-

Posts

1,036 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by No Idea

-

This worked for me so I can recommend your medicine 👍 It took me 10 days to get over it so I hope you get better soon!

- 1,075 replies

-

Thanks druxey I've learnt a lot getting this far and there is a lot that I would do differently on my next build. I relied on the jig that I built far too much when raising the frames due to inexperience. It was only after I fired a centre line down the frames I discovered that some tilt between 2.5mm and 3mm to starboard. On this scale I can get away with discrepancies like this and I'm great at hiding things 👍 So many lessons learnt and no doubt hundreds ahead of me too. I now understand why builders like Albert and bitao make such fantastic building stations - I will too next time. Cheers WalrusGuy - I reckon you need to start scratch building based on your current fantastic build. You know you want too!!

-

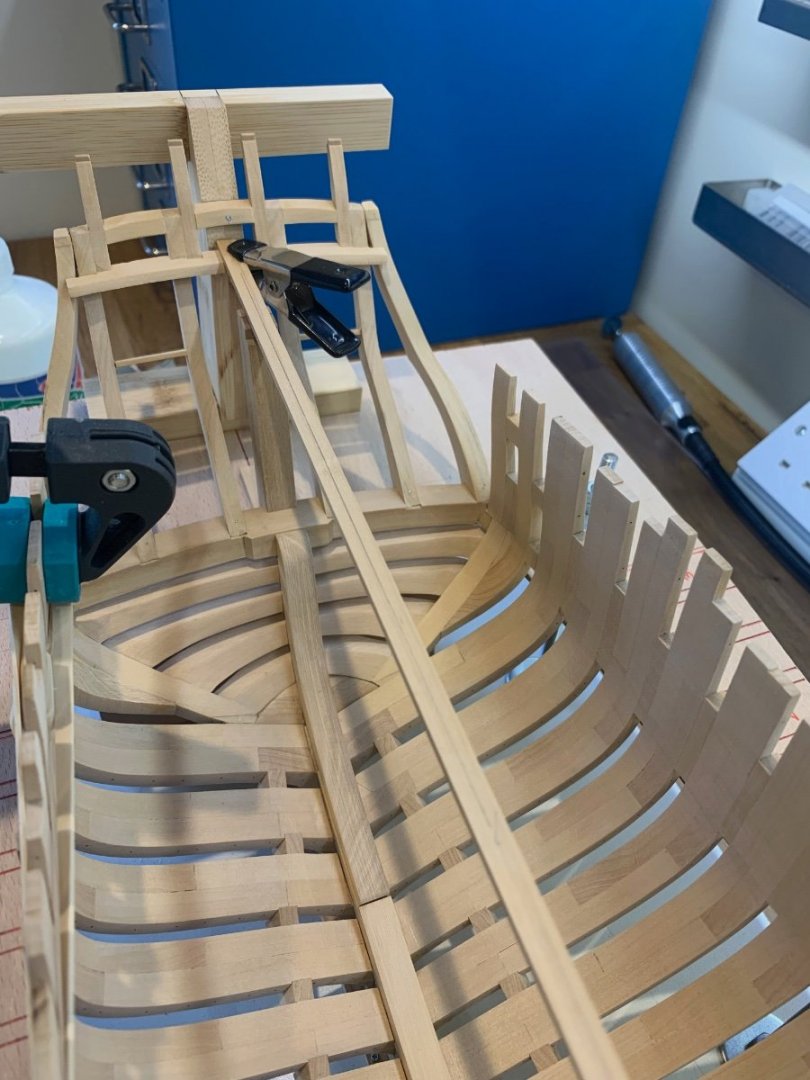

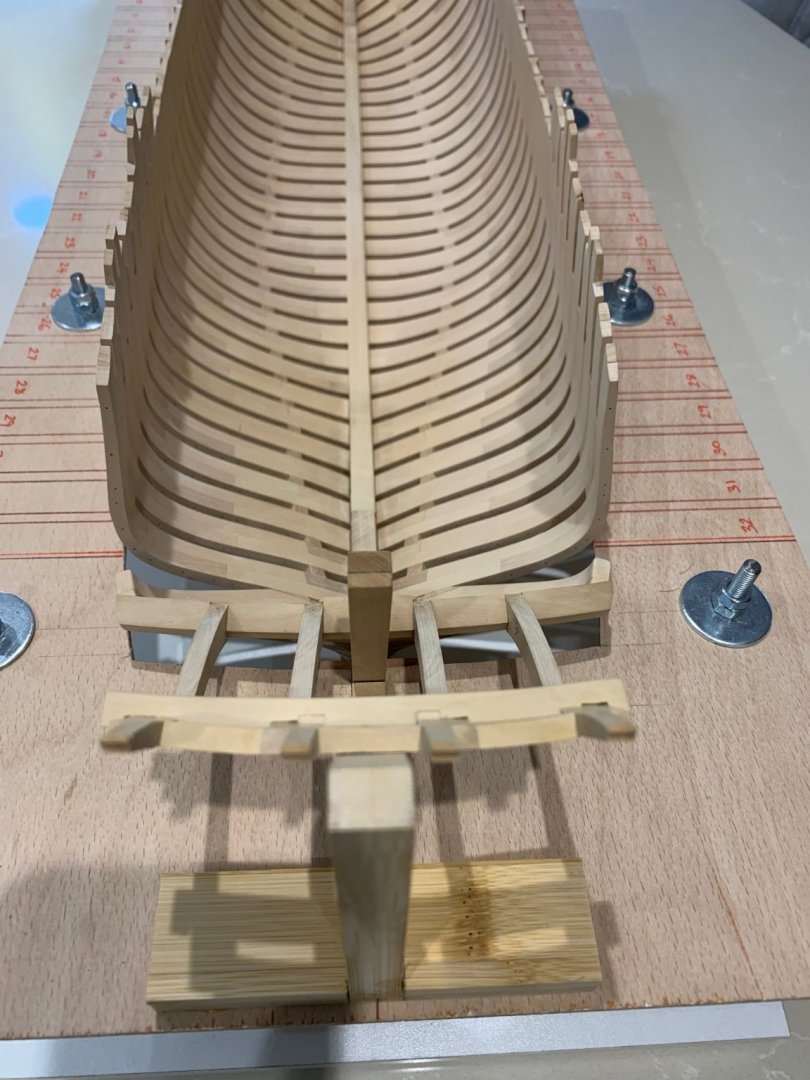

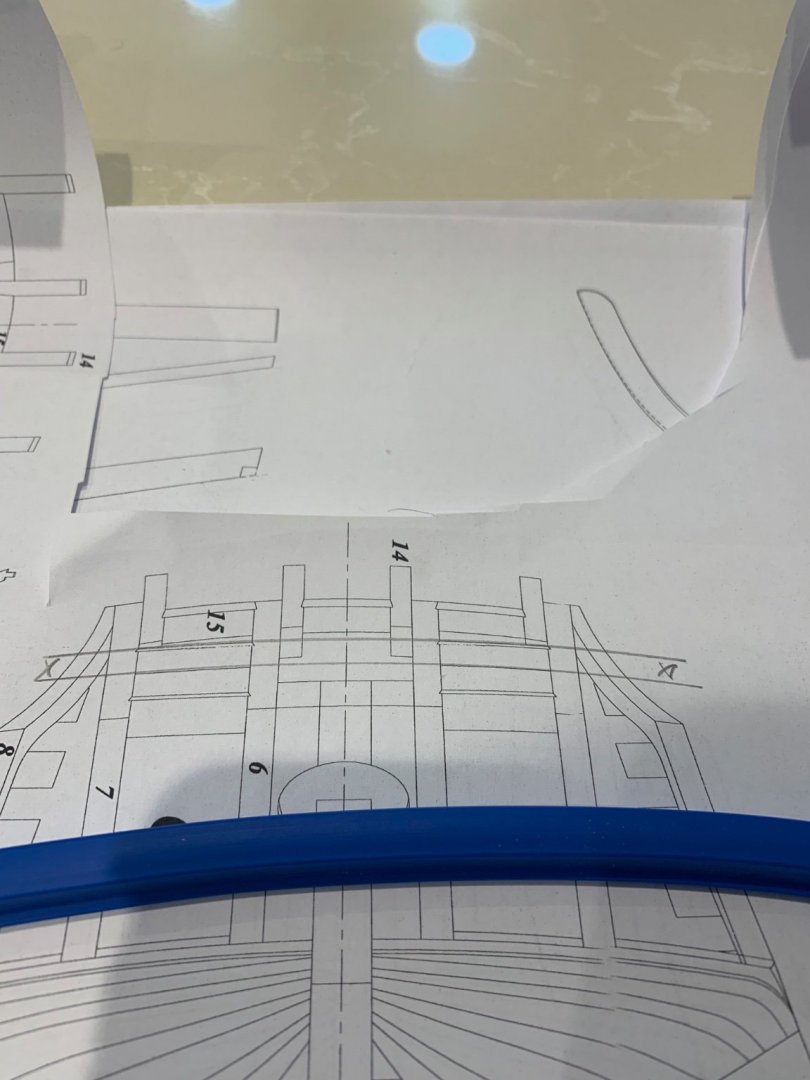

Hi All Some more done and this time it's the port side which just about completes the frame. It went ok as I gained experience on the other side and I'm very pleased the way its very symmetrical. These small frames are not hard to install; they just take a long time making sure that the angles are spot on. I also tied into the quarterdeck beam again and have faired the inside. So its now out of the jig and for the first time I can actually see the shape of the frame - what a moment that was 👍 I can't do any fairing on the outside yet as it still needs some strengthening first but its not that far away. The next job is to make and instal the helm port which will give much more strength to the counter timbers. Its not perfect by any stretch of the imagination - but I'm very happy with the results so far and thanks for all of the comments and likes 🙂 Mark

-

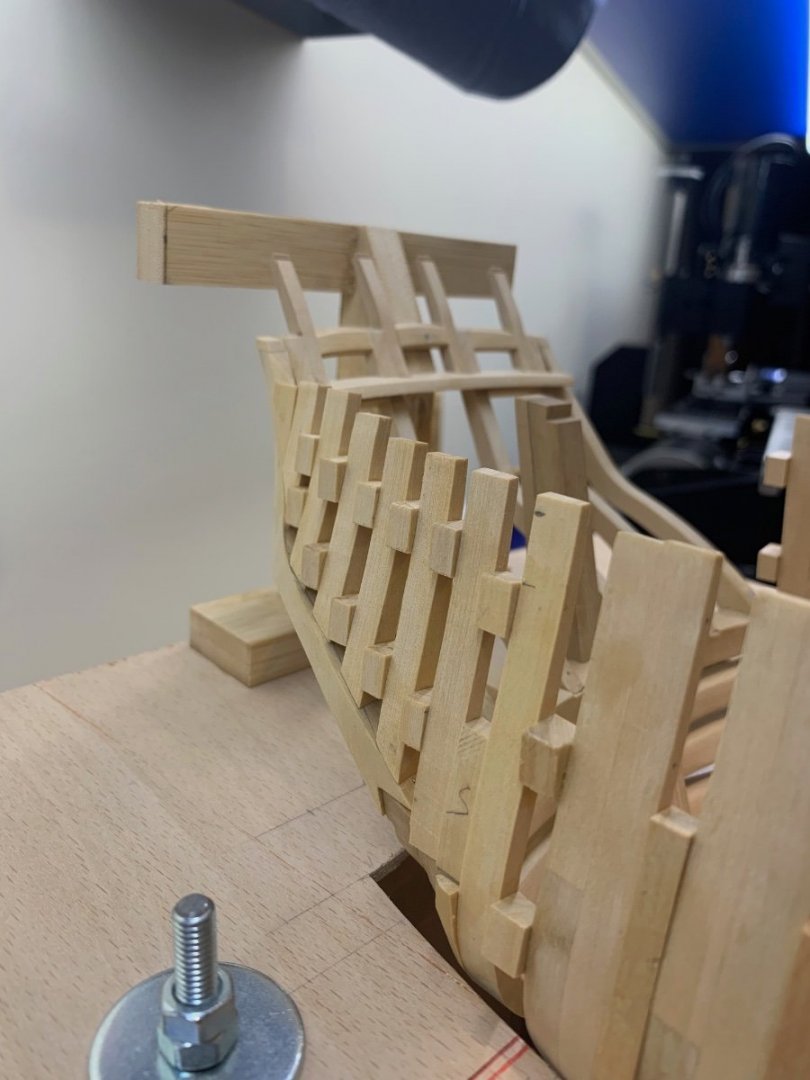

Hi All So far so good regarding the fitting of the small pieces that run up the dogs legs to complete the stern framing. I've now made and installed the starboard side and these are the rough photo's just after gluing. Lots of fairing will be required as I've left these as square posts which I hope that I don't regret later. I've also milled a small recess in the very last filler piece so that I could pick up and support the quarter deck beam. On to the port side now Mark

-

Thanks druxey 👍 Its not a nice thing to catch but I'm well over the worst of it now. As for the chock - cheers for saying that as I realised that I just wasn't going to make a decent part in one piece. I know its not going to be seen when finished but I could say that about 90% of everything thats been made so far. I did what was best for me in the end and I don't think that the frames up the dogs legs are going to be any easier either. I'll just take my time and get them as square and true as possible.

-

Things have been a bit slow for the past week as I've been laid up with Covid - Not the best experience I've ever had but I should be OK again next week. I have though managed to sort out my problem. Why is it that there is always a few places in a build that give the builder a real headache 😂 These 3 pieces on each side have really given me grief to get right and in the end I did have to cheat a bit. The chock/filler piece between the half frame from the fashion piece and the fashion piece extension is supposed to be a solid piece of wood. Having tried about 5/6 ways of making it so that it fitted tightly and failing I decided to make it out of 2 pieces instead. A small give up on my part and the result does look like a patchwork - but its dimensionally correct as far as I have measured and that'll do for me. I just need to sand the starboard side down now to get these parts finished. Thank goodness for that 👍 - Mark

-

Thanks Albert 🙂 As with all builds I've had a bit of a set back today through my own inexperience. I had made the first two half frames which come off of the wing transom and also the angled chocks that secure this assembly even further. It was only when I made the extension top timbers for the fashion pieces did I realise that I had set the first set too far apart from each other. So in essence the stern was too wide at that point. There was no saving it the pieces needed to be removed which I have now done. Its not nice taking a saw to your model but it was wrong so so be it. What I need to do is run something from stem to stern to use as a datum to check that all is well. Lesson learnt and luckily I've got away with it. I'll have another go next weekend 👍

-

tool review Perma-Grit tools

No Idea replied to James H's topic in REVIEWS: Model Shipwrighting Tools, Parts and fittings

I emailed permagrit and asked them to make me some blocks with fine grit on both sides - They did and it was not a problem and I was really happy with what they sent me. Great service!- 17 replies

-

- permagrit

- perma-grit

-

(and 3 more)

Tagged with:

-

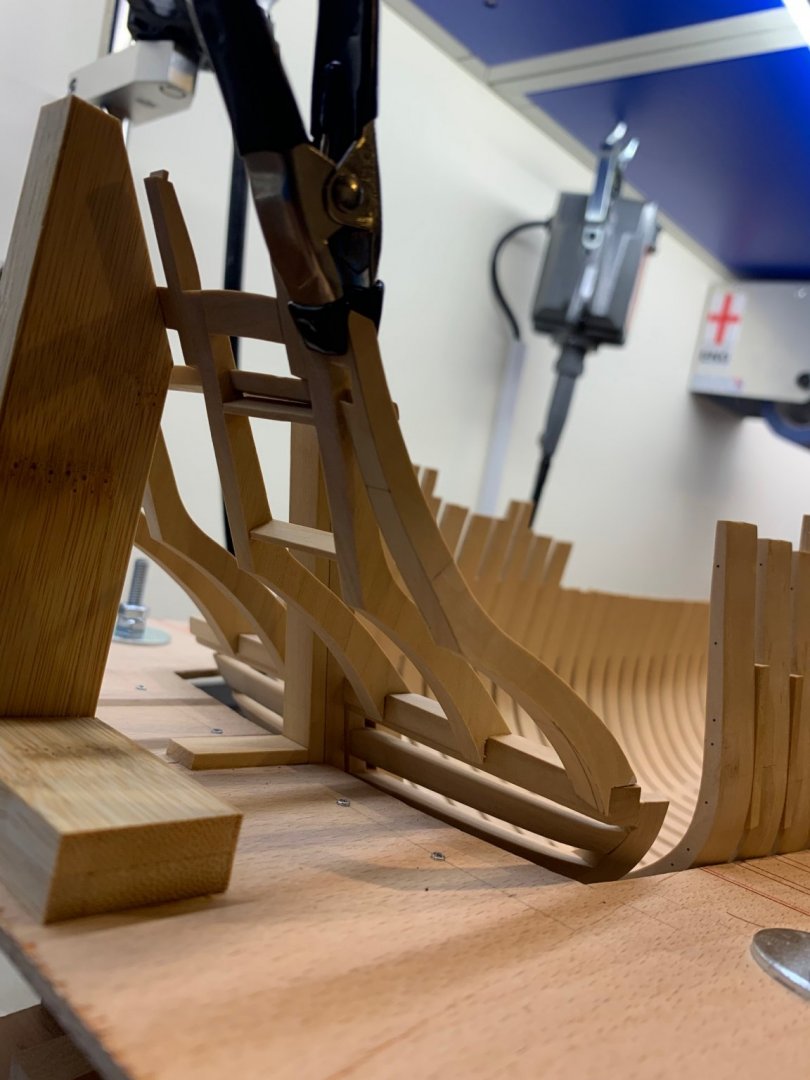

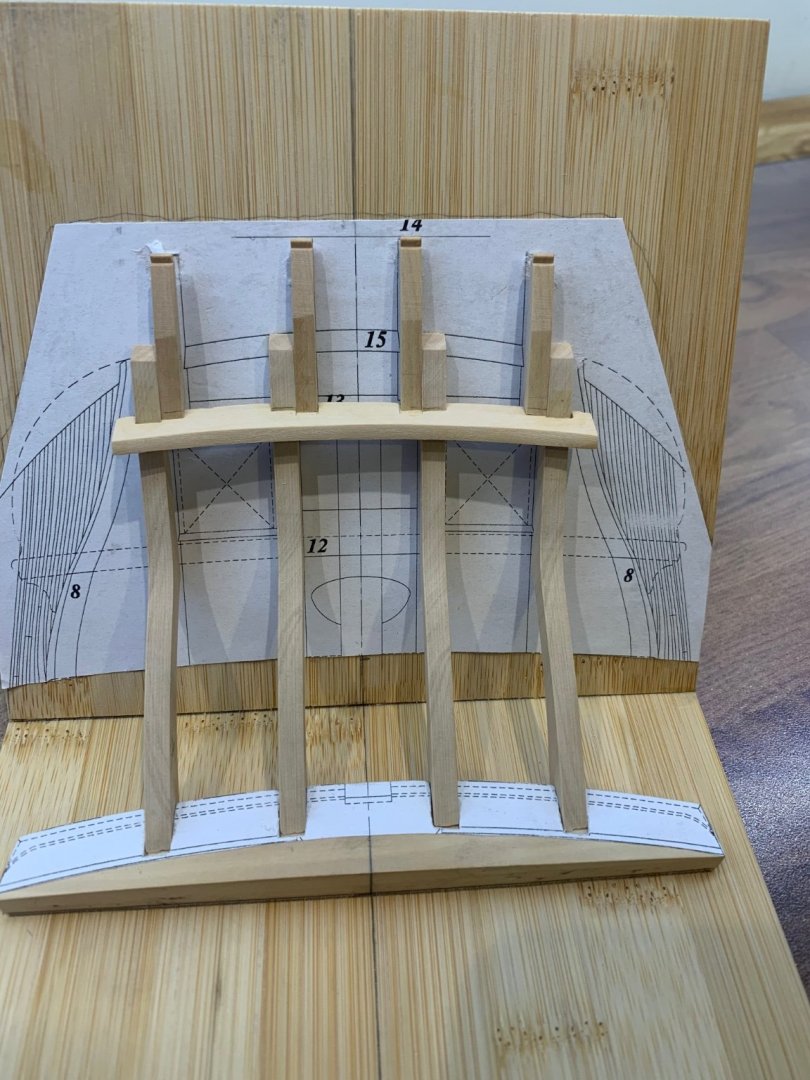

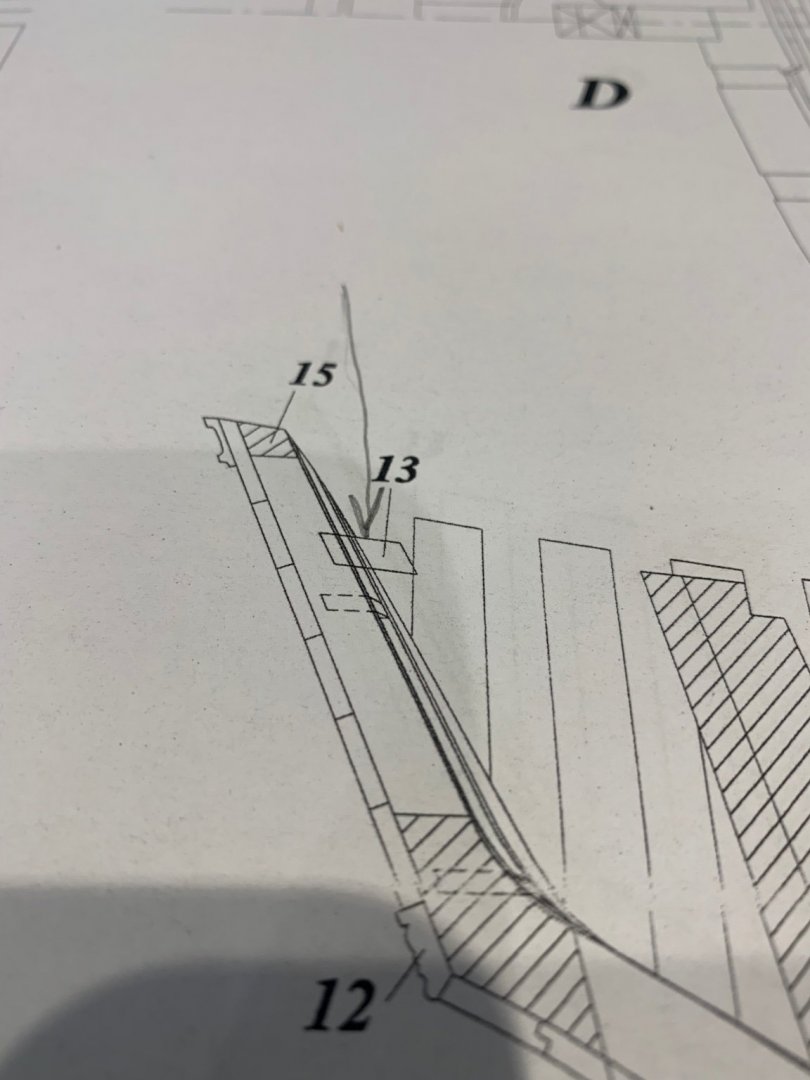

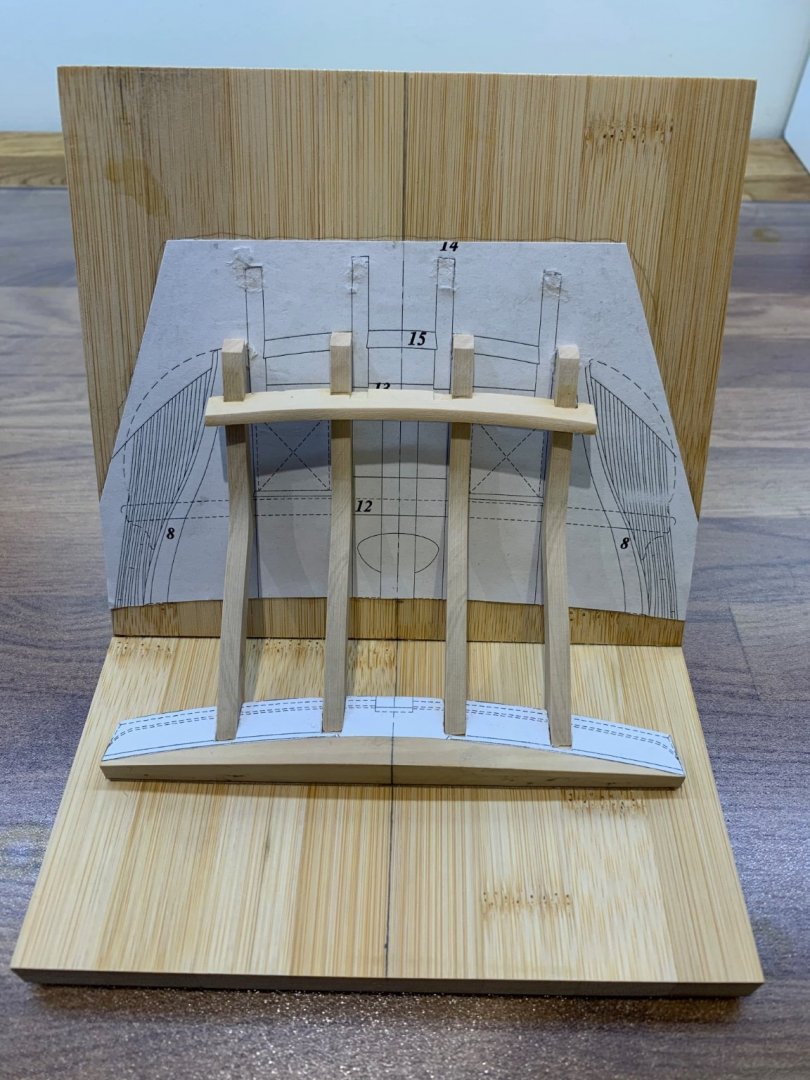

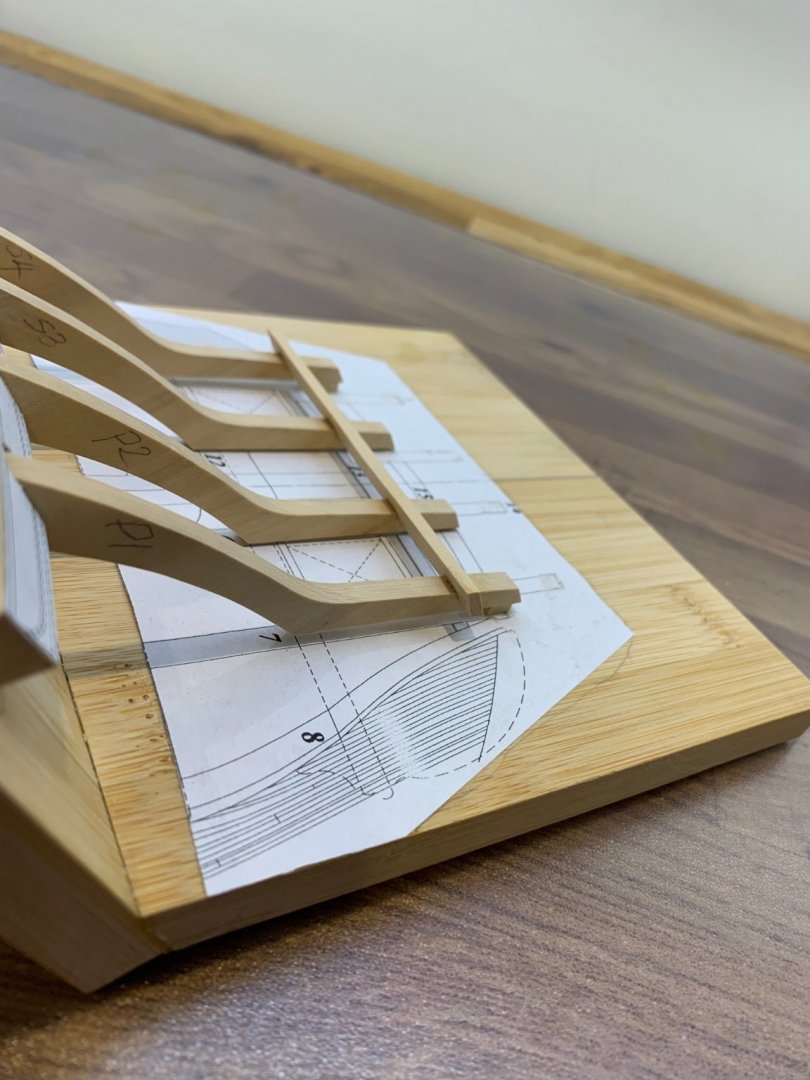

Hi All Moving on from my experiment I've now used the same method to make the actual dogs legs for the ship. The only thing that I did differently was to just take more care marking out their shapes. The practice one was a bit angular whereas the correct shape is more sweeping from the wing transom upwards. As before I cut the birds mouth joints first and then just sense checked them on the model before moving on. They are pinned and glued onto the wing transom and I cut the quarterdeck beam to accept them too. I'll fair them when I get a bit closer with the small frames that now need making as I think that this will give me a better line of sight to get it right. I'm really pleased the way that these have turned out and the stern vault is roughly the correct shape and dimensions too. For other first time POF builders like me I think its worth saying that actually making these parts is not that particularly difficult or time consuming. The tricky part is lifting the drawings onto the wood correctly. Cheers Mark

-

Wow that looks nasty but I'm really glad that you are ok 👍 It doesn't take much to hurt yourself thats for sure. When I was an apprentice we were told that there were two rules when using power tools of any kind 1. Use it only as intended with the utmost respect for own health and safety. 2. Break rule 1 and the tool will do you some serious damage.

-

Sorry I should have said to Riotvan88 - In my opinion all is not lost. You have applied way too much epoxy and have tried using it as a filler and I'm sure that you are aware of this now. So moving forward I would use aluminium oxide paper starting with 120 grit working my way down to 320 grit. This stuff will tear through hardened epoxy so give it a try. I reckon that you have a good 2 or 3 days solid sanding ahead of you so wear a mask. Sanding blocks for this sort of job are not the way to go. You will use lots of paper but so be it. Good luck and the effort will be well worth it - just learn and move on

-

There's nothing wrong with using epoxy on a hull. The Smit Rotterdam is a kit that is also designed with radio control conversion in mind. These boats do get battered a bit whilst being used so epoxy is a favourite with RC builders. I usually use epoxy in combination with fibreglass cloth and it gives a beautifully smooth surface ready for paint. It does need to be applied correctly though as its not a filler its a sealant and gives very good protection. Here's a ship I made a few years ago with one side being epoxied with cloth.

-

Thanks for all of the likes 👍 "Dogs legs" - Wow these are tricky things to make. I've been following Adrian Sorolla's excellent guide and have tried his suggestion on how to form them. He uses a slightly wider piece of wood than the actual counter timbers and basically shapes it slightly diagonally to obtain the dogs legs. Now I've tried this approach and discovered that although it seems quite simple it has two issues that I think can change the shape of the stern slightly. It makes it very difficult to come off of the wing transom vertically as two angles in different planes are required even if coming off straight. More worrying is the way it changes the shape underneath the counter timbers which I believe is called the stern vault. I've made two pieces this way and have found them to be completely unacceptable so I have decided to try a different approach. I have looked at this part square on which requires three timbers being glued together to make a very wide piece to work with. I then transposed the drawings as best I could to get the correct shape which I then cut. The result is actually quite close to what I want. I am now coming off of the transom vertically and the stern vault is keeping its square shape. I have attached a few pictures of my experiment below but I would like to know what others think? Is this a good way of making this part or am I way off base here? The part that is in the pictures is very rough just to try and help me see a way forward with these parts and it is not going on the ship. Any comments or advice would be very welcome and I hope you all have a great Xmas.

-

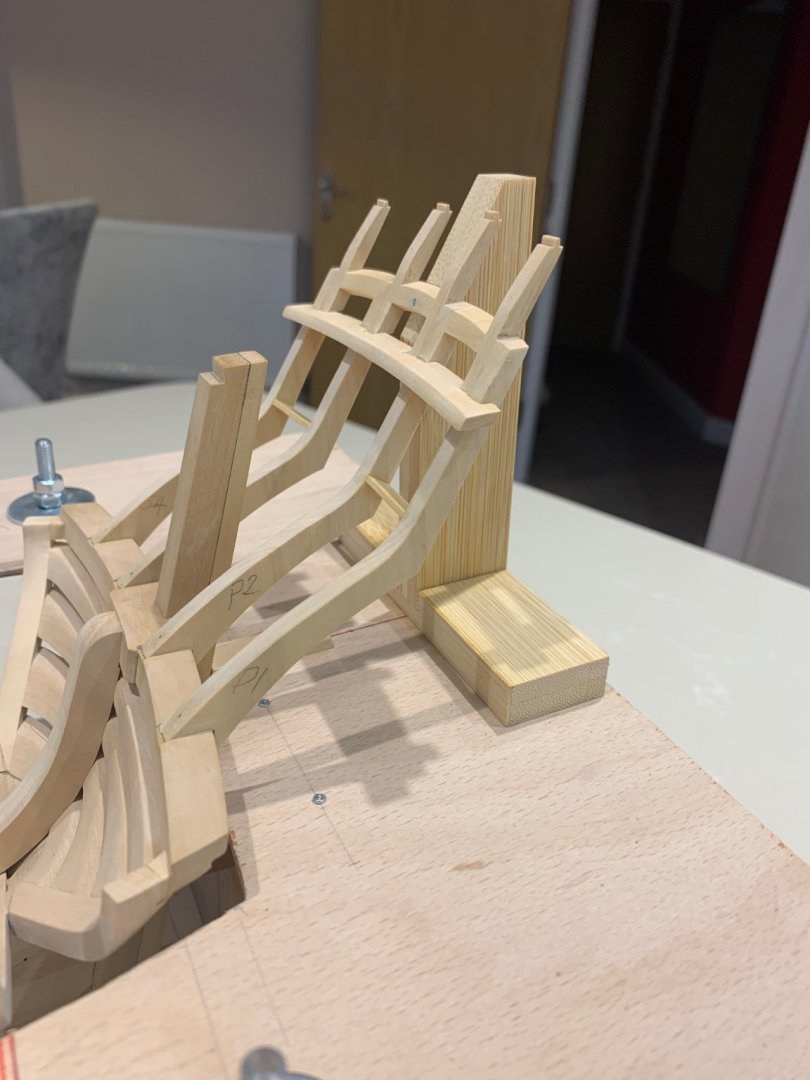

Hi All I've now made the taffrail filler pieces and also the window surround timbers which has made the counter timbers strong enough to remove them from the jig 👍 The counter timbers are now fixed onto the wing transom and are supported to keep the correct angle and hopefully protect them a bit too. I pinned them using some 0.5mm brass as I didn't want them to move whilst the glue dried. I set the angle by taking a measurement from the stem all the way back to the furthest point on the taffrail filler. The only thing that went wrong was the screw head on the support decided to shear off - so I'll have to cut the support away at some point and try and remove the screw from behind. Its on and square so I'm a very happy builder 😃 Now for my next challenge - the dogs legs! Happy Xmas everyone 🎄

-

NAIAD 1797 by Bitao - 1:60

No Idea replied to Bitao's topic in - Build logs for subjects built 1751 - 1800

Once again just beautiful work by you that is so crisp and clean - Happy Xmas bitao 🎄 -

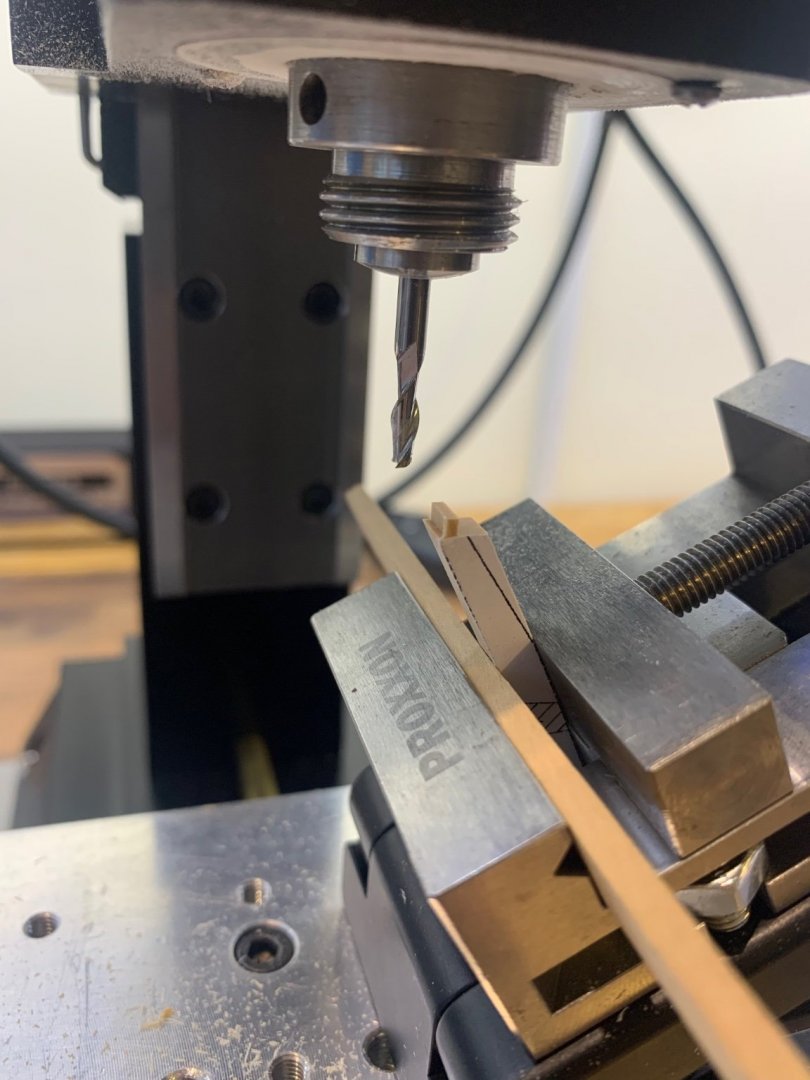

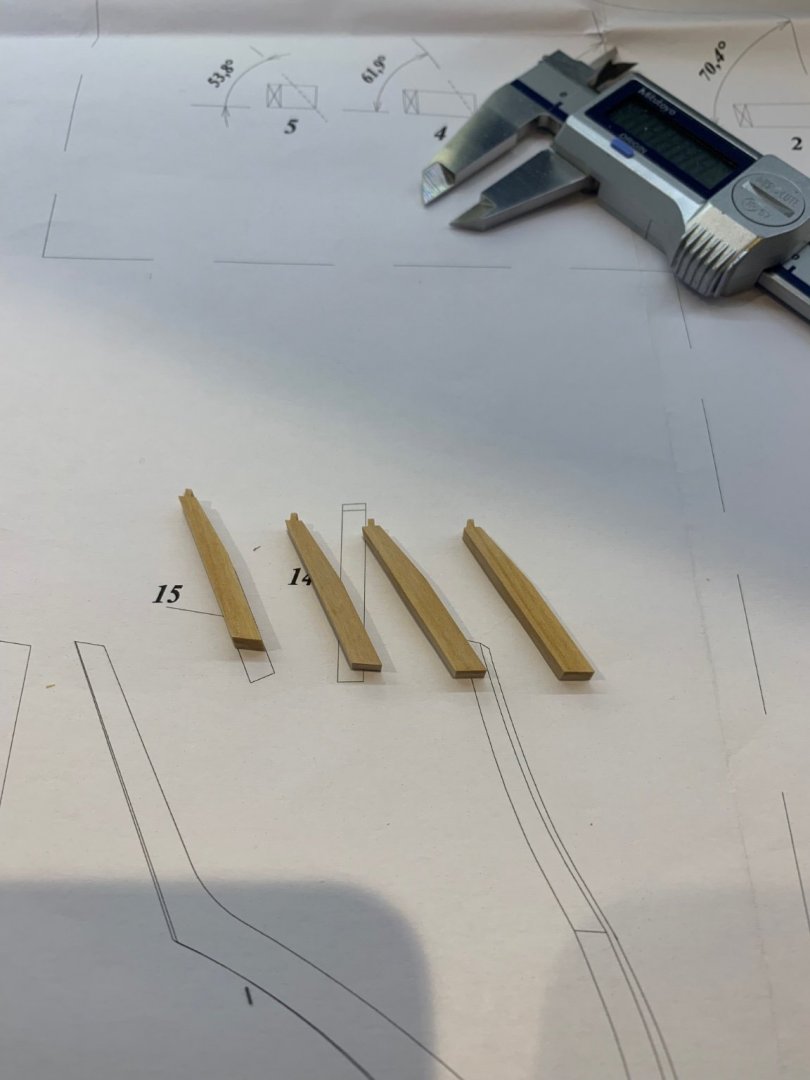

I've had a little more time in the shop today and I've now made the counter timber extensions that run up to the taffrail. They have nice little tenons on the top and were quite easy to make. It was just a case of making sure that I followed all of the existing angles to the counter timbers and beam so that they sat correctly. I give them a 50/50 chance of surviving until the end of the build as they will be pretty vulnerable as the build progresses. So if I have to make them again it's not a problem. I now need to make the parts in-between and the window frames which hopefully I will find some time this week. Thanks for all of the comments and likes too 🙂 Mark

-

HMS VICTORY 1765 by albert - 1/48

No Idea replied to albert's topic in - Build logs for subjects built 1751 - 1800

That really is beautiful joinery Albert -

Mark and bitao thanks for the comments 👍 It is a very tricky piece to make correctly and I think that it’s ok. I’m hoping that I’ve read the drawing correctly and that the dog legs butt up against the beam. If they do then all’s good - if not I’ve probably made it a little short. I’ll soon find out 🤣

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.