-

Posts

12,104 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Old Collingwood

-

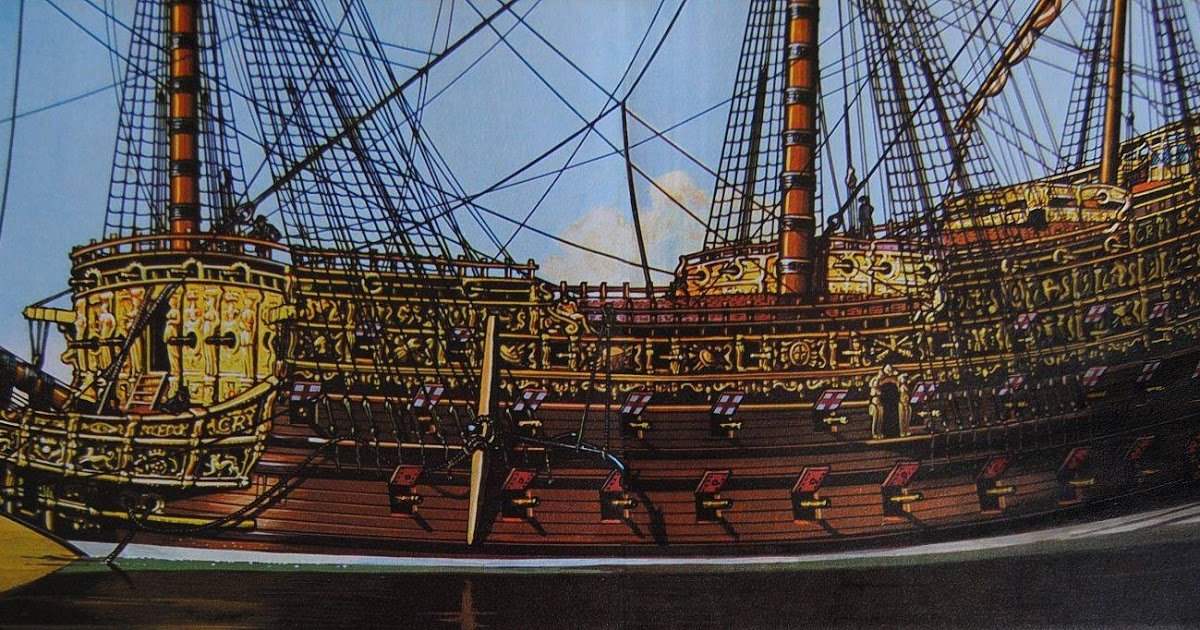

What I mean is the bulkhead on the decks between each deck, on a couple of pics on the net I have seen this shown as flat across the front from port to starboard as apposed to the rounded profiles where the canons point out facing forwards on the decks. This is one of the pics on the net showing flat bulkheads. OC.

-

Evening all, some good progress today I think, the fuselage had set well (nice and solid with no flex you sometimes get) next off was to fit the swivel frame inside for the Four jet exhausts, these are linked by a swivel bar linked to Four hubs that stick out each side that in turn have the exhaust units glued to them (I will leave these off till the main painting is done). I thought I might have some trouble as the instructions call for this to be done before both sides are joined, but I managed to ping them into position as there was a bit of flex in the bars, I set the ngle I wanted then glued the bar in place. Next to be done and an area where I was expecting troubles (as its a commen akward area in other kits of the Harrier) the engine intake surrounds with blow in doors, these doors in the kit come Two options 1) Fully open as in hover 2)Patial open as in ground position, these doors/flaps are gravity affected so when on the ground the upper ones fall open leaving the lower ones shut, but in the hover the draw of the air from the engine forces then open. These units come in Three parts - the main casing - the doors and an inner trunking, putting these together was not an issue and went togther well, but the fiddly bit that normaly creates a head ache (Tamiya 1/48 SHAR) is getting a clean fit on the fuselage, as the sections in between the doors need to sit flush with the fuselage, anyway no such worries with this kit - just some dry fitting and some gentle sanding and the fit was fine, so I glued them in position and just did a small amount of clean up from the glued joins. So far so good - so I thought "Go for it with more" next up the wings, again on the Tamy kit this was a problem with wide gaps here - there and everywere, after gluing the one piece top to the Two bottoms - not mutch tidy up was required, the wing unit basically just went down glued into place. The only issues I had was making sure the front edges of the engine acess cover part of the wing sat down into a ledge in the wing, to aid this I trimmed away slightly along the edge till the wing sat nice and level. The only alarming fault with the kit is - ontop of the wing at the front is a T piece shape section that should just be square in shape, when the wing is in place this leaves quite a noticeable gap that is not really any good for filling with my filler as it sinks, so I came up with a fix with ca underneath and a small square of Tamiya tape held in place by the ca (doesn't look too bad) So here we are at the moment - wing on joins sanded - not looking too bad - a very enjoyable build if im honest. OC.

-

Both Ken, I also used to watch Sharpe when he was on tv - loved the series, used to have a few books also. I have been reading through this timed account from the Battle - very interesting reading - https://www.telegraph.co.uk/news/uknews/battle-of-waterloo/11676475/The-Battle-of-Waterloo-as-it-happened-on-June-18-1815.html OC.

-

What an amazing build - having seen her in the flesh in the 70s at Pompy I guess I have a vested interest in following your fine work. OC.

- 42 replies

-

Evening all, I decided to crack this open again and try to progress it further - Firstly I had to do more dry fitting of the two internal sections (Front cockpit bath/front u/c bay) and the rear main u/c bay, it took a lot of testing / fettling - testing / fettling rinse and repete several times, as the Two fuse halves were just not meeting smoothly, eventualy I got them how they should be. I decided to glue the sections in the one side first - then some more checks and all was ok, so I added a slight bevel on the edges and applied glue to the one face and offered them up together, I used some tape and gentle hand presure to line them up while they set. After I worked on the seems with my knife and fine wet and dry. So his is where I am at. OC.

-

It will literally only be just the cut down farm and a small amount of room at the front - it will have to fit a board no longer than 2.5 feet long and just under 2 feet wide, as it will have to sit on our side unit in a case that I will have to buy later. Thats why I am estimating a head count of between 50-100 consisting of - KGL (Red coats) KGL Light (Green and Grey) 95th Regiment (Sharps) (All Green) French Line Infintry and a few French Heavy Cavalry. OC.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.