-

Posts

13,375 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Frégate d'18 par Sané , la Cornélie

druxey replied to JohnE's topic in CAD and 3D Modelling/Drafting Plans with Software

I'm sure that every captain adjusted mast rake to suit himself and get the best out of his rig. -

Hey, if it works.... It doesn't have to look beautiful as well! Your home made line looks very nice. I assume you intended to make it left hand lay.

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

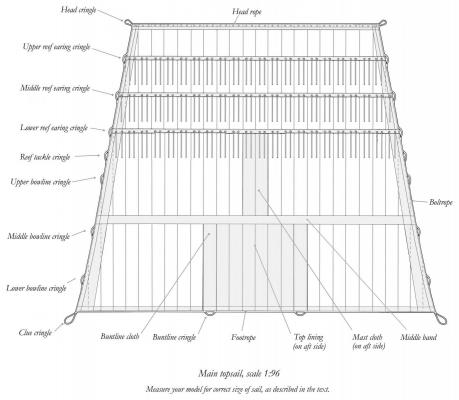

Here is a copy of an illustration from Steel of 1794, showing two reef points in every cloth. However, artistic license (and polys) may take precedence!

-

Beautifully rendered, Magnus. You'll hate me for pointing this out, but there were actually two reef points per cloth on topsails as well as the courses! We'll allow for artistic license here, won't we?

-

The crosspiece is placed low so that you could pass a line under it and haul it up tight on the other side. It gives one a good angle of pull. Over the years I've discovered that nothing on a ship was placed by accident: it's all part of a well thought out or well developed design.

-

Adroitly done, Ed. A nice piece of machining ratchets.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Echo by Maury S - FINISHED - Cross-Section

druxey replied to Maury S's topic in - Build logs for subjects built 1751 - 1800

It's a satisfying moment to cap the timbers, isn't it? Nice finish on your plank sheer rail!- 324 replies

-

Nice drawings! I suppose to prove the workability of this arrangement you could run the complete engine mechanism on compressed air.

-

I love the shape of this vessel now it's developed. It's always nice to see something a little different modelled, so thanks for sharing this with us, Clare.

- 51 replies

-

- wasen

- thermal studio

-

(and 1 more)

Tagged with:

-

And Brunel's machinery still works after 200 years! It's a fascinating story about the beginnings of industrial mass-production.

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

One could always model engineer Brunel's blockmaking machinery at Portsmouth and mass-produce blocks that way....

- 728 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

Heartwarming. Thanks for sharing that moment, Dave.

- 209 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That is a terrific method for turning small items like spokes, Remo. Deflection at those sizes is always an issue.

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Beautiful result, Remo! That is a wheel to be proud of.

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

I agree that one should avoid WW lathes that are other than 8mm or 10mm. Boley and Levin are both top-notch machines. However, I found that the Levin with its collet-holding tailstock is more practical. (A Boley with collet-holding tailstock rather than a runner is very hard to find.) And, as wefalk suggests, the D-bed rather than the 'Reform' style lathe is preferable. For motor mounts, there are cast aluminum stands by Borel that hold both lathe and motor. All these items may be found on eBay. Remember to budget for a nice chuck and/or collets!

-

More Masking Tape Questions

druxey replied to mikiek's topic in Painting, finishing and weathering products and techniques

Mikeik - so much of model making is strategic! One learns to think far ahead, as in a chess game. -

More Masking Tape Questions

druxey replied to mikiek's topic in Painting, finishing and weathering products and techniques

One way to avoid such masking issues would be to not add the strips (I assume these are moldings) until after you've painted the dark green planking. Prepaint the red strips before installing them. That way you don't have to worry about masking at all! -

It's far easier to start with a square sectioned spar, then cut it octagonal, finally rounding off the areas where the spar is circular in section. That's the way real masts and spars are made, not turned. To mark out the four square to make it an octagon, each side is marked across 7-10-7 proportionately. That is to say, each face is divided across into 24 parts and lines set off 7 parts in from the edges. Place the four-square stick in a 45 degree holder or jig and plane or chisel down to the marked lines. From there it is easy to round off from octagonal. (In the shipyard, the mast was planed 16-sided first, then rounded, but for model work this step can be skipped.)

-

Tool for Sanding Inside of Curved Pieces

druxey replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

I believe that Jim is working on a spindle sander. I hope that he is!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.