-

Posts

1,501 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by archjofo

-

Hello Friends, today I show some news of my little naval shipyards. In the quarter galleries were still glued the window. The tiny windows were made of acrylic glass. I have fixed this with Micro Kristal Klear. As a consequence I had to install wooden strips on the quarter galleries yet. These are just decoration. Soon it continues here again.

-

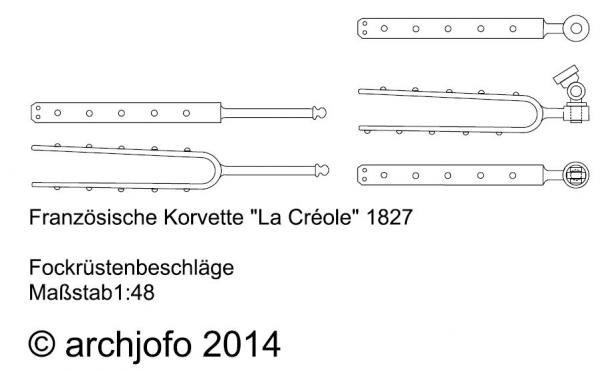

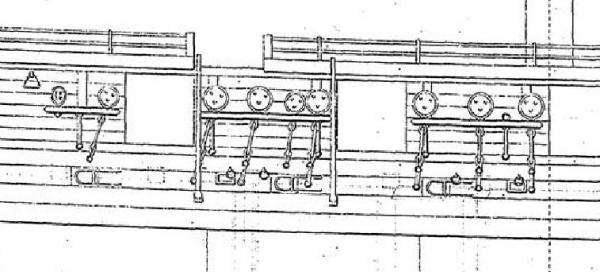

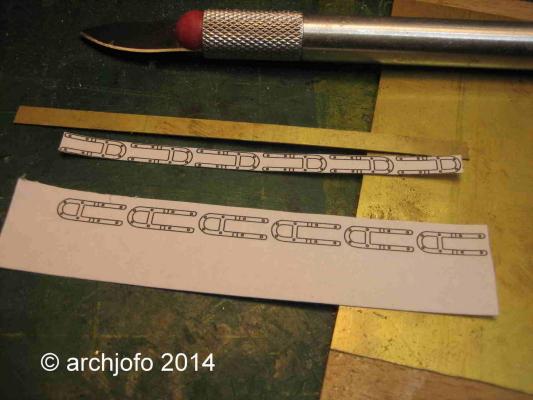

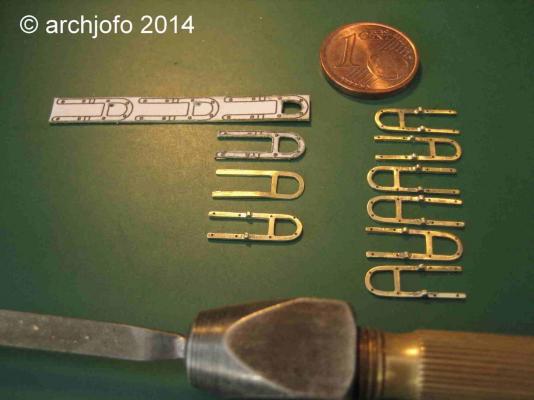

Hello, your positive comments are always pleased me. With other fittings on the outboard walls I want to continue my report. In addition to various eye bolts with rings were also fittings to customize for the fore-channels. One of these fittings is used to hook the lower-studding-sail-boom. The other is for the mooring of the flying-jib-guys. I hope you enjoy the pictures.

-

Hello Karl, the handrails look very realistic. This is a top performance. The idea with the rings you have to remember.

- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

Hello, many thanks für the nice comments. In between, I will still show you how the portholes of the ventilation hatches are constructed. The glass body with a diameter of 1.3 mm were punched out with a specially prepared punch pliers from an acrylic glass plate. Then they were glued with Micro Kristal Klear in a brass tube piece. The brass tube piece has an outside diameter of 2.5 mm. See you soon ..

-

Hi Mark, thanks for your kind words. Here is a little update, with other metal fittings for the outboard walls of the French corvette. I hope you enjoy the pictures. This can happen sometimes. Here's a look into my sorting box with various fittings. In this case also the support for the anchor and the boat davits are seen. Here you can see a scupper valves. The eye bolts to mount outboard. Drilling the bolt holes with a diameter of 0.3 mm drill is a very delicate affair. For one of these fittings 8 holes are to be performed. Finally, an overview.

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

archjofo replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Hello Doris, the standing rigging looks very realistic. You build amazingly exact. Simply fantastic! I admire your work.- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

Hi Karl, I can not repeat often enough myself, but your section model of the BRH is just fantastic. This precision and attention to detail is extraordinary. Here I can learn a lot about professional modeling.

- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.