-

Posts

1,002 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Wintergreen

-

That looks exactly what I did on my first version of the Kågen hull. While the planks themselves looks okay it is the buildup of tiny errors that get you to where you sit right now. The culprit looks to be the second plank, the one above the garboard. It runs too high on the stem. I found out that a nice run of planks looks straight when eyeballed from stem to stern at specific angles. See this post from my build log and the discussion that follows: Don't let your heart sink though. It IS a learning experience! Keep it up!

-

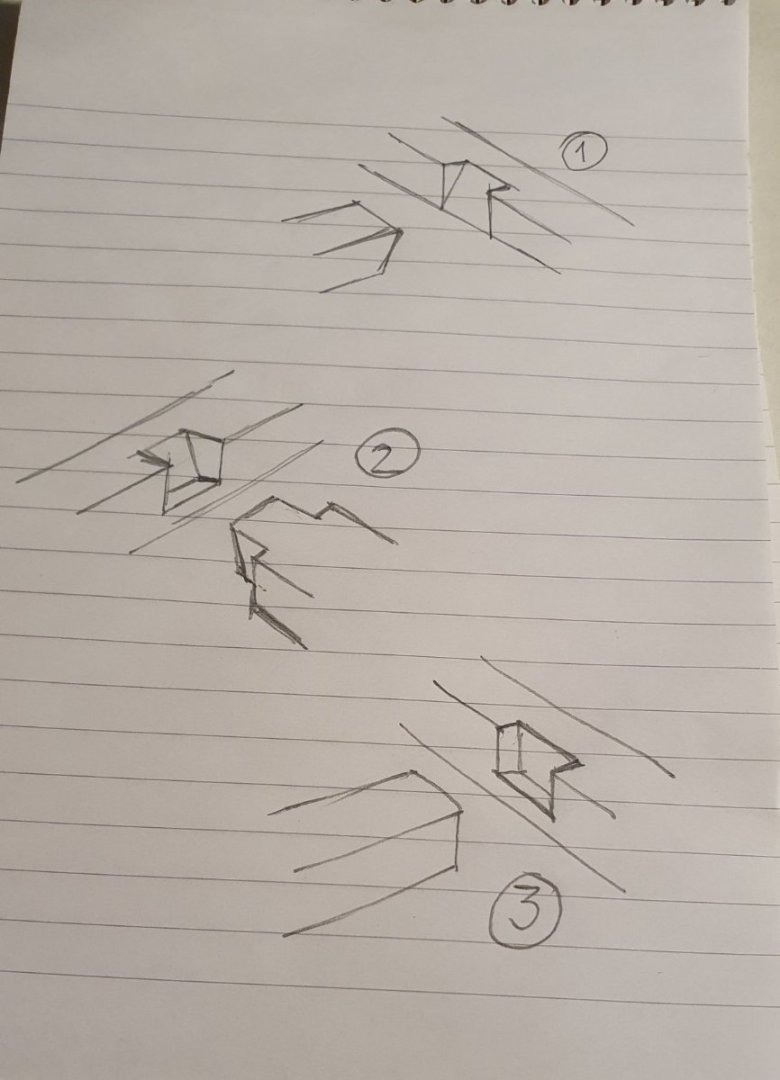

Nope, no pile and hence no drum sander. I will probably start as you with a sanding drum and from the look of it the sanding sleeve should come right off which means easy going between grits. We'll see what I can dream up... stay tuned. Apart from dreaming about tools work is kind of slow with the carlings. Mast partners are in and a couple for skylights. The photo below is a couple of pieces old. If you look closely you can see that I've tested a couple of different notch types. Right now I'm towards full width and full depth, unless the pieces are of same moulded size (depth/thickness...). If the pieces are of same dimension I'll leave a ledge for the carling to sit on and cut a matching step out of the bottom of the carling (3), instead of doing a slanted joint (1). No 2 is what I used for the main hatch and for the main mast partners in the picture below. No 3 is actually easiest to get a good looking joint for me. Cheers!

-

I would suggest that you build all the launches to her. But maybe you already have? However, I like your attitude, you are finished when you say you are finished. A little like the wizards... they are never late, nor are they early, they arrive exactly at the time they decided upon. Time will tell how far we came on our journeys 🙂

-

Just silently following along here. Well, not silent now though... Mark, your attention to detail is remarkable. Fascinating, in fact. Also knowing how long you've been on this project. I don't know how many of you that keep tabs of spent hours? I don't, and that is because it is irrelevant to me. Even if my current project is light years away from what we see here, it is the journey that counts for me. Not how many hours or the cost of accessories. Bellona is looking wonderful, by the way. 🙂 Keep it up! From one leftie to another 😉

-

I guess there are as many ways to do blocks as there are builders 🙂 Your way I haven't seen before, with the strop done that way. Other laminated ones I have seen, like KeithAugs. My very limited experience of block making is that I struggle to get the correct roundness. Mine, this far, always has been to squarish. Those two piles of pre-production block are a promising start I think. A bit more oval and there you have it. Keep it up!

- 118 replies

-

- billing boats

- meta 484

-

(and 1 more)

Tagged with:

-

Oh, wait, what?! I was dozing a little here in the back row. Sorry bout that. Nice to see you back here Siggi 🙂

-

Never realized it before, but those frames are delicate! I also like the tone/colour of the keel, such nice wood. Makes me think I need to experiment with finishers on my apple-wood. Btw, the cutting mat is impressive in all its humonguousness 😉 (don't know if that actually is a word, but it sounds right 😄 ) Keep it up!

- 131 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Byrnes saw belt source in UK/EU?

Wintergreen replied to bruce d's topic in Modeling tools and Workshop Equipment

I guess he does, but with postage, customs and delivery times to Europe, local (to EU) sources are preferred for us here on this side of the pond. -

HMS Euryalus 1803 by rlb - 1:48 scale

Wintergreen replied to rlb's topic in - Build logs for subjects built 1801 - 1850

Ah, so that's the reason for the absence. Don't think that we didn't notice 😉 Makes sense of course. Better to walk away than doing something irreversible stupid. Hm, they say the bollards and the stern timbers are some of the hardest parts to figure out. But on the bright side, when you have mastered it, you have taken a step up the skill stairs 😉 Keep it up!- 122 replies

-

- Euryalus

- Plank-on-frame

-

(and 4 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.