-

Posts

13,288 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Cutting brass sheet

druxey replied to Landlocked123's topic in Metal Work, Soldering and Metal Fittings

Have you annealed the brass before attempting to cut it? -

Possible new technique for making sails.

druxey replied to rckdr's topic in Masting, rigging and sails

With due respect to the model sailmakers out there: any stitching at scales under about 1:6 looks way over-size, as Wefalck has said. -

Seeking information on determining load waterline

druxey replied to trippwj's topic in Nautical/Naval History

Ah, type yclept Gothic blackletter. Haue fun! -

Clamps for deck to frame

druxey replied to zamboknee's topic in Building, Framing, Planking and plating a ships hull and deck

If you are going to use the existing piece, wet it thoroughly on top before gluing and adding rubber bands. -

Sweet lines, vaddoc. She looks lovely so far. Well done.

- 253 replies

-

- ketkch

- gaff-rigged

-

(and 1 more)

Tagged with:

-

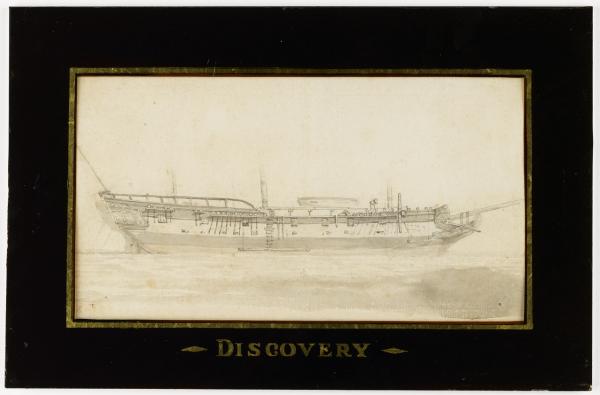

If you are referring to the Vancouver expedition, Discovery was as depicted here (From the RMG collection). She was similar to a naval sixth rate, but with a merchant ship body. (The cross-section would have been fuller and the bow much bluffer.) If you aren't too fussy, I suppose a kit of Fly, a Swan class ship might be adapted to resemble her. (For those interested, the drawing shows ventilation scuttles on the lower deck: a detail usually omitted from official draughts.)

-

ancre LE BONHOMME RICHARD by Jeronimo - FINISHED

druxey replied to Jeronimo's topic in - Build logs for subjects built 1751 - 1800

Very impressive! Congratulations, Karl.- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

Princess royal 1780's British merchant ship

druxey replied to Jparsley's topic in Nautical/Naval History

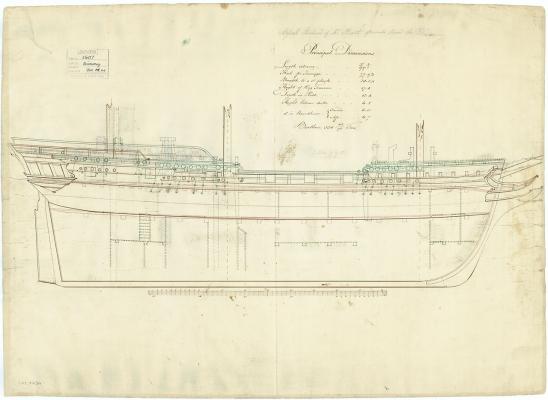

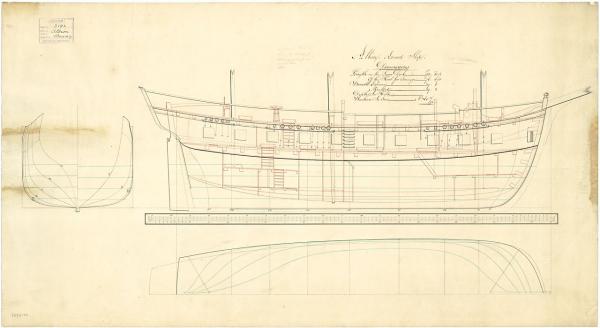

That information is much more helpful! Illustrated below is very much like what her appearance would have been. The plan shows a slightly later and larger ship, after conversion in the navy. Take away all those gun ports and the barricades along the upper deck, replacing them with open rails, and you will have a pretty good idea of what your Princess Royal looked like. (This drawing is from the Royal Museums Greenwich collection, reproduced under the Creative Commons licence.) -

Seeking information on determining load waterline

druxey replied to trippwj's topic in Nautical/Naval History

Hi, Wayne. I was actually given a copy of this Occasional Publication No. 6 last month by a fellow modelmaker. He was dispersing the contents of a deceased model maker's workshop and knew I had an interest in "that early stuff". I'd never come across a copy before and was working my way through the text yesterday. -

I see that no-one has replied to your query in over a month, Holleia. The probable reason is that these weekly publication models were begun by many, but most (if not all) subscribers dropped out after a short while. I doubt if anyone lasted the whole 100 weeks and, if they did, they probably wanted to keep the completed model.

-

Princess royal 1780's British merchant ship

druxey replied to Jparsley's topic in Nautical/Naval History

A little more information would be helpful. Have you any idea of her size or tonnage, for instance? -

Seeking information on determining load waterline

druxey replied to trippwj's topic in Nautical/Naval History

This comes a little late to the table, but I have just come cross a description in A Treatise of Shipbuilding, circa 1620-25, as reprinted, edited and annotated by W. Salisbury and R.C. Anderson (Society for Nautical Research Occasional Publications No. 6, London 1958). It reads as follows (pages 26-27): The next thing to be drawn in this plane of length and depth is the swimming line, which is a principal thing to be regarded for the good qualities of the ship. From that line are set off the decks and ports for the ordnance, higher or lower as we will have them lie to pass; therefore of right there should be marks made on the ship's side to direct the mariner always to keep her in that trim, neither to sink her deeper nor let her swim shoaler. The depth of this line is taken off the midship bend, for where the two upper sweeps intersect each other with respect to the thickness of the plank (which intersection is easily found by drawing a straight line through the centres of the upper sweep and futtock sweep), from thence to the ground line is the true depth of the swimming line. Which depth being marked upon the midship line and upon each perpendicular of the upper rising, draw a straight line from stem to stern. So you have the swimming line desired. -

Yes, those timbers are very vulnerable to damage. Like Greg, I've also experienced the snapping sound that one doesn't want to hear!

- 889 replies

-

Looks like a good strategy, Ben. Those cant frames look lovely.

- 889 replies

-

At what point of modifications would a kit become "Kit Bashed"

druxey replied to thomaslambo's topic in Wood ship model kits

This thread seems to have generated a lot of interest and comment. Let me see if I've got it right: Kit - built straight out of a box using the manufacturer's instructions (if you can understand them!) Modified kit - as above, but with additional details that have been purchased, such as photo-etched sheets, rope or blocks. Kit-bashed - one or more kits that have been cobbled together to represent a different subject than the kit(s) Semi-scratch - from based on a kit, but heavily modified using parts made by the builder, to builder fabricated with some commercial parts Scratch - completely fabricated from raw materials by the builder, no commercial parts Museum quality - an over-used and hence now meaningless term (Yeah, I'm sticking my neck out on this one!) The 'semi-scratch' definition seems to be the broadest, if my summary is correct. Should there be sub-sets in this category? -

Design by Modelling

druxey replied to Hellmut1956's topic in CAD and 3D Modelling/Drafting Plans with Software

I'm not that familiar with the physics involved, Hellmut, but the frictional forces in a sheave will surely vary. The factors to be considered are: 1) friction between the sheave and its pin 2) the angle at which the line enters and leaves the sheave (i.e. how much contact surface there is between them) 3) the diameter of the line and the groove in the sheave (surface area of contact) 4) the coefficient of friction between the two elements 5) diameter of the sheave There maybe other factors that I've overlooked. Of course, multiple sheaves will complicate things even more.... Perhaps this can all be reduced to a vector diagram. Mit grusse -

18th and early 19th Century cutter models

druxey replied to tkay11's topic in Nautical/Naval History

Thanks so much for sharing these photos of your expedition to Chatham, Tony. The folk there are great if they know you are a serious student.- 42 replies

-

- Cutter

- 18th Century

- (and 4 more)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.