-

Posts

217 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DavidG

-

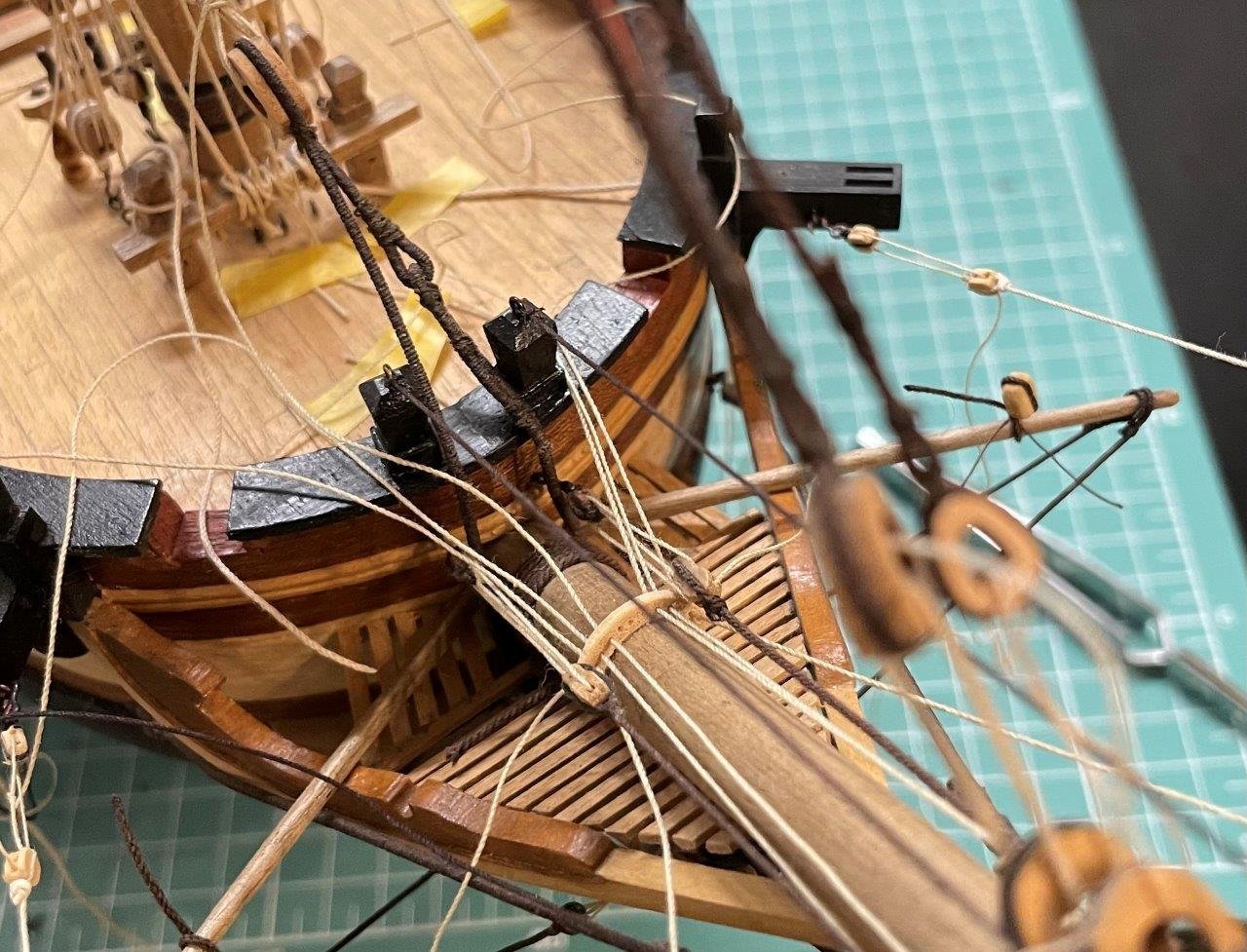

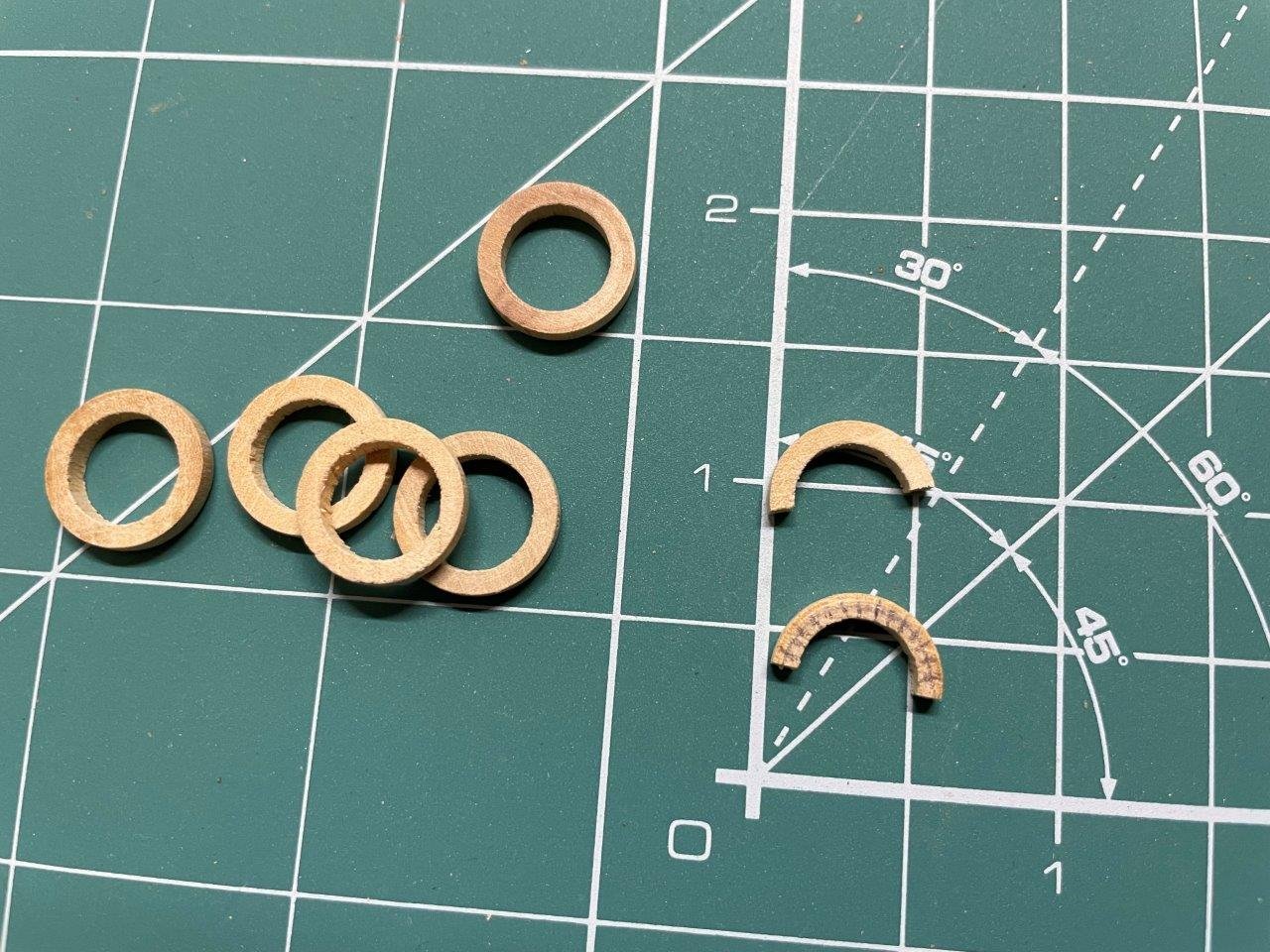

making a saddle for the bowsprit While stepping the masts, I realized the kit didn't supply enough mast foot rings. I used the Occre parts order service from their website which worked very well, and shortly I was sent a whole bunch of the rings, left with several spares. These are actually pretty nice parts, made of boxwood. This came to my mind while thinking on the saddle, and fortunately the size was just right. I split the rings, drilled on the mill and installed on the mast.

-

the MK site shows blocks up to 5mm on their website, I'm not aware of bigger ones. the Syren blocks above was from 2019, I edited the post to make it clear. They are still very nice and consistent.

-

for comparison, here is my collection of blocks from different sources. From left to right: 1 - Master Korabel 3mm pear 2 - Syren, 3mm boxwood (2019 version) 3 - Hismodel, 5mm walnut 4 - old kit block. to be fair, the kit is already built and the worst bits were left over. the concept is still visible, square cuts in brittle wood 5 - Occre 5mm boxwood All of the aftermarket blocks are great. I tend to prefer EU sourcing due to shipping and tax. The MK blocks are really good, but found their availability is less consistent. That's why I went for the hismodel ones for the larger sizes, and I'm pretty much satisfied with them. But the Occre ones are not bad either, they are uniform, cut from good quality wood, and with some rework they can be made acceptable. The problem is there are no variety of sizes, so some upgrade will be still needed, with the involved inconsistency of blocks on the model.

-

Chris, just out of interest.. how do you pack that amount of blocks to your kits? do they come already counted and sorted from the supplier? I can imagine, it can be a nightmare..

-

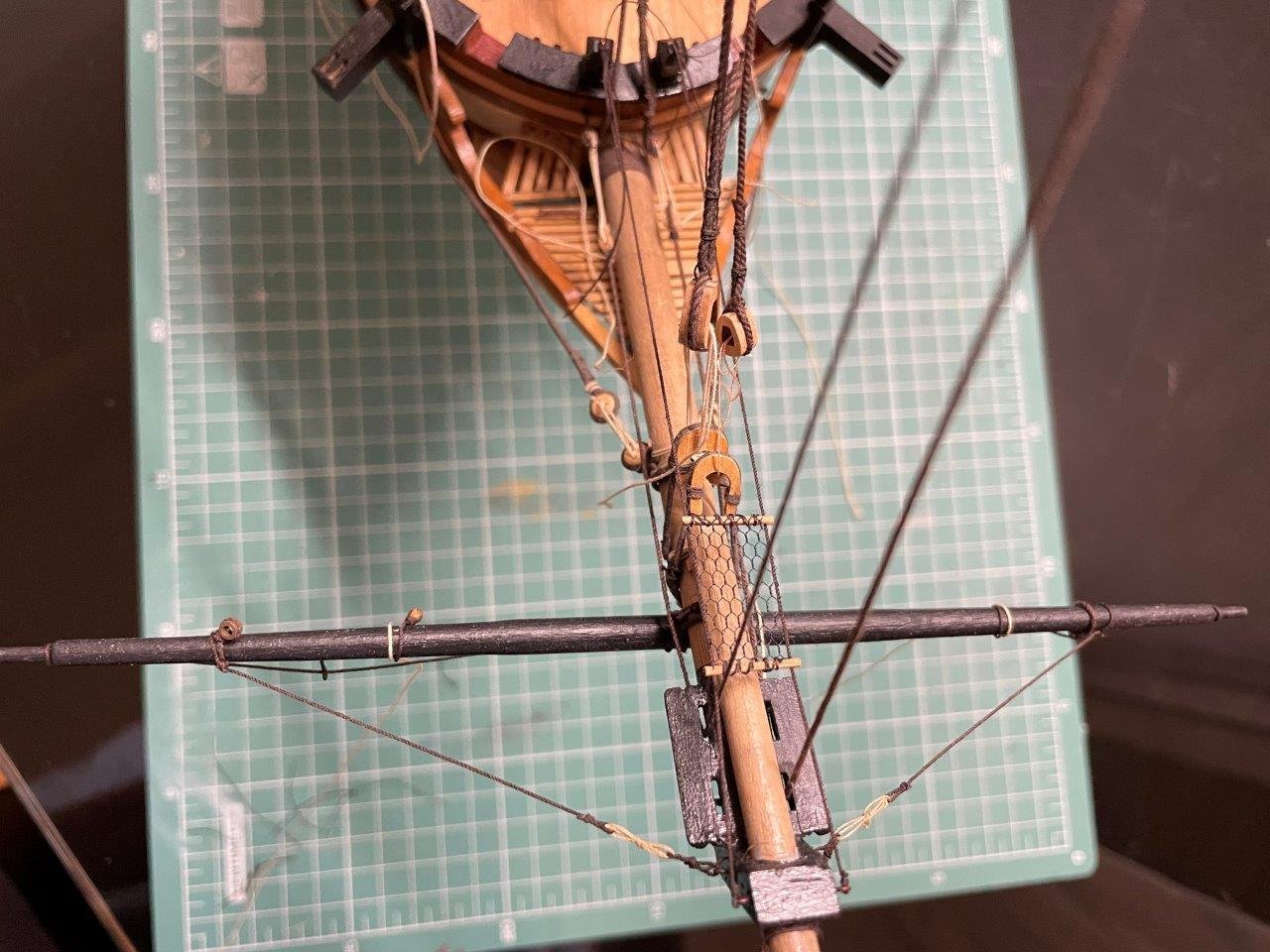

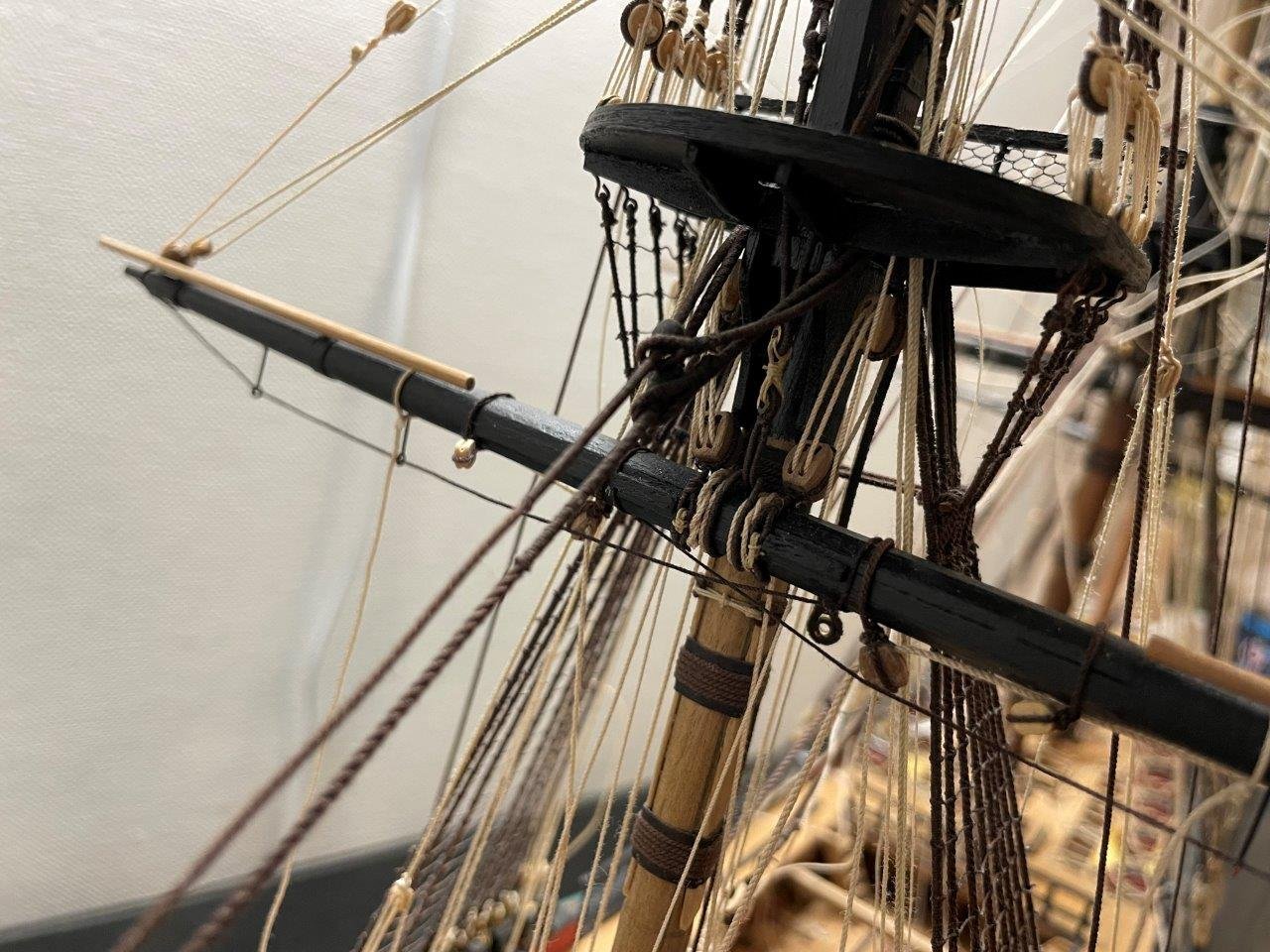

in the recent weeks I added most of the rigging to the main mast, and started to permanently belay the lines. This is the point where my lack of forward planning make some problems, I did not use the kit rigging plan, but neither installed the belaying points from the Petersson book. So I have to do it having a lot of rigging already attached, making some tasks unnecessarily difficult. I had to work around several lines to attach the shroud cleats for the topgallant lifts. Then I moved to the bow section, and made the spritsail yard. Coming to the end of the yard making, I learned to install properly sized clueline blocks; better late then never. This is something I recognized too late, these blocks are small, and I have to live with the bit oversized ones on the other yards. From the upper outside, there are lines for the standing lifts, thimbles for the jibboom guys. Apart from the footropes, cluelines and their blocks from below. The spritsal yard in place. Held in place by a sling, and halyard. Then started to add the fittings to the bowsprit cap, the standing lifts first, they should have thimbles but I omitted them as the ones I have looked out of scale for me. Looking the picture, the port side lashing needs replacement - by eye it wasn't so bad. Bowsprit horses rigged next, from the cap to the timberheads. These lines hold the netting, used for storing the staysail - it was a fun feature to add, while I choose to use tulle instead weaving the lines.

-

Robert, congratulations for your first wooden build. You are a fine builder and your ship will be a great model. As someone, who builds an Occre model for a long time, trying to make it more accurate, let me have some recommendations. - please consider to change the eyelets in the kit, they are too big to scale. Buy 2 packs of 2 mm Amati copper eyebolts (comes by 100). If you don't want to paint them, heat them up with a torch and immerse in water, they will turn dark brown. They can be easily formed into hooks, should you wish. - you will need a selection of blocks sizes, from 2 mm to 6 mm. The Occre blocks are not bad for a kit, but there are no sufficient sizes supplied. Going upwards the blocks will diminish in size, also, clueline blocks should be smaller than the ones for lifts and sheets, etc. There are a selection of blocks available at Syren, Vanguard or Hismodel. I tried all of them, being in Europe the Hismodel ones are pretty good and not expensive. - the same goes for the rigging thread, you can go as far as you want, but consider 4 sizes for standing and running rigging each. Similarly, there is a wide selection to choose from, but standard Amati thread available in different sizes is already a step up and pretty cheap. You need to dye them though, wood stain worked well for me. - I saw many inaccuracies / simplification in the Occre rigging plan. Don't know how it is for Endeavour, but i found a rigging book, like Petersson's great help. Vanguard Models sells it. I see the Occre Endeavour is a nice looking subject. By making small and inexpensive adjustments you can make it even better. My build log have some tips for kit bashing, if you are interested. Keep on the good work, best, David

-

thank you Dave for your words. The kit I'm building is from Occre, not Caldercraft. Overall the hull is pretty solid and goes together well. The materials are not first class, but they are OK for the price of the kit. The kit falls short on detailing and fittings, most of my activities revolve around putting this right (or at least improve them some). For me it's not an issue as I feel like doing some actual modeling. A modeler looking for an accurate scale model to be built from the box may find it lacking. While I never built a Caldercraft kit, from what I see they are on a next level of accuracy, they also provide a bigger challenge to the builder. The Caldercraft Diana is a different ship (a British one), I saw wonderful finished models of it.

-

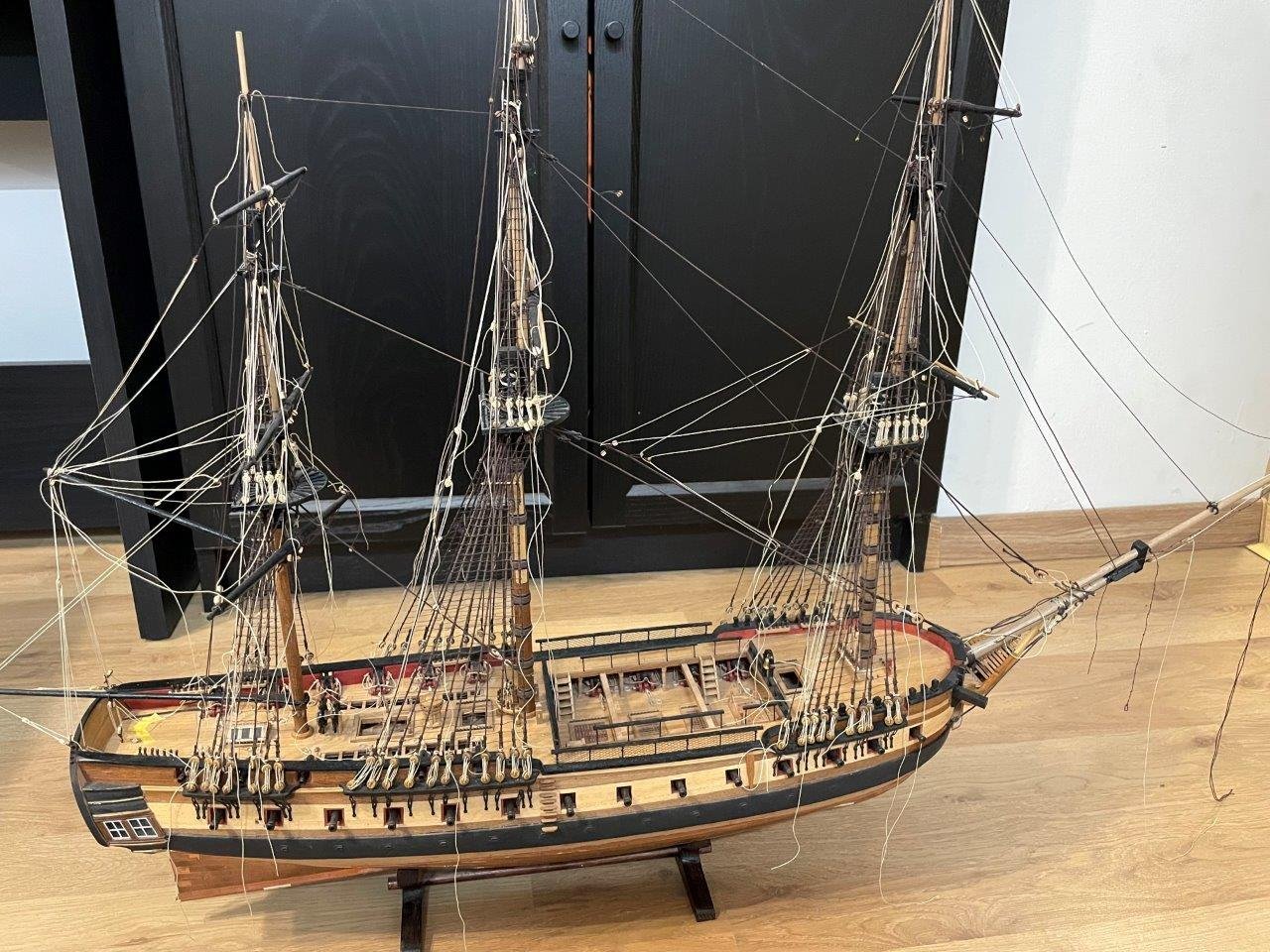

time for an update, I try to do something on the model each day, even very small steps move things forward. With persistent work, I made a total mess of rigging lines over the weeks. then started to tie off the lines, which I'm currently doing. this picture shows the rigging around the fore yard, a significant departure from the kit instructions. I followed the Peterson book to make jeers, sling, lashings, etc. An unexpected side effect, the belaying points prepared by the kit instructions doesn't match, and I have to redo several of them. I tried myself to make a nave line, I never rigged before. It's hard to notice between the other lines, but this one is attached to the trusses, and holds them from above, through a block under the mast top. It's a tricky bit of rigging to run freely between the catharpins and install it on the right side of the main topmast stay (first I made it wrong and had to remove the block from the stay, as I didn't want to disassemble the trusses) the stern area also taking shape. I knocked off the guy pendants so many times, I just left them unrigged for now. finally an overall picture of the model as of now: There is some belaying left, a week of work in my pace, then I move to the bow section.

-

This is a very nice example

-

I vote for the Corel Bellona. There are several build logs here you can check. A nicely built model indeed.

-

Occre kits have a simplified design, but don't cost a lot. Fittings usually are not in proper scale and the rigging plans are less than accurate. If you are interested in the Endeavour, Caldercraft makes a much more accurate kit. That ship is not recommended to beginners at all though, the hull shape is pretty difficult to plank properly.

-

I bought these from an ebay store who were shipping from Italy, as VM was out of stock

-

Master Korabel makes nice blocks in several sizes, including 2mm.

-

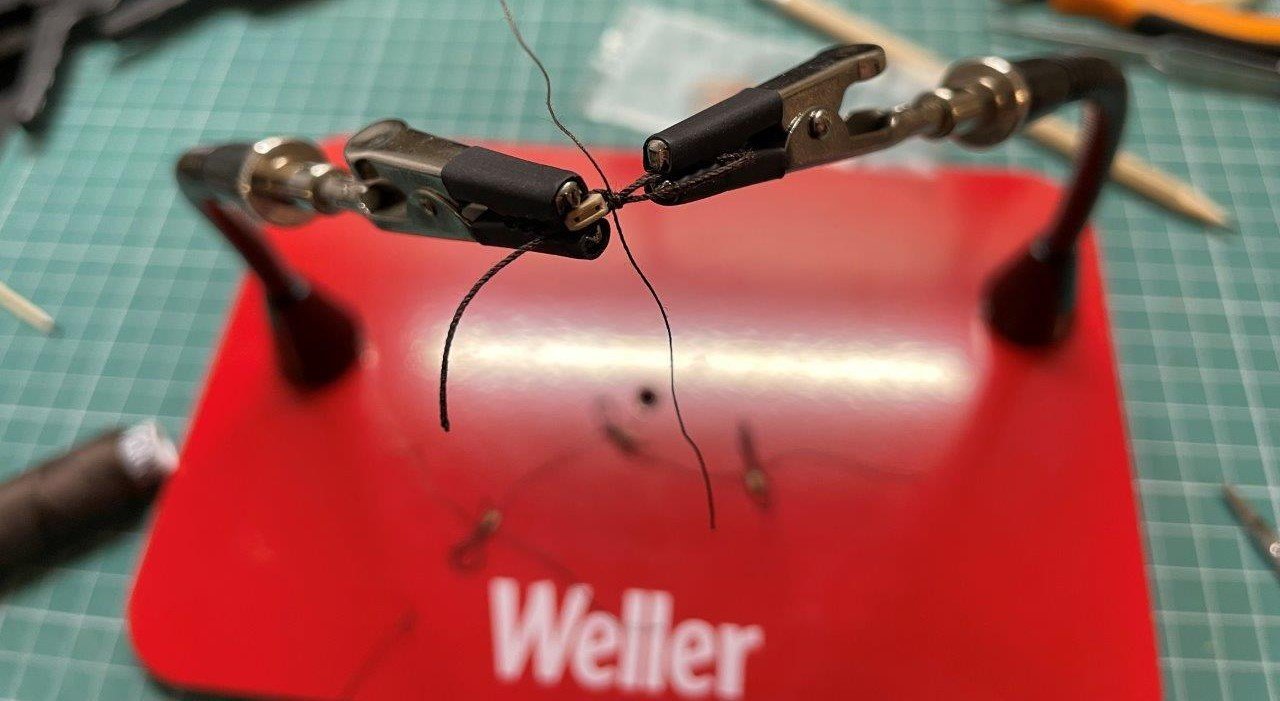

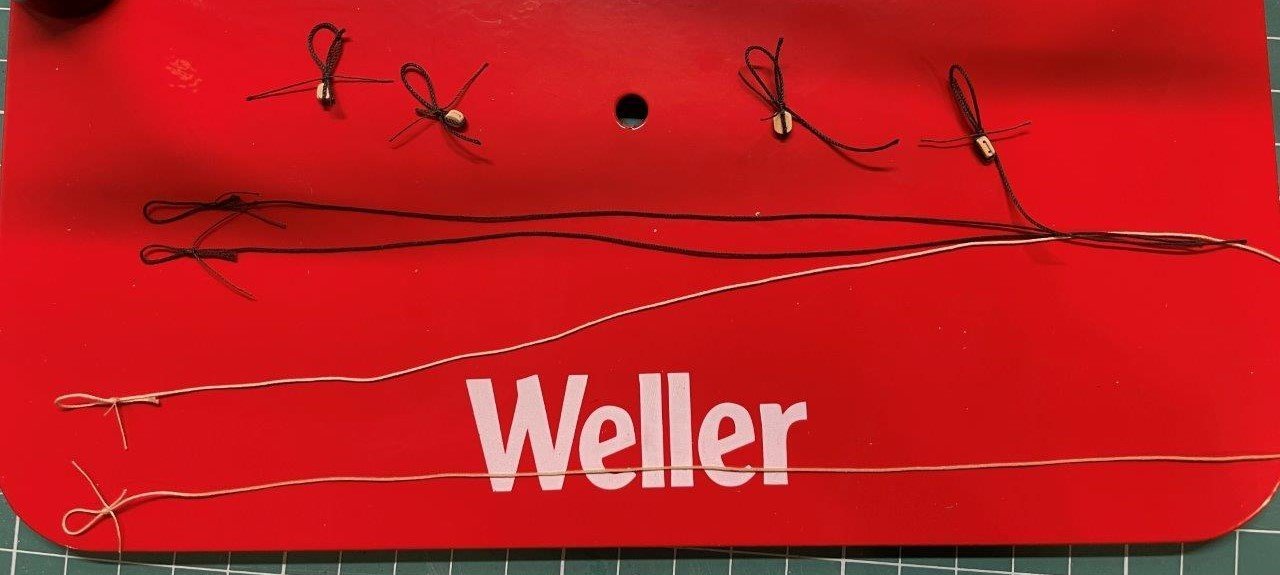

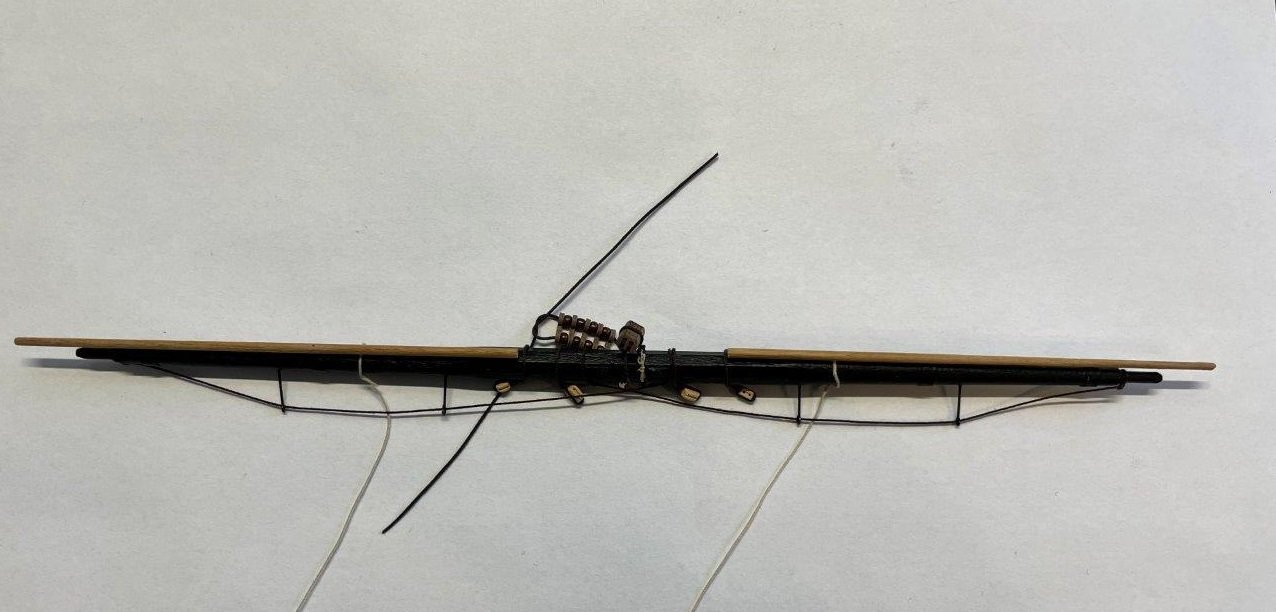

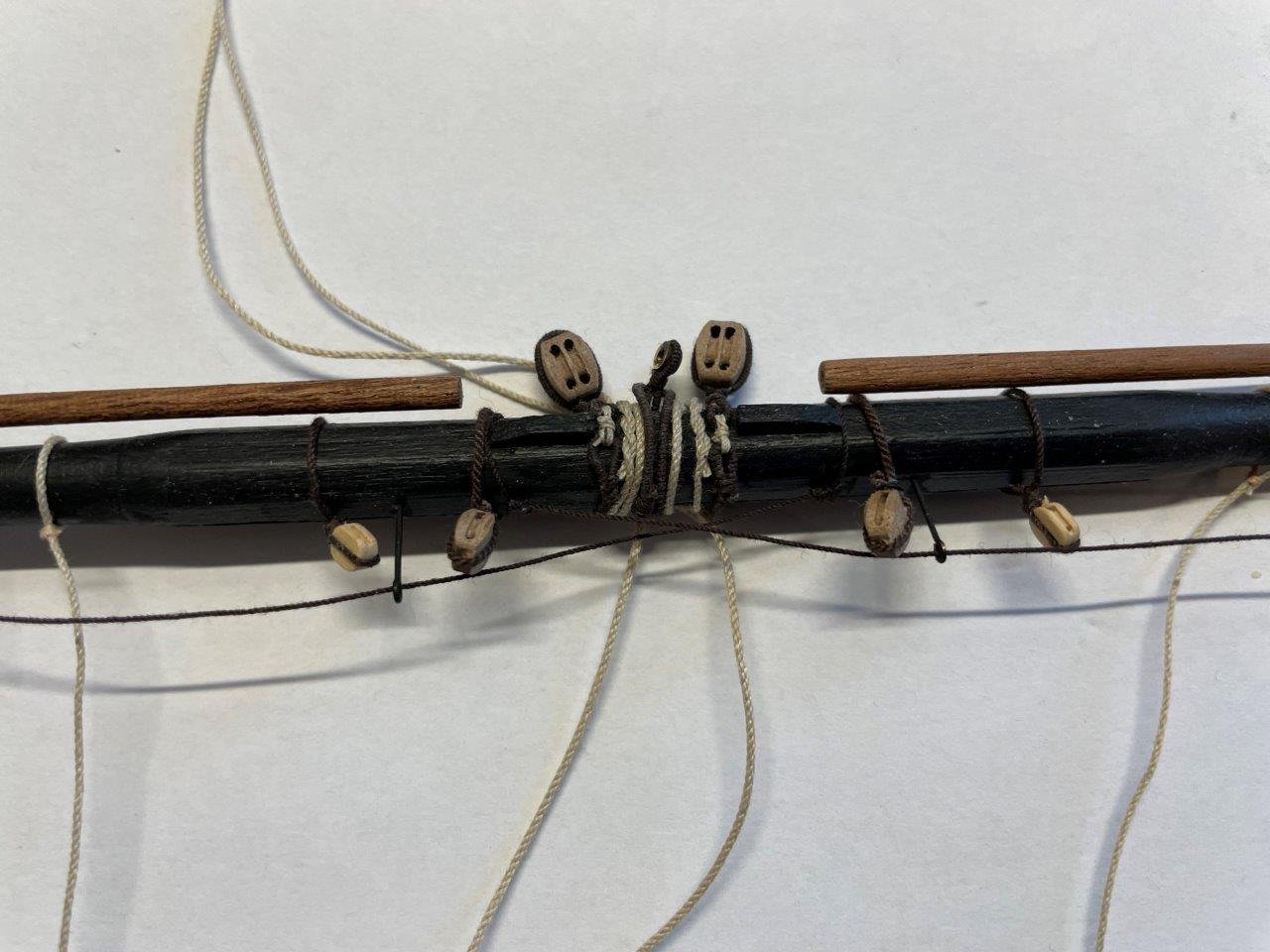

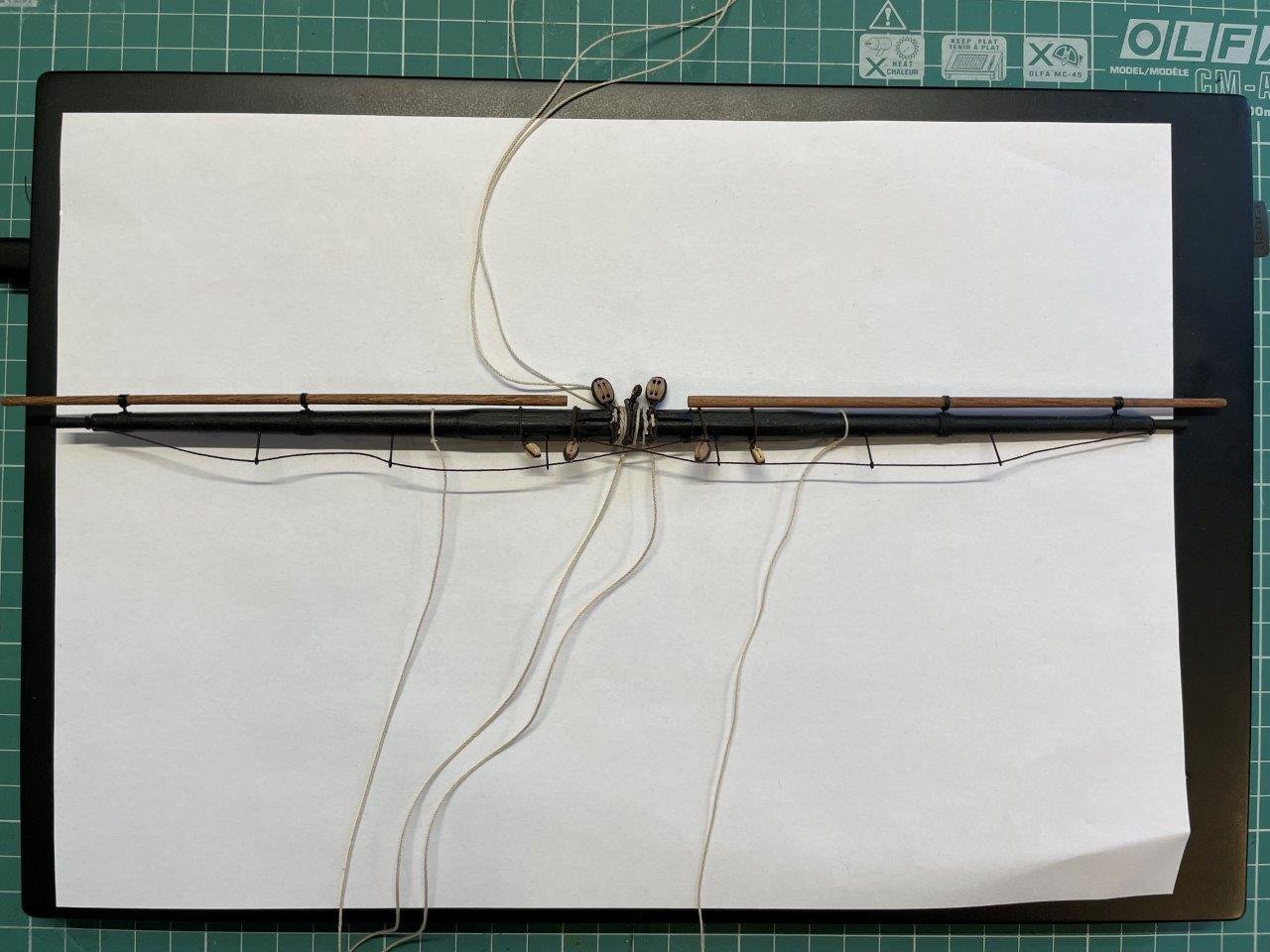

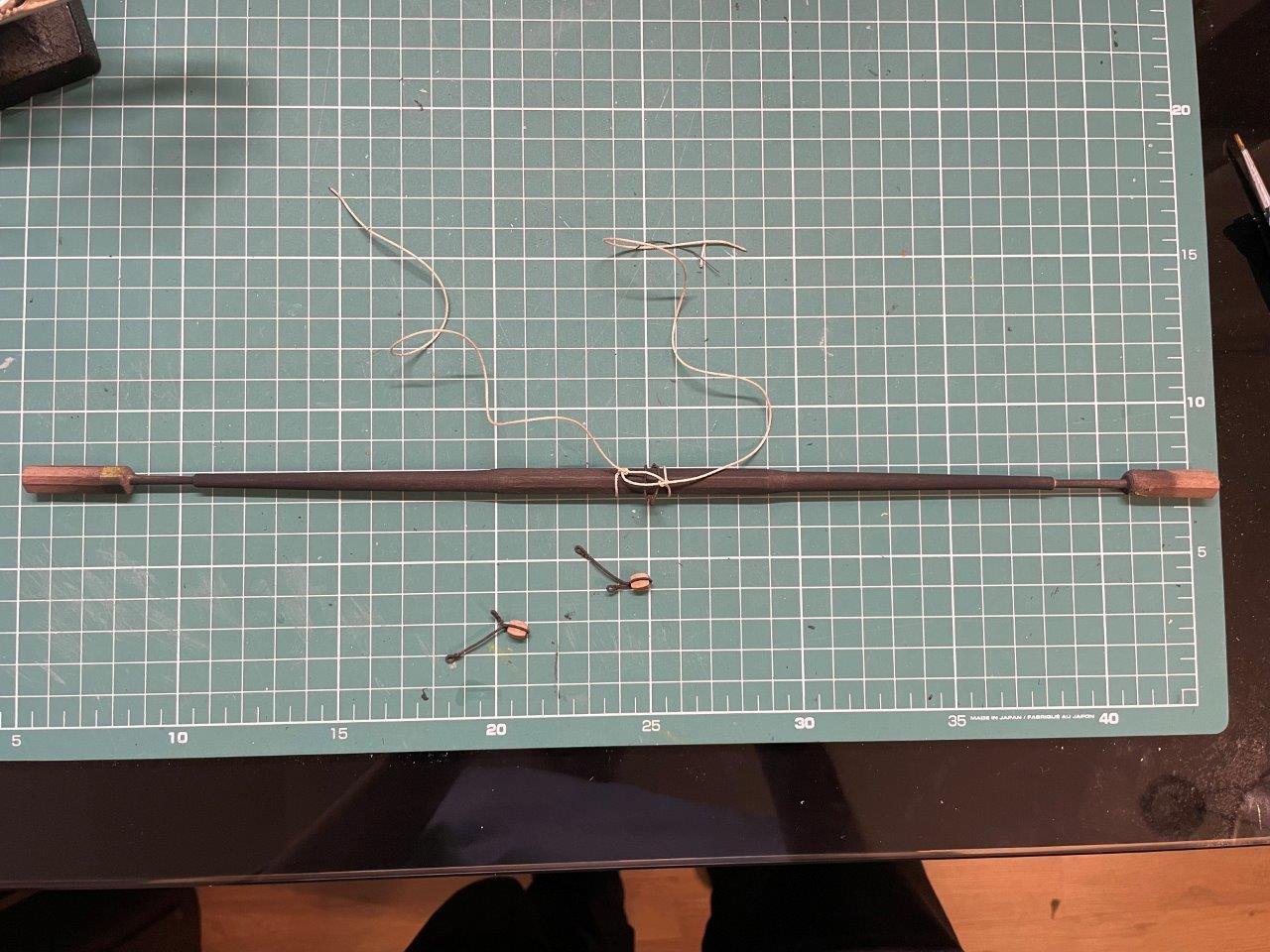

I try to improve the process of making yards. this is my current process making them. I start with square stock, in this case 6mm for the main topsail yard. The most important step is to prime it with white before doing anything (they will be painted black later). This simple step vastly improved the octagonal shaping, now I can actually see what I do. The white background makes the marking clear, and provides good feedback how much wood to plane or carve away. The picture below shows the yard after shaping, the central white lines are remains of the primer. I intentionally leave the octagonal stems at the ends. These act as guides to define the centerline of the planes along the length, and with the help of a thread I can place the stirrups lined up properly (stirrups are copper eyelets in this case, as I failed several times to make proper thread versions with uniform length and having them straight). Then I make the blocks to add, this tool is a new acquisition after not finding Quadhands locally, but basically the same and works great. The required blocks and lines (blocks for the topgallant sheets, clueline blocks, footropes and cluelines). I pull the eyes tight after placing them on the yard and fix with diluted glue. The parrels are made next. I ordered Caldercraft etched parrel ribs in the hope of being more scale (ie smaller) than kit provided ones, but actually they are the same size. They have a cleaner look though so I used them, but made them thicker by gluing them in pairs, as the etched part looked pretty thin. I had the same experience with beads, what I bought in a hobby store was the same size than the kit ones (€0,5 for ~300 of them) , but at least I was able to select similar sized ones. Ethced ribs, paired ones and kit supplied parts: After painting them, I made the parrel with served lines, eyes in the end and a lashing attached. This matches my sources, but the use of served line proved to be a mistake as the thickness made the installation around the mast very difficult due to their stiffness (despite having them wet). Finally cut the stems, painted and varnished the yard and added the fittings. The stunsail boom irons are simulated by paper strips and held in place by brass wire. They are placed 45' forward on the top.

-

yard making continues, I'm getting faster with them. here is the finished main yard, with all fittings installed. The setup for the stunsail booms are probably wrong for the era, sources indicate the iron should attach to the end of the yard, but I already made the yards for the mizzen by the kit plans and decided to go for consistency. there are several lines in the middle: jeer blocks, held together by a lashing (I still have to figure out, how to make acceptable lashings), jeers, truss pendants and the sling. some plans show the jeers are tied to the blocks, but Peterson shows them attached to the yards, woven over themselves. I found it nice looking and chose to do this way.

-

your work is a joy to follow. the painted transom makes the model really unique. as you use acrylics for your paint job, especially mixing them, a wet palette might be for your help. it can be as simple as a wet dish rag with a parchment paper on top, but keeps the paint from drying for hours and really a great aid for mixing. I learnt this by painting my son's (12) board game figures last year. there is a great deal of info from more competent painters than me on youtube, for example this one.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

poor Diana was neglected for most of last year, but recently started to work again, as I really want to finish it and move on. this build will celebrate the 15th birthday this year. A major dusting was due, also had to examine the model and my notes to plan for the next steps. Finally made some running rigging lines starting with the mizzen, which is now mostly finished. After a few weeks I got into practice again. Currently work on the main yard, after spraying with black primer, the truss pendants are being test fitted. In the foreground the jeer blocks are being made. The current stage of the build: thanks for looking in.

-

Cornwell Model Boats sells Mantua castings. They have the complete set for the Vasa : https://www.cornwallmodelboats.co.uk/acatalog/44705-Vasa-Casting-Set-44705.html#SID=88 You may contact them for individual pieces, if you don't need a set.

-

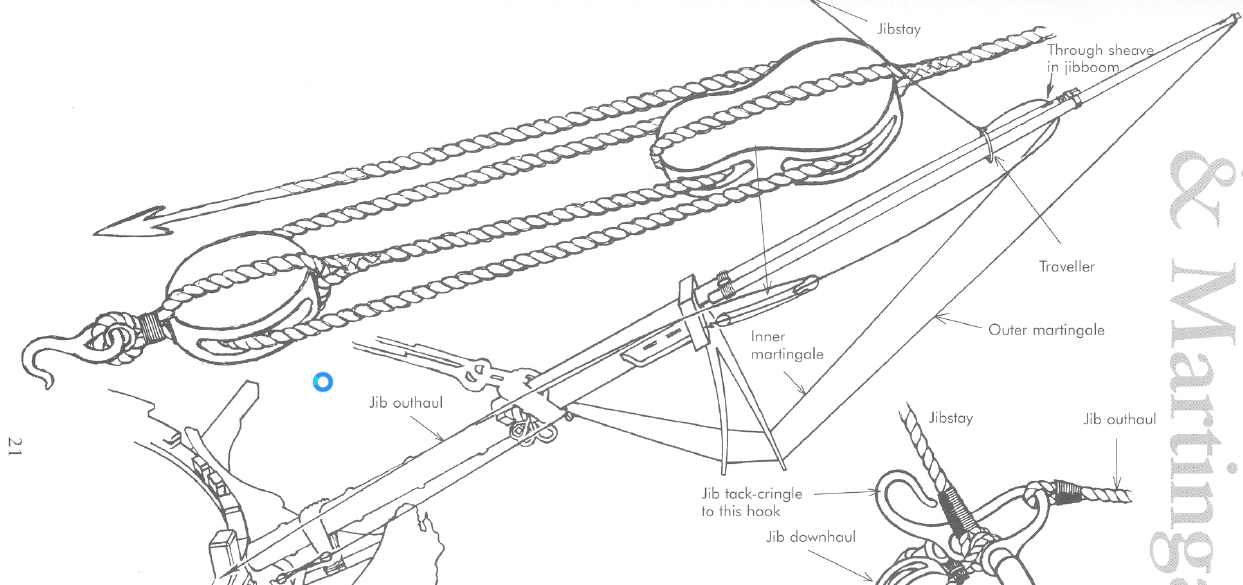

Hi Robert, the line you are referring is called a martingale, which counters the upwards pull of the stays, with the help of the dolphin striker, which is a device to increase the angle of the rope to amplify the downward pull. You took me over by your progress as I haven't rigged this lined yet. To be honest, I don't know what would be the current arrangement for the Diana, but a little research shows several options. Petersson shows it is belayed besides the foot of the bowsprit after leading it through a block below the stay collars. While I try to follow this resource, for me it seems impractical given the different proportions of the Diana (and probably the shown example is a later period due to the double arrangement). A well documented build of the Occre Diana exist in a Russian forum (here). On photo 13 the builder tied off the lines on the big timberhead just besides the cathead (if I see well). It seems to be a viable option. The rigging manual of the Caldercraft Victory (available here) instructs, the martingale tied to the knighthead, similar to what the Russian builder did. Another reference might be the Artesania Latina Surprise, with the manual available here. On page 67 the, line seems to be tied to an eye in the hull below the rails. I hope this helps. best, David

-

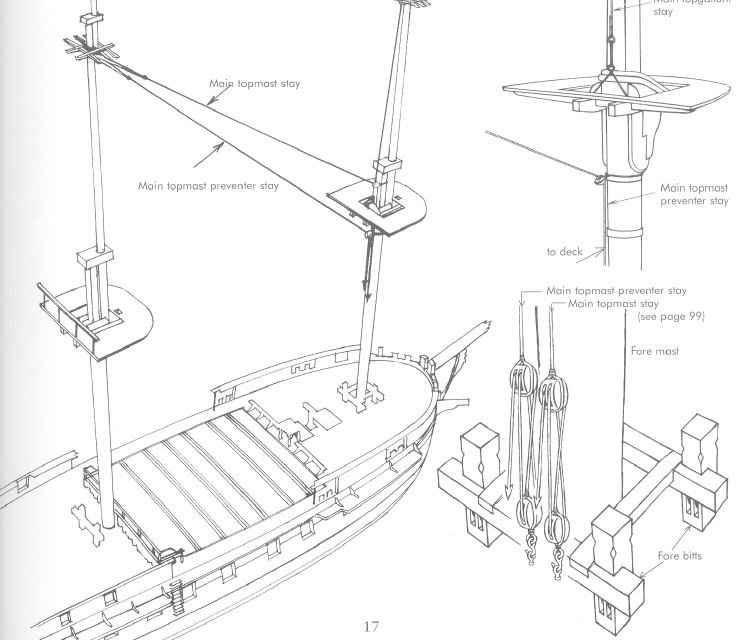

rigging the shrouds before stays is the normal practice. If it is done otherwise, the loop of stays around the topmasts gets below the shrouds which would be incorrect, as they have to be over them. I found it is not practical to finally tension the lines until a much later stage. The braces will pull the shrouds after you rig them, and have to adjust anyway. Also note, the Occre rigging plan show the stays tied off on the middle of the masts. In practice, the lines were belayed on the deck or the mas top as below, if you choose to to complicate your life further

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.