-

Posts

2,516 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Rustyj

-

-

-

-

-

-

-

-

Hi Chuck. That is a really sweet looking model and of course your workmanship is great as usual.

- Ryland Craze, Mirabell61, Canute and 3 others

-

6

6

-

Hi Chuck,

I've worked with you for years and yet your mind and innovation continues to amaze me! Love it.

Seeing this makes me miss my workshop soooooo much. Thanks for the much needed fix.

- SawdustDave, zoly99sask, WackoWolf and 7 others

-

10

10

-

-

-

-

-

-

-

-

-

-

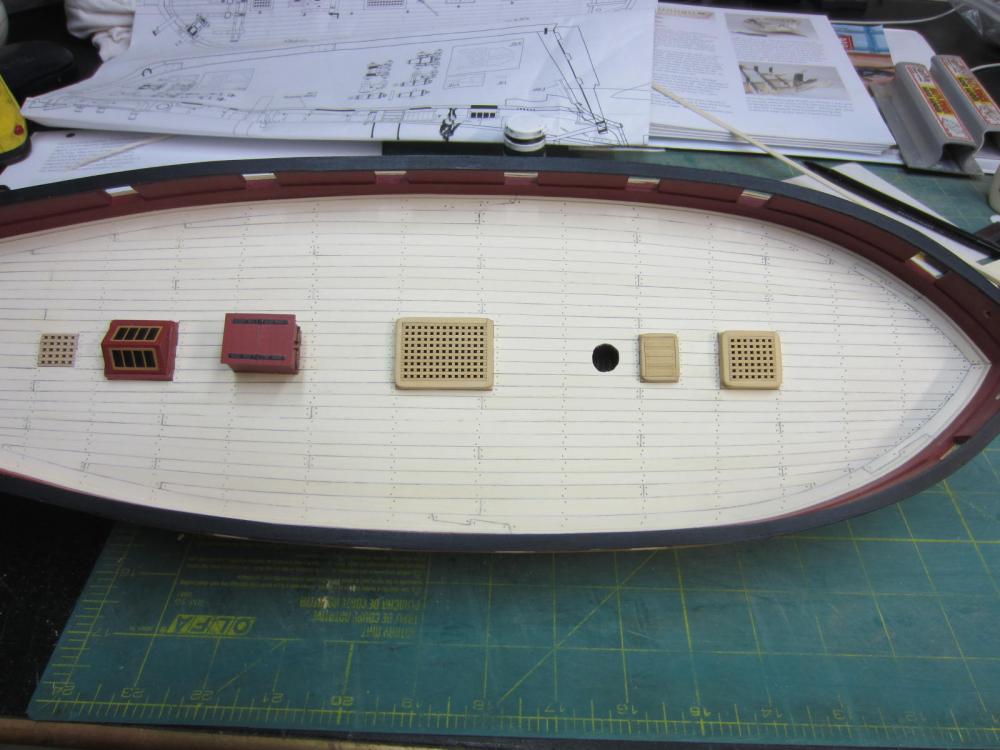

Hi All,

Been real busy here with the renovations and getting ready to move. I managed to

get the deck planked over the past two weeks. The curved planking was a lot of fun

to do in a sick kind of way. J

Here is the planking done through the center of the deck.

After looking it over I wasn't happy with the alignment with the aft most hatch and skylight.

So I ripped off the planking to the skylight and repositioned the hatch and skylight and

re-planked it. Much happier now.

Here is the completed planking and sadly the last that work that will be done for some time to come.

The shop is now officially closed, the Cheerful has been packed up and I'm now starting to

pack up the rest of the shop.

I’ll be living vicariously through all of you and hopefully rejoin you sooner instead of later.

So long for now!

-

-

Thanks Ryland. I really missed seeing you and everyone else at the conference. Hopefully next year turns out better.

- Canute, Ryland Craze, Jack12477 and 1 other

-

4

4

-

-

Hi all,

As you may have noticed things have been really slow in the shipyard.

Renovations at the new house are in full swing and taking most of my

free time. Within the next week or two I’ll sadly be closing down for an

extended period.

Here is a brief update with one more to come. Ok maybe two if I can squeeze it in!

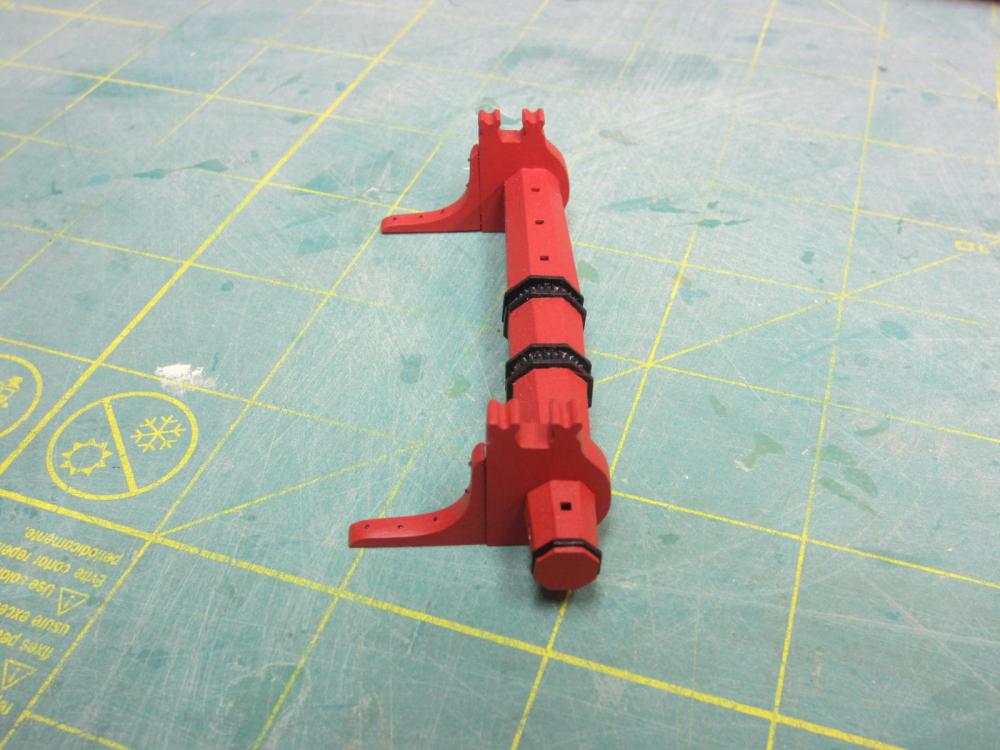

The completed companionway.

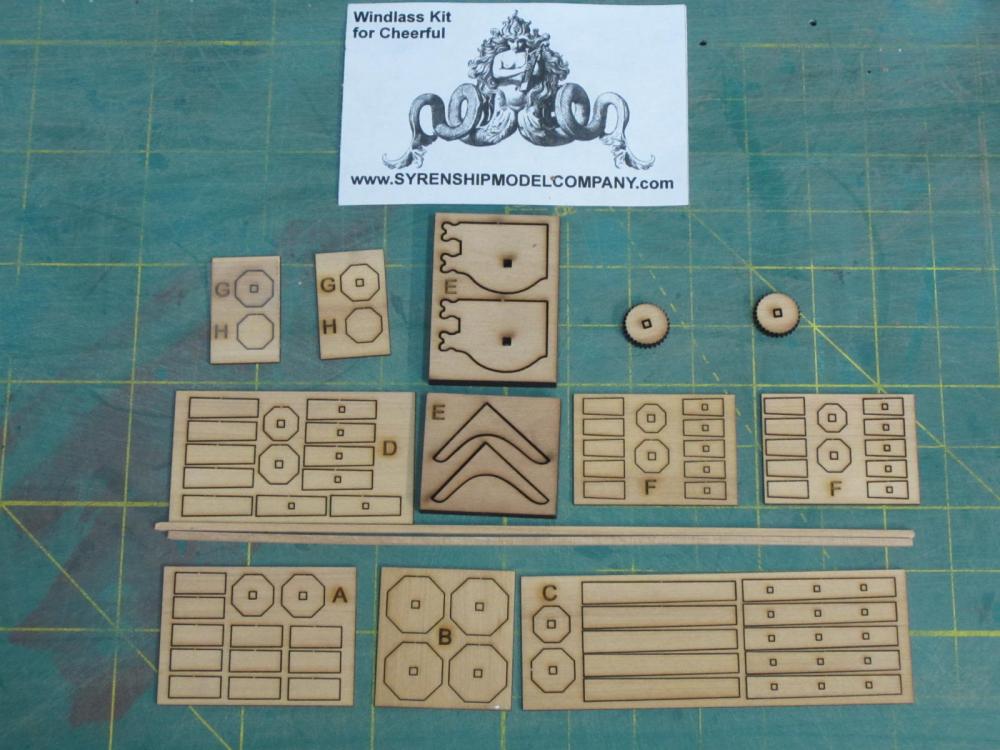

Windless kit from Syren Ship Model Company

Here are the hatches, companionway and skylight placed.

Now I'm ready to start planking the deck!

- KenW, Seventynet, mtaylor and 15 others

-

18

18

-

-

She's looking great and coming along quite nicely.

- Canute, GLakie, Ryland Craze and 2 others

-

5

5

Cutter Cheerful 1806 by Rustyj - FINISHED - 1:48 Scale

in - Build logs for subjects built 1801 - 1850

Posted

Hello Everyone,

Getting real close to opening the shop up and thought I'd give you all an update.

Plus this proves I'm still kickin'.

As you might recall we purchased a different home this past spring. We did a LOT

of renovating to the interior. Replaced 16 interior doors, all the trim molding, took

out the old carpet, new floors put in, two bathrooms redone and on and on and on!

I never want to see a can of paint again.

Then I got one enjoyable moment and that was the creation of a new work space.

Again I'm relegated to the basement but now I'm not sharing my space with the

furnace and hot water heater.

A reminder of the old work space.

Here is the space I have to work with.

The finished interior dimensions are 10' x 18'. Long and narrow but I think I got it to

work. An electric subpanel was run to power just the shop. No worries now of lack

of power or of popping a breaker that would shut down part of the main house.

After framing the walls I decided to use plywood for the walls in place of sheetrock.

This way anytime I wanted to hang something i didn't have to find a stud. Also I prone

to "bumping" into the walls with stuff and this should cut down on the collateral damage.

The cabinets were either from the old shop or ones removed from the renovation.

Countertops are either plywood or a butcher block the admiral didn't put back in the

kitchen. Very sturdy! The counters then received numerous coats of heavy duty poly.

The dust deputy and shop vac are out of the way under a cabinet with the hose coming

through the back to be attached to whatever tool needs it. I also hung the JET air filter

at the end of the shop where most of the power tools will be cutting os sanding wood.

For lighting, and we all know you can never have enough, I used new LED fixtures.

There are a total of four 4’ double tube LED fixture and one 2’ single tube fixture.

They are switched so I can light it up like daytime or if I don’t need to blind myself I

can turn fewer on.

So the renovations and my normal hectic August/September work schedule kept me

real busy. Then throw in the unpleasant surprise of an inguinal hernia surgery in late

September that backed things up even more. But all is mended and doing fine so I’m

back to unpacking the shop, sorting , throwing away, putting away, not liking where I

put it and moving it three more times! Repeat for the next box and on and on.

One other thing that ate at my time was the refinishing of my grandfathers 1930’s

office desk. At some time in its life my mother thought it would be nice to paint it white.

I always remember it being white so it’s been that way for more than 50 years. As you

can imagine it has seen better days. With the cold weather coming I needed to focus

on this or it would have to wait until spring. So lots of stripper, rebuilding drawers,

sanding and staining it is almost done.

As far as transporting the models go there seems to be no damage to most and minimal

damage to a couple. So far that is. I am happy to say the Cheerful was unscathed in the

move and is waiting impatiently.

After a 40th Anniversary trip coming up in two weeks I’m hoping to have the shop

open for business by the last weekend in November or the first weekend of December.

Whew that’s the longest ramble I ever put together. Hope to be back in full swing soon.