-

Posts

1,690 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by scrubbyj427

-

Thanks Yves, you are correct. The only foreseeable resin part on the model will be the QG’s, outfitted and surrounded by boxwood and AYC parts. There may be other fittings along the way that I will possibly offer in resin.

-

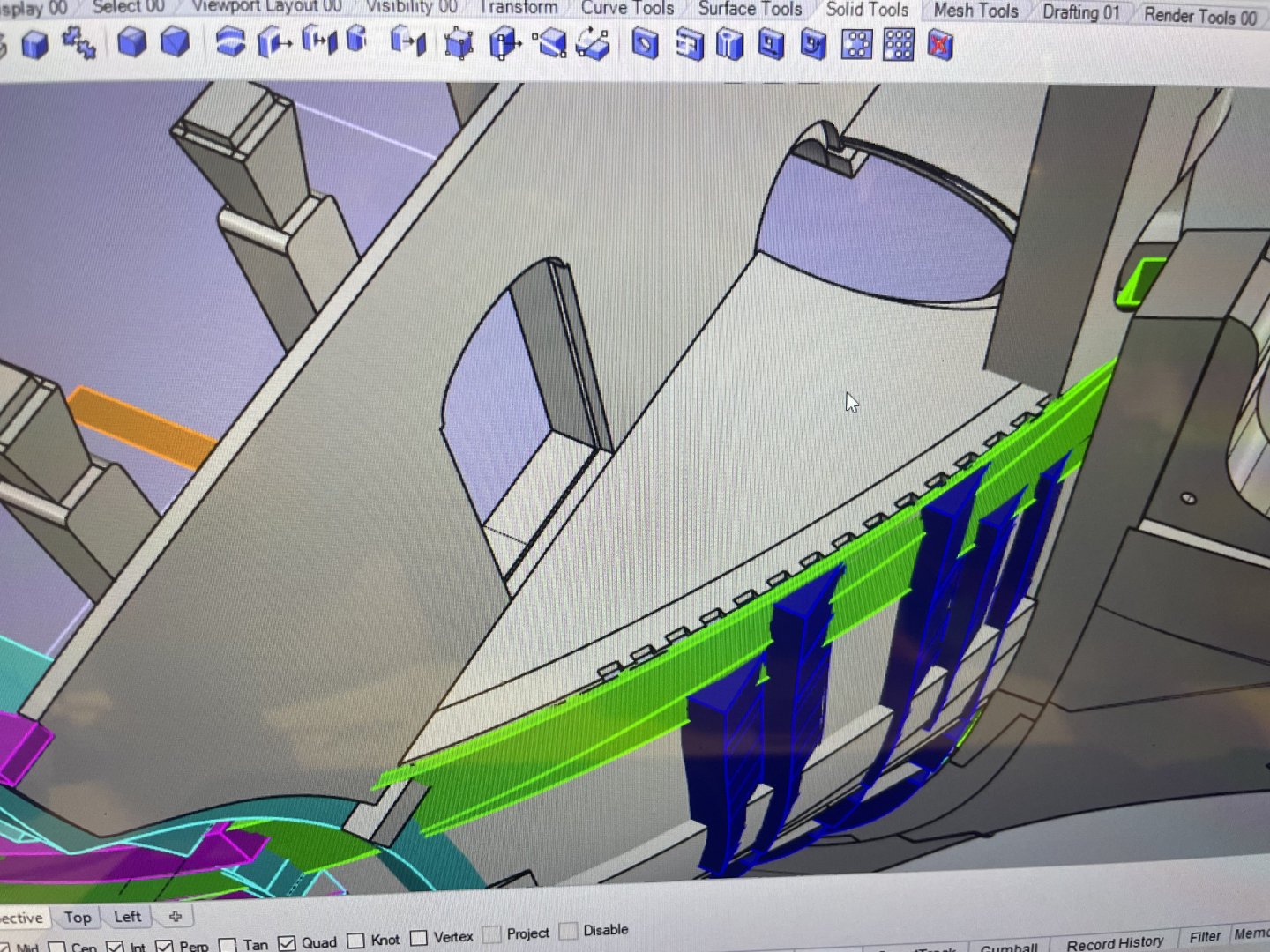

Hi Giampiero, thanks for looking in and your compliment. Yves is correct, the drop is simply a test piece to make any necessary adjustments before it is carved in wood. However the basic QG’s will be printed and outfitted with many boxwood parts, I guarantee that once complete, they will be indistinguishable from a wooden construction. My reason for this is the QG’s on this model are very complex and I didn’t want to leave anything to chance for the builder. I began designing and could offer a wooden construction alternative for the QG’s if there was enough demand. These were an extremely complex assembly in an effort to keep everything lined up. JJ

-

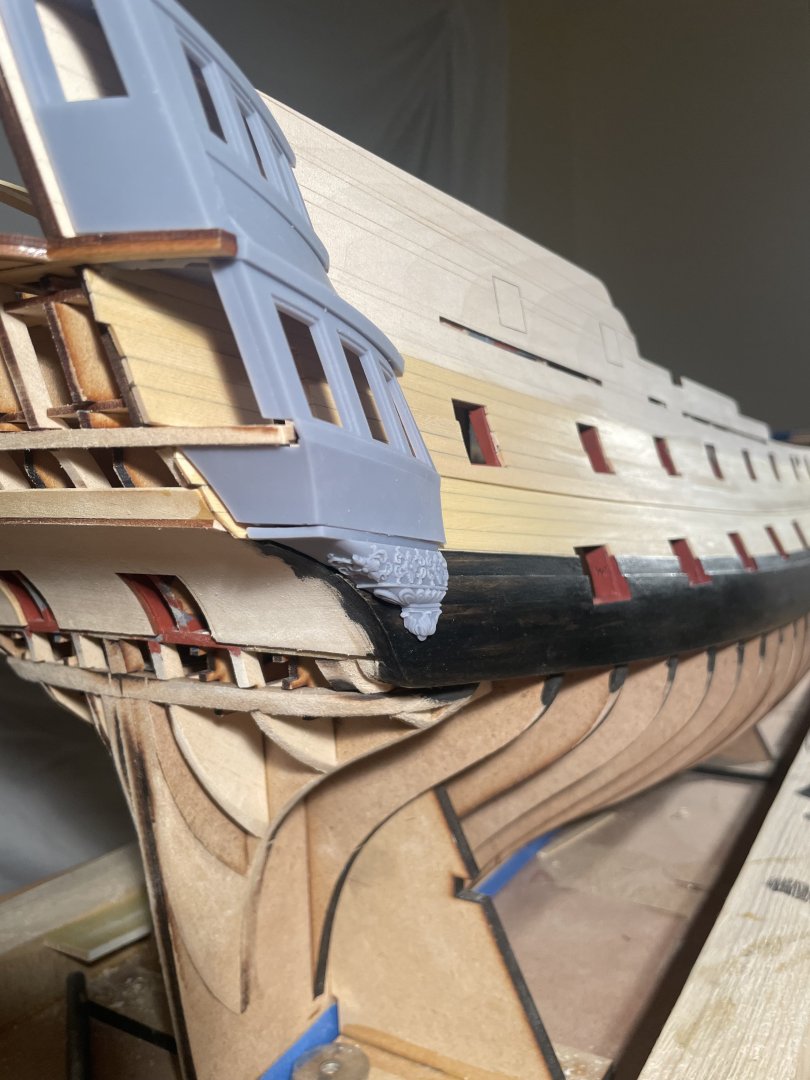

Quick update. received the prototype print for the stbd drop. The fit is nice without any adjustment to the QG or the drop, both are straight off the printer as designed. Will make a few slight adjustments and proceed with boxwood CNC carved ones for the model.

-

I finished the stbd side planking of the main wale up..finally. I apologize in advance to anyone who takes on this planking behemoth! I attempted to give a more “worn” look to the wales, similar to some of the contemporary models I’ve seen, I need to play with it a little more but I think it adds a little character. I still need to clean up the gunports a little more and then paint the margins of the planks after another coat or WOP, but I’m finally making some noticeable progress. Thanks for looking in. JJ

-

Thank you Fred, I’m making a career change that’s going to allow me to dive into Portland almost full time, but I have to wait until January, but I do have some updates on Portland coming shortly. In the meantime, in about a month, ill be able to direct some major efforts towards completion of my Winnie.

-

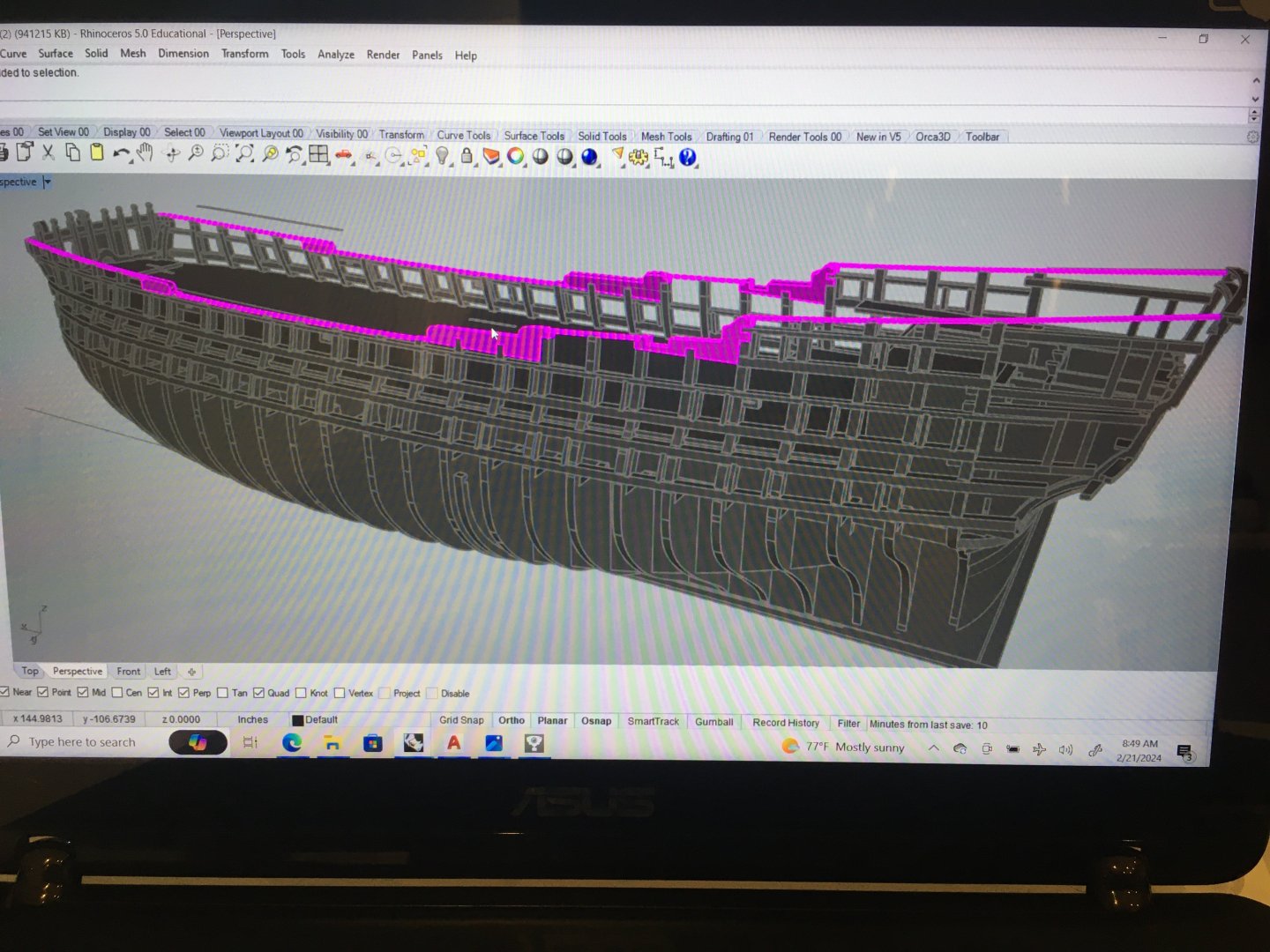

I had to immediately tie all mine together on Portland, some were over 5” long. The longitudinal gunport structure is a good way to do this and kill two birds with one stone. I also utilized the strip along the top, but mine is integrated into the design and permanent and like Chuck, I’ve used it for a fairing guide on the inside and out.

-

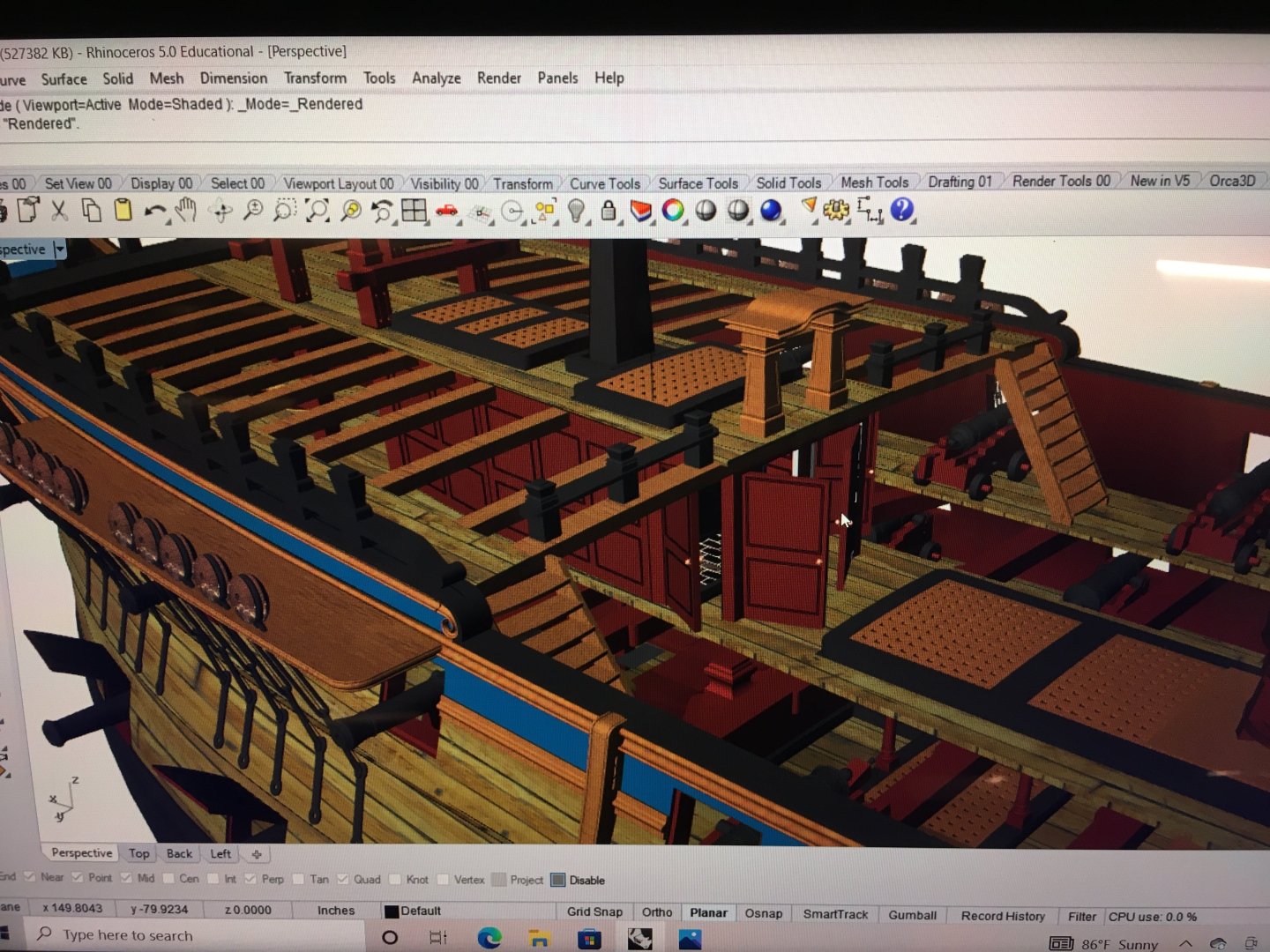

Hi Fred, Thank you! The lower gunports will have all their doors but I will be showing them Open, as shown on the painting. The gun deck will be fully fitted with 24pdrs and visible through the main deck.

-

Your margin planks look great, those were definitely fun to make. She’s looking great!

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Small update: Making some progress with the planking, going to finish the main wales this weekend and start closing in the gun deck. JJ

-

Completed the upper stbd wale, a little tricky in the front area where the grating will eventually go. As you can see in the photo below, the precut sub deck piece has a spacer on it that represents the eventual boxwood piece that will hold the gratings in place below the 3D model shows this piece in place already. This will come later for obvious reasons, it is just too fragile to survive the build. the upper most plank for the upper Wales needs to be slightly trimmed so this place holder sits on top of it as seen below you can see a slight notch at the end of the beak head bulkhead, this plank needs to be bent and shaped first before being notched otherwise it will break every time . The rest of the planks are business as usual, heat, bend, notch for gunports and glue. I started at the lower plank and worked my up. I sanded them down smooth and added some WOP to protect them. Next I will move up with the thinner planks (.045”) to meet the upper panel which is a little thicker to allow some sanding. Very slow and steady. JJ

-

Research in the HMS Ulysses 1797, a Roebuck class ship

scrubbyj427 replied to Kevin Kenny's topic in Nautical/Naval History

Lovely Subject Kevin! I would go 1/48, the detail is much cleaner and easier to manage. The model won’t be offensively large compared to your Thorn model. -

Nicely done Yves! Quite the project you’ve taken on. Very nice display! Inspiring me to work on my Portland further. JJ

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.