-

Posts

1,668 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by scrubbyj427

-

Well Done Steve! She looks great! Chapter 12 really is the icing on the cake. Congratulations on completing your Winnie (well almost). Are you going to drive her down there or attempt to fly?

- 99 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Roter Löwe 1597 by Ondras71

scrubbyj427 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

Very nice work Ondras! Excellent metal work! -

Looking good Gary, you’re moving right along, the end is in sight!

- 389 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I broke every speed limit in the state of Florida, driving out of it as fast as I could with my air conditioning set to “meat locker”.

-

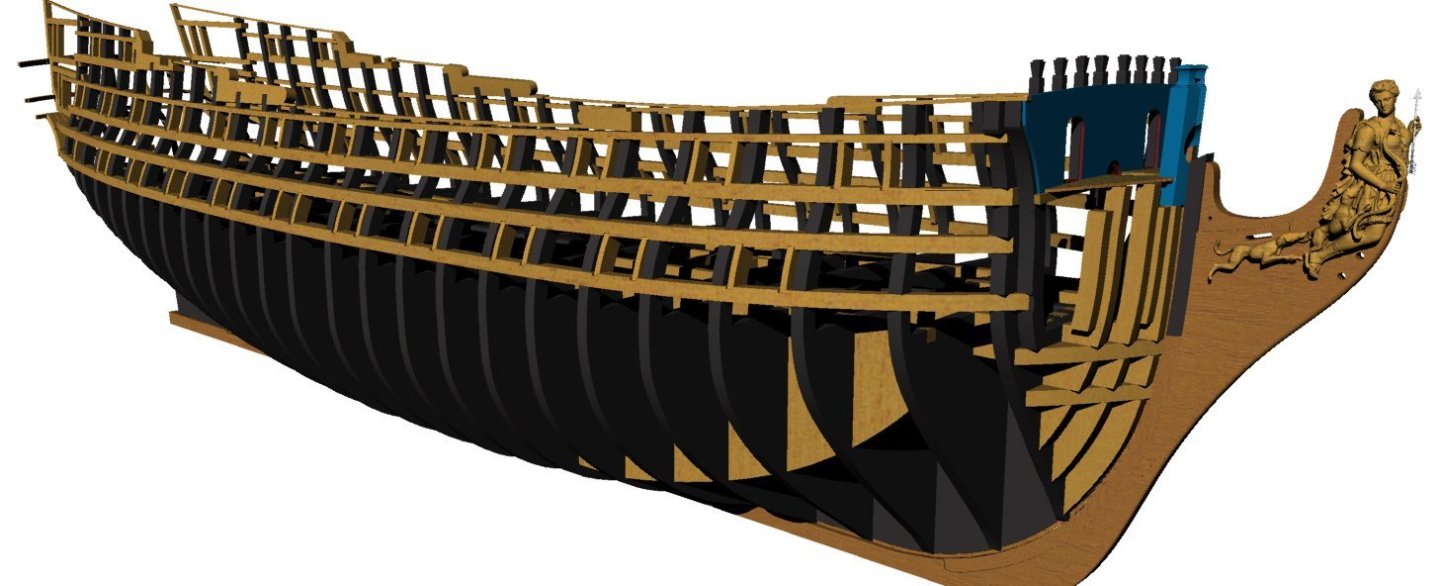

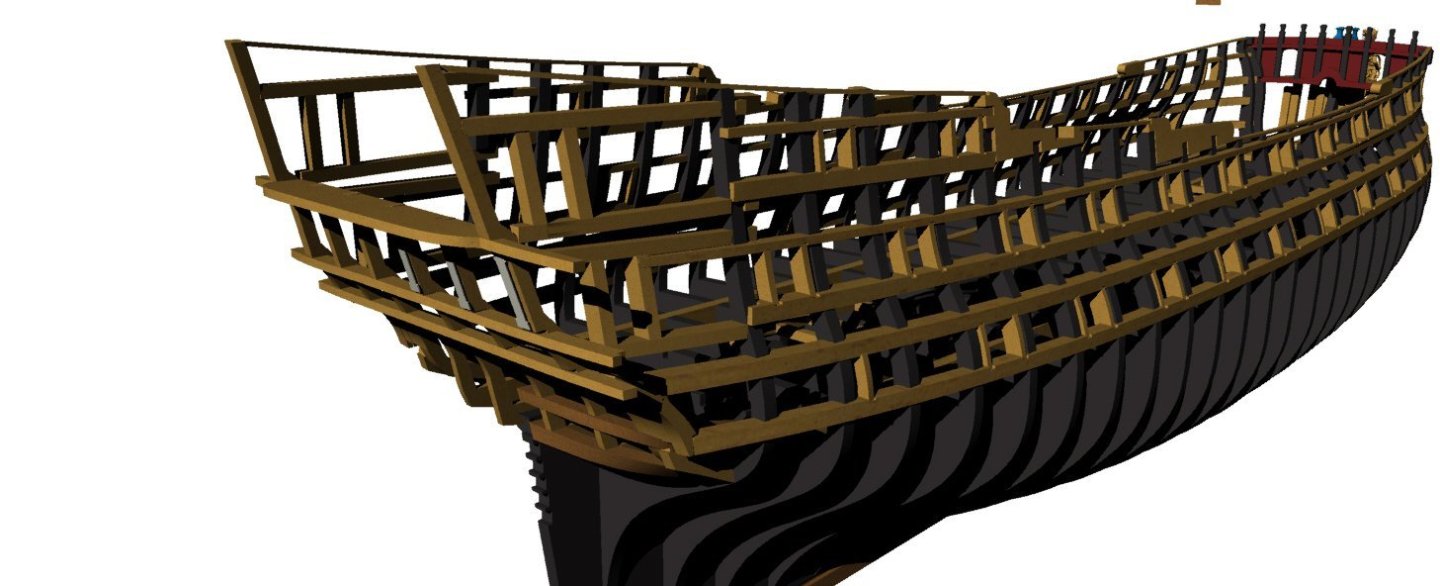

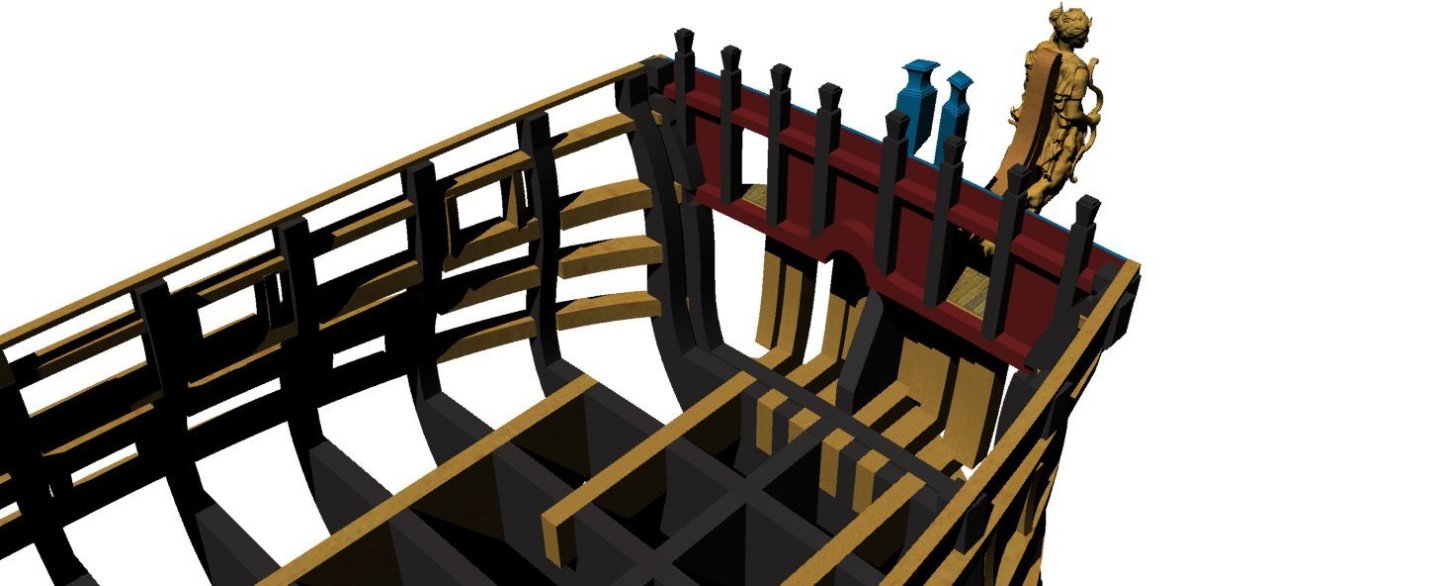

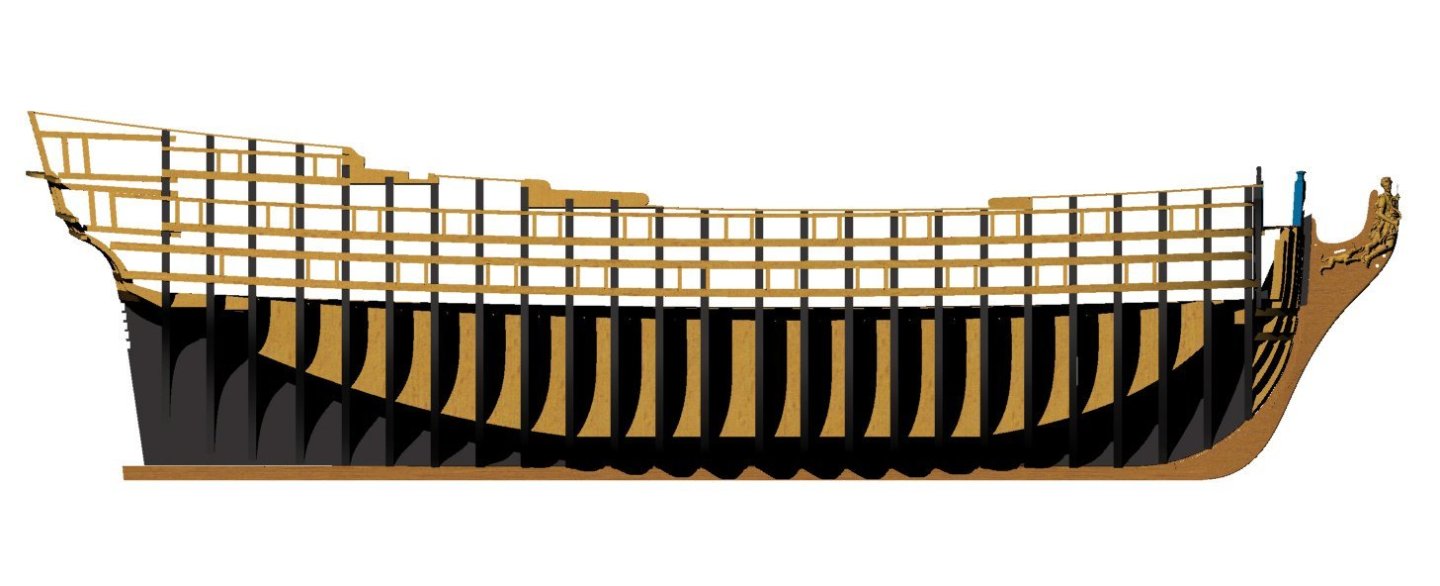

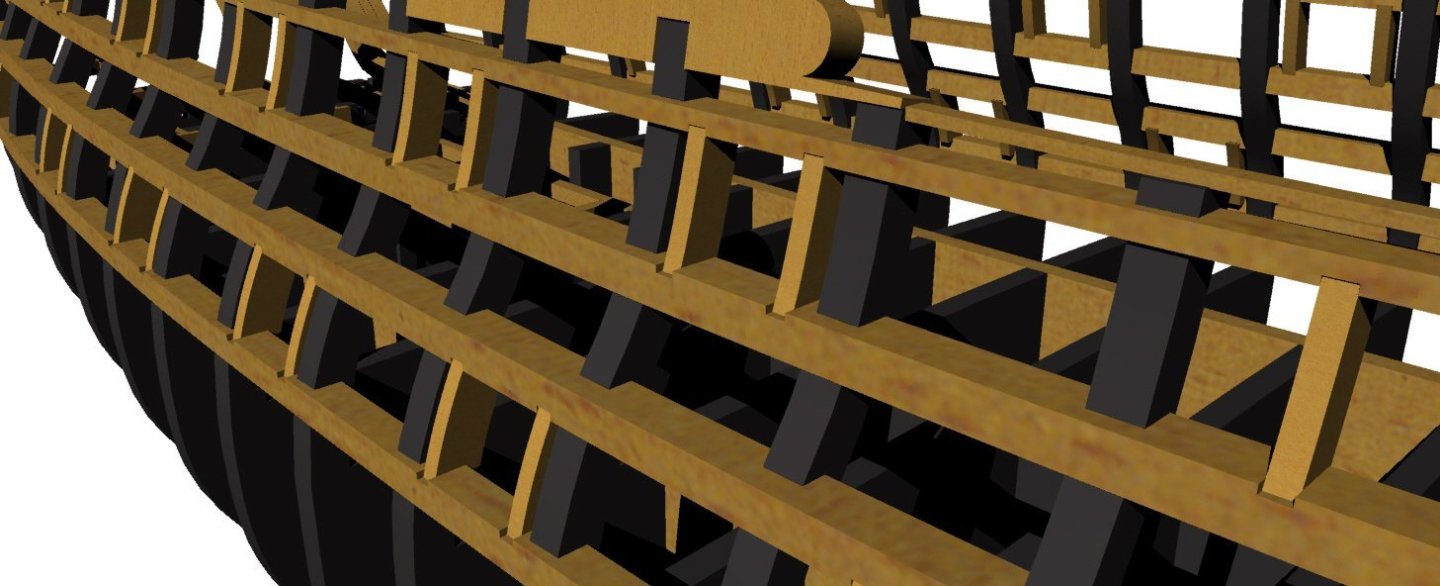

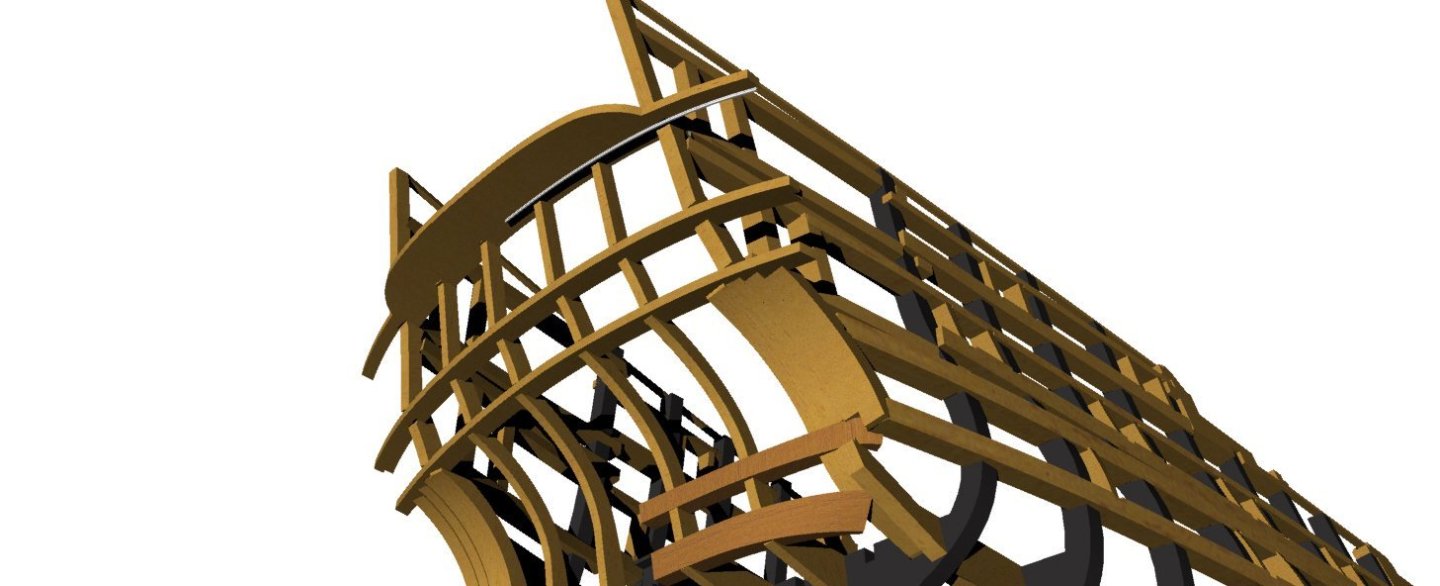

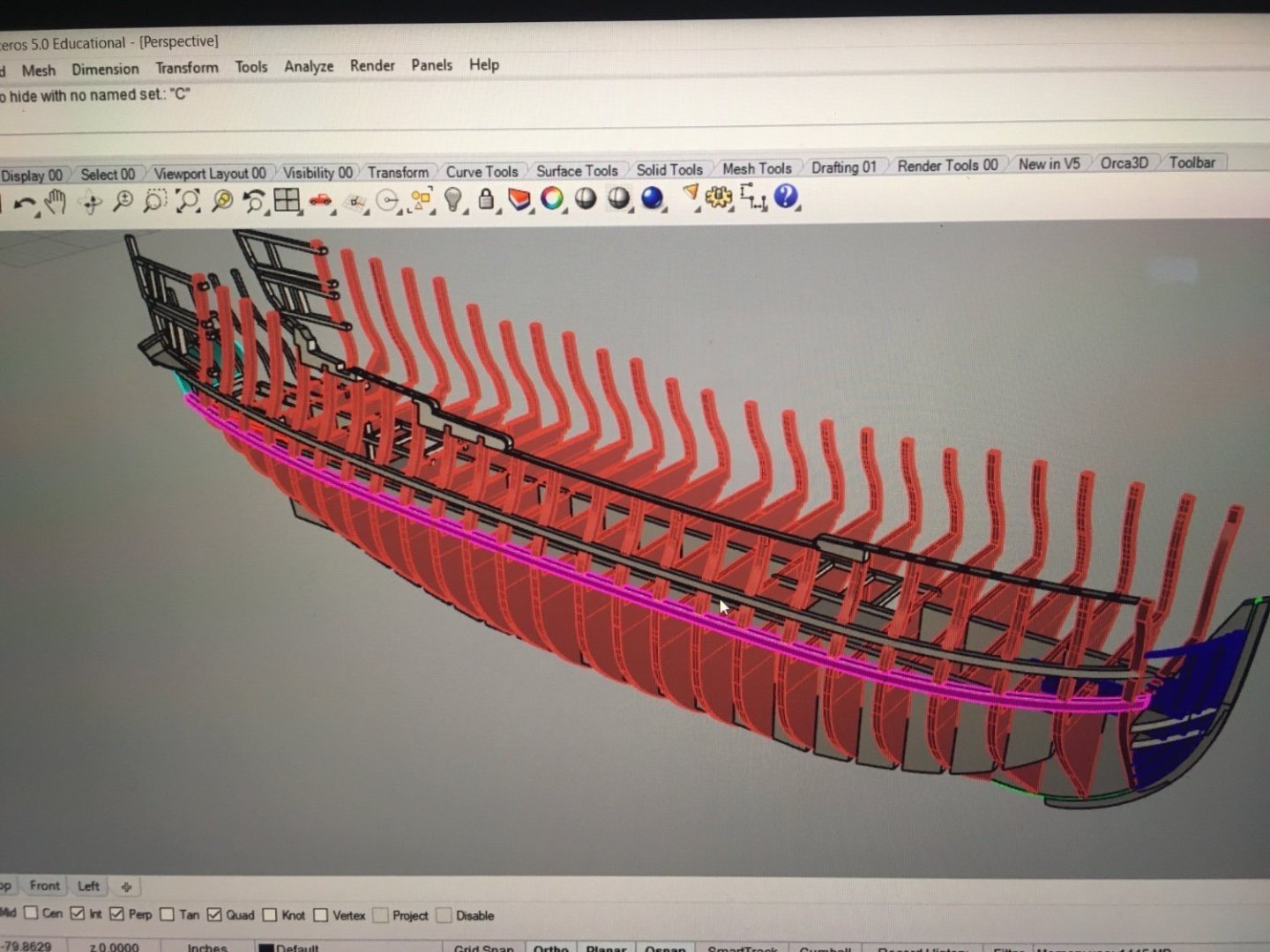

I have a few updates to the design of the structural assembly for the first part of the model, it is almost complete, I need to add a few things like the stern chaser port framing, some sheaves and tie in some of the structure in the stern. Otherwise this is pretty close to what I will begin assembling in September, this will lead into Planking and Q gallery assembly, I am well ahead in that aspect of the design and will probably begin test building that separately alongside the prototype build. Comments and questions are welcome. JJ

-

Nice work Glenn, looks great!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looks really good Glenn, I had the same issues with the char and I actually kind of like it, it’s almost like free weathering on the wheels. The laser does seem to char deeper depending the grain orientation. Overall I’d say your guns turned out perfect.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looking really good Steve, you’re almost there.

- 99 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looking good Glenn! Moving right along.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

HMS SUSSEX by KarenM - FINISHED - 1:48

scrubbyj427 replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

Wow! What a stunning model! Incredible work! -

HMS SUSSEX by KarenM - FINISHED - 1:48

scrubbyj427 replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

This is an incredible build! Amazing work! -

Thanks Glenn. There’s an incredible amount of work and investment that goes into this, lots of design and redesign and I haven’t even began physically building it yet aside from what I’ve shown. It really adds another layer of admiration to the Winchelsea project as well as others such as the work Chris produces. JJ

-

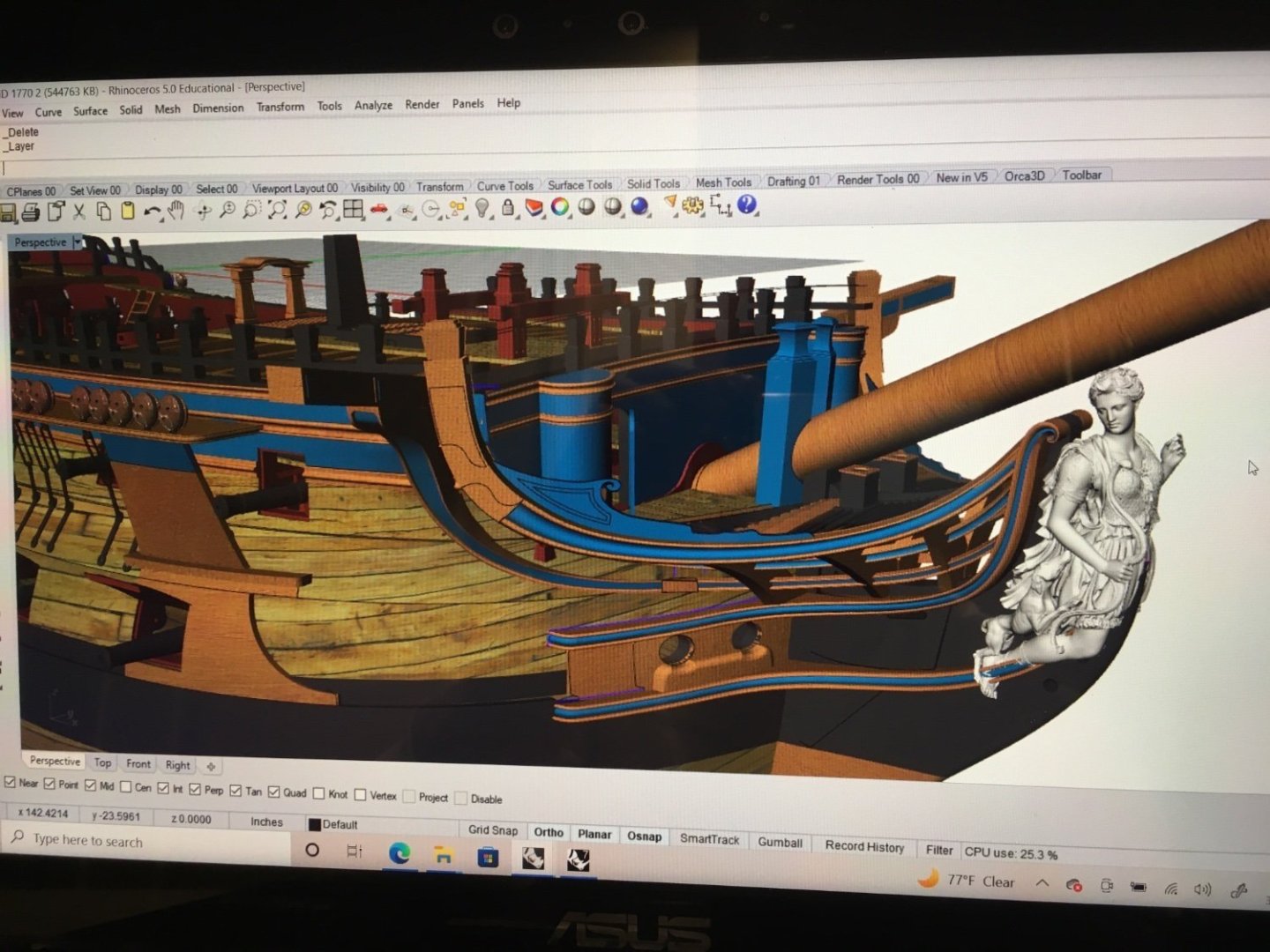

Hi Matt, the figurehead was produced exactly as the figurehead for the Winnie. I provided a 3D model of the knee to @Jack H along with the rough dimensions and paintings of the contemporary figurehead and Jack did the sculpting work in Zbrush. From there the file can be produced into a real wood sculpture with a CNC machine. Keep following this log for updates on all the stern carvings as they are in the works currently. I’m finishing up the initial structure design of the model right now. I hope to be building the actual prototype by September.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.