-

Posts

2,792 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by AON

-

-

-

I have the LVT Veritas chisel set and used them often but I can't imagine cutting these notches after gluing in place.

I guess by the time I'm done may have a different opinion on the matter but not today.

Also, I imagine needing to reach under the beam for holding lodging or hanging knees with a finger so not getting too far ahead would be of benefit providing room for my bear claw hands... but not having done any as yet I am likely wrong.

- Thukydides and mtaylor

-

2

2

-

-

-

Contract reads that there are lodging knees and standard knees at each end fayed into the timbers except for the three foremost and four aft most beams and to sides of those beams for the 2nd futtock riders which are to have one lodging knee.

Standard knees have their athwartships arm on the deck.

So, memory being what it is, it is a good thing I double checked as I thought the first few had standard knees as opposed to hanging knees.

No mention of any hanging knees for the orlop deck.

-

First the good news.

I'm slowly learning how to easily make and notch the beams.

Fitting is slow work. I use a crude sliding stick to measure the distance then cut the stock slightly over size and trim it to fit.

I could measure off my framing plans... make a mental note to compare the measurements of the next beam I make... nope, better write that down.

The bow has quite the curvature to it in both axis so that takes some concentration to shape the ends of the beam to rest or nest in place properly.

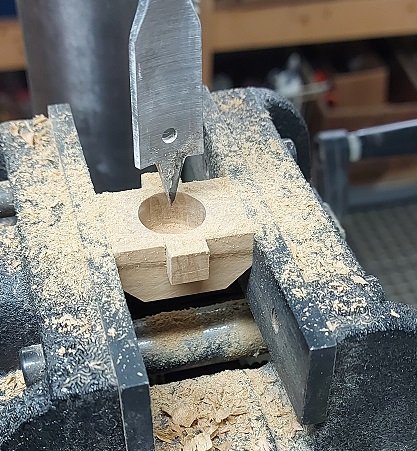

I mark the depth of the crutch cut on two faces and was originally sawing multiple notches prior to chiselling out to the mark but I find just notching the extreme ends is enough. I saw just inside the pencil line. The sawing keeps the ends from chipping. Then I fit the crutch stock into the notch and open it a bit as required.

So I've progressed to my first two beams having the crutches installed and all glued in place.

The third beam, the one with the arms, is notched and ready to install and the fourth beam is marked and ready to notch.

I mark the crutch notch locations off the plan I made for the gun deck. The contract stated the orlop deck beams are laid out like the gun deck above it. This is important to understand as I am about to mention the bad news. First I use my plumb to locate the centre of the beam. I have a string stretched from stem to stern on centre. My plumb is suspended from my height gauge beam and I inch it over, string beside string. The nib or point of the plumb is now just off one side of centre on the beam so I pencil mark the actual centre of the beam to one side of the plumb pointer. Then I place the beam, located with the centre mark, over my 1:64 scale paper plan for the gun deck and mark the notch locations. Easy enough.

When I stopped late yesterday I left myself a note to work on the standard knees for the first few beams. Standard knees run vertically upwards above the beam. I have to check if they start actually on top of the beam or along side of the beam... make a mental note... nope, I'd best write that down too.

This morning I awoke with a premonition I'd done something wrong.

Double check and the plans show quite clearly that the orlop deck beams have none with arms like the gun deck above has.

So the bad news is I made a beam with arms that is now scrap. The good news is I didn't glue it in place and I now know I can do it. Yeah me!

-

Excellent video! Answers all the questions.

- thibaultron, rlb, mtaylor and 1 other

-

4

4

-

-

If they are ball bearings they are not designed for a side force. As the spindle is vertical I'd suspect they are tapered roller bearings that will take side loading by design so light taps with a soft hammer/mallet should dislodge it.

If not tapered roller bearings then the machine is a poor design mechanically speaking.

If you use the long threaded bolt you might damage the threads. The rod should be a larger diameter so as not to engage or contact the threads at all.

-

Welcome to the forum!

Your comment about bending planks was interesting.

Some steam, some soak, some "iron"... but it shouldn't be that difficult to do.

I hope you have an opportunity to try again with the help of this group!

- mtaylor, Keith Black, AJohnson and 1 other

-

4

4

-

I do not have this machine but, having said that, there should always be an access hole on the far side to knock it out with a rod if/when it sticks.

If you cannot see it, there must be a cover over it. It should be a tapered hole.

Can you remove a cover?

Put a towel or something below to catch it as it drops out.

Good luck

- thibaultron, Canute, mtaylor and 1 other

-

4

4

-

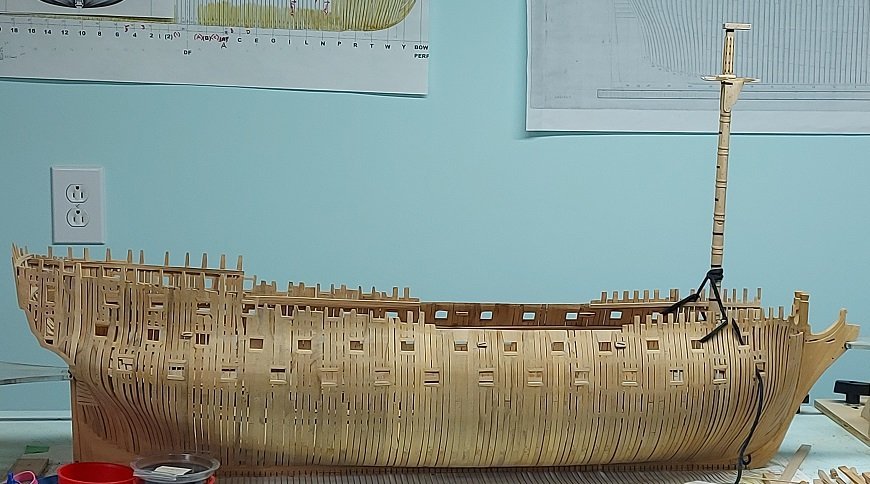

Thank you TBlack for that vote of confidence.

Here is a photo of the beginning of the orlop beam fitting. It may be slow going for awhile - until I gain some confidence in myself.

I hope what I learn here will help with the gundeck beams.

The orlop beam layout is described as similar to the gundeck beams above it but smaller in size.

- mort stoll, Thukydides, fake johnbull and 5 others

-

7

7

-

1

1

-

On 1/28/2024 at 6:06 AM, AON said:

Regarding the 22 orlop beams and the original contract.

They are the only beams that do not mention a rounded or rise dimension per the contract page 7.

[**correction: page 1 states it is rounded 2-1/2" which is a mere 1/32" at 1:64 scale]

I corrected my post #1625.

Started on the orlop deck yesterday

As the rise or rounding is quite minimal and this deck is below two others, I will treat it as flat, to make it easier for me.

I am happy I decided to do this deck as being a novice I am finding it quite the challenge.

Two beams fitted near the bow and the first tries of each are in the scrap bin. (Actually they are put aside to resize for the ledges and such)

I hope to get better at this soon.

I'll post photos when there is something I'm proud of.

- mort stoll, mtaylor, Wintergreen and 2 others

-

5

5

-

No sir. Your message was quite clear to everyone but me. You even had the correct emoji!

There is only one whale appendage here... oh wait... you meant silly person. 🤣

That good sir would be me!

Regarding the 22 orlop beams and the original contract.

They are the only beams that do not mention a rounded or rise dimension per the contract page 7.

[**correction: page 1 states it is rounded 2-1/2" which is a mere 1/32" at 1:64 scale]

I suppose due to being below the waterline there is nowhere to run off to but down to the bilge.

These beams range in size from 15-1/4" to 12" square. (0.238" to 0.188" or 6 mm to 4.8 mm)

I've cut up stock at 0.235" square and will use that throughout the orlop deck to simplify something that will barely be seen.

- Wintergreen and davyboy

-

2

2

-

Now that is quite funny!

I'm sorry you had to explain it.

- Wintergreen and No Idea

-

1

1

-

1

1

-

I don't visit this topic often enough.

Allow me to add a late Welcome to the group from a fellow Ontari-ari-ari-oh-ian with roots well anchored in the rock.

- Keith Black, Tyguy35 and mtaylor

-

2

2

-

1

1

-

Welcome to the group. Hope to see you building and posting about it soon.

- mtaylor and Keith Black

-

2

2

-

I actually did one other thing to personalize it. The hint of which is mentioned in my very first post. Possibly in 100 years someone will have a reason to get inside with a small camera and discover it.

- Wintergreen, scrubbyj427 and druxey

-

3

3

-

Made and installed the main and mizzen mast steps. I simplified them as they won't be seen.

One thing was desperately needed to be added... a coin for good luck.

I have an 1896 Queen Victoria 5 cent Canadian silver coin. About 15.35 mm diameter. It is quite battered up and worth about $12 max. on a good day.

I drilled out the bottom of the main mast step with a 5/8 spade bit, inserted the coin face up, and installed it in place permanently.

Am I ready to start the deck beams?

I think so.

Have to remove the masts first and put them back in storage.

-

-

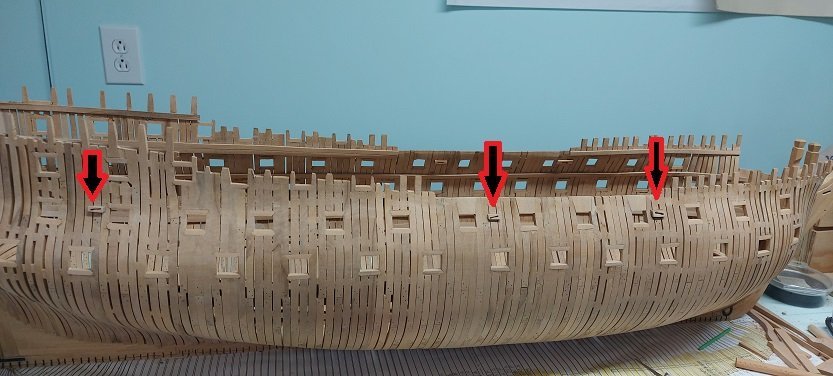

Completed the three sets of fixed blocks... but after having reminding myself not to get cocky and triple check what I'm doing I ended up drilling the last two backwards.

The sheave was tilted the wrong way. I had one glued in and was starting to carve the last when I realised the error. I quickly removed it and cleaned up the hull.

Had to cut two new pieces and carefully mark them before drilling.

- mtaylor, KARAVOKIRIS, GrandpaPhil and 7 others

-

10

10

-

Thank you Håkan

If that minor chipping was a problem for me I actually would have thrown out the whole model a long time ago.

There are many mistakes made and corrected along the way that only I or a close up with a camera can see.

These are all my honourary awards for not having given up.

I actually put a dab of white glue in those chip spots and rubbed some sawdust into it, let it dry a bit and passed sand paper over it lightly to hid it a bit.

If a plank is placed over it it would never be seen again.

-

Excellent idea.

I'll send the Model Shipwrights of Niagara group the link too.

- mtaylor, Ryland Craze and Canute

-

3

3

-

Managed a couple hours in the shop this afternoon.

First was cutting out the sheave block holes through the hull. I managed only two of three that pass through the starboard side of the hull.

I cut out between the holes using an small X-acto saw blade as it would fit in the hole.

Then I opened the rectangular hole with small files, checking for fit regularly. There was some chipping.

Once the block fit I ran a pencil mark around the block next to the hull then I sanded the inboard and outboard end of the block to be 1/16" proud of the mark.

The pencil mark was slightly clear of the frame so the "extensions" out and inside of the frame was slightly more than 1/16" which is 4" at scale.

I then clamped the block in my table vise. Drew a straight set of pencil lines above and below the sheave holes at the hole extreme diameter as a guide.

Using a scalpel I scored along the lines in an effort to avoid chipping the surface of the wood when chiselling.

Then I micro chiselled out the sheave opening between the holes, shaped the sheave and chiselled the rope groove into the sheave.

Then turned it around and did the other side.

All pencil marks on the block and hull were erased, followed by light sanding.

The blocks were then glued into the frame holes permanently.

I have the two fixed blocks on the port side to do next and then there is one last set that passes through the frames forward of these.

They are ever so slightly larger at 13" (0.20") versus 10" (0.16").

Not necessarily very noticeable at this scale but I'll do my best.

HMS Bellerophon 1786 by AON – scale 1:64 – 74-gun 3rd Rate Man of War - Arrogant-Class

in - Build logs for subjects built 1751 - 1800

Posted

I like how you used the stiff cardboard to square things up.

I tried notching on the model a short while ago. I had to open a notch a bit. I did not like it at all. It will take much more practice.