-

Posts

2,792 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by AON

-

-

All dry, water sensor/alarm installed, and a standing pipe and floor drain gasket on order from New Jersey (they don't sell these in Canada).

I made a mess of the nice clean shop floor yesterday, cut and sanded my upper and gun deck clamps. Went to install them and it seems I hadn't quite done a good enough fairing job inboard at the upper deck level. So I'll be at that today.

- GrandpaPhil, bruce d, mort stoll and 1 other

-

4

4

-

It is almost back to normal now. Should be 100% by tomorrow night. We've lived here over 20 years and this is the second rain storm that the sewer system couldn't handle the run off. After the first we made sure to get everything off the floor but over time the memory fades and we get lazy. Not too much lost but the perimeter drywall got a good soaking. Some boxes ruined, stuff for donation turned to garbage and one extension cord to our cycle gone kaput. Most stuff was in rubbermaid tote boxes so that was fine No tools lost but all my sawdust was caked to the floor of the shop with a trail to the drain. Three stains on the floor to deal with.

I built extra shelves well off the floor yesterday for any new stuff. The fans have done a good job drying things out but the humidity has gone to my paper plans hanging in the corner. At least the model was upstairs on the dining room table so she is fine.

I'll be installing a stand pipe rubber gasket in the floor drain for next time.

- GrandpaPhil, mtaylor, flyer and 4 others

-

7

7

-

Since it was raining quite alot this weekend I decided to go down to my basement shop to make the additional deck clamps.

Discovered about 2 inches of water had flooded the basement coming up from the floor drain.

The wife and I have been purging, cleaning, drying it all out since. Taking our first trip to the city dump tomorrow morning.

-

- mort stoll, No Idea, druxey and 6 others

-

9

9

-

Finished the repair work and sanding.

Last item before turning my thoughts completely inwards is to install the lowest transom beam, located above the wing transom and the two aft gun ports. Seems to be called the helm port transom beam.

I've also been thinking about closing this log as it has grown quite large and opening a Part Two build log that will deal with my tackling the installation of the decks and onwards.... but first that last transom beam.

- fake johnbull, No Idea, bruce d and 7 others

-

10

10

-

Finally got back to it... working outside.

Cut and installed the cills at the starboard galley door locations and the aft poop deck gun location for the carronade.

Presently working on a larboard or port side and fixing an error. I accidentally cut the timber tops down at the wrong location for the carronade. Removed the centre timber stub and sarphed the outside two. Added a scarphed block to the forward timber... did likewise aft... and installed the new centre stub. I need to add the chocks, do some sanding and I can move on.

- mtaylor, yvesvidal, scrubbyj427 and 8 others

-

11

11

-

-

-

17 hours ago, flyer said:

Conclusion: I will scratch the spritsail topsail and it's yard and adapt the rigging of the spritsail yard accordingly. The spritsail yard with a furled sail will be triced up by about the same amount as all the yards are braced. I will also add the missing guys to the spritsail yard.

I think you made the right decision.

-

-

-

Might I suggest...

If you dilute white PVA glue in water (50/50) and brush this on the rope it will dry in the shape you set it.

Don't use CA glue as eventually the rope would become brittle and fall apart.

Alan

- BobG, yvesvidal, Beef Wellington and 1 other

-

4

4

-

-

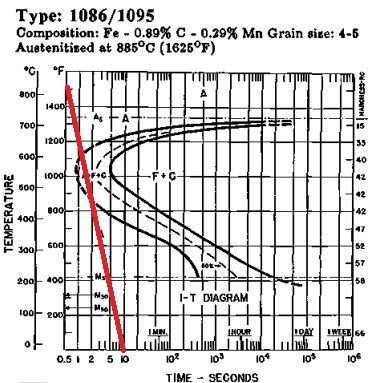

Yes. Above the "As" line.

But when going by colour one person's red can be another's orange!

This is the case for my wife and I. It has to do with the number of cones in your eyes.

So it is better to go a little higher then to find you were to low... but we aren't building rockets so maybe it isn't so important.

- mtaylor, billocrates and TomShipModel

-

3

3

-

and lastly...

Most industrial heat treat companies soften their steel by cooling it very slowly, over hours of computer controlled heating temperature drops in a heat treat furnace. This forces it to cross the transformation lines higher on the curve so the material is even softer (HRC25?). This would be ideal but we hobbyists do not have the means or time to do this.

From what I've learned today about home quenching in oil I would personally avoid it. Hot water should work as well but the blade is so thin that allowing to air cool shouldn't take an unreasonable amount of time.

- billocrates, TomShipModel and mtaylor

-

3

3

-

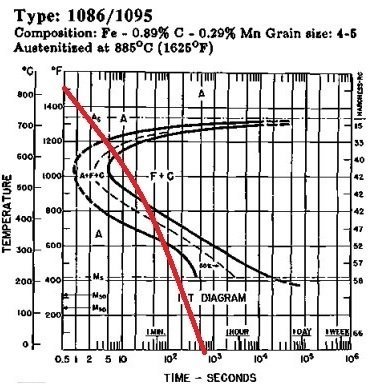

In this figure we are showing air cooling from 1500°F to warm in 600 seconds = 10 minutes (?). We pass completely through the transformation curve. Where this happens is in the Pearlite phase and is about a hardness of HRC40. Once it completely cross that third line it cannot become anything else. This is considerably softer and easier to machine than Martensite.

I believe this is what Druxey described he does. As his scrapers are not for production use he does not bother to re-Harden, Temper and Age his scrapers.

If you were to do this it would be a case of heating the scraper to 1500°F, allowing it to air cool to become warm to touch, only because it was worked on and any localized heating may have changed the microstructure in the area. Then Temper it by re-heating it to 275°F in an oven and holding at that temperature for more than one hour to phase to achieve a hardness of about HRC63 to 65. Finally you would shut off your oven and let everything cool naturally in the oven to room temperature to Age it, make it more ductile, less brittle.

If you did do all this you would have a harder/tougher/longer lasting scraper... but is it necessary?

- TomShipModel, billocrates and mtaylor

-

3

3

-

Good evening Kevin. I will do my best to explain what it all means...

I was taught to read these diagrams 50 years ago so if there is a professional metallurgist out there that can do this better than me please step in.

I will explain the Isothermal Transformation Diagram (T-T-T) as simply as I can in three postings - this being the first.

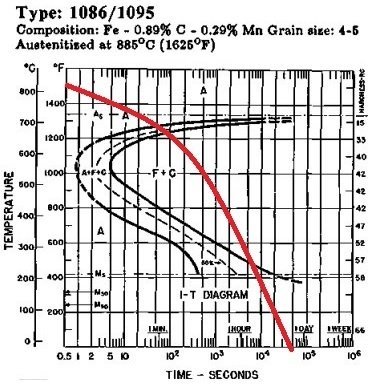

Hacksaw blades are made from high carbon steel (C1095) and this is the Time-Temperature-Transformation diagram for it.

On the left is a scale for temperature. On the bottom a scale for time in seconds. On the right a hardness scale in Rockwell C (Rc) where Rc15 is soft and Rc58 is hard... so soft is towards the top of the graph.

There are three swerving curves in the middle of the diagram. The one on the left is the start of transformation from one structure to the next. The one on the right is completed transformation. The one is the middle is 50% transformation. You can interpolate 25% and 75% from that.

You must heat the blade above the "As" line, a horizontal line at about 1375°F to completely transform into Austinite. So you heat the high carbon steel blade to a Red colour which would be above 1400°F... in the "A" or Austenitic zone and to soften the material you want it to cool at a rate that will cross all the transformation lines in the upper "F+C" zone. Once it crosses that far right line it is fully transformed and cannot become anything else.

F+C is Ferrite (soft) and Cementite (hard). The higher you are the more Ferrite is formed and the softer the material will be. This is the Pearlite phase. The lower you are the more Cementite is formed and the harder the material will be. This is the Banite phase. At the very bottom of the graph is the M zone... Martensite. This is very hard and brittle.

The hacksaw blade is very thin and so heats up and cools down very quickly.

What you did was oil quench from 1400+°F to warm in possibly 10 seconds (?) or more. If you draw a line from 1500°F to 10 seconds (red line on the diagram) you see the material passes through the knee of the transformation curve but does not completely transform. Instead it passes into the "M" zone and becomes mostly Martensite, hard and brittle at possibly HRC66.

- mtaylor, TomShipModel and billocrates

-

3

3

-

-

Thanks D. So you do not quench at all.

Kevin

Hack saw blades are usually 1095 carbon steel.

TTT is the Time-Temperature-Transformation diagram. It shows at what temperature and over what time the microstructure changes Austenitic to Ferritic + Cementitic)

I believe low red heat is not 200 to 300 F it is more like 1000 F and well above the flash temperature of some oils.

-

Are your degrees F or C?

In your research did you find the T-T-T diagram for the material to understand what happens in what time frame?

-

A very good video that shows the process quite clearly.

Thank you for that... but I have few questions about the process you followed.

In your first stage annealing (softening) process you do not quench the part.

Why?

Do you not want to freeze the microstructure in its new homogeneous crystal phase?

After re-hardening you Temper the scraper in your (toaster) oven.

At the 14:01 minute mark you mention putting the part in an oven at 250° to 300°F for 1 hour

At the 14:48 minute mark you say 350°-400°F for 2 hours

Which did you do?

With a hacksaw blade likely being a rather thin piece of 1095 grade steel wouldn't 350°F for 10 minutes be adequate?

You quenched in oil.

What oil did you use? Motor oil, cooking oil?

Is there any concern of flash ignition?

Some cooking oils flash ignite at 600°F and the part is rapidly cooling from about 1500°F or less.

Some motor oils flash ignite at 400°F to 600°F.

I understand oil is a slower quench and less stressful on the steel.

Why not hot water?

I believe cold water might be too much shock and crack the metal.

Would it be better quenching the blade holding it vertically in the quenchant and swishing it about gently to get an even (front and back) and efficient (heat transfer) quench?

Thank you Kevin.

-

Kevin

I emailed you five slides from Toni's PPT presentation that I saved for my personal library.

I do not have permission to post them.

Alan

- mtaylor and Kevin Kenny

-

2

2

-

I didn't recognize the piece to have been a hacksaw blade. Seemed much deeper than what I use but is probably just camera and scale.

Toni Levine had made a wonderful presentation on making and using scrapers at a MMS or NRMMS Club meeting. I'll check my files to see if I have anything useful from my screen captures. I believe she used a hand held dremel and metal cutting disc.

Get back to you in a couple hours.

- mtaylor and Kevin Kenny

-

2

2

-

A couple guys in the MSON use old hacksaw blades to make their scrapers.

Heat it with a torch to cherry red and fast quench in water to anneal it and then file the teeth away and cut molding shapes into them.

- druxey, mtaylor and billocrates

-

3

3

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

in - Build logs for subjects built 1751 - 1800

Posted

Yup...and they either connect to the sewer, run off to the street and collect in the sewer, or a stone pit at the far end of the yard. That works wonderfully until your run off water is overflowing (ground water flood) causing the sewer system to backup because it cannot handle the volume...then you have a flood in the basement.