-

Posts

423 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Richard Griffith

-

-

Excellent adice from Jaager. BTW, juglans nigra is the Laten name for American black walnut. Don't use it, or any other open pore wood, nor any soft wood for deadeyes or blocks.

I use dogwood which works like boxwood. Dogwood grows here in Connecticut so it is easier to get and cheaper than box. Maple, apple, cherry, pear, and similar are the best.

Keep building and above all, have fun.

Duff

-

A very good question, and all very good responses. To 'sumarize' and to add my comments:

You are the artist, you decide the level of detail, the paint, the overall effect.

You decide if you are having fun. When you make the ship for yourself - family - friends, then the process of making the ship is very important. As Henry said, enjoy the ride,

You decide if you will enter the ship in a judeged contest. Now the ride is still important but the level of artistry,attention to detail, scale fidelity, fit and finish, and overall effect went much higher. It is still your decision.

Above all, have fun - enjoy the ride~! Duff

- hollowneck, robnbill, CaptainSteve and 8 others

-

11

11

-

Another method I use is to attach the brass to a thin piece of plywood with double sided carpet tape. I then run this through my small table saw that has a fine toothed blade.

I am suprized that you can not cut it with a knife. I clamp the brass between a piece of acrylic and a steel straight edge and score the brass. Go about half way through and it will then break off.

Duff

-

-

Very nice~!

This is an excellent example of cross over to another hobby and medium, namely, the plastic modeling. There are many clubs and websites devoted to plastic modeling (cars, planes, armor and figurines) which discuss various ways to paint and weather, especially the armor folks.

Keep building, and above all, have fun.

Duff

-

Nearly all of the foregoing are great/

For me. back in the 1960's, when I was a teenager and had already built the Revel Cutty Sark, Thermopoly and USF Constitution, I stumbled across a book in our local library - 'Ship Model Building' by E. Armitage McCann. I keep a copy in my library (of 120 maritime books) because he grabbed my attention and moved me into scratch building.

Although his work is crude by today's standards, he captured my inspiration and kept me involved in model ship building.

So my point is to read widely, and fine what moves you.

Duff

-

Hey Marc, ooooooh, nice outline of this book. Me thinkin' I gotta get this........

Duff

-

-

I agree with the prior posts - if you are cutting thin basswood, it will do a decent job.

For thicker wood, for hardwoods, and for brass and aluminum, I use a miniture chop saw from Harbor Freight. The cicular blade is about 2 1/4" diameter. I made an adjustable stop to the outboard side so I can cut identical sizes. If anyone would like a pix of it, pls let me know.

The price at Harbor Freight is under $30, and they sell replacement blades for it. Micro Mark is currently selling the same unit for under $30 with their current heavy discount.

Duff

-

Hi Rich, or is that Darth.....

The Connie had jack stays along the top of the yards to which the sails were attached with robands (short pieces of small ropes). Jack stays are iron rods 7/8" diameter secured along the top of the yard, slightly forward of top dead center, with eye bolts.

If your model scale is small, you might elect to omit the jack stays and just tie the sails to the yards with robands.

I have not looked but this site may have pictures of jack stays and even sails bent to them. Hope this helps. Duff

-

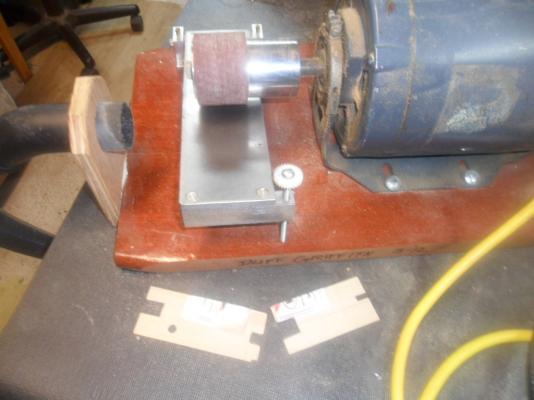

Here is another idea. I used a 1/3 hp electric motor, a steel plate for the platten, hinged to 2 pillow blocks which I made for a steam engine-never completed, and added a vacuum support. The pictures should be self explanatory but should have any questions, fire away.

The advantages include:

1. I can sand very small pieces by pushing them through with plywood pushers (see the plywood with square cutouts),

2. by removing the vacuum support, I can sand large frames one side at a time,

3, it uses 1.5" commercial sanding sleeves exactly like Tad shows above, and

4. it cost me about $10 in materials and a few hours work, mostly turning the steel holder that is clamped to the motor arbor.

Duff -

Good tips, all.

Jeff at the Hobby Mill also has a great tip: see http://www.hobbymillusa.com/byrnes-saw-operation.php on this forum.

Good luck, keep your fingers clear of the blade and have fun.

Duff

-

Hello Scratchbuildmike, you have a good point about cost verses benefits. It is not so much that the blade turns some of the wood into sawdust (as does scraping) but rather the cost of the table saw/planer/sanders/vacuums/blades/ and your time involved. Without having the machinery, then mail order is a good deal for many folks.

I choose to cut my own because:

1. I can control the quality of the wood, its color, and its final size;

2. I use the machines to build other things such as toys for the kids and their kids (grand kids are so much fun!);

3. I don't have to wait for mail order, and there are no shipping costs (I seldom buy wood that needs shipping);

4. I can make planks, beams, frames etcetera out of any wood I can get my hands on.

A note on veneers: I don't favor them because most of them have cracks, and many are brittle from age. The cracks are made by the huge knives used in peeling the thin veneer from the log. Some high end veneers are made by sawing but you will be paying extra for these. Veneers do have their place and the cracks might not be problematic if you control their application to the model ship.

Keep building and have fun. Duff

-

Impressive; have to give this try.

Thanks, Brian, aka Timbers B Shiverin, and welcome aboard!

Duff

-

-

I also have this book, ISBN 9781591147121 and it is beautiful.

However, it did not come with any plans. Does the edition distributed in Europe contain plans?

Thanks. Duff in the USA

-

Good morning Clare, your questions are important and relavant yet the answers are very complicated. Flags changed due to changes in sovereigns and who was present at the launch, for example the Lord High Admiral, or various other high officials. You would need to decide on the period for your project, and specifically the ship you build, then do some research. I cannot be more helpful with such a large, compicated subject.

One book I have that provides much information is "Flags at Sea" by Timoty Wilson, ISBN0112903894. Another less useful book is "Flags for Ship Modellers and Marine Artists" by Alec A. Purves, ISBN0851772811. There are others, perhaps even more useful, but I have not needed more info, yet.

So, decide on your ship, then find the info on flags. Good luck and have fun.

Duff

-

Wow. looking forward to your progress, Farbror!

Duff

-

wq3296 makes an excellent point and I agree with him/her.

Wasa was mentioned in a prior post, which got me thinking about her, so I pulled out my copy of "Wasa I: The Archaeology of a Swedish Warship of 1628" to look at the plans for the decks. BTW, Wasa is 98% complete (except for the rigging). Her decks are asymetrical, planks are seldom straight, they differ in width and length, the hook scarfs in the waterways differ port to starboard, and there are some 'planks' that are almost square, eg small. There are steelers, jogs and all manner of sizes. This tells me that the builders would use what ever wood they could get their hands on and then shape it to the spacing.

One item that does not appear is a plank with a sharp end. Many are spiled but the ends are never cut to a point.

Marine archaeology can dispel myths and provide answers, when we can get such artifacts. Duff

- uss frolick, Louie da fly and mtaylor

-

3

3

-

Hi Adrieke, prior posts are good advice.

For me, I run a Delta 14" band saw and put a wide blade on it for ripping. Wide means 1/2" with about 8 teeth per inch. My band saw has only one speed setting so I adjust my feed rate to what the saw and blade can handle. Tension the blade per owners manual and check it during the cutting as it will heat up and expand.

I do not bother with a rip fence becuase of the wander. I plane the bottom of the my wood so it is flat, sometimes the top too, run a pencil line along the top; and then saw to that, adjusting the wood so the blade stays at the pencil line.

When I want multiple planks, I will rig a home made fence which is a 3" tall piece of wood cut to a narrow, almost pointy edge set just forward of the teeth. This acts as a fulcrum. Keep the wood stock against this fulcrum. It lets me prvot the wood so the blade stays on the pencil line and provides the same width for each plank. (I will post a photo after I find my digital camera.)

Even when I get the planks the same width, wihch is rare, the planks are too rough to use on a model; they need planing in a thickness planer or thickness sander, or hand planed, what ever you have.

Duff

- janos, qwerty2008 and flying_dutchman2

-

3

3

-

Lextin, that handle is super! As a compliment to your artistic talent, I will make one for my own use.

Duff

-

Looking good Marc, keep at it. Duff

-

HI Keith, one can not have too many clamps, cramps as some people say.

I have lots of wooden cloths pins in 3 different sizes that I shape for special jobs, lots of plastic spring clamps in several sizes, brass bar clamps, metal spring clamps in many sizes and shapes, fly fishing clamps, auto hose clamps, macinists clamps, women's hair spring clamps, small quick release clamps that Dr. McArdle recommended in his book Sussex, plus other as one finds in hobby stores - you get the idea.

And then there are rubber bands, an essential clamping device, wooden parralell clamps, 'c' clamps, wood worker's bar clamps, pipe and bar clamps, and more.

Many can be had cheap, and I always look for clamps at tag or jumble sales. Plus you can make some for difficult situations,

Duff

-

Thanks all. I can now attempt to make them, and correct my spelling.

Have a safe and enjoyable holiday season~!

Duff

- geoff and CaptainSteve

-

2

2

Maximum length of a deck plank

in Click Here for Topics dedicated to planking!!!!

Posted

Hi Bindy, lengths were determined by supplies. Gun decks were oak, other decks of fir or pine.

According to Gerald Delacroix (Le Gros-Ventre 1770), the lengths were about 37 or 38' long. I checked Jean Boudriot's books and he seems to show similar lengths, (I have La Jacinthe 1825 and The 74 Gun Ship 1770.)

I then checked Dr. McArdle's book HMS Sussex 1693 and his lengths agree with the above, even though Sussex is English and 100 years older, it does give an indication of what the shipwrights used.

Mark suggests 60' but suspects that may be too long; I think so too. If the shipwrights had some 60 footers, they would have used them but generally, if you keep to a max lenght of about 34 to 36 feet, your build will look right.

Keep building and above all, have fun ~! Duff