-

Posts

26,273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

Les, Soak them in acetone. Depending on how long the CA has cured and how much, it may take awhile.

-

Steve, That's lovely bit of work for the spotlight. The control is very realistic.

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Correction.. not "cheat"... adapt, improvise, overcome.

- 473 replies

-

- greek bireme

- dusek

-

(and 1 more)

Tagged with:

-

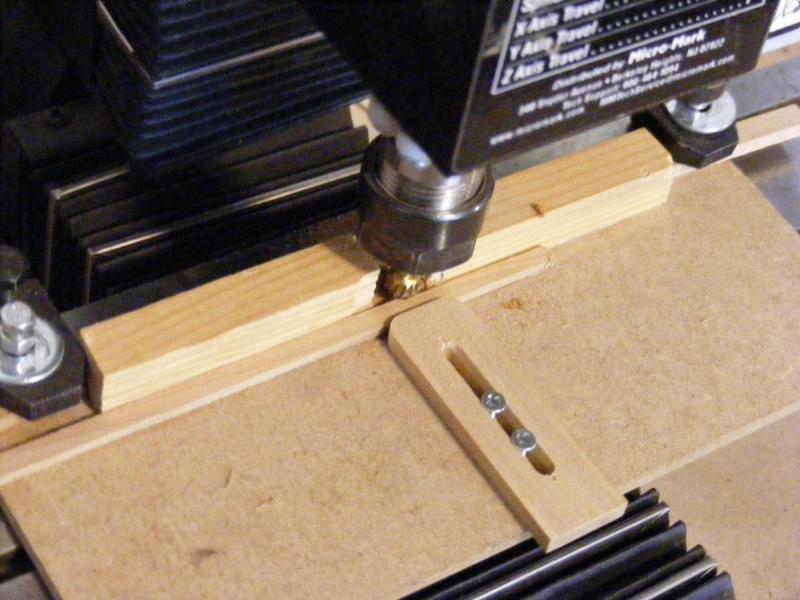

Patrick, I used a ball mill and the mill with my fixture for doing profiles. I think I posted this once before but here it is again. Hi Vivian, Thanks for the comment and it's great to see you back. I hope you can get back to your models.

-

Minor update to show that all is not folly and folderol... The waterways are completely in and the beams marked with the centerline, the carling locations for hatches and mast partners, and also for the line where the center thick stuff will end and the normal deck planking begins. (See the first photo). I also ran a test using cutoffs from the beams, I made a "fixture" for lack of a better word. I cut some 1/8" cherry and tacked it to the beams to see if there's any issues using the laser to cut the planking. Nope... even leaves a nice black line for the caulking (see the last two photos) and with care, I should have some better planking than if I tried to sand/plane in the taper, etc. . Also there's a bit of waterway to show the profile. Tomorrow (or however long it takes) will be devoted to cutting and fitting the carlings.

-

So I'm taking it that it was either shipyard preference or whatever the rigger felt like that week? I think you have and had your work cut out for you, Chuck.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Fascinating build, Greg. I didn't realize that the Yamato had a hanger deck.. almost an aircraft carrier in addition to being a battleship.

-

I had to go back a few pages to see what you meant. Oh... blue air time in my neck of the woods. But it's a great recovery you're making and the stack looks great. To steal David's line and add to it.. a Master Brasssmith your are.

-

Uniforms of the Royal Navy and Marines circa 1724?

mtaylor replied to timboat's topic in Nautical/Naval History

There's a book of contemporary paintings.. Fighting Ships by Sam Willis that contains many deck scenes with Marines and sailors. I've seen a few sites such as: http://www.royalnavy.mod.uk/news-and-latest-activity/news/2014/october/20/141020-royal-marines-uniforms and this: https://www.google.com/search?q=royal+navy+uniform+history&biw=1374&bih=746&tbm=isch&tbo=u&source=univ&sa=X&sqi=2&ved=0ahUKEwjW6L3kz93PAhUJ1CYKHTREBAoQsAQIOAshould lead you in the right direction. -

ancre La Salamandre by tadheus - 1:24

mtaylor replied to tadheus's topic in - Build logs for subjects built 1751 - 1800

I'm just following along in awe of your ship, Pawel. Just beautiful. -

The hull is coming out very well, Charlie. I'm impressed. The fan blowing out the window is a great idea as long as the neighbors don't object. And it's probably a lot quieter than shop vac. Good on you for the face mask.

- 362 replies

-

- active

- revenue cutter

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

mtaylor replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Nenad, I think what you're calling an awning is just a canvas cover over the hatch which would have been normal for the ship at sea. I've seen these in some pictures and in other pictures, it's just the plain wood slats. The hatches were for access to the cargo area and so had to be protected. On ships with grates, those were to provide light and fresh air to the crew working on the lower deck. You might ask this in the Deck Furniture area if no one else answers.- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Indeed Bill, it's my laser cutter. Greg the peg leg sailor (If my brain remembers correctly) started calling it the Deathstar and the name has stuck. Edit: Yes, it was Greg after I speculated that maybe I could build a death star after upgrading the tube...

-

Thanks for looking in, the comments and the "likes". As this is being written, waterways are going in and the center deck, carlings for the hatchways, and the center thickstuff areas are being marked out. Still thinking of pre-cutting the planking on the Deathstar instead of shaping each plank by hand. Micheal, I want her out, but have very mixed feelings with a fear that I'll break something while still working on the hull. I think I need to suck it up and do it after this deck. Bill, It's a pretty tight fit but it's also glued with PVA into the frame. I'll be following Hahn's lead on this and cutting the frames as close to the line of the top rails as possible and then sanding, filing, making a mess, etc. as needed. I'm thinking it's easier to cut it free than try to undo 120 frame joints (60 frames times 2 futtocks holding it in place) using isopropyl.

-

Mike, I'd solder the loops. There's nothing more frustrating (well.. there probably is....) than to have some bit of rigging come flying off due to pulling too taut, bumping it, etc.

-

Thanks everyone. Sam, she'll come off probably after this deck is done. I fear waiting until the forecastle and quarter deck are done will risk some damage. I have a work cradle designed but not built. Having said that... there's really nothing stopping me at this point from taking it off now. Must rethink and be logical and rational... Denis, There's 2 ladders (one officer and one crew) that are under the quarterdeck. One open but under the boat on the gundeck and another under the forecastle. There there's he two from the quaterdeck/gangways to the gundeck. The ol' gundeck is going to be a busy place soon.

-

Windlass purchase link

mtaylor replied to frenchguy's topic in Metal Work, Soldering and Metal Fittings

Wefalck That is stunning. I thought I was looking at the real thing until I read the text. -

I'm with the others.... I got a dollar says it's started before Christmas.. "Maybe just seeing how the parts go together" is common reason around here.

- 473 replies

-

- greek bireme

- dusek

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.