacore Class (1856). If it is like earlier contracts, it will at least have scantlings for all the timbers. Between body plan and scantlings, there may some help for your project. https://www.rmg.co.uk/collections/objects/rmgc-object-572899

Allan

-

8 hours ago, Darius359au said:

a reasonable price compared to what was being asked online

I see copies listed in very good condition for US $5. Abe Books has a great reputation and they are one of several sources https://www.abebooks.com/servlet/BookDetailsPL?bi=31527379389&ref_=ps_ggl_18382194370&cm_mmc=ggl-_-US_Shopp_Trade0to10-_-product_id=COM9780853440918USED-_-keyword=&gclid=Cj0KCQjwib2mBhDWARIsAPZUn_nGDa5BJUHKzwKOPtXMJLF1aGxaUQ8u_v1_4yHgD4oSwu-HbVkPBVcaApm-EALw_wcB

-

-

Welcome to MSW Dave!! I truly hope you post photos of your 3D printed models and how you go about the entire process in an appropriate forum here at MSW. Would you do other cruise lines ships as well?

Allan

- mtaylor, JeffT and Keith Black

-

3

3

-

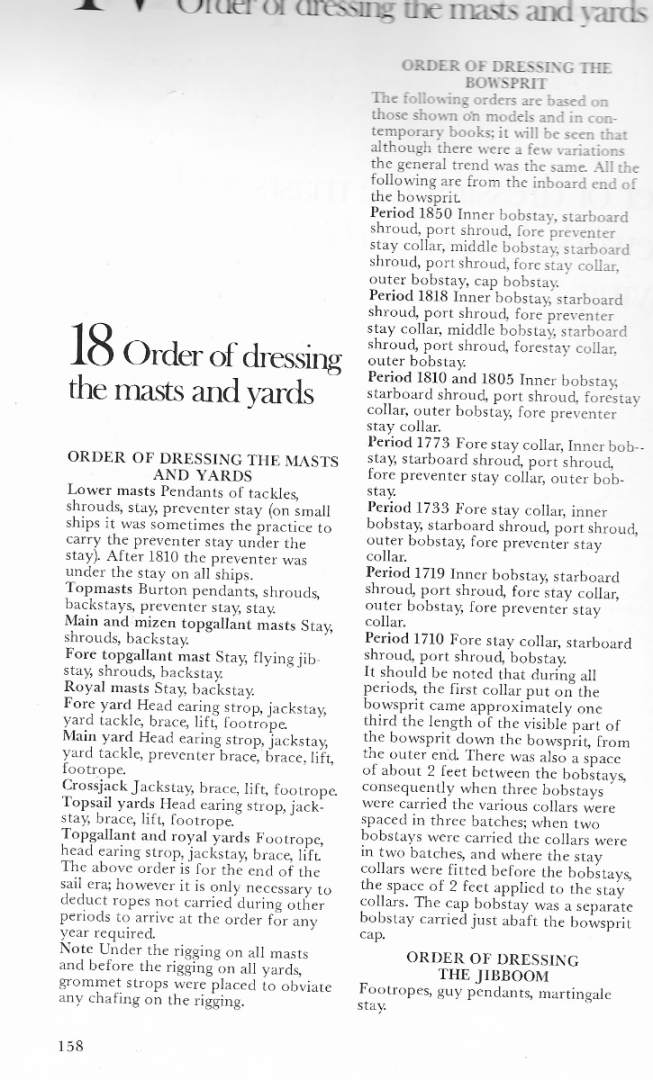

The order of dressing was pretty standard and is listed in detail below. This is from David Lees' Masting and Rigging English Ships of War, page, 158 but it should do well in applying to an American naval vessel. Anyone making masts, spars and doing rigging, be it kit or scratch building would do well to invest in a copy of this book.

Allan

-

Next time you need to make slots you might want to try a router bit. Going further you could buy or make a drill holder which can be set up so you can use it as a mini router and get perfectly even slots. There are a lot of sources on line. One example of the bits is in the photo below from Lee Valley. Drill bearings are not really made for lateral movement, but for making the occasional slot in wood the bearings will hold up for many years.

Allan

- Roger Pellett and mtaylor

-

2

2

-

Thank you Pat and Allan, very much appreciated.

In recent months I brought this diminishing thickness up on several build logs as the wales strakes stuck out so far they could not seat in the rabbet. It was suggested by an admin that I start a subject about this thus this string, and to your point, it was pretty much meant to be without a time frame other than the era of wooden ships with wales. Thanks again

Allan

-

- mtaylor, Glen McGuire, Ferrus Manus and 1 other

-

4

4

-

On 7/29/2023 at 8:01 PM, dvm27 said:

This is consistent with contemporary practice and I believe easier to execute.

While painting on paper has been my go to, that is really an interesting tidbit Greg. Practically speaking I find it far easier to do, and I like it even better knowing it had been done on the beautiful models we see at Preble, RMG, et al. To both you and Druxey, do you have any thoughts based on your experience as to which paper you like to use best? I have gone to using silk span rather than stiffer paper but it is just a matter of my own preference with no scientific reasoning behind it.

Thanks

Allan

-

29 minutes ago, Blue Ensign said:

Quite amazing the improvement a good scraping makes to a deck, and with 1mm depth of board there is little fear of over doing it.

I agree with you that scraping is a great way to even things out compared to just sanding. Birdseye, there is a great little article on scraping and sanding at

https://thewoodwhisperer.com/articles/sanding-vs-scraping/

Allan

- CaptnBirdseye, jpalmer1970, mtaylor and 3 others

-

5

5

-

1

1

-

7 hours ago, alpayed said:

Conclusion?? I DON'T KNOW Interesting discussion though.

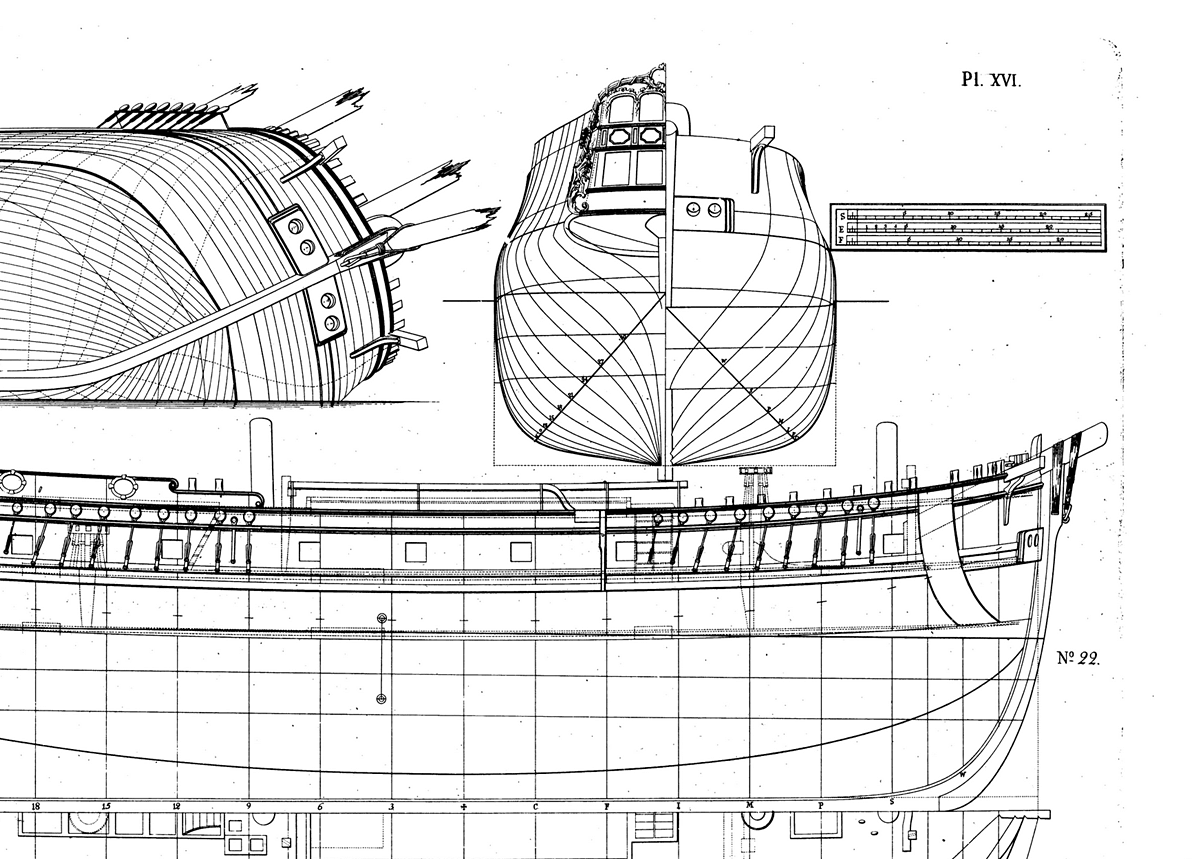

LOL Thanks Allan. These are great drawings and I have bookmarked the Architectura Navalis Mercatoria Stockholm, 1768 website. One thing that jumped out at me is in plate XVI top left. The wale appears to be a layer on top of the planking, or, the planking below the wale has pointed ends that I thought were not acceptable by any nation. The index of these drawings calls these merchant ships. Could the planking methods be different in nature than British naval vessels?

Allan

-

When using tape to mark a line on wood, it is not so easy to keep some leakage or feathering from occurring. Sometimes it is a good idea to apply the tape then paint a seal along the edge with an appropriate clear coat. Once dry it seals the edge, then paint as normal. It usually saves a lot of touching up.

Allan

-

13 hours ago, DocBlake said:

so each piece requires a template to be carefully cut out and rubber cemented to the frame piece, then bevelled then cleaned of residual paper and cement.

HI Dave

Looks like it is too late for this project, but for the future you might want to try printing the plans on sheets of label paper, then you can cut out the pieces, peel off the back, and stick on the wood. MUCH easier than cementing paper to wood. If you only have preprinted paper plans rather than plans on your computer, a flash drive or similar device, the paper version can be scanned on most home printers then printed on the label paper.

Allan

-

There is a great little book by David Antscherl from SeaWatch Books for $5 on how to make realistic sails using silkspan.

Allan

Steel's Tables - New Clear to Read Version - Digital Download

in NAUTICAL RESEARCH GUILD - News & Information

Posted · Edited by allanyed

There are several errors in Steel's Elements and Practices of Naval Architecture as well, usually scantlings on two lines transposed such as breadth having the thickness dimension and thickness having the breadth dimension. Even with these few miscues both the Steel rigging and building books are great, the only drawback is that they apply to a somewhat limited time frame.

Allan