-

Posts

1,690 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by scrubbyj427

-

I like the red as well Kevin, I’m going to do the same on mine. It shows the panel definition really well

- 1,127 replies

-

Thank you Alan, it’s been a lot of work and it’s nice to finally see it get off the ground. It appears you’re just down the road from me.

-

Hi Greg, I’m currently getting going on a website, as soon as I have something I will post a link. Ben and Dusan are building two prototypes to prove the structural design and provide input while I build ahead and I’m still writing instructions. This is a massive model and the instructions are very long for chapter one.

-

Thank you Ben, it’s coming along. Going to finish up the vertical fillers today and move onto the final port forward frames.

-

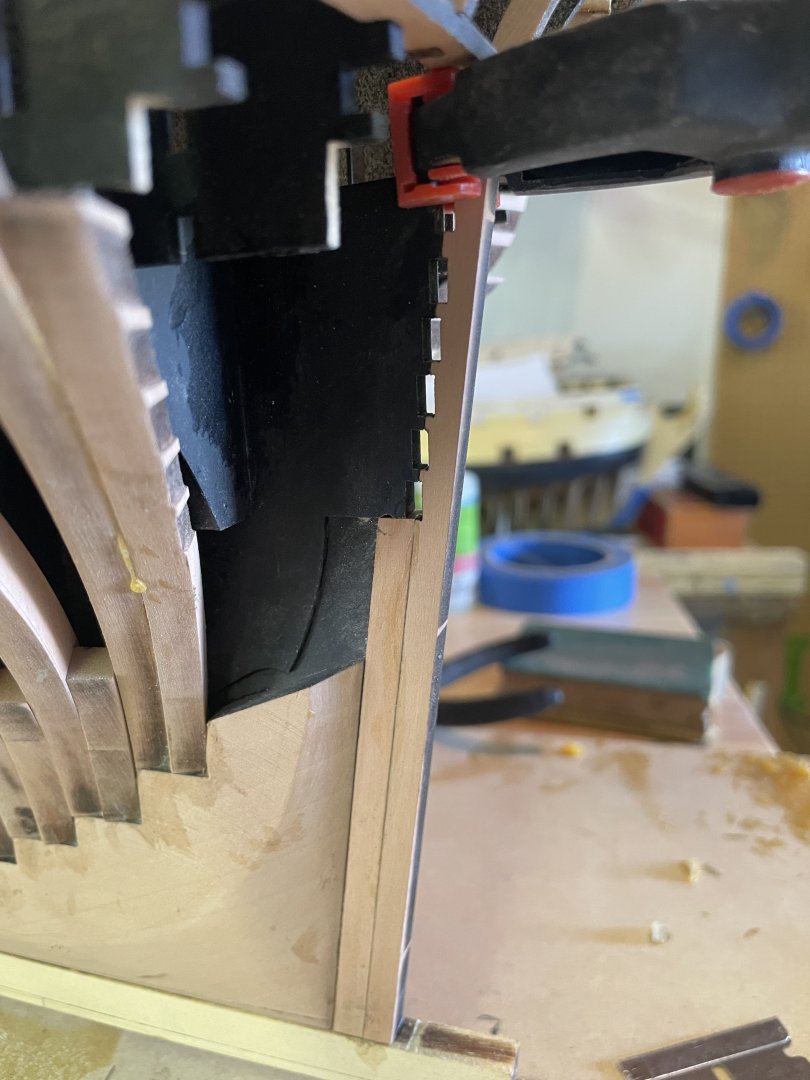

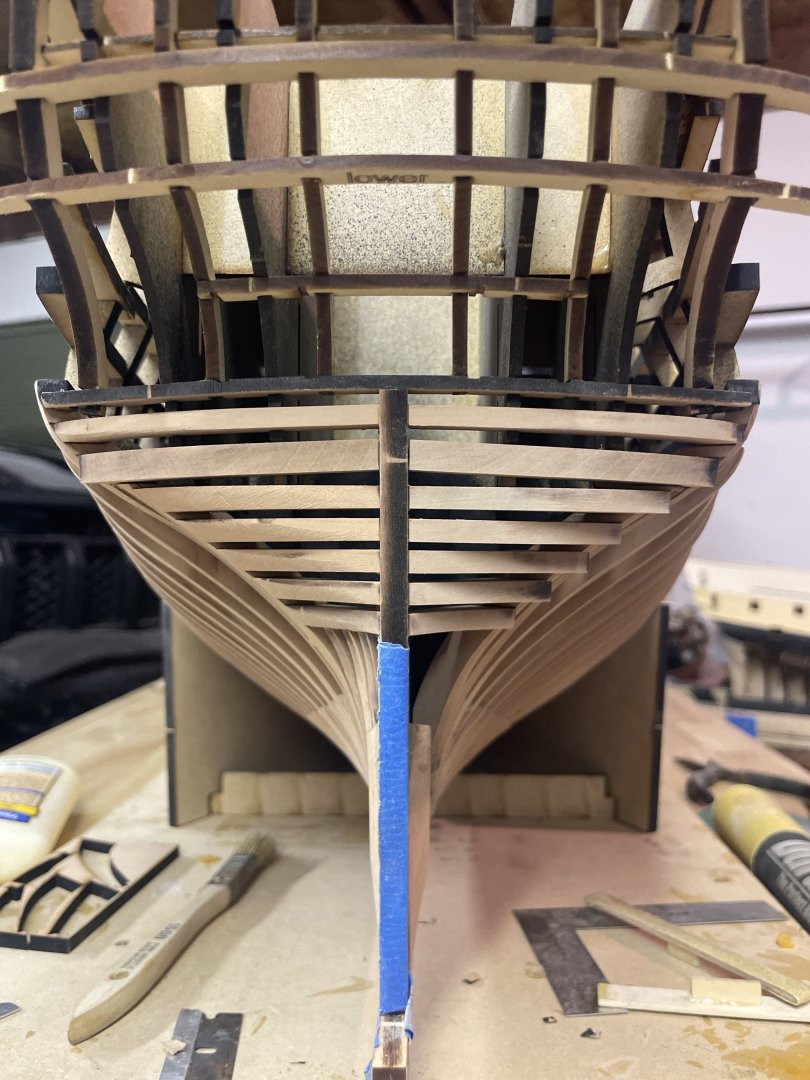

Hey guys, I’ve been working on the wing transoms today and I have both sides complete, a few revisions were required but it all went together pretty well except for the vertical fillers, they are a pain but they turned out decent. first we start with the inner post as seen below. It should fit nice and tight up to the deadwood, keel and the top of the bulkhead former. Note that it is .25” and is supposed to be thinner than the keel next is the second inner post piece, again same deal as the first one but also double check that it aligns with the wing transom cut outs on the former. Production model kits will be different than mine at the top of this piece as I revised that uppermost wing transom to have receivers for the post and the former. you can now start with the upper most wing transom which is .1875” and requires a slight bend, so use a heat gun and give it a little arc. Please pay attention when you glue it, that it’s not glued to the transom jig, there are receivers in the jig to hold this piece in place but only glue it to frames 52 and the inner post slots. Also note that you will need to bevel the transoms to run parallel with the angle of the inner post above you can see one of them in place before i beveled it. Also note that I dry fit them all before glueing and actually installed from the bottom up that way I could see the fit from the top. after they are all dry fit and in place you can begin glueing. once they are all solid you can work on the vertical fillers. I’ve given you an angle indicator line but there’s also the angle of the deadwood. This is a big sand and test and sand and test again job until you get them right. after this is all dry we are going to sand the bejesus out of this part so fair everything up. There’s a ton of extra material on those wings so you have room to work. the 5 lower wings are all parallel but the upper three, two have a bend in the top and the third one down (#6) angles down. This is shown in the painting and the framing plan. You can see it in this last photo. Now that the stern frames all work I can move on and finish the port forward frames, from there I can begin fairing up the hull which will be a monumental task, pear certainly doesn’t sand like AYC. Once the hull is faired I will run two strakes from the garboard up and two from the main wale down. Once the ports are framed and the planking from the wales up are complete this will pretty much conclude the first chapter of the build. JJ Quote Quote selection

-

HMS RESOLUTION 1667 by KarenM - 1:48

scrubbyj427 replied to KarenM's topic in - Build logs for subjects built 1501 - 1750

Your figurehead turned out amazing, I’m curious to what machine you used to cut this? 4 axis? -

kit review Kit Review - HMS ENTERPRIZE (1774) by CAF MODELS

scrubbyj427 replied to kljang's topic in REVIEWS: Model kits

I wonder how this actually happens, are they buying his kits and reverse engineering them or somehow getting into his design files? I can’t imagine the quality and fit of a reverse engineered kit is worth anything unless it’s completely copied/redesigned with some software… otherwise it would take less time and effort for one to just design their own.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.