-

Posts

1,770 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by SawdustDave

-

-

Dan.... Having spent the last two hours on this amazing log, I am completely blown away. This should be a virtual Modelers Handbook in advanced building technique. Can't remember learning so much in only a couple of hours....and that is only your first ten pages! This is not a build to be rushed through. I cannot thank you enough for sharing your work.

Dave

-

-

-

While still working on the first bulkhead module, I have managed to complete the deck planking of the waste area, and begin building the bulwarks with gun port frames.

The gun port frames, shown in the previous posting are created as seen here by simply using a perfectly shaped block to glue up the four sides. The block form assures the frames are very precisely the same size and perfectly squared up.... This assembly creates two frame units.

Each frame, made of bamboo strips, is just over twice the width needed, so I am able to split them with my mini table saw, and get two frames from each unit.

Here are the gun port frames glued in place with custom fit panels glued between each...

And here are the five frames in place with all the custom fit panels....

-

"Burn out"....Been there, done that. Had to put it down for over two years.

- qwerty2008 and Omega1234

-

2

2

-

-

And I've been accused of being fast.... You go GET'EM Mate!

- IgorSky, Omega1234, qwerty2008 and 1 other

-

4

4

-

I took a look at those plans Lextin.... Understand why you want to build this one. Looks nice. Looking forward to your log posts.

- Omega1234 and qwerty2008

-

2

2

-

-

-

Whilst plodding steadily along fitting deck planks to the waist area and building the first bulk head module, I have a couple of off-ship projects going on.

Because of the number that will eventually be required, I am building gun port frames along with the task of trying to come up with a quality mold that will give me consistent parts for the little crowned wreath.

I had to go to "Smooth-On" Rubber Mold Compound to get a good repeatable mold.

Not at all happy with the first attempt posted earlier.... but think I may have come up with something more acceptable....had to invest in new Alumilite casting plastic compound, since, after five years of sitting around, my old stuff just would not mix and set properly.

It takes about twenty minutes to pour a new piece and remove it from the mold.

- qwerty2008, mtaylor, cristikc and 12 others

-

15

15

-

Sculpey it is George. And, yes, it is much quicker than wood carving with very good detail results. Very easy to make molds to cast repetitive shapes like these little wreaths. It would take me a solid week to carve 32 of these parts.... not to mention the difficulty of getting them all to look the same.

I'm a big sculpey fan, but I doubt the wood carving artists would look upon it with great favor.

Although I get by fairly well carving wood, let's face it.... I'm getting old, and I would like to finish this ship while I still have my health. ha ha ha

-

Among several side projects being worked on is the first sculpting of the crowned wreaths that will fit around each of the six bulkhead gun port holes.

First the sculpting....

Used to create a casting mold....

Paint with a metallic gold....

My first SOS sculpted ornament. One down, a thousand to go....

Actually, this first one appears a little on the "fat" side, but I'm pretty sure it can be "skinnied-down" with a little more work. Never satisfied....

I count 32 of these little wreaths on the plans.

-

Before painting this module black, I wanted to get a (very rough) visualization of the way I will be trimming it out and adding ornamentation. Finding so many versions out there among many previous builds, I decided this is one area I can pretty much treat about any way I choose.

I'll be attempting to go with the way Doris built hers.... having an upper and lower doorway and six gun placements.

There will be two cap rails with short stanchions between.

This bulkhead is very important because it establishes the height of the bulwarks of the half deck.

-

-

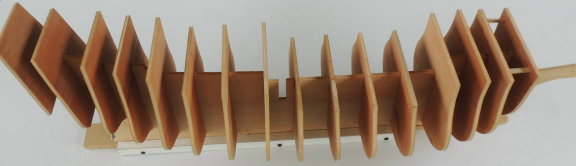

That really wasn't so bad. In fact, it allowed me to use the same pattern I created to go ahead and cut out the profile frames for the forward bulkheads.

Decided to build this as a one piece module that can slide right into place and aligned perfectly with the upper deck surface. The dry fitting was perfect.

I think I will go ahead and add the planking to the face before installing.

Back to work.

- zoly99sask, yvesvidal, NMBROOK and 11 others

-

14

14

-

Lou... the hull planking seen here starts just below the waste deck in order to establish outer parameters of the waste deck bulwarks, and allow me to add frames and mark gun ports, begin planking the waste deck, etc.

I'll get back to more hull planking as soon as I put this bulkhead issue behind me.

Thanks for dropping in mate.

-

-

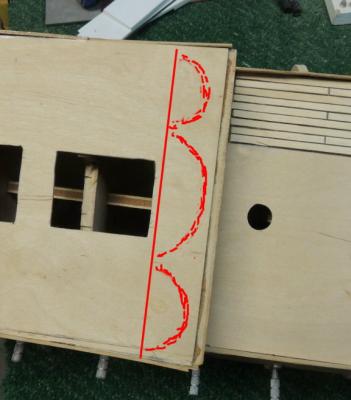

Got a little problem here....

I had noted early on, that the bulkheads of these plan sheets were flat surfaced, as opposed to having the profile seen here (taken from Denis Pink's build)....

Had planned to simply build the profile out from the flat bulkheads. Upon further study, I find that the aft bulkhead is too close to the main mast to do that....

Looks like I'm facing a major rip-out here.... all the way back to the red line.

Plus, I'll have to address that grating as well.

No great problem either way, just hate I didn't spot this issue before I began planking the waste area.

Fortunately, it still looks good for building out the forward bulkhead as planned.

BTW.... I didn't like the looks of my planking experiment once dry-fitted .... went back to individual planking.

-

-

-

-

BREAKING HISTORIC NEWS!

In my research, I have uncovered a never-before-seen document that will change the history books.

In 1634, at the order of King Charles I, British forces invaded Malaysia for the sole purpose of raiding their harvest of bamboo trees!

Learning that bamboo is the strongest and most enduring wood product in the world, superior in strength and resilience to other natural fibrous building materials, with a higher compressive strength than wood, brick or concrete and a tensile strength that rivals steel.... King Chuck decided his Sovereign of the Seas MUST be planked with laminated bamboo. He also discovered there was no bamboo in England.

That's right mates, after all these years, I have just discovered that the entire hull of SOS was planked with bamboo!

Now isn't that a crazy coincidence, since I just this very day happened to pick up another bamboo serving tray at Wal-Mart.

Crazy world huh?

OK, I was kidding about King Chuck invading Malaysia?

But.... if he had known about bamboo at the time....who knows?

- CaptainSteve, dgbot, Jack12477 and 4 others

-

7

7

-

Cutty Sark by NenadM

in - Build logs for subjects built 1851 - 1900

Posted

Very nice work my friend.

Doing very small work like that.... I used to use two pair of drug store glasses taped together. That was before my daughter gave my a pair of jewler's "flip-up" magnifiers to go on my regular glasses. Now, after two years, I can hardly work without them.