-

Posts

2,450 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Rustyj

-

-

-

-

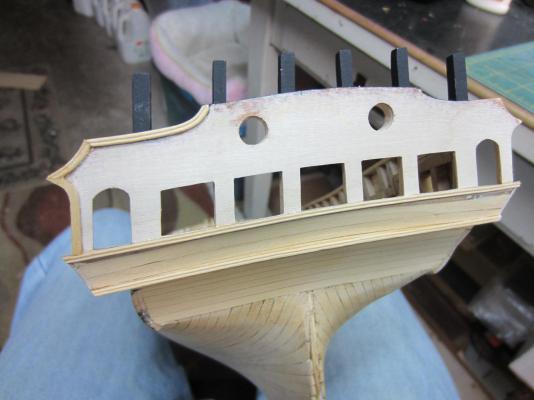

Thanks Augie and Chuck, also thanks for the offer to re-cut the windows. You are right the angle was

off and now makes this an oh crap moment. I adjusted the rear most upright and that corrected the

angle for the rest of the windows.

Here is the new angle.

For the roof I had to make shingles and as Chuck described slicing them from a strip of 1/8” boxwood instead of

cutting from a 1/32” sheet was much easier. The pieces are cut a little thinner than 1/32” and then sanded to clean

them up and make them even thinner. The shingles were placed one row at a time. Once dry the tops of the shingles

were sanded smooth to match the roof angle so the next row would sit flat.

This catches me up on the work I had done while my pc was down. Now I have to decide do I rip it all out and get the

new windows at a different angle or continue on and make the columns for between the windows. Hmmmmmm.

- egkb, michael mott, gjdale and 25 others

-

28

28

-

Hi All. Sorry for the delay in posting but between pc problems, the holiday and general family stuff I’ve been a

little busy. That’s not to say I haven’t gotten any modeling done. Well now that I have a new pc and I’m not using

the Admirals laptop and the backup files have been transferred I’ll start getting caught up.

I have completed the moldings on the transom and while doing so I noticed a minor problem. Self induced I must say.

The upper counter is supposed to be uniform from port to starboard. Mine wasn’t! It was easy to correct this but in doing

so it threw off the height of the bottom of the quarter galleries. They are supposed to set on top of the black strake. Mine

will be into the black strake. It was the only way I could correct my error without tearing out the transom and wales. It just

goes to show the relationships between so many portions of the build. Miss on the wales placement and it alters the counter

which alters the quarter galleries.

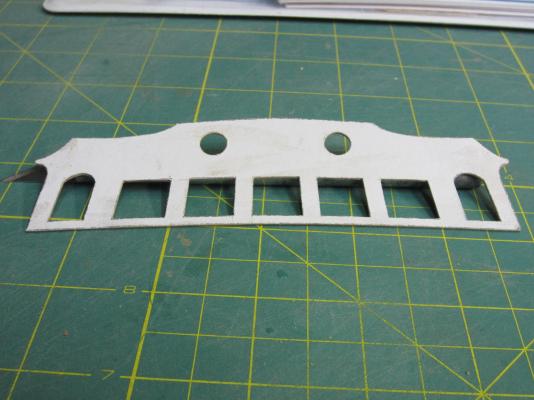

Here you see a set of laser cut lights and trim on laser board that I got from Chuck. This is really nice

stuff. Very thin and delicate but durable. I don’t the gentlest touch but the outer lights survived my

handling.

More to come in a bit.

- druxey, Ryland Craze, WackoWolf and 23 others

-

26

26

-

-

-

Thanks Jason,

I made my scraper from a leftover Confederacy scrapper.

I just used small files to form my desired profile as Chuck describes.

-

I’ve started working on the fancy molding on the transom. The molding is cut from 1/32” thick

stock and is 1/16” wide. The shapes were traced and then rough cut out with a scroll saw.

I then sanded them to their final shape. I then used a scraper to obtain the profile I wanted.

Here is where I’m at so far.

- Sjors, KenW, avsjerome2003 and 22 others

-

25

25

-

-

I noticed your files do you use cheapo ones like me and replace them often or are they nice ones that stay sharp?

Thanks ASAT and Joe,

They are relatively inexpensive ones. I only use them on wood and I’ve had them for 5-6 years now. They are

still in an acceptable condition but once they head south I won’t feel bad about chucking them.

-

-

-

Thanks Ben. Of course!

-

Oh yeah I see major potential for an oops moment!

-

Thank you all for the kind words and all of the likes. It is very much appreciated.

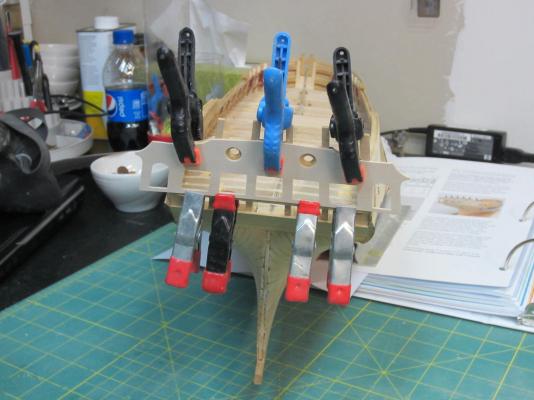

Well I’ve started chapter 6 now and started working on the stern. To start I have to cut the transom out of

some 1/32” plywood. I pasted the plans on and then cut it out with the scroll saw getting it close. I then

used various sanding tools to get it close to shape.

The windows were cut out using an x-acto and finished with files too.

Then the assembly was glued to the frame work.

That's it for now!

-

Hello all,

Well I’m happy to say I’ve completed the planking on the portside too. No stealers or drop planks this

side either. All that is needed now is a good deal of sanding and then some wipe on poly. I have to say

planking this way is more time consuming but it works so much better and the run of the planks is much

easier to maintain. Definitely the way I will plank from here on out!

One thing I want to point out is that I handle a model a lot when I’m working on it.

Because of this I would inadvertently rub off some of the pencil marks. To make sure

I didn’t lose the main belt line mark I used a sharpie to mark them. Then if I accidently

rubbed off any markings I could go back to the main mark and redo them.

After I check the hull over and make sure it’s all set I will move on to the stern.

- Trussben, Chuck, fnkershner and 31 others

-

34

34

-

Oh that is so sweet! Well done Chris.

-

Hi Greg and Ben,

Oh I've used the white glue sanding trick many times. There were only a couple of spots where I needed to do that. The joints that bother me the most were ones that weren't a tight as they should be but were filled with glue and dry before I saw them so there was no sand n fill possible. Oh well trying harder on the port side.

Chris, I could see where doing that with tung oil would work. Not so with the poly as it dries real fast.

Thanks everyone for stopping by and the like. Continuing to make progress.

-

Hi Chris,

I can't wait to see you finish her up. I doesn't seem like it's been five years either.

-

Thank you for such kind words.

Nick. Practice, practice, practice. When I first started I rejected as many as I was accepting. I would

think walnut would also be a bit harder to get a smooth run. Also I use a sanding block whenever possible.

It helps me keep a clean edge.

-

Thanks Chuck,

If someone hasn’t tried it they can’t believe how much nicer it is to plank this way. This is my planking

method now.

Hi Sjors, Thanks but yes it can be done much better. Next time I’ll need to get the seams tighter and

the width of the planks isn’t uniform enough yet.

-

Hi Everyone. Thanks for the comments and likes.

Sorry for the delay getting back to you all. My PC's hard drive started failing and had to take her to the doctor.

During that time I was able to complete the startboard side planking, sanded it down and applied one coat of

wipe on poly. The good news is that I was successful in doing it without any drop planks or steelers. The bad

news is after sanding it a few joints aren't as tight as I would have liked.

All in all I'm happy with my first attempt at this type of planking. Hopefully the next one will be better

and the planks a little more uniform.

Well I'm off to the port side to start the last two bands of planking.

- augie, rafine, ChrisLBren and 30 others

-

33

33

-

-

Need advice with Byrnes saw

in Modeling tools and Workshop Equipment

Posted

Another thing I found that helps is to make sure the blade is not too high. I usually keep my blade set just 1/8" higher than the wood I'm cutting.