-

Posts

3,568 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Piet

-

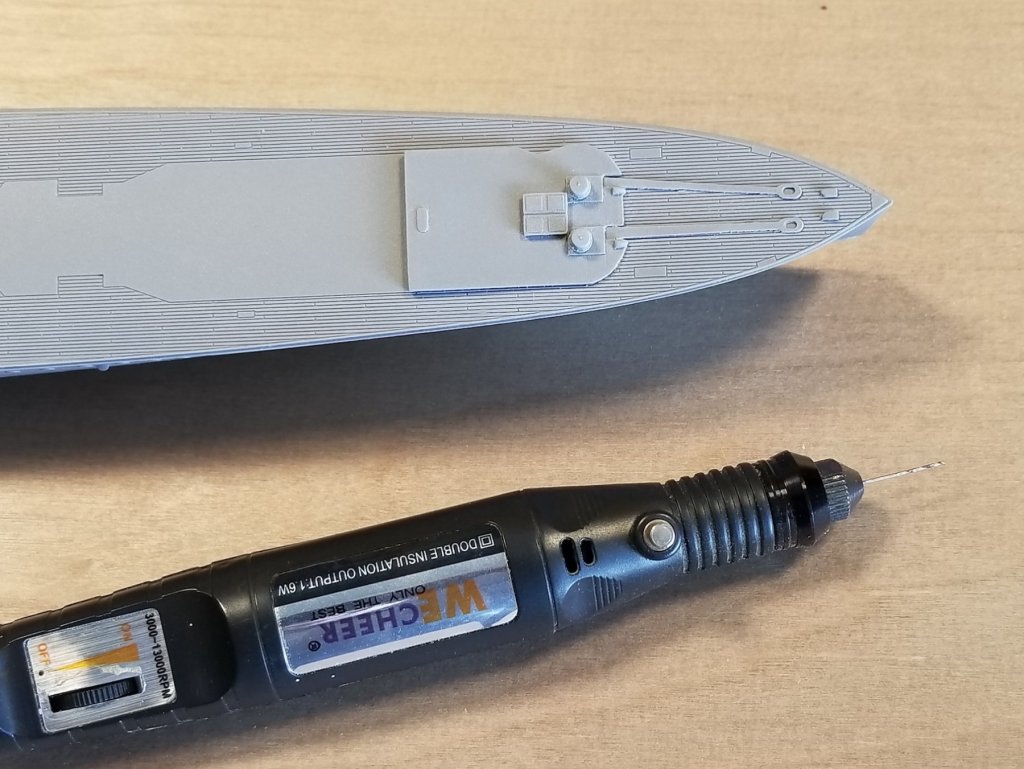

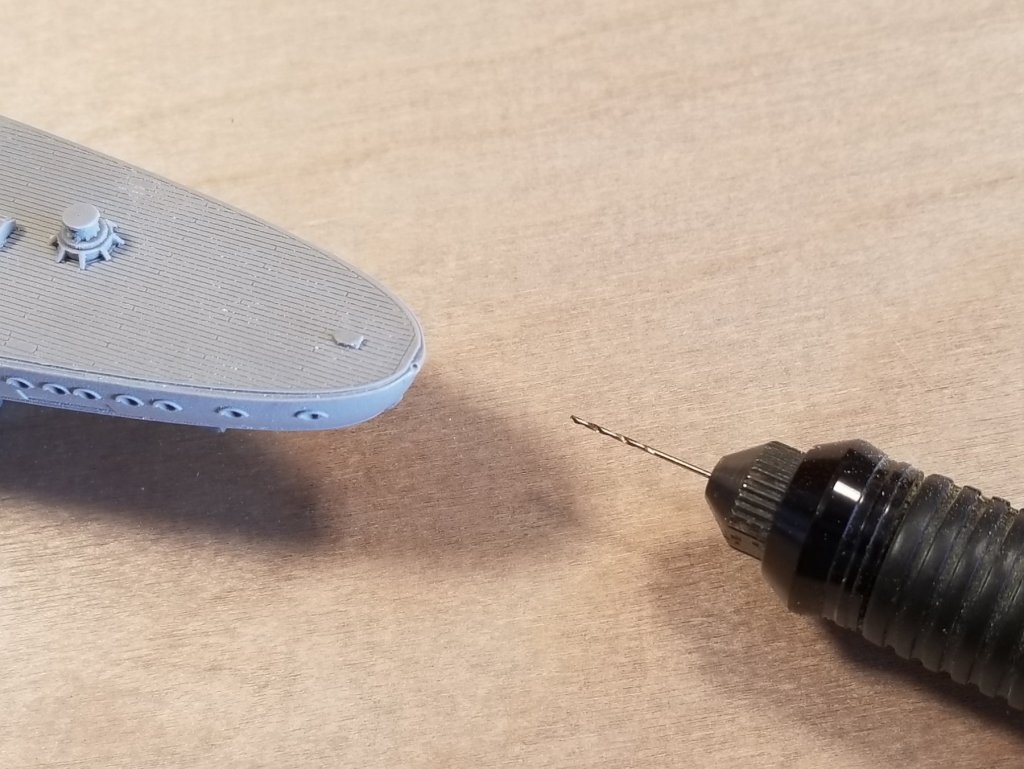

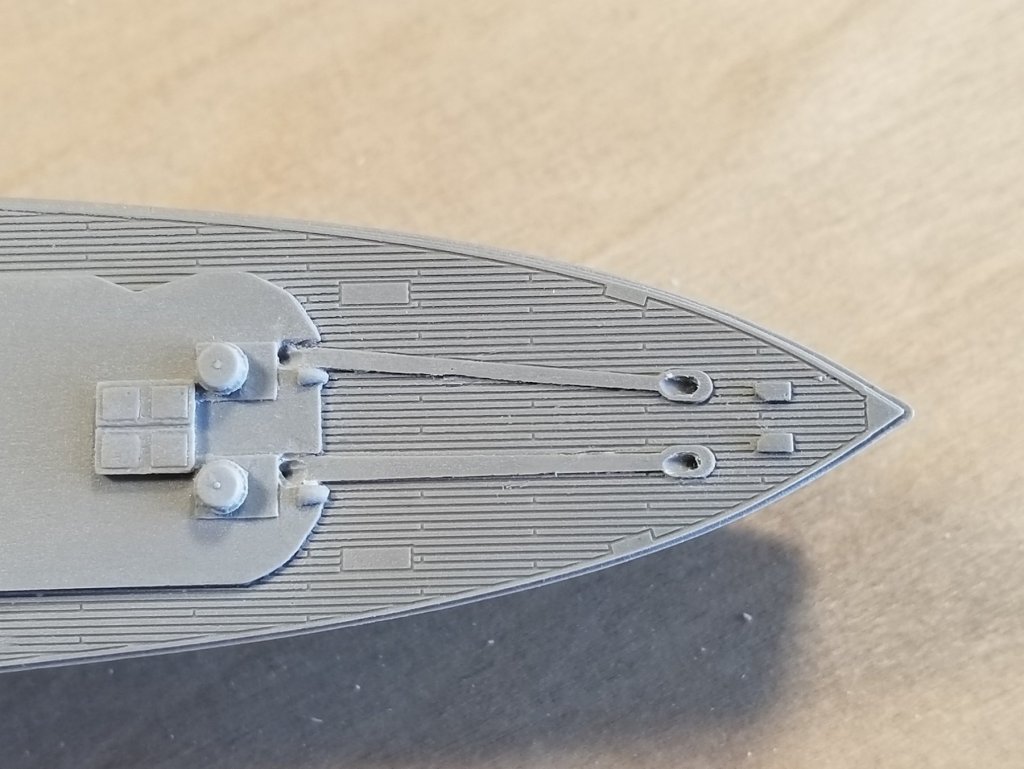

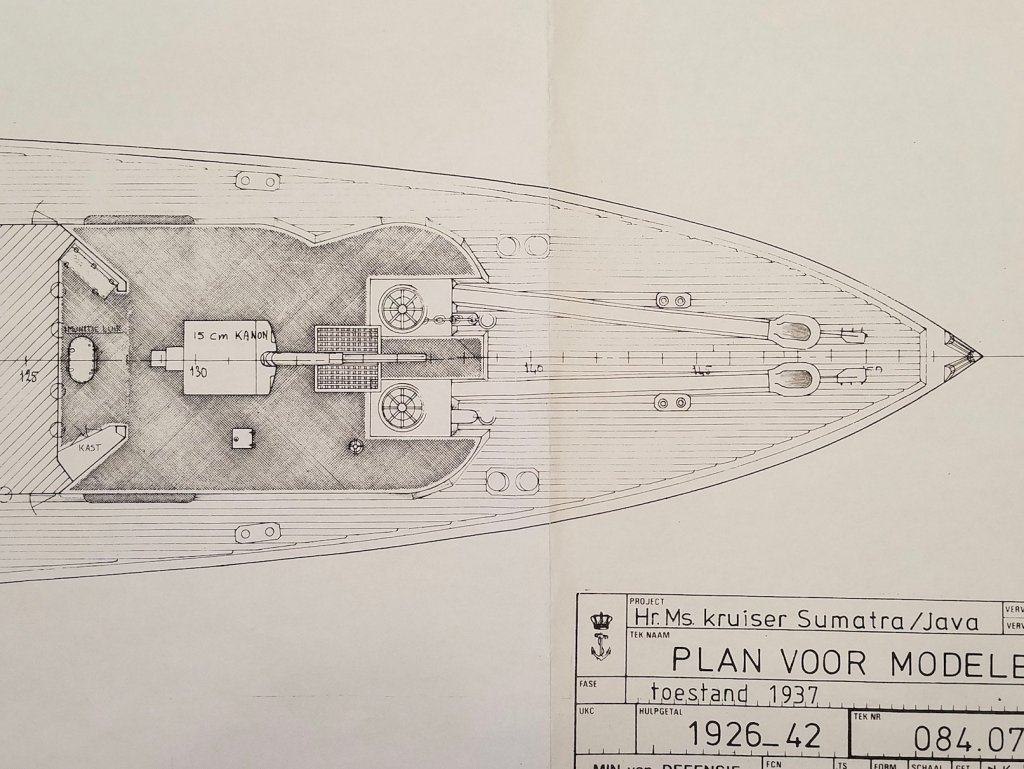

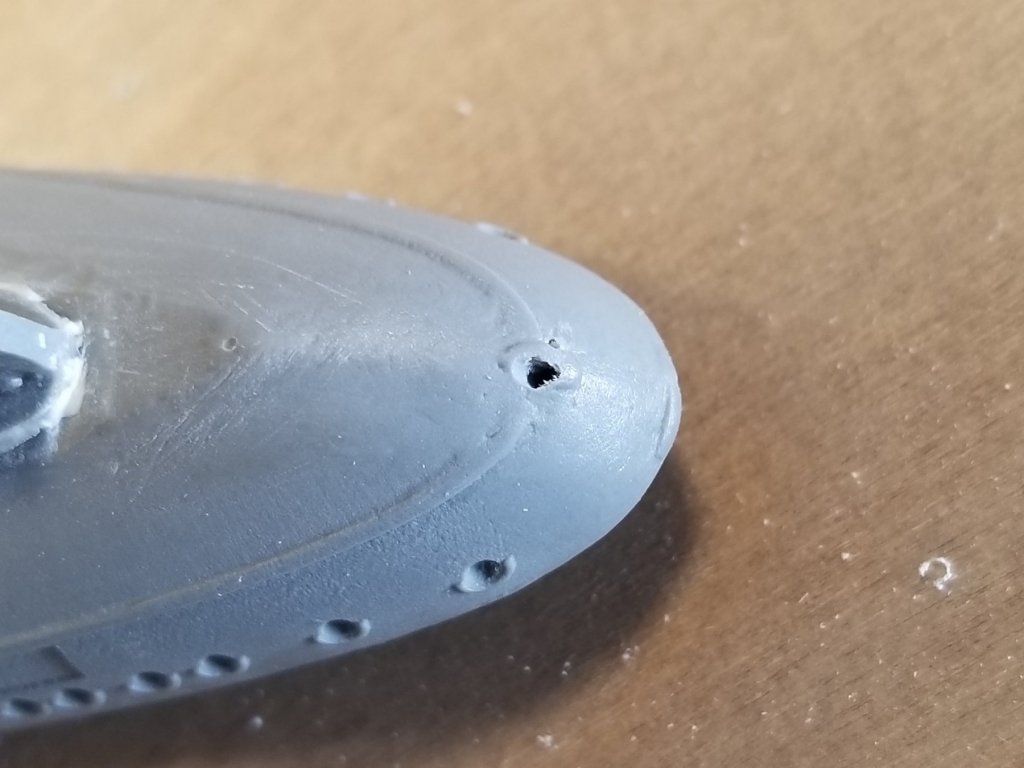

Yes Jan, and I'm glad they did. They also made a film of gunnery practice in 1941 that showed a brief moment with my father on it. He was asked, or better yet, commanded to observe the result of his gun. Presumably his as my conversation with a surviving officer indicates and a remark from one of the survivors in the water looking for him. I copied and saved the URL but not the YouTube video. The video is no longer accessible by the owner due to pirating. I would love to have a copy. Today I'll cover days 4 and 5, which brings us to November 18, 2017. I carefully dressed down the filler in the glue line from the day before. Carefully, because I didn't want to damage the detail on the castings. Fortunately this line will be painted with a black stripe and the water in the diorama will also partly cover it. Then I drilled the holes for the anchors and anchor chain On day 5 I cemented the keel extension for the paravane attaching hardware, the rudder and the propeller shaft supports. Sorry, no picture of this work. Here are a few pics I made for my archive. I used a slow curing two part epoxy cement to give me enough time to position the two halves perfectly. As it turned out I should have used a extra cement for it to ooze out but allas there were a few spots that will need a little filler. As you can see I brought it inside vecause the garage was a little cool and wanted the cement to cure faster. Cement is cured and I put some filler in the needed spots. The alignment of the hull parts came out perfect, I'm a happy camper. Here is my little electric driven all purpose drill, burr, grinder, etc tool with a small drill bit. I forgot to note the size but think it's around a #70. Ready to drill the setrn anchor hole. I drilled the forward holes a little larger so the chain can be stuffed inside with drop of CA. The chain I bought was a tad larger then scale but we'll work around it. This is a copy of the bow detail from my scratch build drawings. I think that Boris from Pacific Cross Roads a magnificent job did on the detail and accuracy in his molds. Stern anchor hole drilled. This shows "Java" at 30 knots. I added this picture to show why I decided to add the bottom half. I was afraid that in showing "Java" at 29 knots in the diorama there would not be enough hull and wind up with a gap I needed to cover with water, which would make it less realistic. No matter now, I'll have to work with the extra depth of the sea. Another note of interest, at full speed of 31 knots "Java" would kick-up a rooster tale and flood a good part of the stern deck. During the battle the fleet had to reduce speed in order for the slower ships to keep up. Another thing with "Java" was that she had a leaky stern deck and the rooster tale water would leak inside. Yeah, she was really showing her age then. Cheers,

- 378 replies

-

- java

- pacific crossroads

-

(and 2 more)

Tagged with:

-

Thanks Jan, yes, I think I have that one because I remember the photographer's shadow and using one of those Kodak box cameras. I think I have gotten most all the pics of "Java" from Maritiem Digitaal. True about the wooden decks and I like the contrast with the grey, adds a little color. I have been able to retrieve many good photos, some in higher res then others. There are a few I like to order from the Australian War Memorial in high res. Cheers,

- 378 replies

-

- java

- pacific crossroads

-

(and 2 more)

Tagged with:

-

Yep, that piddly stuff takes a lot of time but in the end it's all well worth it Mark. Your first one sure looks good. Cheers,

-

Hello all, It's been a busy day for me, a lot of yard work, getting the yard ready for spring, cleaning a lot of dead stuff away. Well you know the drill. This will be Day Two, November 15, 2017. Most of this day was taken up with busy work, like Gwen's printer would not print black, shopping etc. She has a cheapy ink jet printer and doesn't use it often. I told her to print just one page a week to keep the jets open. In retrospect I should have done that, knowing her. I tried to clear them but no luck. There were a few other problems I managed to fix for her. I went to Hobby-Lobby to get some paint for the "Java" model and bought Acrylic paint in a dark grey, a medium grey and a light grey with a bottle of wood color for the deck. It turned out that the greys were a little too light so I mixed some black into each bottle to make it come close to what Boris suggested. I also decided to paint the deck in a wood color instead of black. I picked acrylic for the ease of clean-up. As I was browsing in the store I found a metal necklace of very fine chain. Hmmmm, me thought, would look nice on "Java." Bought that as well. I started with the two hull halves that needed some dressing for a good fit. I took a long piece of 180 grit, laid it flat on my workbench and by moving the mating surface back and forth I managed to get to a pretty good fit for both halves. Well, by this time it was time to punch out and go back inside the house. We'll continue tomorrow with the cementing action of the the hull. Anchor chain for "Java." Like you didn't guessed it. Trueing up the top half of the hull. Trueing up the bottom half of the hull. Both halves close to a pretty good fit. Here are both halves loosely put together. The grey color is as all the resin parts are. Cheers,

- 378 replies

-

- java

- pacific crossroads

-

(and 2 more)

Tagged with:

-

Thank you Lawrence for your kind words. Difficult to tackle this build? Well, sort of, but it brings back memories again, some good, some not so good. This way all of us can learn something from recent history. Thanks also too all who came to visit and clicked the like button. Cheers,

- 378 replies

-

- java

- pacific crossroads

-

(and 2 more)

Tagged with:

-

Great progress Denis. She's really looking very spiffie. Cheers,

- 378 replies

-

- t78 norden

- billing boats

-

(and 1 more)

Tagged with:

-

Wow John, nice framing wok and great progress, even with everything that's going on around you. Cheers,

-

Very well done Patrick, awesome build. I showed it to Gwen and she too was awestruck. Cheers,

-

Nice work on those boats Nenad. Cheers,

- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

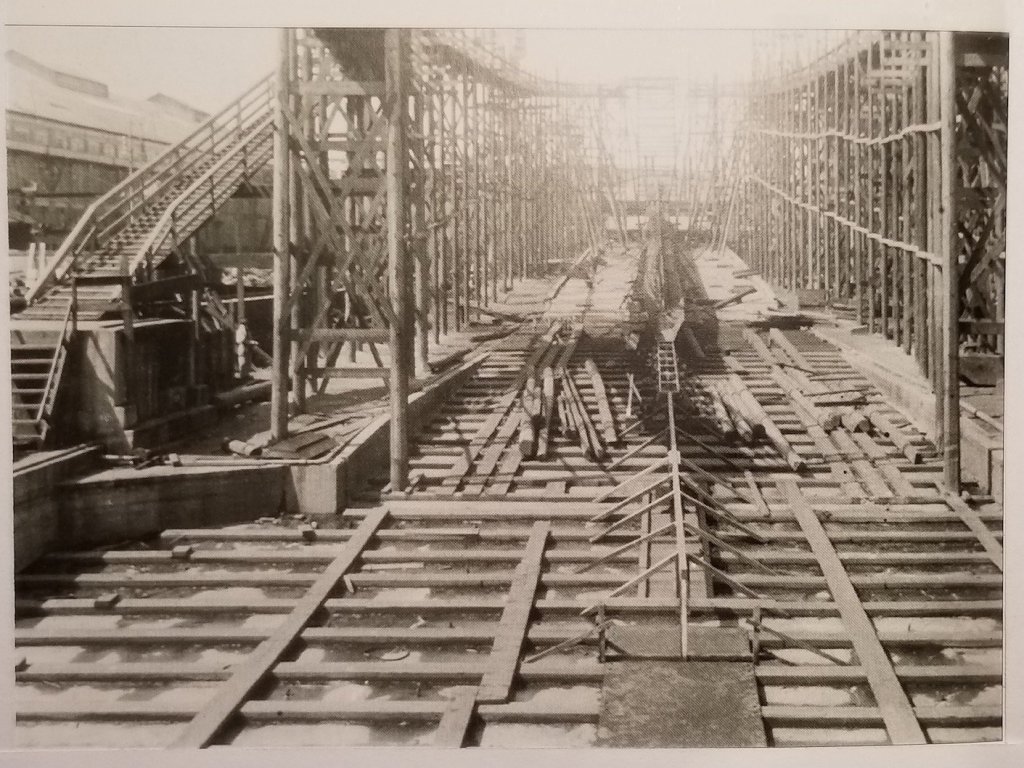

Hello everybody, Time for another post. This will be an extension to my Day One post and I like to call it "Hr. Ms. Java, the beginning." This means that there will be "the end." Not only of this build log but of the ship itself. I have gathered a few photos and will annotate the. Java's keel was laid down May 31, 1916. at the "de Schelde" shipyard in Vlissingen, the Netherlands. Hull construction in progress. The bulkhead you are looking at is where the stern section broke off when the torpedo exploded with the consequent explosion and fire from the ammunition explosion stored in there. The diver photographer Kevin Denlay, informed me that fact. "Java" ready for launch on August 9, 1916. "Java" sliding down the ways. "Java" being outfitted in "Vlissingen" to made ready for her proving runs. Hr. Ms. Java as she appeared sometime in 1926. Cheers,

- 378 replies

-

- java

- pacific crossroads

-

(and 2 more)

Tagged with:

-

I like your sense of humor Nils! The added population of crew really makes the model. Guns smoke to the forum eh Nils? Well, I am building a kit model of a WW II warship in a diorama, I hope, with guns blazing. One never knows what'll appear on this forum. Cheers,

- 692 replies

-

- eagle of algier

- chebec

-

(and 2 more)

Tagged with:

-

Lots of nice looking "stuff" done Denis, great progress. Cheers,

- 378 replies

-

- t78 norden

- billing boats

-

(and 1 more)

Tagged with:

-

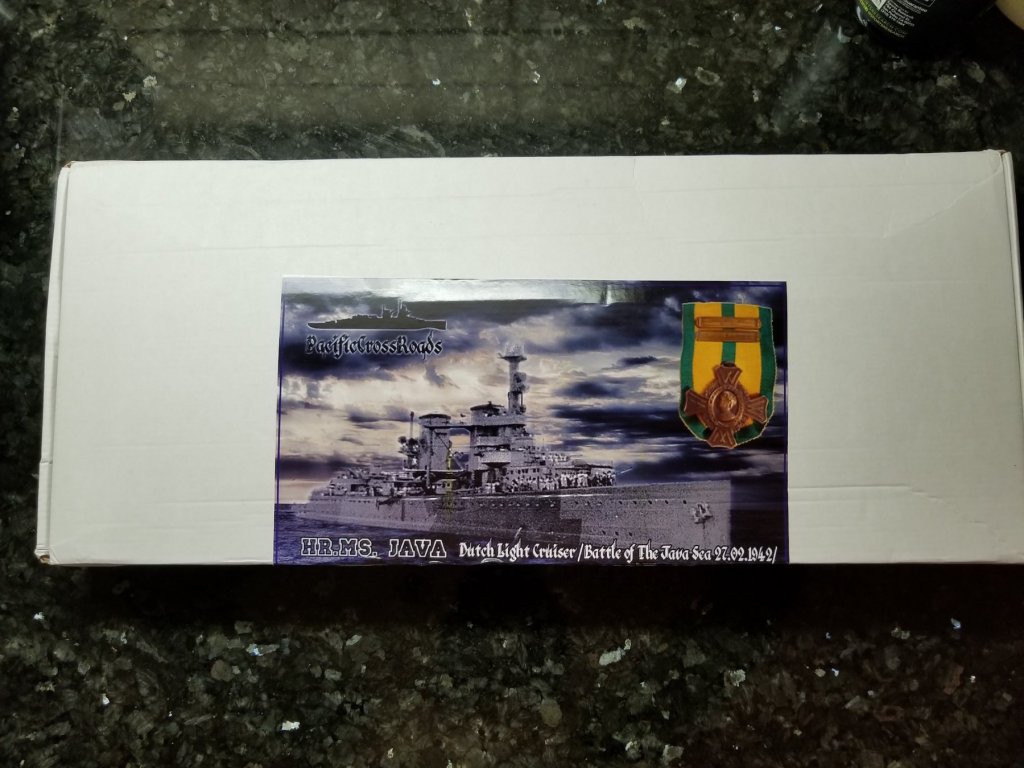

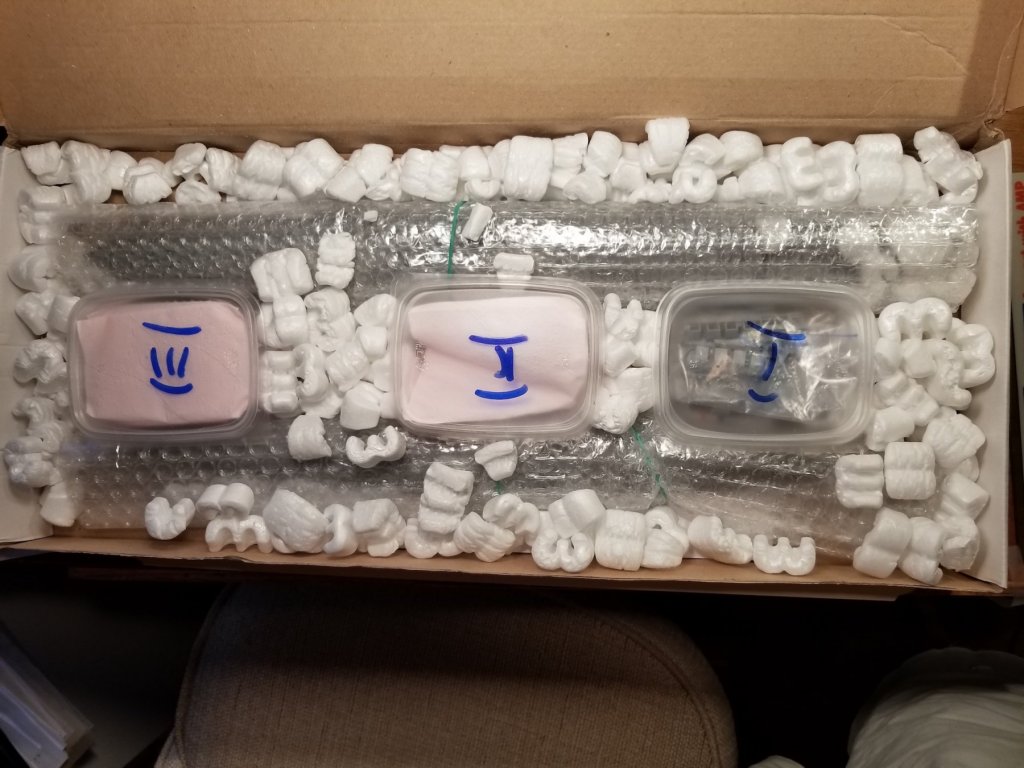

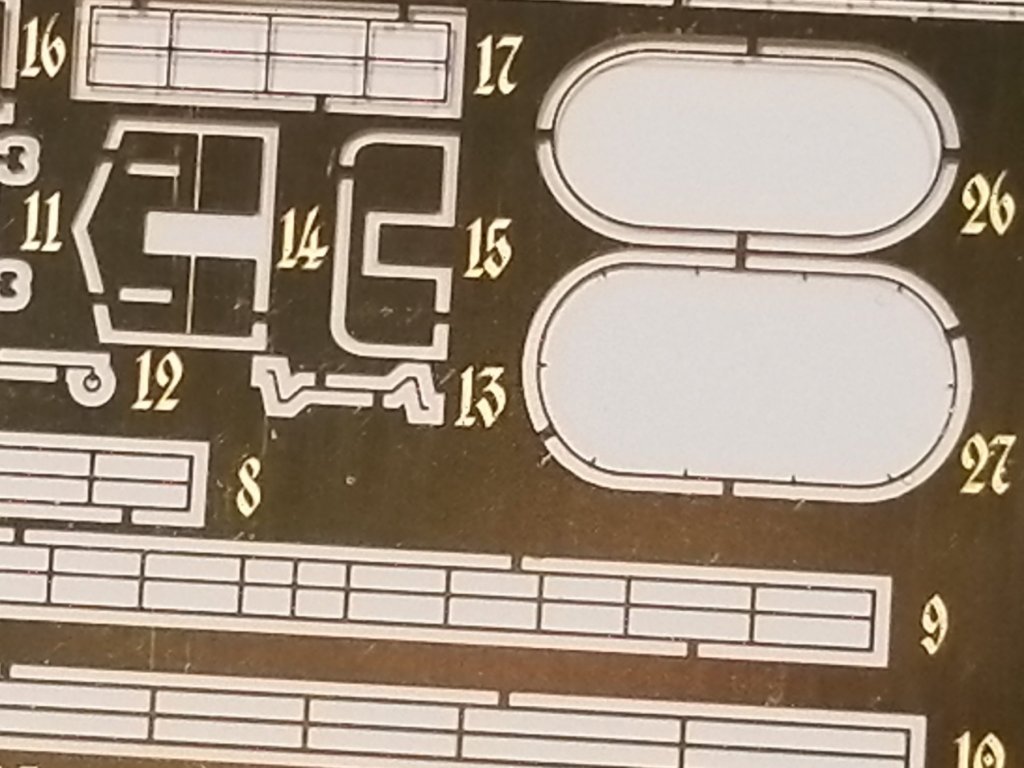

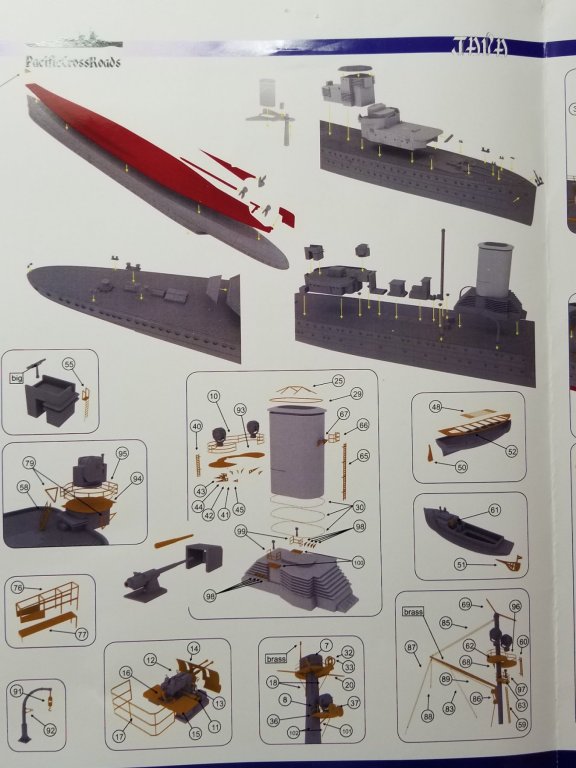

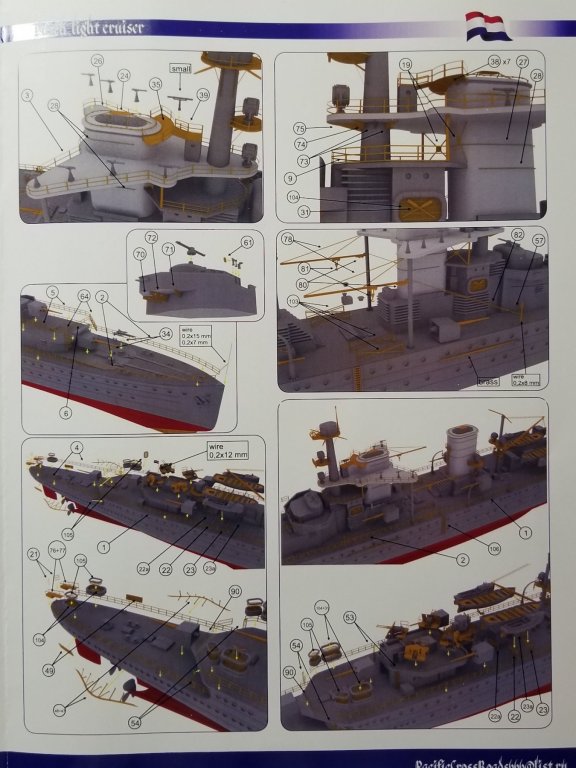

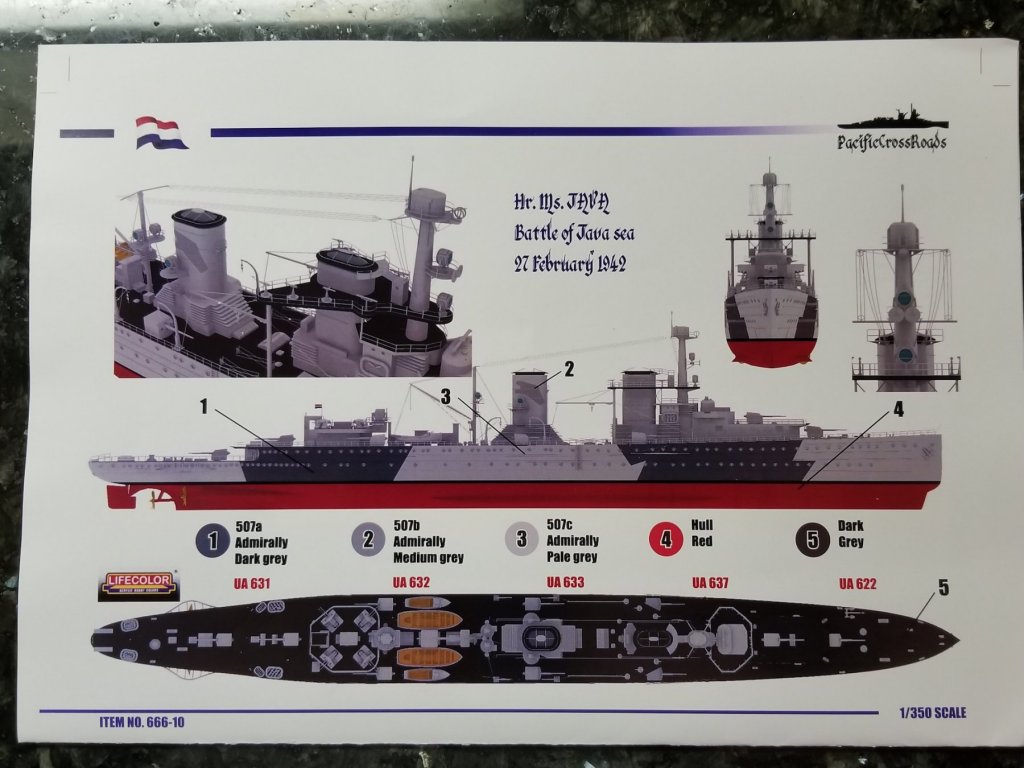

Thanks Mark for your kind words, and also my thanks to those who clicked the like button. Well, it's now time to post Day One, November 7, 2017. As I have mentioned in my introduction this build log will be reported in the past tense until we arrive at the current date. I received the postal package with the "Java" kit from PacificCrossRoads in St. Petersburg, Russia. I was naturally very anxious to open it and take a look at what the kit all contained. My first impression was the immaculate precision of the molded parts, there was hardly any flashing to clean off. The only two items that required some dressing were the separation edges of the two hull sections that needed to be cemented together. This will be accomplished in the next day or so. There were three small plastic containers with most of the small parts and a bag with the larger parts. Boris also included a second PE sheet, which I strongly recommend buying when you order this kit. With my experience, you'll need it as I have, you will damage one or more of these VERY small and delicate parts. The instructions are on a one piece of thick glossy photo paper, folded in half with photos of the parts as they are assembled with the PE parts with their numbers. I am fortunate in having a set of drawings for a 1:50 scale model for this ship and compared the two for familiarization. These drawings depict the ship in her 1937 state. I also have a large book with the history of the ship, filled with photos. These proved to be of less help because of the picture size. But it gave me enough to feel comfortable tackling the build. At first I planned to just build the model and put it on a static display like I did with the resin model of the O16. But thinking about it in the next few days I thought it would be nice to show the ship as she was during the last day of her life in the afternoon of February 27, 1942. She will be in her three color grey camouflage with guns blazing in a seascape diorama. Ambitious project for a first time effort like this but it would be impressive if I can pull it off. Normally people would only build the model from the waterline up and just setting or lightly sliding the model into the "sea." But looking at photos of "Java" at 30 knots part of the hull shows below the waterline. So, I resided to cement the two hull halves together as if she is going to be static. This means of course that the "sea" has to be thicker. How I am going to make the "sea" is not yet decided. There are several ways doing it and have not made up my mind yet because I am now dealing with the added hull thickness painted in red. So, overall, I am very impressed with the quality of the molds and look forward in tackling it. Here are the photos of the kit's contents. I may have to split it up into two posts, we'll see. Cheers,

- 378 replies

-

- java

- pacific crossroads

-

(and 2 more)

Tagged with:

-

Wow, you have been busy catching up after anchor cable redo Nils. A bunch of lovely swivel guns and more crew members, very typical for that sort of ship I'd say. Nice work. And yes, I am a faithful follower. Cheers,

- 692 replies

-

- eagle of algier

- chebec

-

(and 2 more)

Tagged with:

-

Thank you Jim. Denis, Ken, John, Jack and Dave for dropping in, you are always very welcome in my cluttered office/studio. I may have mentioned it but I am using my drafting table as the "dockyard." Thank you all for your kind words and recognition of the selfless acts of duty of my father and all those who put their lives on the line during the struggle for freedom. Yeah. my life and that of my wife Gwen have been a trip. She too was a guest of the Emperor of japan and her father too served in the Dutch Navy Reserve as a Lieutenant Commander. Good thing is, he survived a POW camp. He got caught trying to escape with a load of refugees, Ausy, American, Dutch and Brits to Australia on one of his companie's ships. Here is a bit of historical trivia you may not know. Through the Freedom of Information Act I obtained copies of the Japanese High Command's orders to exterminate all POW's, men, women and children, in September of 1945. Now ask yourselves this, when did Japan capitulate? August of 1945, right? Just one month separated us from a most brutal way of dying, thanks to that necessary order by President Truman to drop the two atomic bombs. But here I am - among the best bunch of friends anyone can wish for. Let's move on and build ships, models that is It's a little late to start my "Day One" post but to answer Denis' question, the model is 18 inches long overall, 1 7/8 inch wide and 7/8 inch from water line to the deck. Scale is 1:350. Cheers to all,

- 378 replies

-

- java

- pacific crossroads

-

(and 2 more)

Tagged with:

-

She/he is a great companion to you Nenad, pets can fill your days with joy and love. Cheers,

- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

I'll throw in my two cents - love the fine scroll-work balustrade Nils and so much "busy" stuff on the deck. Fantastic work. Cheers,

- 692 replies

-

- eagle of algier

- chebec

-

(and 2 more)

Tagged with:

-

Very nice work on the pilot house and decking Denis. Cheers,

- 378 replies

-

- t78 norden

- billing boats

-

(and 1 more)

Tagged with:

-

Hello everyone, Let's start with the specs of this ship, followed by her overall history and the final few days in the campaign. I'll also attach a photo of the captain. There is semi comical story attached to my father's association with Captain van Straelen. I hope to share it with at the right moment. Ah yes, memories. Class overview Name: Java class Builders: Koninklijke Maatschappij de Schelde, Flushing - Java Nederlandse Scheepsbouw Maatschappij, Amsterdam - Sumatra Wilton-Fijenoord, Schiedam (cancelled) - Celebus Operators: Royal Netherlands Navy Preceded by: Holland class Succeeded by: De Ruyter Planned: 3 Completed: 2 Lost: 2 General characteristics Type: Light cruiser Displacement: 6670 tons standard 8087 tons full load Length: 155.3 m (509 ft 6 in) Beam: 16 m (52 ft 6 in) Draught: 6.22 m (20 ft 5 in) Propulsion: 3 Parsons geared steam turbines 8 Schultz-Thornycroft boilers 3 shafts 73,000 shp (54,000 kW) Speed: 31 knots Range: 4,340 nmi (8,040 km; 4,990 mi) at 11 or 12 kn (22 km/h; 14 mph) Complement: 526 Armament: 10 × Bofors 150 mm guns 8 (Java) or 6 (Sumatra) x Bofors 40 mm anti-aircraft guns 8 × Browning .50 machine guns Armour: 7.5 cm (3.0 in) belt 2,5 to 5 cm (2.0 in) deck 12.5 cm (4.9 in) conning tower 10 cm (3.9 in) shields Aircraft carried: 2 Fokker C.XI-W floatplanes All float planes were left ashore because admiral Doorman was afraid of the volatile aviation fuel during battle conditions. In 1937, Java was modernized at the Naval Dockyard in Den Helder, Holland. The modifications include adding an AA-battery of 4 double Bofors 40 mm-guns, replacing the fire control system with a new Hazemeyer set and shortening the masts. Java could also carry 10-12 ASW depth charges, 36 mines, split – with one third below deck in the ammo compartment and the rest on the aft deck on narrow tracks. She had one smoke machine and no torpedoes. May 31 1916 Hr Ms. Java is laid down at Koninklijke Mij "De Schelde", Vlissingen [Piet's note: this was also the date of the Battle at Jutland] August 9 1921 Java is launched [Piet's note: already obsolete] May 1 1925 Java is completed after countless delays, such as strikes by the dockyardworkers, shortages of materials and modifications to the original design. December 4 1928 Fleet revue at Yokohama to celebrate the coronation of Japan's emperor. May 20 1937 Fleetrevue at Spithead 1937 The Java is modernized at the Naval Dockyard in Den Helder, Holland. The modifications include adding an AA-battery of 4 double Bofors 40 mm-guns, replacing the fire control system with a new Hazemeyer set and shortening the masts. January 3 1938 Java is commissioned with her new "look". She was sent to Gibraltar Strait to escort Dutch ships shortly after. May 4 1938 Java leaves for the Dutch Indies via Suez. April 1940 The cruisers Java and De Ruyter, the supplyship Zuiderkruis and two divisions of submarines are on stand-by in the Java sea after rumours about a Japanese fleetconcentration near Formosa. April 27 1940 Commander, later Captain, Ph.B.M. van Straelen assumes command. May 10 1940 Germany attacks Holland in the early morning. This means for the the NEI, that all German merchant ships were to be captured as soon as possible. A boarding party of the Java succesfully captures the Hapag-freighters Bitterfeld (7659 gt), Wuppertal (6737 gt) and Rheinland (6622 gt) in Padang. January 18 1941 The Java makes here first convoy trip from the Ajoe archipelago with the merchants Brastagi ( 9247 tons gross weight), Kota Nopan (7332 gross tons ) , Kota Baroe (7281 gt) and Kota Tjandi (7295 gt). The convoy was dissolved on January 23 in position 03.00 South, 161.25 East.[Piet's note: Adjudant Petrus W. van Warmerdam became part of the crew on the first of this month] March 1941 A refit is hastily broken off after the news the panzerschiff Admiral Scheer was operating in the Indian Ocean. Despite search efforts by both ships and aircraft, nothing was found. April 23 1941 Java leaves Suva with two merchants, bound for Brisbane, Australia July 1941 Java makes rendez-vous in Torres Strait with the passengership Jagersfontein (10083 gt), which has a contingent of American aviators on board, which later become known as the famous "Flying Tigers". She escorts the ship to Java. November 1941 The Java is on escort duty between Suva and Soerabaja. December 8 1941 The Netherlands declares war on Japan after the attack on the American base Pearl Harbor. The Java was at this time enroute to Singapore where she was to operate under command of the British Admiral Layton. The Java is part of most convoys bound for Singapore until early February, but also makes a trip to the Cocos Islands to find out if it was still free of Japanese troops. December 12 1941 Java departs Singapore to rendez-vous with convoy SM 1 (3 British, 1 Greek and 2 American ships). She escorts it from December 13 to December 15, together with the Dutch destroyer Evertsen, the Australian armed merchant cruiser Kanimbla, and the British destroyers HMS Encounter, Stronghold and Tenedos December 31 1941 The Java is part of the escort for convoy BM 9B, but has to break off because of propellor damage. January 18 1942 The cruiser Java and the destroyers Evertsen and Van Nes make rendez-vous with convoy MS-2, which consisted of the large liner Aquitania with HMAS Canberra as ocean escort. This ship has about 3500 men aboard bound for Singapore. The convoy arrives in Ratai Bay on Sumatra where the troops transfer to six smaller Dutch KPM-steamers and one small British ship. This convoy then leaves for Singapore (now designated MS 2A) where it arrives safely on January 24. The Java is also part of this convoy. January 26 1942 A report came in about a Japanese concentration of ships off western Borneo, near the Api passage. Admiral Helfrich orders the cruisers Java and Tromp with destroyers Banckert and Piet Hein to intercept and destroy this convoy. Later reports show the "convoy" consists of one freighter and numerous very small vessels, after which the Dutch ships retreat. January 31 1942 Java joins the the escort for convoy DM 2, which arrives in Singapore on February 5. Java had already detached itself on February 4 due to fuel shortage. She becomes part of the Combined Striking Force on February 3, probably. February 13 1942 Java joins the Eastern Striking Force (cruisers De Ruyter and Tromp under Rear-Admiral Doorman) in the afternoon while it passed through Sunda Strait. This force is enroute to intercept a Japanese convoy bound for the important port Palembang on North-Sumatra. Doorman decides to wait for destroyers to assist him and he plots a course for Oosthaven on Sumatra. On arrival, the heavy cruiser HMS Exeter and the light cruiser HMAS Hobart join him. The destroyers arrive the next day. February 14 1942 The fleet leaves Oosthaven in the afternoon for the Gaspar Straits with the following strength: cruisers De Ruyter, Tromp, Java, HMS Exeter and HMAS Hobart along with the Dutch destroyers Van Ghent, Kortenaer, Piet Hein and Banckert and the American Barker, Stewart, Bulmer, John D. Edwards, Pillsbury and Parrott. The ships head for an area notorious for navigational hazards. February 15 1942 At about 0430 hours in the morning, the destroyer Van Ghent hits the Bamidjo reef in Stolze Strait. Doorman had ordered a relatively dangerous formation with the four Dutch destroyers steaming alongside eachother. Banckert and the American destroyers could barely miss the reef. After leaving Stolze Strait at about 0800 hours, the fleet sets a western course about 45 minutes later. Unfortunately, they are spotted by a Japanese plane at 0920 hours (a catapultplane from the Japanese heavy cruiser Chokai) and a few hours later, the first aircraft attack. It were seven "Kate"-torpedobombers from the carrier Ryujo, this time not armed with torpedoes but with bombs. None of the ships was hit. They were later reinforced by numerous other aircraft, but no ships sustain "real" damage, although the Barker and Bulmer are pretty beaten up. [Piet's note: My father told us about this attack where the captain looked up with his binoculars and when he saw the bombs released he ordered a change of course. I will post a picture of the Java under attack, taken by the Hobart] February 16 1942 The Striking force enters Tandjong Priok ( Batavia ) at 0830 except for the Java and destroyers, which have a smaller oil capacity. These ships refuel in Ratai Bay on Sumatra from the Dutch tanker Tan 1. Doorman leaves in the night for Tjilatjap. February 17 1942 Arrival in Tjilatjap February 18 1942 Departure from Tjiltjap in the evening for an attack on the Bali landingforces. She's accompanied by the cruiser Java and the destroyers Kortenaer, Piet Hein, Ford en Pope. The first ships leave the harbor safely, but Kortenaer is not so fortunate. She stranded on a sandbar and has to wait for the tide. A second force leaves Soerabaja later this day. February 19 1942 Nightaction off Bali. Read more about the Battle of Badungstrait here. The Java was hit by one 4.7-inch shell during this engagement, which wounded two men and did some minor damage. February 20 1942 Arrival in Soerabaja February 25 1942 The Striking force (De Ruyter, Java, Houston and 7 destroyers) goes to sea in the evening to make a sweep off the Madoera coast. No ships are sighted, the ships arrive in Soerabaja on the 26th. February 26 1942 Nightsweep in the Java sea with the Striking Force. The ships are attacked by aircraft at 0900 in the morning of the 27th and Jupiter is missed by light bombs, but didn't sustain any damage. Arrival in Soerabaja on the 27th. [Piet's note: In the morning of the 27th my father came home to say goodby. That was the last time I saw him.] February 27 1942 Doorman leaves port in the evening of the 27th to intercept several convoys heading for Java. Unfortunately, he was spotted and engaged by the Japanese covering force, consisting of 2 heavy cruisers (Nachi and Haguro), 2 light cruisers and 14 destroyers. The effectiveness of the CSF was hampered by difficulties in communication. In addition, the Japanese had a 2 to 1 advantage in 8"-guns. The Java was hit by a Japanese "Long Lance" torpedo from the Nachi at about 23.32 hours near the aft ammunitionstack, which exploded. The AA-deck with the 40 mm-guns caught fire and the stern broke off near the longroom, causing flooding in the aft engineroom and a heavy list to port. All electrical equipment shut down and the only thing the crew could do, was to abandon ship as soon as possible. No boats could be lowered without electricity, so all possible livesavers were thrown overboard, such as rafts, bamboosticks etc. The Java sank in about fifteen minutes, taking 512 crewmembers (including Captain Ph.B.M. van Straelen) with her. She sank in position 06.00 S, 112.05 E. December 1, 2002 A diver expedition on board the motor vessel Empress which initially set out to find HMS Exeter, find the wrecks of the light cruisers Java and De Ruyter. The wreck of Java lies at a depth of 69 metres on her starboard side. APPENDIX II CONTACT REPORTS BEFORE AND DURING THE BATTLE OF JAVA SEA (Times are -7½) FEBRUARY 26th: 1. 1150: 30 transports, 2 cruisers, 4 destroyers. Position: lat. 04°50' S., long. 114°20' E. (near Arends Islands), course 245°, speed 10 knots. (This was sent to Admiral Doorman at 1250.) 2. 1440: 2 Isuzu class cruisers, 2 destroyers. Position: lat. 06°25' S., long. 117°13' E., course 315°, speed 10-20 knots. (Admiral Helfrich sent this report to Admiral Doorman at 1445.) 3. 1700: Dutch reconnaissance plane attacked by 2 cruiser catapult planes at lat. 06°05' S., long. 113°15' E., and lat. 05°40' S., long. 113°05' E. (Plane reports upon return at 1900; report forwarded to Admiral Doorman at once.) 4. 1830: U. S. Army bombers bomb Japanese convoy, course unknown. Position: lat. 05°30' S., long. 113°00' E. (northeast of Bawean). (This report was received at Soerabaja at 2220, after which it was forwarded to Admiral Doorman, who complained of the delay of 6-8 hours in forwarding of reports.) FEBRUARY 27th: 5. 0255: Admiral Doorman received the following amplification of No.4: Convoy lat. 05°30' S., 113°00' E., 18 or more ships, 1 possible aircraft carrier or battleship. Six fighter planes protecting convoy reported by Dutch Navy plane at 1440/26. 6. 0510: Report of Dutch reconnaissance plane after landing broadcast to all Allied warships. (a) 2030/26 1 heavy transport, lat. 05°20' S., long. 113°38' E. (b) 2230/26 2 destroyers, lat. 05°12' S., long. 112°20' E. (c) 0005/27 2 transports, lat. 05°28' S., long. 112°24' E. (d) 0020/27 1 transport, lat. 05°42' S., long. 113°00' E. --87-- 7.(a) 1340: 20 ships, unknown number of destroyers. position: lat. 04°45' S., long. 112°15' E., course 180°. (b) 1345: One cruiser. Position: lat. 04°04' 5., long. 111°07' E., course 220°. (c) 1350: Great fleet with 2 cruisers, 6 destroyers, 25 transports. Position: 20 miles west of Bawean, course south (Cf. report No. 10). (These reports sent to Admiral Doorman at 1445 and (c) causes him to go out for Battle of Java Sea.) 8. 1555: 3 cruisers, 5 transports. Position: lat. 06°50' S.,77 long. 112°10' E., course 190°. (This report was sent to Admiral Doorman at once.) 9.(a) 1630: 5 large ships, several small. Position: lat. 06°20' 5., long. 115° 30' E., course 315° (bombed by Allied planes). (b) 1757: 35 ships, including 1 cruiser, 4 destroyers. Position: lat. 05°I0' S., long. 111°35' E., course 170°. (These reports forwarded to Admiral Doorman at 1805.) 1830: Admiral Doorman reports that the enemy is retreating and asks position of the convoy. 10. 1700: 45 transports, 3 cruisers, 12 destroyers. Position: 20 miles west of Bawean (Cf. report No. 7c). Bombed by U. S. Army bombers. (This news received unofficially at Soerabaja at 1930 and relayed to Admiral Doorman. Official report not received at Soerabaja till 2125.) 1850: U. S. PBY-5 (PatWing 10) leaves Soerabaja to shadow enemy convoy. 11. 1955: 3 cruisers and 8 destroyers. Position: 30 miles southwest of Bawean, course north. (Seen by American PBY. Pilot believes this is our striking force and sends no report.) 12. 2235: 28 ships in two groups of 16 and 12, 1 cruiser, 1 destroyer, courses 300° and 330°. Position: lat. 06°07' S., long. 112°05' E. (This report was received at Soerabaja at 2352 and forwarded to Admiral Doorman. The De Ruyter almost certainly sank before he received it.) 2300: Dutch Catalina Y-67 takes off. Its pilot received with his instructions a list of the above contacts and two not listed above: 13. 1800-0227: 4 cruisers and 4 destroyers. Position: lat. 05°40' S., long. 111°35' E. 14. 2100-0227: 9 destroyers: Position: lat. 06°20' 5., long. 111°50' E. (These were at the time thought to be our own, but this seems unlikely.) --88-- FEBRUARY 28th: 15. 0130: 2 cruisers, 4 destroyers about 25 miles distant from the convoy on course toward it. (U. S. PBY pilot at first believed this was our striking force and did not report the contact till 0150.) 0212: U.S. PBY-5 turns back to Soerabaja. 16. 0200: Convoy position: lat. 05°40' S., long. 111°40' E.78 17. 0335: Report forwarded from Soerabaja (a composite of the reports of PBY-5 and Y-67): Convoy of 39 transports in two columns 1,500 yards apart, course north, speed 10. Three destroyers in column right flank, 1 cruiser and 2 destroyers in column left flank. Two cruisers and 6 destroyers moving toward convoy at high speed. Position as of 0212, lat. 05°56' S., long. 112°46' E. 18. 1430: Convoy position: lat. 05°55' S., long. 112°05' E. (Report of Dutch Y-60.) 19. 1552: Convoy 60 ships. Position: lat. 06°15' 5., long. 112°15' E., course 90°, speed 10. (Report of Dutch Y-60.) --89-- Table of Contents * Previous Chapter (Appendix 1) Footnotes 78 This longitude may be an error for 112°40' E. Cf. report No.17. (Report of Dutch Y-60.) Last updated: June 14, 2002 Transcribed and formatted by Jerry Holden for the HyperWar Foundation Ktz. P.B.M. van Straelen, commander of HR. Ms. Java before and during the Java Sea campaign. When the fleet arrived in Soerabaja the evening of February 26 my father got permission to go home in the morning of the 27th for a goodby. That was the last time I saw him. That image is still engraved in my mind - he was dressed in his his dress uniform, with his saber strapped to his side as well as a side arm. As he walked out of the house to catch the steam tram back to the harbor he took me aside and we had a man to man talk. He knew that he was not coming back, the odds were just too great. He ordered me to never divulge anything of our conversation to my mother and sister. Please folks, don't feel sorry, this is part of life. The good thing is that it formed my own character to what I have become and for that I am very grateful. Cheers,

- 378 replies

-

- java

- pacific crossroads

-

(and 2 more)

Tagged with:

-

A very warm welcome to Chris, Jan, Ken, Mark and John and thank you for joining me on this journey. Jan, Mark and everyone, the like button is just a symbol to indicate the participation of all of you and doesn't mean you "like" what happened in the past. You like what I am doing and not what is associated with it. Indeed Ken, it is an obscure part of the war, I call it "the forgotten war." Good seeing you here as well John. Okay, let me now add the history of the ship, her specifications and I thought to also include the detailed history of her war years, but that'll be in my next post. Cheers,

- 378 replies

-

- java

- pacific crossroads

-

(and 2 more)

Tagged with:

-

WOW!! A double WOW WOW! Looks very good Hennie, impressive.

- 192 replies

-

- sovereign of the seas

- sergal

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.7eb8cefffb999c2249bf3480837ce483.jpg)

.thumb.jpg.8eb8a81e4c579ea8312452a3d0de3259.jpg)

.thumb.jpg.bf46952edf06fb6962c1e56152e80366.jpg)

vlakvoordetewaterlatingbijdeKon_Mij.DeScheldeteVlissingencopy.jpg.f456cba6314df3c422492a3e48dad72b.jpg)

inaanbouwbijdeKon_Mij.DeScheldeteVlissingencopy.jpg.d9491de3e538a1aa5432e4d99a6ae395.jpg)

debijdeKon_Mij.DeScheldeteVlissingencopy.jpg.2a5daf8f3a09c0e2e3f80cc2c9caec80.jpg)

debijdeKon_Mij.DeScheldeteVlissingencopy.jpg.344d5d47cd62b34af0e76e1d7a29b93e.jpg)

tijdensdeafbouwbijdeKon_Mij.DeScheldeteVlissingencopy.thumb.jpg.5e319d95adae95ddbac636bdb54e88dc.jpg)

.thumb.jpg.c93d5e941c3d839e0839a281bcfba1e3.jpg)

.thumb.jpg.5624408cb3065d6503d8e8cec0e602a9.jpg)

indeslagindeJavazee..jpg.b9ab80424115f8bacd351e359c834cab.jpg)