-

Posts

1,690 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by scrubbyj427

-

Thank you Dusan, im looking forward to it as well, I should have an update on those today. Hi Ben, I used the Caldercraft red ochre just like I used on Winnie, I’m not a fan of bright reds and prefer an older look. In fact I’m even considering adding a little age To Portland as seen on some of the contemporary models. Will see. As for the wales, i will be doing them straight just like the Bristol model and the POB Portland. Ive been thinking about templates for the port surrounds since I started designing the model and I still am. Like the Winnie I just eyeballed them on the POB Portland and they turned out nice. But I’m still thinking about how I could make a template to do this. Stay tuned.

-

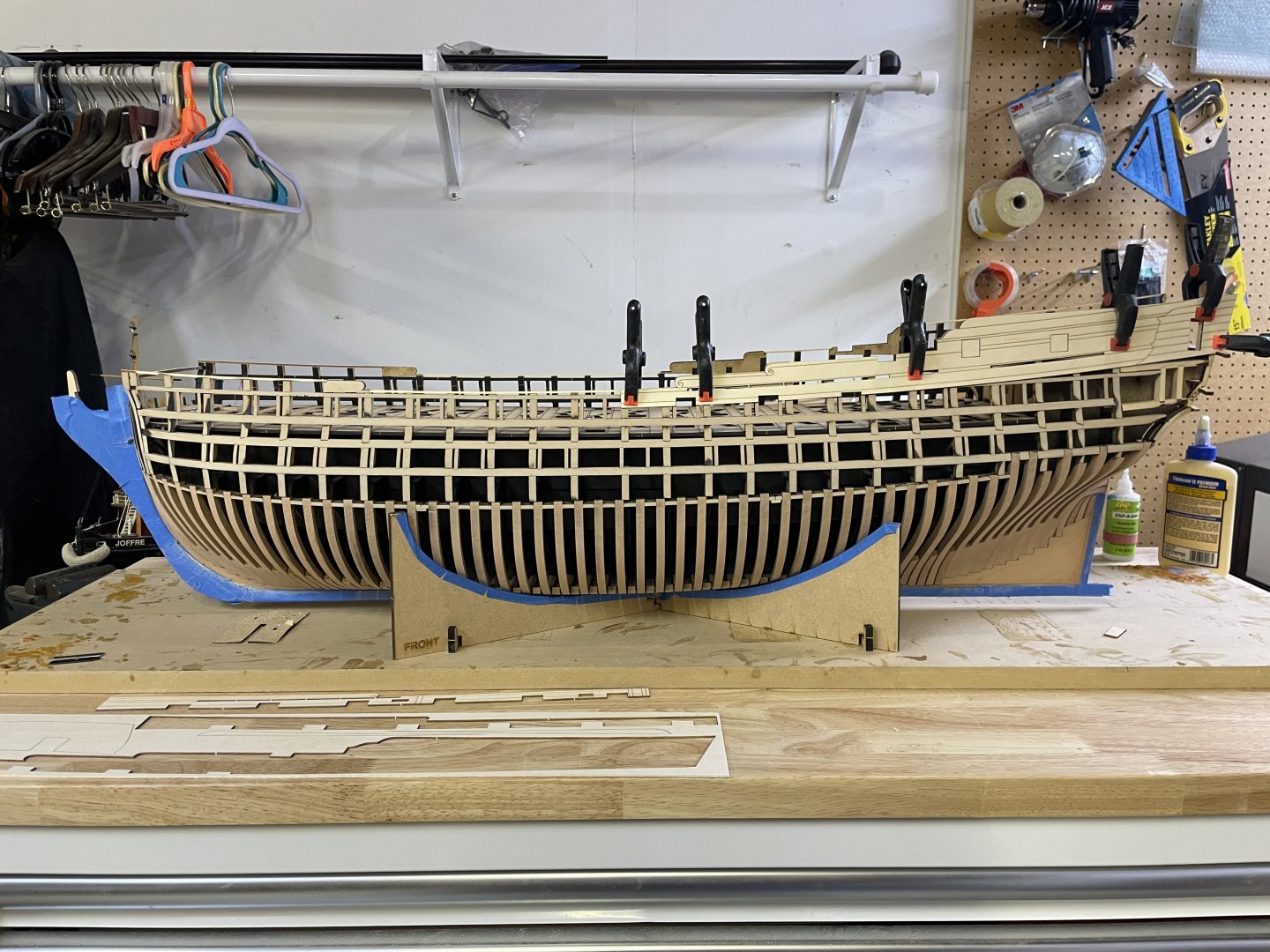

Officially underway on chapter 2 now, I have all the Gunports primed, block sanded and painted. Tomorrow I will start milling wood and begin planking from the main wale up.

-

Today I got back to work on Portland, I faired up the lower counter and added some high build primer on all the gunport frames. I used a solvent based high build primer to seal up the MDF, it soaked it up like a sponge. I’ve always been a little concerned about swelling when adding water based products to MDF, the primer also makes sanding and finishing the ports nice, it fills small gaps or joints in the port framing. Ive also been working on planking guides that will attach to each bulkhead and assist with spilling, more on that soon.

-

MONTAÑES by Amalio

scrubbyj427 replied to Amalio's topic in - Build logs for subjects built 1751 - 1800

What amazing work! Stunning model! -

Yes I’ll be using AYC for the planking. Probably do the wales the same as the POB model.

-

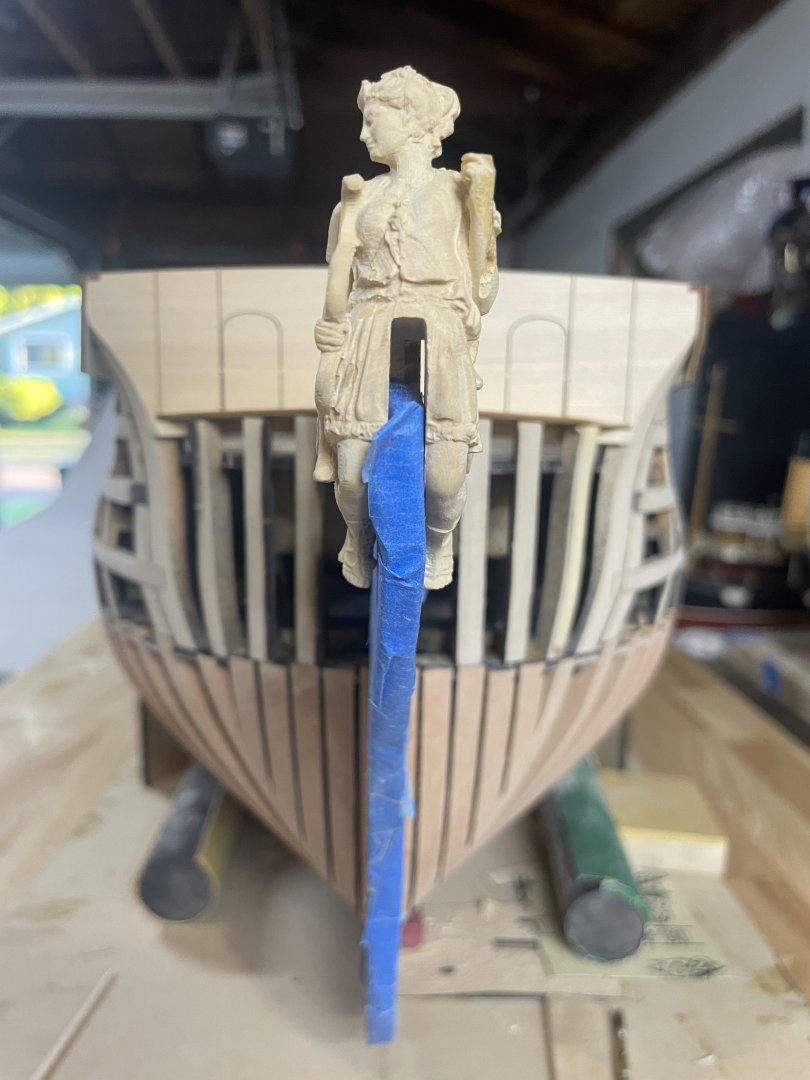

Moving into chapter 2 I’ve attached the frieze panels and added the forward false sub deck for fairing reference. Now it’s time to primer and prepare the gunports for paint and line off the upper hull for planking. Finally it will begin to look like Portland!

-

Thanks guys. It’s slowly starting to look like something resembling a Portland class ship.

-

Port side mostly complete now. Some minor block sanding to do now and then permanently attach the frieze panels and prep for planking.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.