-

Posts

1,025 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by No Idea

-

Hi Slowhand - for the parts that you have listed to make; both the mill and table saw would be a good investment. However you could make all of those parts on a mill but that comes with experience. So to answer your question - If budget is not an issue I would buy a Byrnes table saw and a Proxxon micro mill as this would make the process more precise and quicker. They are both quite small but also both extremely capable, so after a purchase you just need to practice your art. There are many YouTube videos to watch but if you have no experience of machinery you're local collage generally does classes. Seriously you only have one set of fingers and both of these machines would remove them in a heart beat. I have both machines and treat them with the utmost respect and I was tool room trained as an apprentice. So great machines but do your homework and get some help if you have never used machines like this. Also there is no comparison between a scroll saw and a table saw. There is far more comparison between a scroll saw and a band saw but again not entirely. Scroll saws and Band saws are for shaping wood into shapes. Well as far as simple modelling work goes anyway taking out of the equation roughing out large pieces of timber. Table saws are for precise straight cuts and rebates etc Mills make precise cuts in already precisely cut wood unless you have a big mill which most people do not. Confusing I know but there is not one tool that is better than another. They all do very different tasks in my opinion for what its worth

-

Hull Planking Question

No Idea replied to tomsimon's topic in Building, Framing, Planking and plating a ships hull and deck

You know..... we built lovely model ships and conversations like this make me wonder why people join forums - They must read this and think I’m not getting involved in that. I wonder how long my forum ban is going to be for that then -

Great post - I too use my use my thickness sander a lot. As an example I've just used it today to to sand 4 x 450mm long planks that are 140mm wide down from 8.5mm thick to exactly 7.9mm thick. Thats a lot of wood to run through a small machine but it did it great which is a nod to its amazing design and quality build. I too have the same problems to over come and the biggest problem by far is the outfeed is too short for me. I over come this by clamping the piece using my thumb to the outfeed side but its far from perfect. I've resigned myself to loosing the last 10 - 15mm of each piece as it always tips up towards the sanding drum no matter what I do. If someone could produce an extension I would buy it in a heart beat as this would definitely improve my sander. Another thing I've found is that sometimes I feed the piece in and due to my lack of concentration it sometimes turns a bit. An adjustable guide would be great but all of these things add a cost to what is such a fantastic machine for our hobby. Its a lovely bit of kit and I'd be lost without it

-

Hull Planking Question

No Idea replied to tomsimon's topic in Building, Framing, Planking and plating a ships hull and deck

Hi tomsimon - Your question is one that I wondered when I first started building and for me it came back to one thing - time! If your in no rush and are happy to take your time then carpenters glue or better aliphatic resin is my choice. It gives me loads of time to place whatever I'm gluing where I want it and the clean up is so easy. It is for me the laid back enjoyable way of building. If however you need to build somewhat faster, then CA can be dropped between the carpenters glue to grab what your gluing much faster. I find this method very unforgiving but thats just my way of building - others find this way better. Try both and you'll find what suits your building technique -

Hi Everyone Making joint lines stand out seems to be quite a personal thing the way that they are achieved. Some builders use card and some pencil to name only two methods. My question though is which joints should be highlighted. Should it be just the keel parts or is it again personal choice? For example should the joints on the frames be highlighted or is this going to far? Whats people’s thoughts on this as I’m just starting a new build and would like to know your thoughts Thanks Mark

-

tilt arbor table saw

No Idea replied to Anthony Hearne's topic in Modeling tools and Workshop Equipment

Yes that’s right and why you also use the larger diameter blade too. Jim recommends a certain blade on the website. It’s never going to be as easy as have a tilting arbour saw but why have another saw just for that purpose. It does take practice but doesn’t everything -

tilt arbor table saw

No Idea replied to Anthony Hearne's topic in Modeling tools and Workshop Equipment

Hi Anthony - there is a fence fitted to the tilting table which I always use. Small stock I have found does not have to touch the bed as the tilting table is now the new bed. It’s hard to explain but once you’ve had a good play it all comes together. I’m sorry that I cannot be more descriptive -

tilt arbor table saw

No Idea replied to Anthony Hearne's topic in Modeling tools and Workshop Equipment

I’ve got the tilting table and I find it easy to use. The reason is I actually use it and like any tool the more you use it the easier it becomes. It was a bit awkward at first but so was my first block plane. Once mastered it’s a great bit of kit and I do not regret my purchase at all. I’m just waiting on Jim to contact me so that I can upgrade the table to the larger size. -

Cheers Bruce - This is what I use here's a pack of 3 for £7.99 https://www.amazon.co.uk/Sakura-Pigma-Graphic-Pigment-Calligraphy/dp/B01M24ONH8/ref=sr_1_16?dchild=1&keywords=3mm+chisel+tip+archival+ink+pen&qid=1606586152&sr=8-16 Have a play first but I have found that my best results are by using it on both planks that meet. Good luck!

-

In my experience the best cut off switch is my wife - when she comes into my workshop and tells me enough is enough and dinners ready Always works for me!

-

Hi All Not my sale but I found this today if it helps any builders on here. I use mine quite a lot its a great little tool. https://www.ebay.co.uk/itm/Aeropiccola-Electric-Plank-Bender/324371420787?_trkparms=aid%3D111001%26algo%3DREC.SEED%26ao%3D1%26asc%3D225076%26meid%3D9afe999851414b62ae580618277f14b5%26pid%3D100675%26rk%3D2%26rkt%3D15%26mehot%3Dnone%26sd%3D293634870779%26itm%3D324371420787%26pmt%3D0%26noa%3D1%26pg%3D2380057&_trksid=p2380057.c100675.m4236&_trkparms=pageci%3A4cfe2134-2689-11eb-8ac4-7aadce336392|parentrq%3Ac74023d21750a4d361e9136bfffa690c|iid%3A1 Mark

-

Glue for Templates UK

No Idea replied to No Idea's topic in Building, Framing, Planking and plating a ships hull and deck

Thats great thanks very much for your help - I'm off to buy a glue stick and get going on this build -

Glue for Templates UK

No Idea replied to No Idea's topic in Building, Framing, Planking and plating a ships hull and deck

Hi Per thanks for the reply - do you use something like this Pritt stick? https://www.amazon.co.uk/Pritt-Original-Childproof-washable-cardboard/dp/B004QFI99Y -

Hi All Could someone please recommend a good glue that I can purchase in the UK for fixing my paper templates to the wood for cutting out and shaping? I would imagine that the templates will be in place for quite a while but I don't want to do damage to the wood underneath when I remove them. Thanks for you help Mark

-

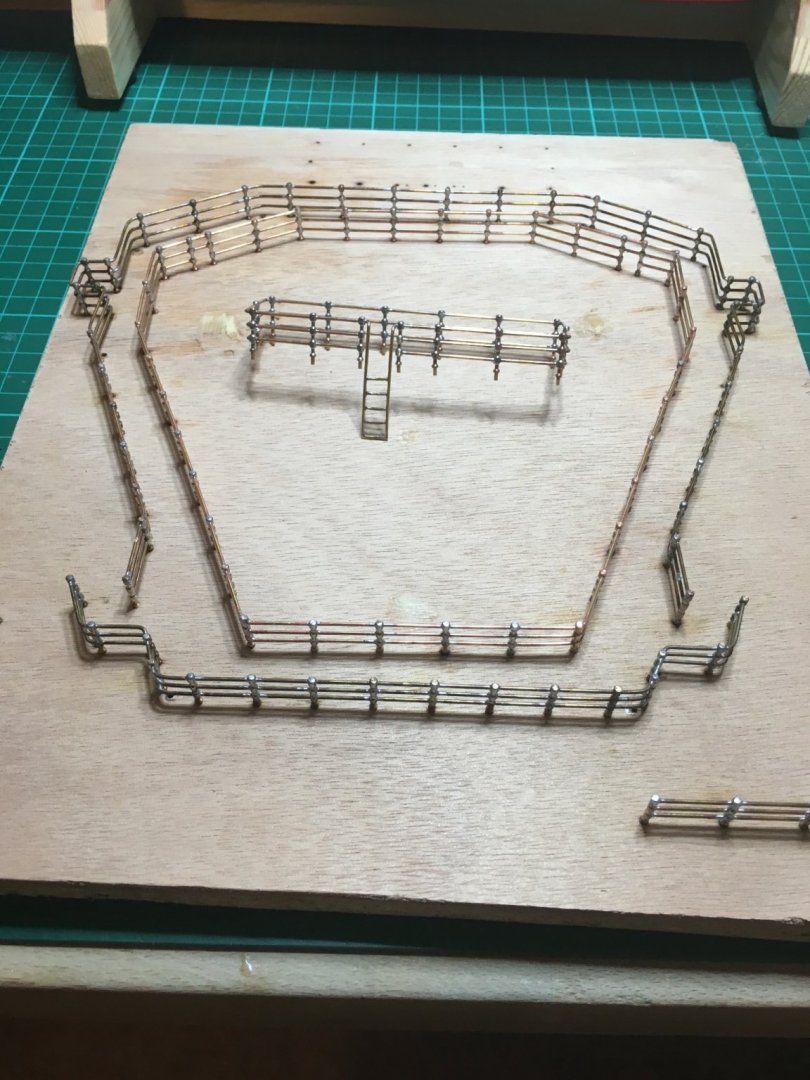

Hi George - The build looks great. For stantions I used billings own 3 hole brass ones that can be purchased from Cornwall Model Boats if that helps. Here's a link to nearly 700 photo's of my build just in case it helps you. https://modelboatmayhemimages.co.uk/album/bXv Mark

- 90 replies

-

- fairmount alpine

- billing boats

-

(and 1 more)

Tagged with:

-

WOW ......................WOW............Your work is just beautiful. I just find this build so inspiring - fantastic work.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

I helped a friend who was struggling using silver solder. His problem turned out to be he was cleaning the joints using sand paper which was contaminating the joint. A quick swap to wire wool and the problem was solved.

-

Hi Bob I have to say that I've used the miniature block plane to finish off just about all of the planks on my current build. I use this and a Lie Nielson violin makers plane and although the latter can remove more in one pass I would say that they are equal in capability on my builds. It's a great little plane that genuinely does the job in both removing excess material and cutting bevels. I have sharpened it twice in 3 years and it hasn't let me down or shown any signs of wear either Mark

-

Hi James if you don't use these suppliers give them a try. I've just had 8 planks for Castello delivered for a very reasonable price - and they cut them to the thickness that I wanted rather than what was advertised on their website. They also ran them all through a jointer for me so that I have good edges for my table saw at no extra cost. I agree that actually the ebony you get is a good price - but it would take me two lifetimes to use that much of it so that makes it prohibitive for me.

-

My wood suppler sells ebony https://shop.exotichardwoods.co.uk/african-black-ebony-sawn-board-no-5.html £200 for one small plank of it. The dust from ebony is also quite toxic too. If I was in a club where 3 or 4 of us needed some it would be worth it but not for me at this price. I'll leave it to the guitar builders as lovely as it is. I too would either dye or paint the wood.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.