-

Posts

695 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RichardG

-

I saw this on Dubz's Syren build http://modelshipworld.com/index.php/topic/1070-uss-brig-syren-by-dubz-model-shipways-164-18-gun-brig/page-10#entry55759. I think the vinegar cleans and the salt darkens the copper. I did find a recipe which is salt, vinegar, and ammonia http://www.wikihow.com/Age-Copper. I'm not all that keen on ammonia though.

-

Copper Patina. As per the title I'm looking at "Overall Artistic Presentation of the Ship". For me, I don't want a green color but a dark brown. I.e. the background of this picture from the USS Constitution. For a more accurate look, I suppose green highlighting could be done. Going to the internet (where else!). Lot's of recipes. Most of the jewelry links seem to tend towards uneven finishes, decorative but not what I'm looking for. These were some links I found interesting: Color: http://www.oldcopper.org/special_topics/patina_finishes.php. No real information but I like #4 (Florentine Bronze) in the examples. I found a recipe for Florentine brown here https://www.sciencecompany.com/patina-formulas-for-brass-bronze-and-copper-W160.aspx and here http://www.artchemicals.com/kb_results.asp?ID=809. The chemicals are not especially expensive (although shipping may be). Of course the quantities would be enough for a lot of models. The recipe for "Antique Green" is "Solution hot (180 to 190°F), metal hot (200°F), cold wash water applied after metal has cooled to around 100°F. Wash solution over metal surface, let dry, then wash piece in cool water. Repeat until color develops.". Definitely not. There's also a book for the really adventurous "The Colouring, Bronzing and Patination of Metals" https://www.abebooks.com/products/isbn/9780500015018/11203772100 Before spending any more money, I'm going to try: Making a nailing stamp. Testing to see if I can actually get a patina to work on the copper tape (salt and vinegar for a start). Richard.

-

See my post here http://modelshipworld.com/index.php/topic/14942-the-best-copper-plates/#entry464779 for some information. I'm sure lots of other people will be able to provide more information. I absolutely agree that the bright copper doesn't look right (to me anyway). Part of my experimentation will be how do "un-brighten" it. Various folks have used chemicals (e.g. vinegar and salt) to do this. The tape seems to haves a coating of some sort, I need to work out how to remove it. Richard

-

One of my reasons for considering copper plating is that I don't want all the details showing through . I am concerned about the nailing to scale (I'm looking at pinpricks only at my 1/50 scale). The copper tape I've bought to experiment with is 0.03mm/0.0015in thick (roughly, I wouldn't trust my calipers to be 100% accurate at those sizes). Any thinner and I wouldn't be able to use it. Actually that's probably thinner, 1.5mm full size, than real life. Although thinking about it, I should probably sand/prime the surface first to make sure there are no surprises (it's 30 years since it was done). So thank you for that! Richard.

-

Yes. My build has been very slow the last few months. Some of that is procrastination, the rigging on the plans I have is much simplified and I want to get it more accurate but I've a lot to learn and absorb first. Other things, work, 2 kids, etc. get in the way (but not in a bad way). But the nice thing is that's a hobby. Unlike having a kitchen redone, one can take a break for a day, a month, a year. I don't have a deadline and it's small enough that I can just to put a cover over it to keep the dust off. The process has not completely stopped though. I can still find time to be on this site, do a little bit of model work for 15 minutes some evenings. I also filled my need for some larger woodwork over the holidays by building a new mini-work bench for the model. And if you find that you want to give up completely - well that's not such a terrible thing to do (although I really hope you don't - your Endeavour looks too nice for that). All the best (especially with the house). Richard.

-

Books for historic rigging reference

RichardG replied to pshrynk's topic in Masting, rigging and sails

I have the book by James Lees, it's very good. The other I'd not seen before - and now I want it! Just be careful shopping around. I've bought about a dozen used books from Amazon, AbeBooks, and Alibris. I've been happy with the condition of all of them (often better than the descriptions implied). But the prices you'll see are all over the place! The Harland book on AbeBooks runs from $31.57 to $379.45. A new copy on Amazon is being offered for a mere $512. Richard. -

Those traveler rings are really good. I'm still working out the rigging on my 1816 Revenue Cutter - I hope I need one . The rest of the rigging is also an inspiration. I will be continuing to follow and will returning again (and again) when I actually start. Thanks for all you do here. Richard.

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Greg, It's been a real pleasure watching your progress on this and your earlier builds. I still don't know how you manage it at that scale though! Have a great new year and I look forward to more posts! All the best, Richard.

-

I think, given the scale, making separate plates or overlapping the strips is probably not required (as the picture from wefalck shows). An indentation to mark the plate's edge would be enough. Of course this has the added advantage of being easier. As shown in the Bellona picture from Chuck, bands aren't required either. As for the thousands of nails in the Minerva model, impressive but no. I'm still at a stage where I can turn the hull upside down, so I'm going to give it a go. Richard.

-

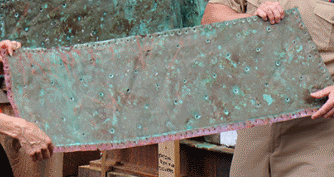

Charlie, I've been debating with myself as to adding copper plating to my 1/50th scale Dallas. It would be more accurate and partially cover the less than perfect hull planking. Copper tape seems the best way to go but the nailing pattern is difficult. The copper nails used were small and they were close together. The excavation of the 1812 American China Trader ship Rapid shows it had an average copper sheet of 1.21m x 0.35m. At 1/50 that would be 0.953" x 0.276", so 1in of 1/4in tape would be close. However the total number of tacks in a sheet is 124! The tack heads were 1 - 1.25 cm with average separation of 4cm (at the edges). At scale this would a 0.25mm head and 0.8mm separation. The tacks were flat headed so the dimple at scale would be very small. This is the nailing pattern This is a picture of copper sheathing from the USS Constitution (from https://ussconstitutionmuseum.org/2016/11/18/new-copper-sheathing-2/) I think I'll try a make a stamp first. If that works, the tape is cheap and I can always take it off if it looks bad (or putting it on drives me nuts ). Richard P.s. the information on the Rapid can be found here: http://www.academia.edu/358814/The_Introduction_and_Use_of_Copper_Sheathing_-_A_History

-

ancre Le Fleuron by juzek - 1:27

RichardG replied to juzek's topic in - Build logs for subjects built 1501 - 1750

Impressive :-) -

I personally would shelve it and take a break. Despite its frustrations, you're supposed to enjoy this hobby. Gutting it out should be left for life's difficulties. All the best, Richard.

-

Because it's fun . I think that's the definition of a hobby. And look at the results! Richard. p.s. This hobby has made me want to retire (but still 2 kids to get through school first ).

-

Small Wooden Clamps

RichardG replied to Bill Tuttle's topic in Modeling tools and Workshop Equipment

Ed Tosti has lots of clamps. See these posts: http://modelshipworld.com/index.php/topic/232-hms-naiad-by-edt-160-frigate-38-1797/#entry2879 http://modelshipworld.com/index.php/topic/3453-young-america-by-edt-extreme-clipper-1853/page-53#entry266516 I hope this helps. Richard -

I like that! This is one collision I am looking forward to seeing Although I don't a great deal of woodworking, I've loved wood since I was a kid (both as a tree and material). I do very much admire the non-wood models you see on this site, but for me it's not the same. All the best, Richard.

-

Tools and Supplies for My "Shipyard"

RichardG replied to daveward's topic in Modeling tools and Workshop Equipment

I have a special (scary number) birthday coming up in a couple of months. I'm hoping to get some tools but $300 on just planes is too much (I want some chisels, files, and books as well ). However they do this smoothing plane for $34. This is now on my list. Richard. -

The Payne engraving is on the RMG website - in color! http://prints.rmg.co.uk/art/501270/sovereign-of-the-seas-br-1637 and some details at http://collections.rmg.co.uk/collections/objects/231209.html Richard

-

Chuck, Just to be clear, my like for the post was not for your suffering . I'm blessed with 2 daughters (the oldest is a junior at high-school, so she's already looking at schools and scaring her parents when we look at the cost). Richard

- 1,051 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Ed, This site http://www.modellingtimbers.co.uk/19.html has 42 LPI copper chain. I've not bought anything from them, the site was mentioned in this post http://modelshipworld.com/index.php/topic/14025-source-for-larger-sale-blocks/#entry434745 BTW, your work is wonderful. Richard.

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

I think your definition of large and mine are not the same . Looking really good. I still have trouble working out how you manage to work at this scale. I'll keep watching though. All the best, Richard.

- 342 replies

-

- dreadnought

- zvezda

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.