-

Posts

541 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by FrankWouts

-

Beautiful and steady work Glenn!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Beautiful work Steve! Please keep your updates coming! Frank.

- 99 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Aha, now I see indeed, at first it looked 'paintish', but not quite.... When rounding the bulkheads more to the bow, it looks that you oversanded the upper part, but only just a bit to my eye, the upper part where later the (upper two planks) planking on it should almost hang over a little for the anchor davids? I tried to draw in your picture what I mean. But perhaps this could be an optical illusion in the photograph. I had it a lot with some left over char here and there that simulated shadows that aren't there at all. Also, I'm not sure if I'm looking at your 'Winnie 1'or 'Winnie 2'? Bit confusing, for me at least. Perhaps check with the bow cap template if you also have the form correct. It should prevent lots of headaches later on. If not quite the shape, now you can still correct it by adding a little strip or some filler and sand back to the correct shape .

-

Simply very beautiful work, again. I know the feeling when having to pull a plank, or more... Taking a deep breath and start again, specially with those special shaped ones. But afterwards you have that rewarded feeling when all conforms to the plans in your head: and the plans. Yours is still a very high benchmark for all of us Mike! Frank.

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Beautiful work Rusty! Frank.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

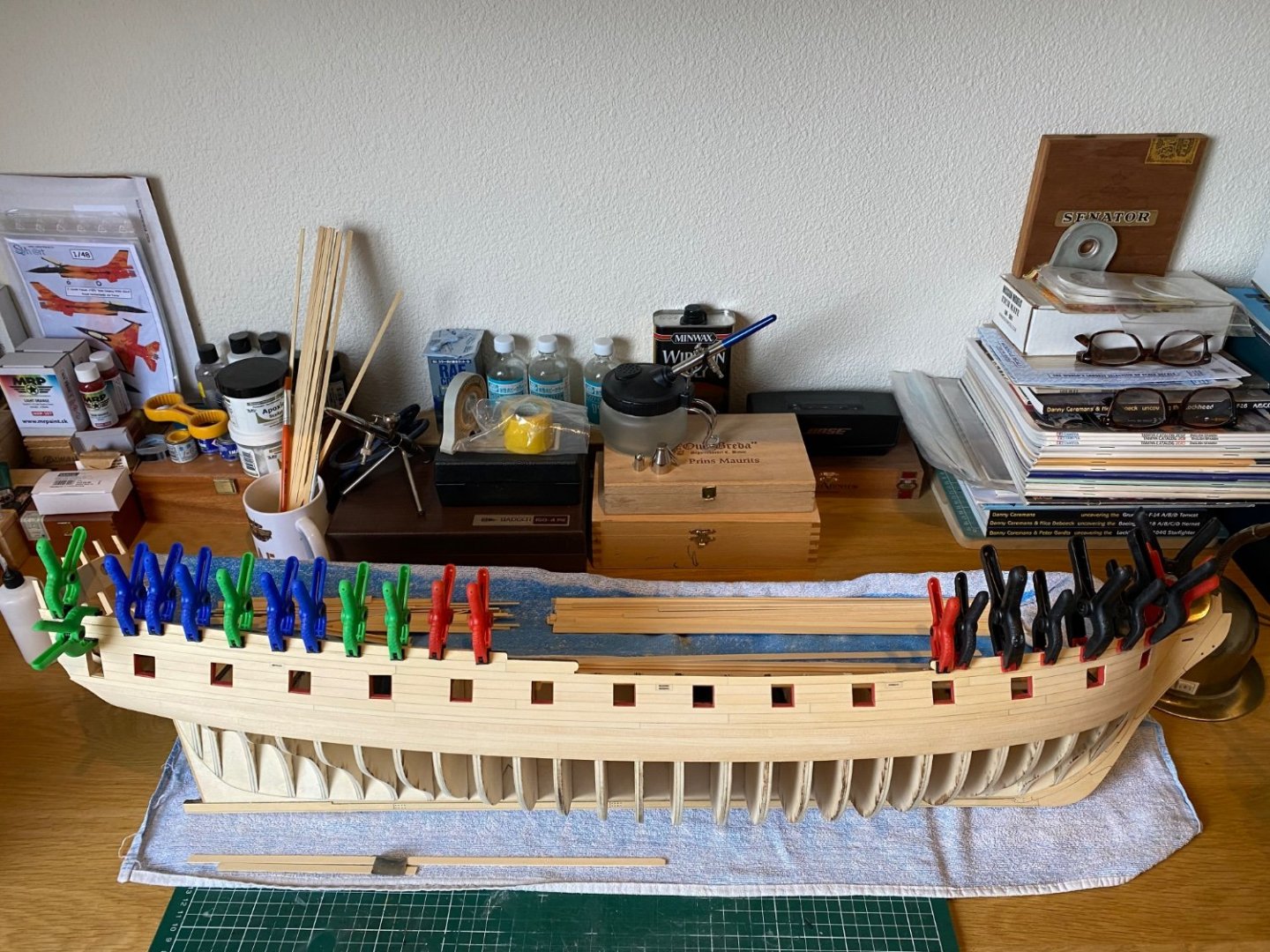

Thanks, Rusty and Dusan! I was anxious if the bow template would fit on my Winnie, and everything seems to be allright, it seems to fit within less than half a millimeter tolerance… I cut the portside one and turned it over by the way, the print is on the other side. The first thing I did not oversand I guess…LOL.

-

Bob, The result of your build is simply beautiful, despite your "small tremor in one and arthritis in the other", you show great talent and perseverance and to me that's what I admire most. I'm not looking for small deviations or some corrected errors in a model, but simply admire them as a whole and in the details and enjoy them. And yours is certainly an example to admire and enjoy looking to for hours. I simply hope to get as far as you with the same quality and beauty some day. Then I've proven to myself that I can do this: you've already more than proven that to me! Frank.

-

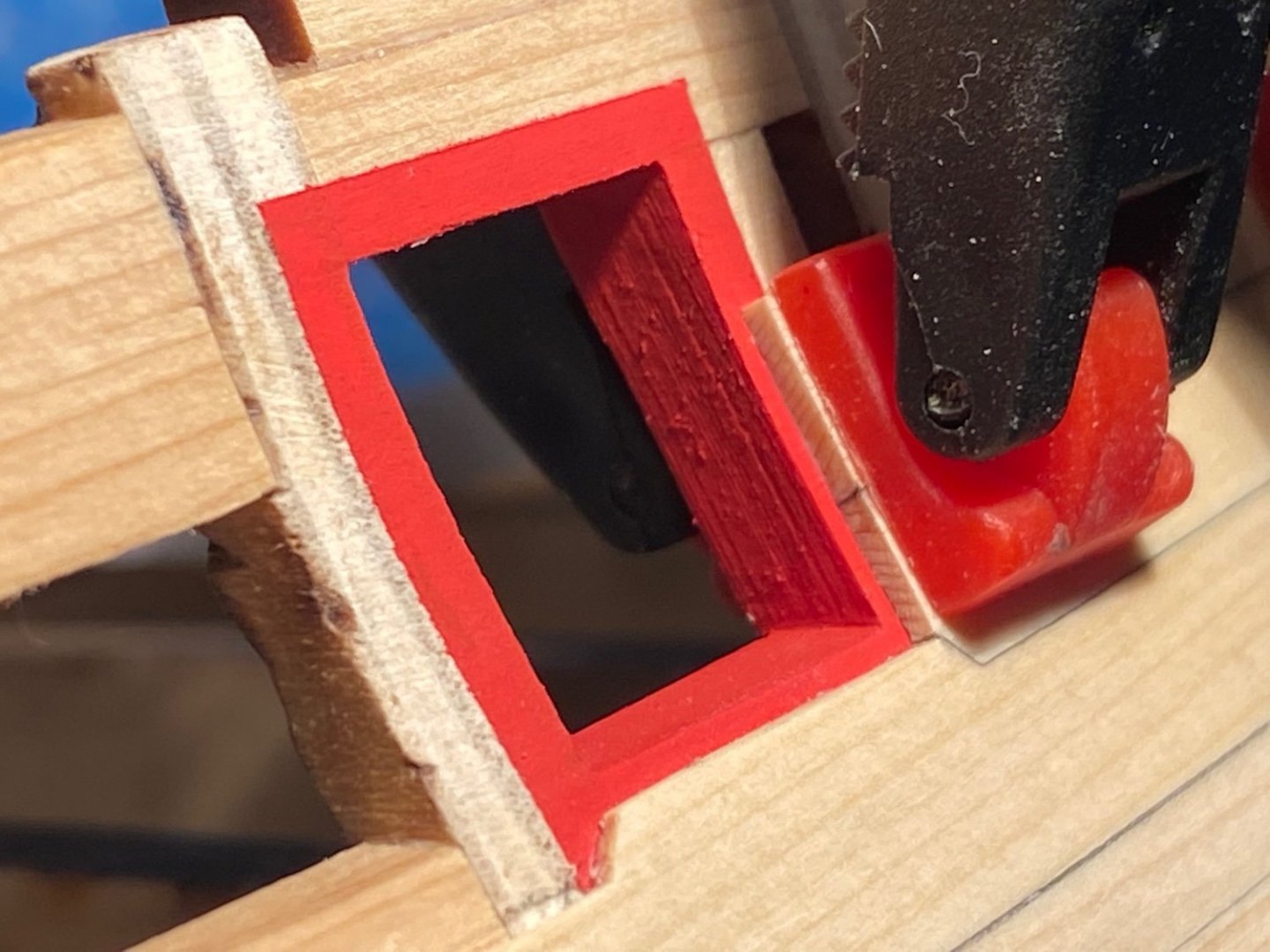

Thanks Chuck, Mike, Jorge and Kurt! And the likes which are always a big stimulus for me! @Jorge Diaz O I use vermillion red Humbrol 60 , as the Red Ochre color from Admiralty is too harsh to my eyes, too much towards redbrown/purplegrey/blue. I have it and I tested it and, though perfect paints they are, I personally don’t like this red ochre. Maybe this is because in my life I have seen too many window shutters and church doors in vermillion red on our antique houses and churches in Europe from the 17th and 18th century. The vermillion will shine through nicely after I’ll wash it later on with strongly dilluted darker redbrown oil paint like burnt sienna. You’ll have much nicer and warmer antique appearance afterwards. But I’m not sure if I’ll go ahead with this, as the vermillion as it is now looks beautiful to me. My photos and lighting aren’t what it should be, I’m not a photographer at all. The vermillion red looks more orangish, brownish than in the pictures. Also scaled down to 1:48 colors, should always be lighter and with little more grey tones in them than in real life. So an exact copy of the real color is wrong anyway in scale. Too dark and without the distance (waterdamp, dust in the air) grey tone effect in them.

-

Hi all, just a small update to let you all know I’m still working on my Winnie… I made a correction on the width of the upper layer of wale planks, replaced the upper row as I forgot to measure the exact thickness of the 7/32 AYC wale plank bars . Ofcourse they’re a little thicker than 7/32, as we get value for money from Chuck. So I ordered the Byrnes thickness sander as well. The total 5 wale planks are now exactly 35/32, and the wale curve that was determined by the batten is still preserved. My planks will be the exact thickness as indicated on the plans from now on: this won’t happen to me again! Cheers, Frank

-

Very neat planking Glenn, your're catching up with me!

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

40 lpi chain: https://www.hobbylinc.com/a-line-brass-chain1240-links-per-inch-ho-scale-model-railroad-accessory-29216

- 399 replies

-

- cutty sark

- revell

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.