-

Posts

4,133 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by glbarlow

-

Thank you. I kinda enjoy writing the log, I likely get carried away from time to time. I think your 12 frames are no small achievement, I'm sure there is a lot of work in those.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Matt, it looks a lot like yours 🙂 - it really is a signature statement for the model - it just stands out. Looking forward to having a deck.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Ron, I appreciate the comment. Photography is my other hobby, I feel like I'm giving short shrift to these photos using only my iPhone. One day I'll have to get out the good stuff and a true white screen, meanwhile I convey what I can. I appreciate your stopping by.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

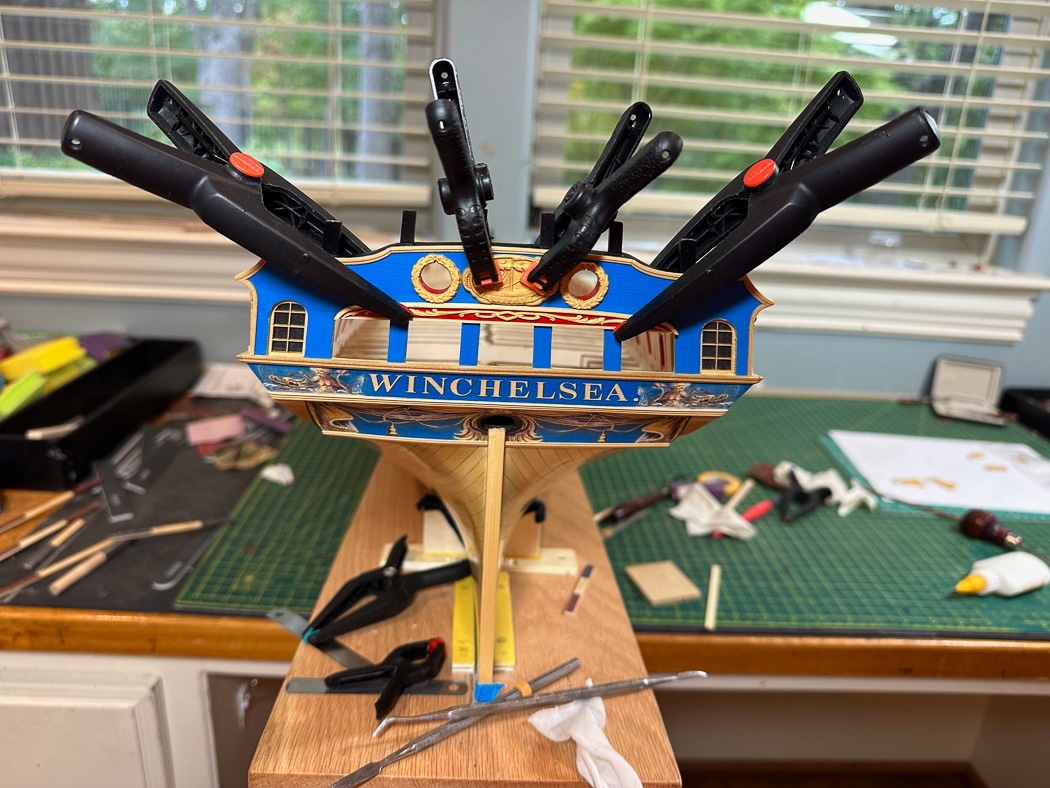

The Transom & Chapter 3 are Complete! I started my Winchelsea November 10, 2021, one year later I have completed Chapter 3. The framing, planking, and a good deal of the external hull work are now finished with the first three chapters. Chapter 4 takes me inside to the bulwarks and the deck, I’m looking forward to doing something new and different. The transom and the stern in general on Chuck’s design is certainly a signature element that separates it from other models, at least ones I’ve seen or built. From the very first step of carefully mounting the frames on the bulkhead framer to adding the last carving it has been a journey all in itself. For those that follow, take whatever time is needed in Chapter 1 to frame it up right, it pays big dividends later. First up are the top and side mouldings, laser cut and for me a near perfect fit, though with lots of char. The sanding sticks I made up helped, but the biggest help was rubbing on Gojo Pumice Hand Cleaner, it takes most of the char right off. Credit @Stuntflyer for sharing this with us, it works great. Just wash it off and let the pieces dry before installing. I had added the mouldings and decorations for the upper and lower counter a while ago, covered in an earlier post. The transom is another adventure. There are these beautiful carvings, I am fortunate to have a boxwood set, they are pure art. Following Chuck’s direction I sealed them with Sanding Sealer. “Not WOP?” I asked, ‘no’ was the answer and I now know why. The sanding sealer (Old Masters) imparted a beautiful golden touch to the already perfect boxwood. Buffing them out with a soft cloth (pieces of old cotton t-shirts) brought them to life. Now the goal was to glue them in the right spots and in a way they are all interconnected once complete. It’s crowded back there, not a lot of room to negotiate space for each, I spent a good deal of time looking at the plans, studying the work of other builders, and of course checking it against Chuck’s model, then it’s clamp on, clamp off, test fitting (as shown in the above photo) each piece and each piece together. There is an order they have to go on starting with the cove, which has to fit window edge to window edge, be the right height (or what’s above it won’t fit) and depth (other carvings use it as a seat). It includes the most intricate and fragile of carvings in two pieces, I was very careful with it when building this little bit of artwork. Once on the wreaths (wreaths, who thinks to put wreaths around some port holes, 18th century ship builders that’s who) and the center medallion go next. You could almost stop there and have a nice looking transom. I mentioned the figures are inter-related. After lots of clamping I decided the fish need to be set at the right angle for the other figures feet with fire coming out of them (not sure about the feet on fire thing, I’m sure there’s a story) to fit below. After I had spent time carefully painting the transom I now sliced it up with my # 11 blade and also gouged the back of the figures (carefully) to help (or help me believe it does) the glue to better adhere and mate the two for eternity. As I mentioned it’s crowded back there and Neptune’s head goes above the moulding. So naturally, me being me, I screwed that up and had to request a replacement part, which Chuck kindly provided. I also added the columns using the same process as the quarter galleries, the extra upper moulding pieces again making great caps for each column. There is also a six piece set of moulding connecting the cove to outside edges and rounding the window. Another fun thing to carefully match up both alignment and thickness, and, me being me, the extra’s Chuck includes were extra no more. Note the fishy on the left has a little extra carving on his tail, Neptune’s trident staff must neatly lay in there. I also had to round the staff and cut a little notch where it meets the tail. The benefit of multiple looks at clamping pieces to determine fit and location before the glue left the bottle. Finally Neptune and his bare-breasted lady friend take their place. Here was another moment for clenched teeth and held breath, a notch must be cut in the bottom of both so they sit convincingly on the cove moulding. Slow and steady wasn’t enough, I went at a crawl constantly checking the fit and wishing I had no more to do, until I didn’t - then a sigh of relief. Chuck recommended rounding the legs and shoulders, it is a nice touch that gives a more lifelike look to my stern riders. Two naked ladies looking at each other were added, sitting there on the on the columns and the lower moulding along with a pot-bellied king and another bare-breasted women to the side coves. So, did sailors spend a lot of time leaning over the side looking at these not-bashful ladies… As I mentioned, the stern was a journey by itself, here’s a little short movie sharing that journey. winnie stern.mp4 And it’s done. This photo makes the figures appear gold, they are not at all or even close to it. I'm still learning my iPhone 14 Pro, it’s supposed to be a much improved camera, so far I'm thinking I liked my 12 Pro photos better. Gotta work on that. With that Chapter 3 is complete. To record the moment and my first Winchelsea anniversary here are a few more photos: As always, thanks for stopping by. The likes and especially the comments are always appreciated. I recognize I’m but one of many Winchelsea builders and little I offer is new from those that have gone before, I just try for the entertainment value of seeing how this one is put together. Next up, my ship gets a deck.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hope you’re doing better Mark. I’m really enjoying building Winchelsea, it’s a journey for sure. 1:48 is a great scale, somehow everything seems more realistic at the larger sized. And as you note, easier on the hands with the larger pieces. Whatever you do I wish you the best!

- 505 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Me too. I have a set of different sized re-imagined soft makeup brushes (new, never used for makeup).

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Have to finish chapter 3 first😊 I bought an extra bag of cannons to experiment and tried several methods. I’m sure I’m doing it wrong but to answer your questions - I tried the same black primer I used on Cheerful’s brass cannon but determined with the resin cannon and my ironworks matte paint it wasn’t needed. I also tried the primer alone. - I should have airbrushed the cannon, but with just the eight I hand brushed them having thinned the paint some. Probably when I get to the rest of them I’ll do all the remaining barrels with the airbrush for efficiency. - The paint definitely has to be completely dry before the weathering powder is applied. - I tried the Krylon spray fixative and paint on varnish a couple of times on the experiment barely and didn’t like the result. I didn’t use it on Cheerful’s cannons, over a year later they still look fine. I just have to keep my fingers off the barrel and can use the buff out brush one last time after they’re installed. Thanks for looking in, I hope that helps. EDiT: Just to clarify. Matte Fixative and Matte Varnish are both excellent choices to finish off barrels and I may yet regret not using one. Time will tell.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you. No coat hangers used though. This wire is much thinner and easier to bend. 😊

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I keep thinking about how long it is taking me to do 8, knowing there are 24 more to go. I’d have to return to sender😁😂

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

There’s a lot of detail in the gun overall in my opinion. I can’t speak for other builders, just not something I felt was needed.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

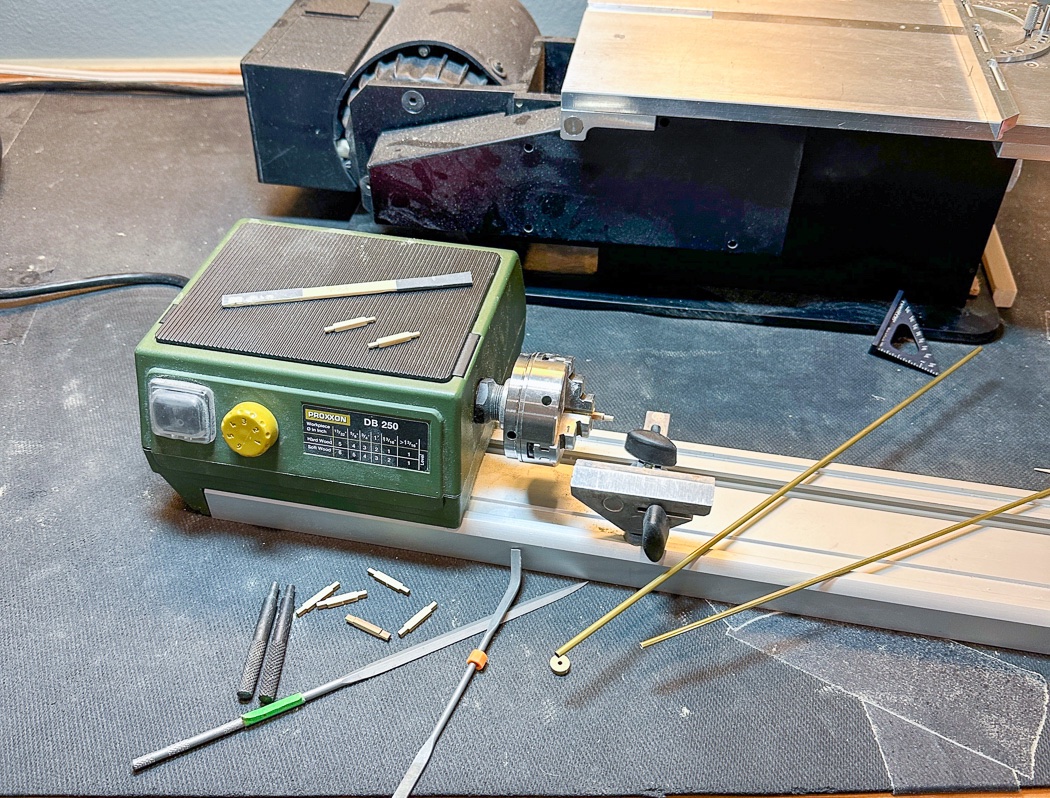

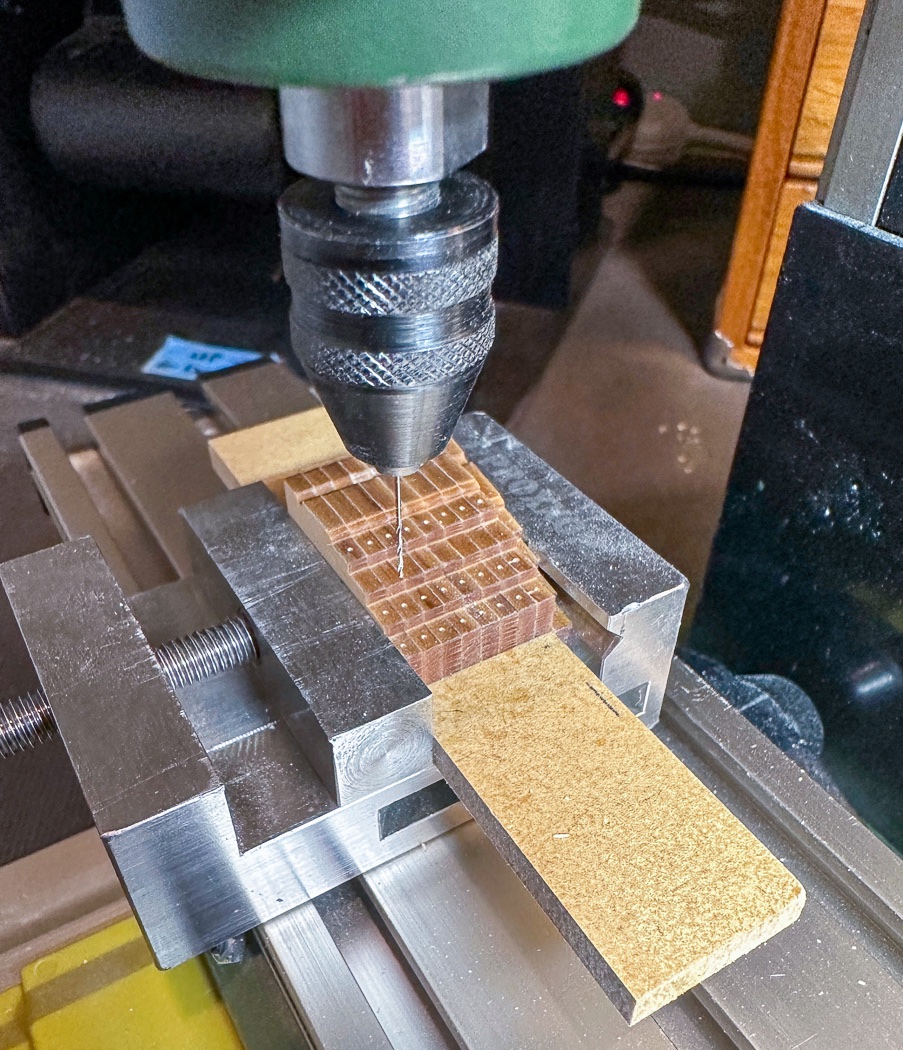

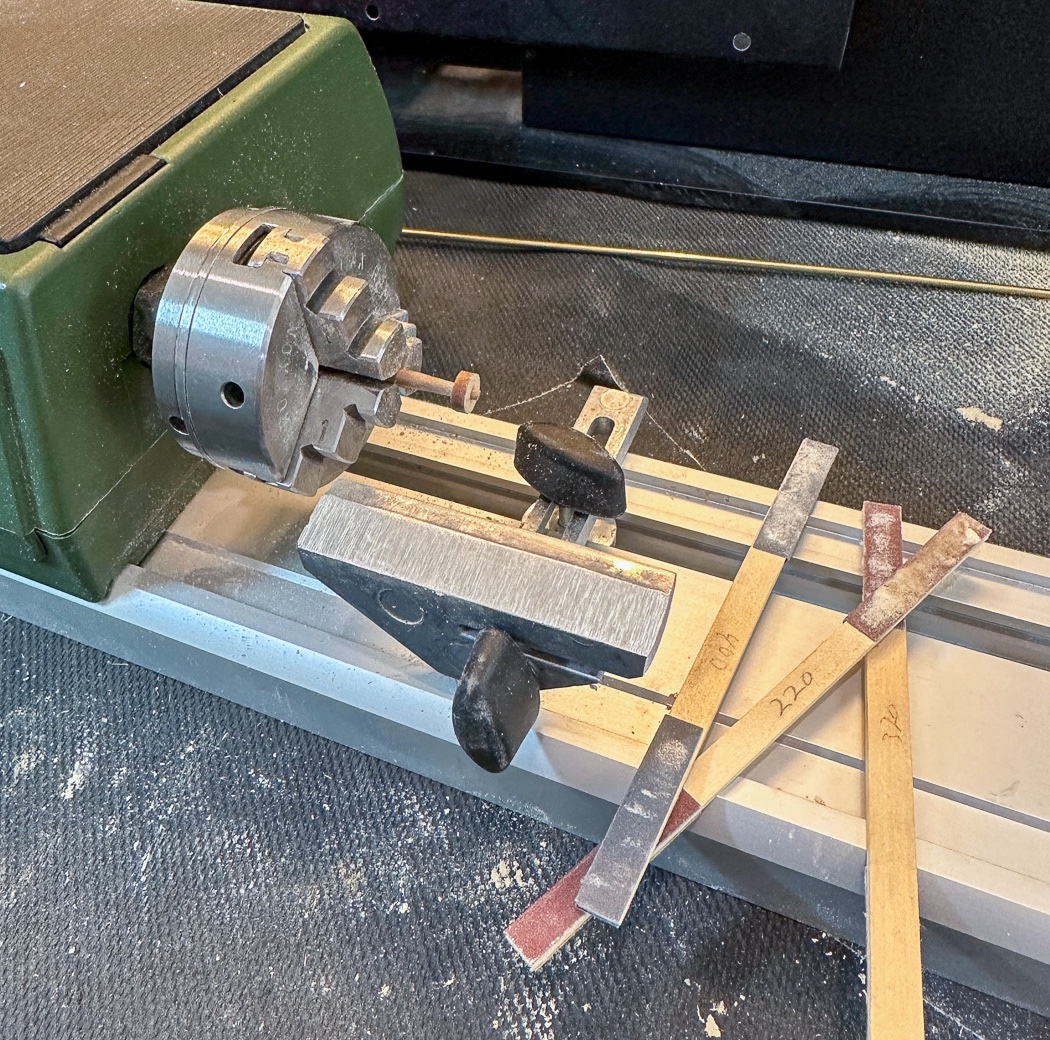

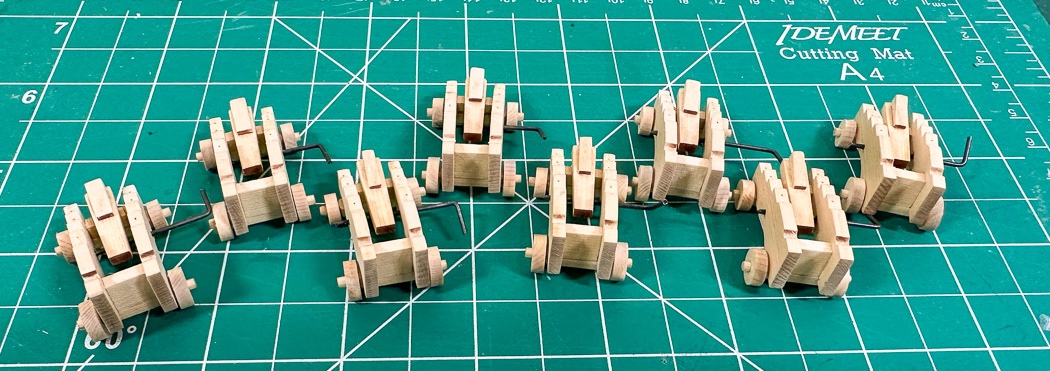

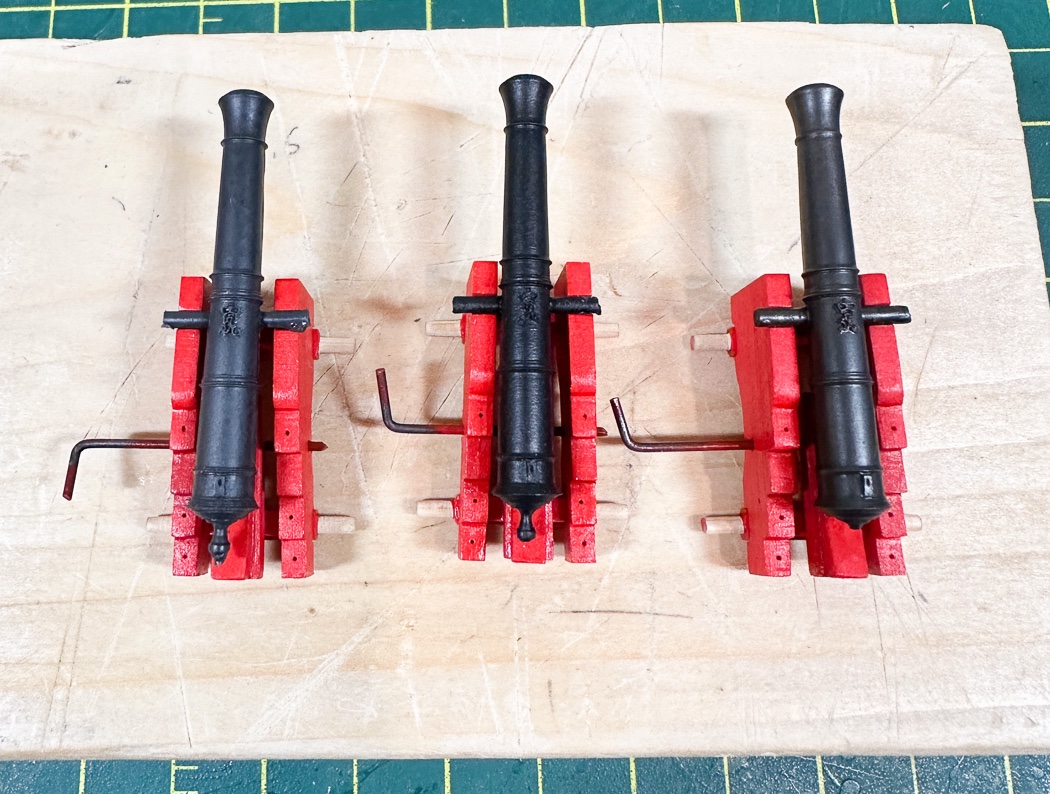

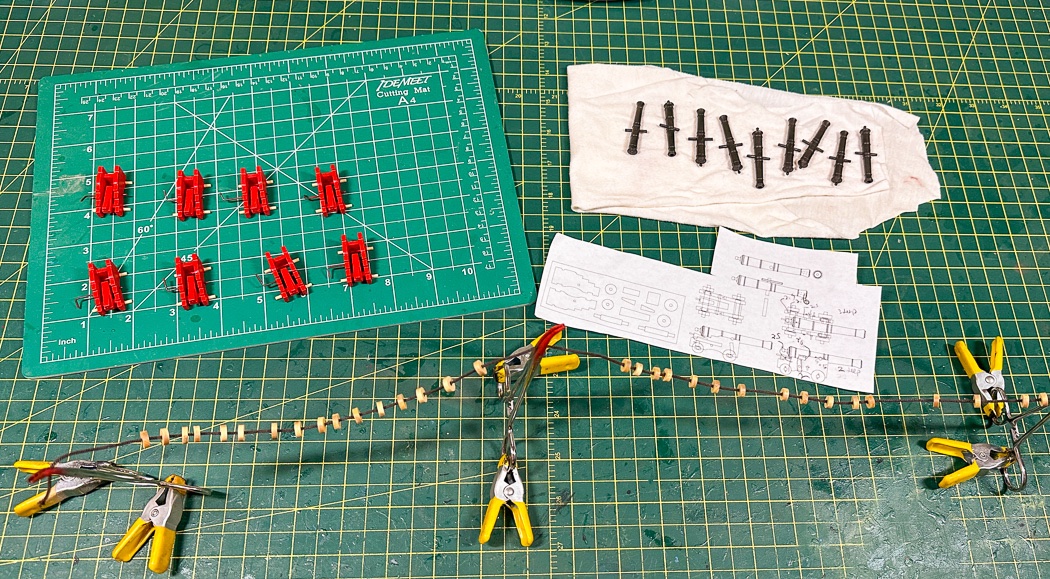

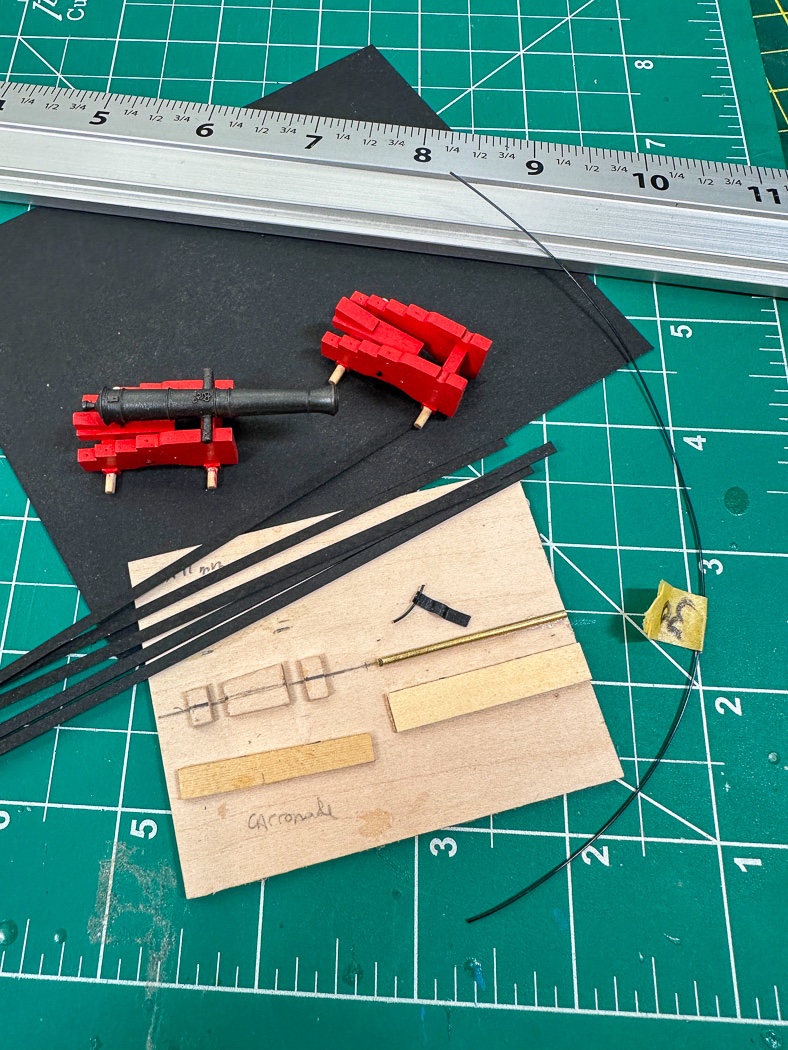

Cannon - It’s a Process I managed to break a couple of parts preventing me from completing Chapter 3, of course Chuck has since kindly provided replacements. In the interim I elected to start production on the 32 cannon I’ll ultimately need for my war ship by building the first eight. This many of anything for me requires a repeatable process, doing these eight helped work out that process. Upfront I acknowledge some of what I describe below comes from Chuck’s excellent instruction, some of it is my own, some from other builders like @Rustyj, @DelF, @James H, and @Stuntflyer, some of that I modified, some I probably absorbed from others and think its my own. That’s the wonder of this forum, many of us have built many cannon in many different ways, we all learn from each other and in doing so make it our own. I’m just out to efficiently make the many cannon needed for Winchelsea - So with that disclaimer and for your reading entertainment, here’s how I'm doing them. Like others I’ve opted for red carriages with natural wheels and axels. All edges and backside of all parts have a lot of char to remove. It’s a slow tedious process that can only be done one part at a time. There are no shortcuts. The red paint I’m using, Winsor & Newton Crimson, won’t cover char so it all has to come off. This photo is at the end of a lot of sanding with 320 and 400 grit paper (with 8 axels still to go). With all the char removed, first up was the combination of the carriage bed and quoin. I drilled a hole for the handle, I’m using 8mm belaying pins from Crafty Sailor, they look great and for me are the right scale. On a side note, this little bottle, learned from @DelF or more specifically his wife I recall, is a great applicator for PVA. I have a large bottle of quality white wood glue I transfer to this little bottle found on Amazon under Fine Line Applicator, standard tip. I put my Proxxon DB250 lathe and these home-made sanding sticks to work, turning the trucks to remove the char. 32 trucks later … I put the lathe to work again rounding the axels, a brass tube (which I later cut to a shorter length) helped with the rounding and confirming a consistent size to match the wheels. 16 axels later… I had this little jig from Cheerful (I keep all my old jigs) I put it to work on the mill drilling the required holes in the carriage sides. I set the right location for one then rotated all the carriages through drilling the one, set it for the next hole and did all again. There are 4 holes on each carriage side. 64 holes later … I made a new jig to hold eight carriage sides, again marking first location on a row, moving the mill back to front to drill the same hole 8 times, marked the next row, then the next. Once all three rows done, loaded the other 8 and did it again. 48 holes later … On to the barrels. The resin barrels are excellent for the detail they show. So much better than applying the tiny King’s crest to a brass barrel as I did for Cheerful, but he sprue has to be gently removed without breaking off the cascabel, ask me how I know this. I chose the same method I’ve done in the past by next painting the barrels with Admiralty Ironworks Black. Its nice matte finish is fine on it’s own. Instead I added Doc O’Brien’s Rusty Brown by cycling through this brush set left to right, each to its purpose from application to buff out. I don’t know why Rusty Brown produces such a nice gun metal gray on top of the Ironworks Black, but it does. It doesn’t show up very well in this photo but here are the three stages, starting resin, painted black, weathering powder applied. 8 barrels later … After assembly of the char-free parts, using the perfect jig provided by Chuck shown in the first photo, it’s off to the paint shop for the carriages. I’m not super confident with an airbrush, specifically getting the paint from the tube to the right consistency. I seemed to have gotten it right this time using Liquitex Airbrush Medium and remembering the mantra ‘milk not milkshake.” Good that I remembered to tape the axels since I want them natural. 8 painted carriages later … Next up, a coat of WOP to the axels and the trucks, threaded through a line and left overnight to dry. 32 wheels and 16 axels later … Not done yet, time to do the metal work - lots of eyebolts and split rings to make from 24 gauge wire. I’m using a #41 bit to form the split rings and a # 61 bit for the eyebolts. It took me a few times to remember how I did them for Cheerful, I got the hang of it again and methodically wrapped, twisted, cut repeat. For me the smooth surface (so not to scratch the wire) needle nose pliers and quality flush cutters are essential. I’ve found jewelry makers supply stores have the best tools for this type of metal work. 56 eyebolts and 16 split rings later …. (I was on a roll and made more, I'll need lots more later) The eyebolts take up seven holes on the carriage, the remaining eight are bolts simulated with 25lb black monofilament fishing line. Just glue, insert and snip a little proud of the carriage. 64 cut lines later … I’m using black card cut in 2mm strips for the cap squares and following Chuck’s look with a “hinge” and the front and hook bolt on the backside. Simulated with 25lb black fishing line (so I don’t have to paint cut wire) and 24 gauge wire for the hook. I re-imaged a jig I used for Cheerful to pre-shape the card so it will lay easily and consistently on the carriage for gluing. I found it easier to add the front hinge on the jig. 16 cap squares and 32 hinge sets later … I finally have one completed cannon, here being inspected by mini-me, I still have seven more to mount barrels and add the cap square and hinges. Once the eight are complete I’m going back to finish Chapter 3 - knowing I still have 24 more to do, part of my reason for this post is a reference for me to look back to when I start the next set. They do look pretty cool once complete. It is though, a process. Thank you for stopping by, hope this was helpful or at least mildly entertaining. As always thank you for the likes and the comments.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

While crews, sails, and dioramas hold no interest for me to do personally I must say yours is interesting to follow and see how one is properly done. Definitely has to be one of the more unique Sphinx builds. Well done.

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Or you could bring Winchelsea out of on hold status😁

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Just found your log. Very nice work. I enjoyed building Flirt, Speedy’s sister ship. Paused at completing hull to build Winchelsea, but will get back to the rigging at some point. Too late now but as I’ve done with Winchelsea, I think the one side pencil caulking is a great look, the separation really makes the planking pop. However I didn’t do it on Cheerful and it looks great too. Derek is a great mentor and valuable resource, follow his work and you can’t go wrong.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.