-

Posts

1,690 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by scrubbyj427

-

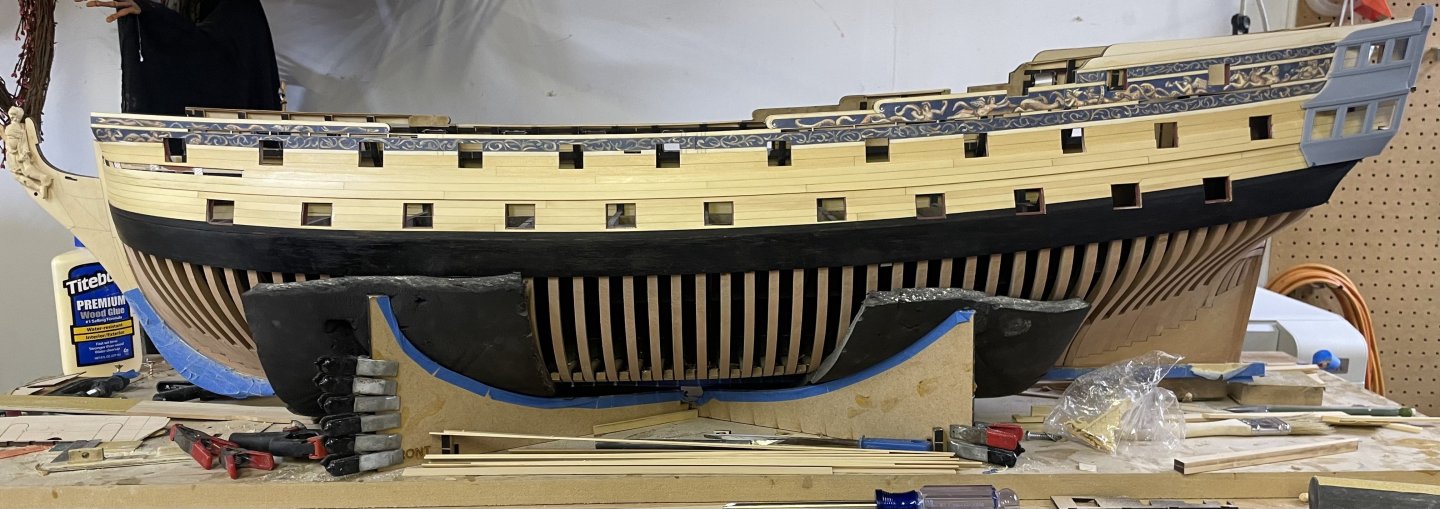

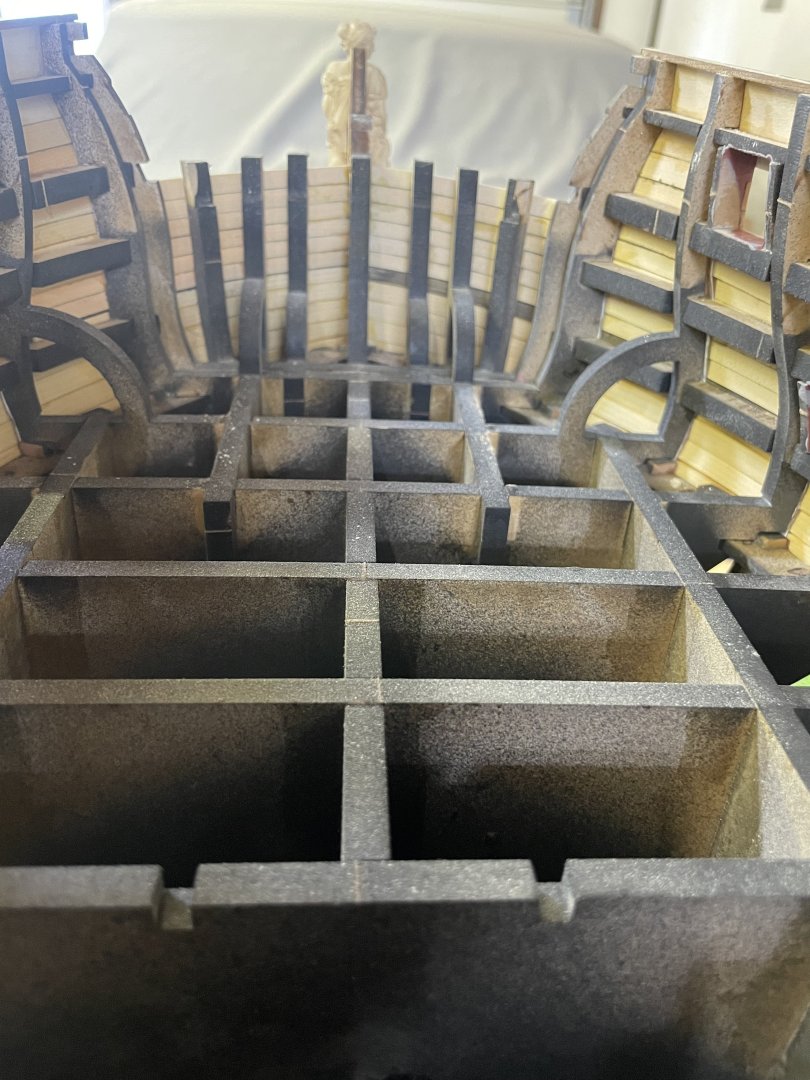

Last night I completed the port side main wale. I also began removing the frame jigs in order to fiar up the inside, especially the bow area so the beak head beam can be permanently installed and the remaining channel wale plank can be installed. I will be removing the stern frame jig soon and that requires a few steps in order to carefully extract it. Will be going over that soon you’ll notice a slight notch was made in the hawse piece to slide the beam by. with the jigs removed and the planking completed (aside from the last channel wale planks), the hull is quite ridged now and will hold its shape without worry.

-

Thank you hmcarlin. I’m very close to having all the ch1 bugs worked out and will be going into producing kits shortly. Thank you VolkerB. Stay tuned. Thank you Glenn. Very much looking forward to adding the carvings and making moldings… all the fun post planking stuff. Haha

-

Thank you Kenny. Looking forward to finally getting back to work! Thank you Christian. Hi Matthias, I started developing them and then quickly realized that I was far from proficient in the software and I was far better off enlisting Jack @Jack H for the job. Jack also produced the carvings for Winnie so I knew I was making a good decision there. Thank you Mike. Thank you Greg, hoping to produce a few test pieces with them soon., I’ll post results. You and me both, Ben. I will have all the planking completed this rotation home.

-

Back at it today with Portland, right off the plane and into the garage! I finished the port side hull planking, got it all blocked out and coated with WOP, now I can move onto the black strake and then the wales. Also some goodies shows up, the remaining carvings for the model. These are the first production run in boxwood and look pretty good. With each set of boxwood carvings you order, a set of stainless scrapers are included. These moulding profiles are taken from the drawings or Portland and the contemporary example of Bristol. The instructions will have a key that shows where each profile belongs on the model. I couldn’t help myself and had to take a test run on a few of the rejects. These are just taped on and fitting pretty rough but you get a good idea of how it will look. There’s still a long way to go on the quarter galleys and the stern of the model. Before the rest of the carvings can be attached. JJ

-

L'Amarante by marsalv - 1:36 - POF

scrubbyj427 replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

As always Beautiful work Marsalv! -

Thank you Kenny, stay tuned as I will be updating Portland in a few weeks as I progress into chapter 3 of the build.

-

L'Ambitieux by Nek0 - Altaya

scrubbyj427 replied to Nek0's topic in - Kit build logs for subjects built from 1501 - 1750

Incredible work! -

Thank you. Should be ready to make some available soon. i have not considered Planking it anymore than necessary lol that’s a lot of plank work. I have a POB one that I will be planking at some point though. Thank you! She’s coming along.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.