-

Posts

1,553 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mike Y

-

Incredible accuracy! Something I tried to aim for, but was not as pedantic as you are, so have a few minor alignment issues here and there Please resist the temptation to lower the bar and make shortcuts. It is common to see people being super precise and detailed when making a keel and deadwood, and then speeding up when it's time for frames. You seem to keep the same precision from the beginning of the build!

-

ancre Chebece 1750 by Jeronimo - FINISHED

Mike Y replied to Jeronimo's topic in - Build logs for subjects built 1501 - 1750

Brilliant building jig! And the lines are very elegant and unusual. -

The led strip is 1m long, but it is sold in 25cm increments - so you can buy a lot more or a lot less

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

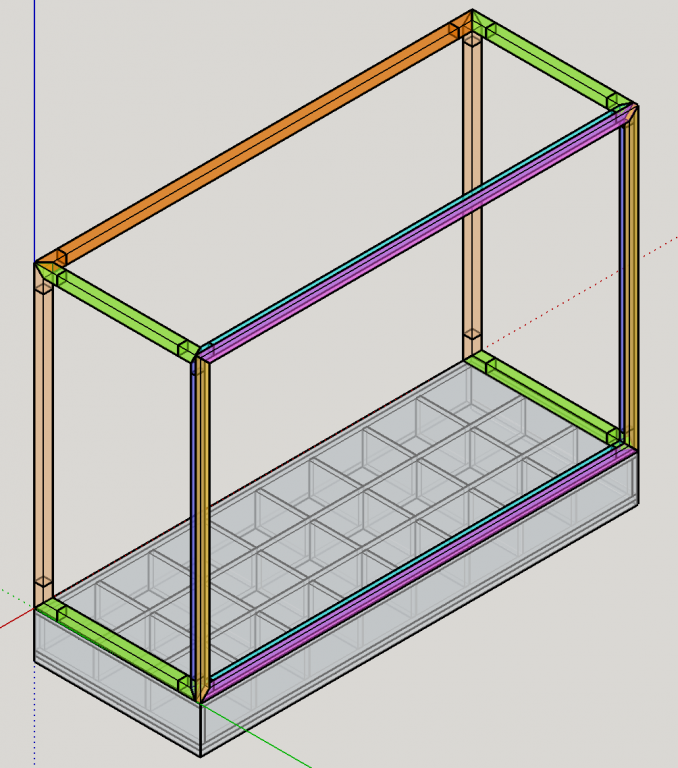

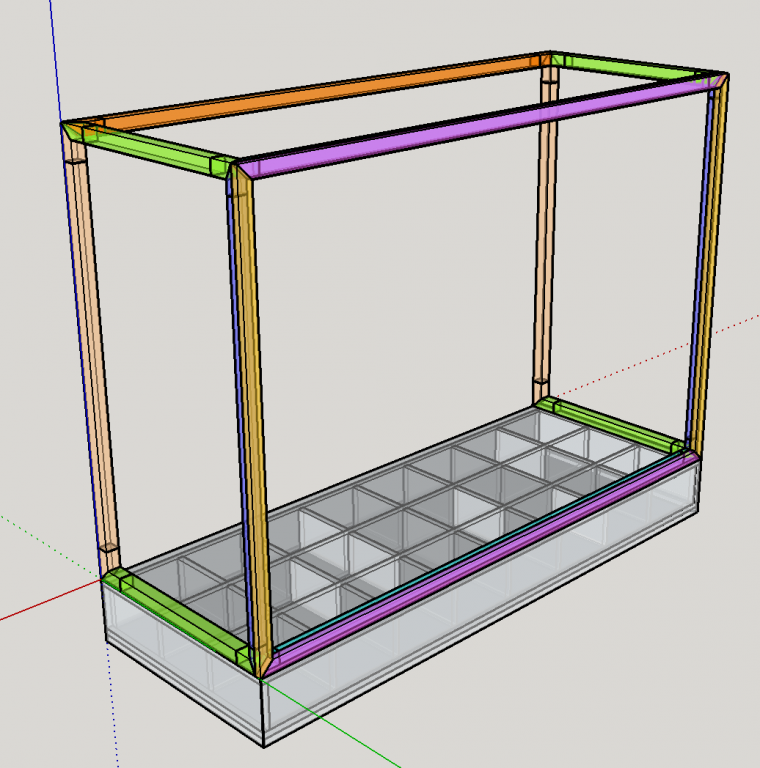

Truly appreciate all the hints and comments, pointing that sometimes less is more and display case should not take a lot of attention from the model. Well, thanks! So I simplified it, will get rid of that rounded corners, and use three-way miters to join the parts of the case. Apart from that - same design. The main ingredients have arrived! Swiss pear for all exposed parts (will use plywood for the torsion box that will provide the foundation). And the high quality LED strip with a proper power source and dimmer: https://www.led1.de/shop/lng/en/solarox-highcri-power-led-strip-pro-ii-with-samsung-leds-warm-white-3000k-20cm.html Estimated cost so far: Wood: 105 EUR ($116) LED stuff: 135 EUR ($150) Glass (optical clear grade plexiglas, 3mm, 0A570 HC): 105 EUR ($116) Total: 345 EUR ($380) Going to finally make some sawdust this weekend!

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

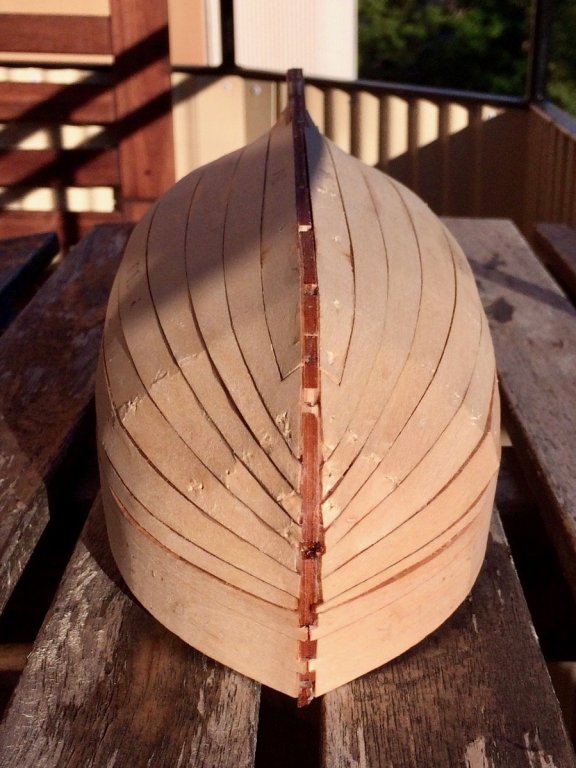

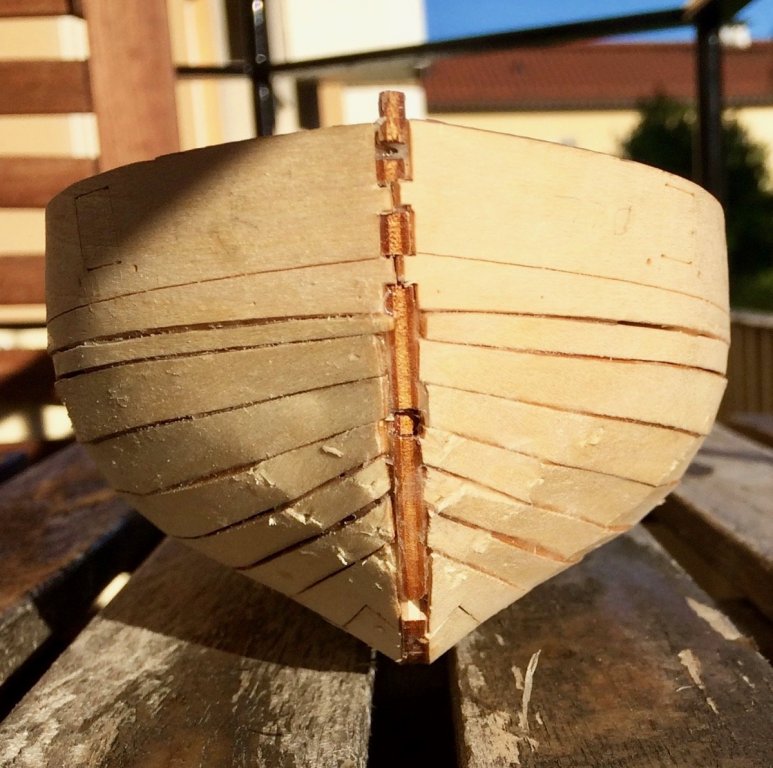

Thanks for likes and comments! Re manual - haven't really used the text part of it yet, pictures are quite self-sufficient, and the text is written in a very heavy and formal way (like a precise specification), which should be handy in some complicated parts of the build. As expected, very rough and ugly first planking was easily faired Now it provides a smooth and round foundation for planking. Daria enjoyed it as well - she liked the transformation of smth rough to smth smooth. That took some efforts though! Sanding: Scraping: Smooth vs rough: End result: She ended up complaining that I was sanding myself too much (we were doing it in turns), and insisted that I should not touch it, let her finish without assistance. Hoorray! P.S.: the build is on hold due to summer holidays that Daria will mostly spend with her grandparents, so will be back in September!

-

No updates for a while - Daria has a number of hobbies and interests, plus a birthday party season, so we had a long break Some awkward clamping, second pair of hands was very useful when trying to install these clamps: Lego break One of many "other things"... Using sander to shape the last plank: Last one is installed! End result. Looks super ugly, but this is a first layer that would be hidden under the second one, and I really did not want to overcomplicate it by introducing steam bending into the process. And without steaming planks crack in the bow. Now aiming to fair the hull and hide this horror with a nice second layer, made of veneer

-

Found these: https://www.led1.de/shop/lng/en/solarox-highcri-power-led-strip-pro-ii-with-samsung-leds-warm-white-3000k-20cm.html Are they good? It is Samsung, not some noname thing. Though the CRI index is 85, not 95 (hope it is real CRI, not Chinese CRI index). Is that a big deal, or it should be ok?

-

Yes, 95% of them are just cheap stuff from aliexpress and ebay, intended to be used in kitchen lighting and similar applixations. I need just one meter, but of museum quality, not a crappy leds.

-

Very precise and lots of methods to learn, thanks for sharing! unusual type of a vessel a well

-

Looking for a high quality LED strip (for the display case). It should be dimmable and have a high CRI. I read some good reviews on this forum for FlexFire brand, but it seems to be impossible to get in Europe Would appreciate some recommendations for shops and brands in UK / Germany / anywhere in EU.

-

Adjustable height table.

Mike Y replied to Ulises Victoria's topic in Modeling tools and Workshop Equipment

I use IKEA's electric version (bekant), and super happy with it. They exist in two widths and also an L-shaped version: http://www.ikea.com/us/en/catalog/products/00263218/ http://www.ikea.com/us/en/catalog/products/50263225/#/80263224 http://www.ikea.com/us/en/catalog/products/60263220/ Smooth and stable. The only thing to keep in mind - I would not use a hammer / mallet on it, this can damage the mechanism. -

Very thought-through spacer and frame arrangement! looking forward for the fall, but maybe in a meanwhile you can share other things that you do in the workshop?

- 889 replies

-

Grant, thanks for the feedback. I do not like the bulky look of the standard cases, so was trying to make it elegant. But making proper mitered corners will be quite challenging, they might crack without reinforcement. These corners look smoother. Or maybe I am overthinking this, as usual

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

HMS Naiad 1797 by albert - FINISHED - 1/48

Mike Y replied to albert's topic in - Build logs for subjects built 1751 - 1800

The colour scheme is very nice! -

Brian, trying to keep the model clean is already a big problem. Keep in mind, my "workshop" is in the living room Surprisingly, most of the dust on the model looks like a regular dust, not a wooden dust. I ended up covering the model in plastic film, which is ugly Fine dust gets between frames, and it is not easy to get it out even with compressed air. When I will start the deck framing, it would be nearly impossible to get id of the dust inside the hull. So the display case is a necessity for me. I am just trying to make it less ugly, so it would be a model of its own Hence this decorative joint, inspired by the joints in the model itself.

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

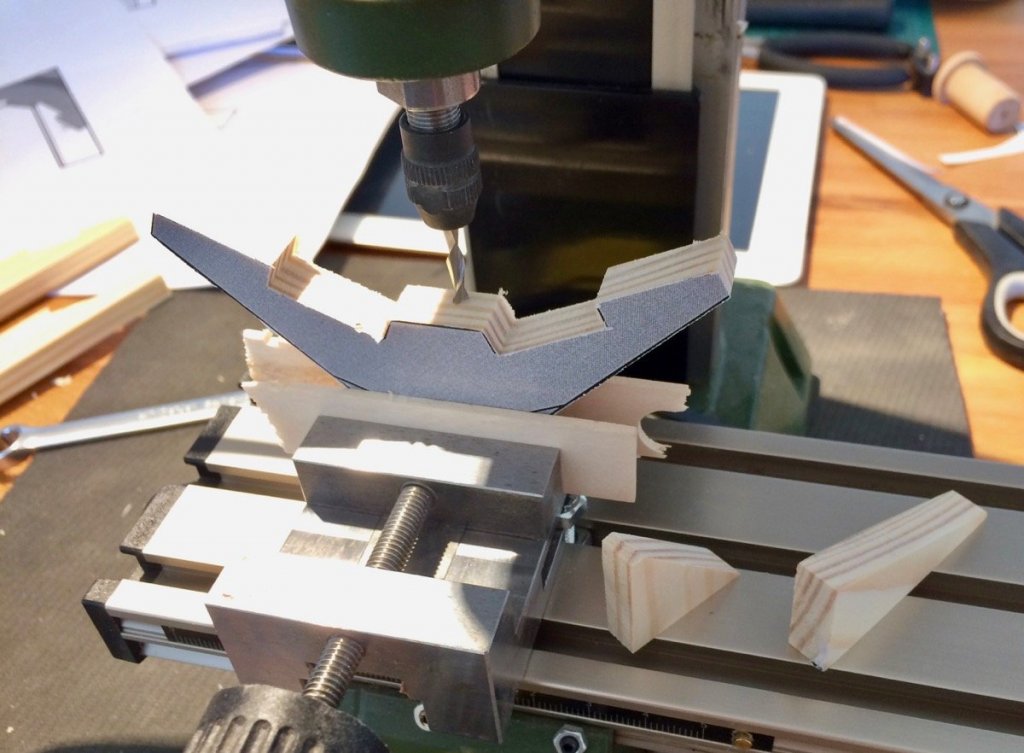

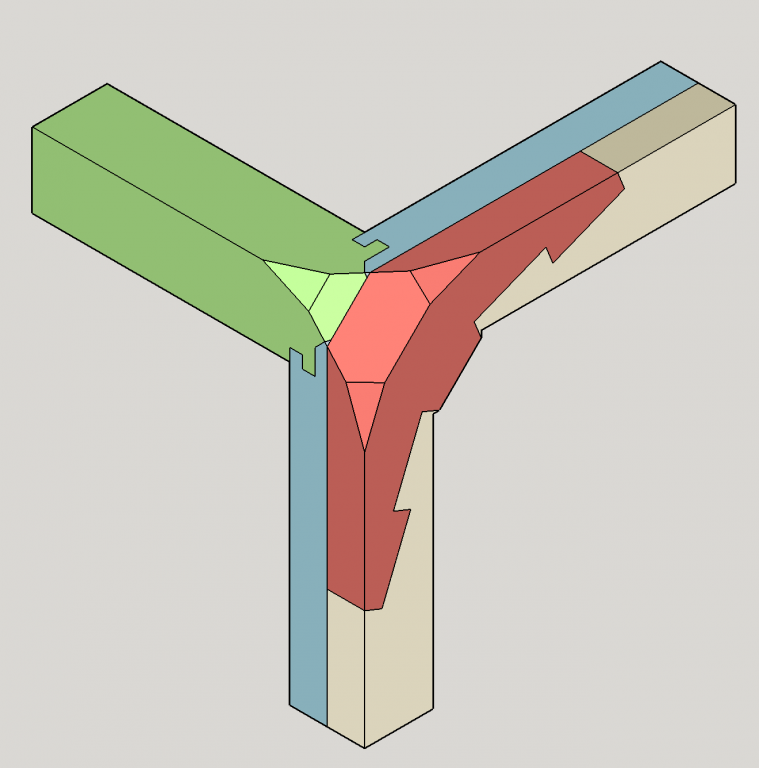

Finally done with all the gifts! This Christmas season was way to long So back to the display / dust case for the Cromwell. Tested the corner joint design on a piece of pine scrapwood. Here is the joint drawing: Milling scarf joints was easy, using various angle blocks to make sure that they all have the same angle: Side joints were more tricky, not possible to mill easily. Crosscut sled came in handy: Resulting parts. Nevermind some chipout, it is pine: Glue-up was tricky due to a number of angles that must be square: Result: Now the most risky part - making that weird shaped corners. The front part of the joint will be detachable and will hold the front glass, but to make the corner it should be clamped together with the non-removable part: Then caaaarefully shaping it on a disk sander: Adding some bevels, the bevel guide was handy! Done! So that joint is quite manufacturable, which is a good news! This is the first and only attempt, no scrap pieces. However: 1) Side joints are too miniature (3mm lips) and are easy to chip out 2) No need to add that miters on the side joint - they only add complexity and no real visual effect. 3) Building the display case will require some ridiculous precision - making sure all stock is precisely dimensioned, careful alignment and squaring. Will definitely need to buy some extra wood. 4) Worried about wood shrinkage/movement and getting out of alignment due to humidity variations... What do you think?

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Procrastination continued, made a napkin holder as a gift, this time it sooort of related to ship modelling? Walnut, cherry "frames", maple and ebony strip, Osmo finish (a bitch to apply in a tight corners, should be really applied before assembly).

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

You are building it so quick! The log started just a month ago, and you already have most of the frames in place! Envious! Though there might be a big of fairing ahead

-

Maybe it would make sense to make them longer than needed, scribe the cutoff lines, and join together with spacers or battens above the cutoff line?

- 889 replies

-

Hjx, it is mostly "swiss pear" - european pear tree that gets is pink/brown colour after kiln drying. If your wood is rough - pass it through the planer or thickness sander first, otherwise sanding will take a lot of time. Nothing special for polishing - just sanding with Mirka sandpaper, grits 220 -> 400 -> 600 -> 1200, sometimes up to 2000. Different brands and kinds of paper leave slighly diferent finish, so your grits may be slightly different. Sanding on a flat surface (paper clamped to the table, moving the wooden part on the paper, not vice versa), or with a cork sanding blocks of various shapes. Never sanding freehand. That is all to avoid rounding the edges, which is unavoidable if the paper has a soft backing (fingers, foam, etc). quite frequently I scrape the wood after sanding with 220 or 220 -> 400, using heavy duty xacto blades for scraping (holding the blade with fingers, without a handle. This helps the blade to follow the lines of the wooden part). Do not forget to round the sharp corners of the blade to avoid scratches. It is also very handy for curved surfaces, where sanding block might not be convenient. I use an optivisor to check the surface and see if I sanded enough, or there are still some scratch marks after the previous grit. frankly, I never checked if what I am doing is an overkill. The difference between grits is quite visible when the wood is not finished, but after finishing - not sure if it is possible to see a difference between 600 and 2000 grit. But fine grits take very little time, so I do it anyway Sanding is a very important - few min of sanding each part makes a big difference to its look and feel.

- 968 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

There is definitely a market for benchtop air filters that could be just put on the back side of the workbench, pulling air through the filter. The main problem is getting a powerful enough, but quiet motors and propellers.

-

It looks great and built in such a short timeframe! Looking forward for the next log, hope it would be full of interesting jigs, fixtures and methods. Sharing them is fun!

- 132 replies

-

- triton cross-section

- cross-section

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.592fc5b42ac731db9d71f802d92bf0c1.jpg)

.thumb.jpg.09b3146c62c4f55c4e0ba379769719ee.jpg)

.thumb.jpg.e2ae9240447940753976fbca9a071129.jpg)

.thumb.jpg.bf54eae23510bf1e615cf163a173fae8.jpg)

.thumb.jpg.906eedfedf4818ecfc23b6952038bad2.jpg)

.thumb.jpg.306a9d5a859a2f7012117f4a21bbfc8a.jpg)