-

Posts

2,213 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GuntherMT

-

Very nice looking stern, great improvements on the kit standard in my opinion.

- 51 replies

-

- bounty

- billing boats

-

(and 1 more)

Tagged with:

-

I emailed HobbyMill earlier today - Jeff is closed down until October 13th (vacation I presume), so it will be almost a month before he will even see my email to give me an ETA on wood. I am not sure I'm patient enough to wait that long, but I haven't really read enough of the instructions to have any sort of feel for how long it will be until I get to the deck planking point.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

I ordered a full set of replacement blocks from Syren. I already have Syren rope for this build. Now I'm looking for replacement deck planking. I might need an intervention.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

The best thing I've ever gotten for my Dremel was the flex-shaft attachment. Very easy to hold the much smaller and comfortably shaped end of the flex tool, and clamp the Dremel into a vise, or rig a hanger for it, as they say the flex end should remain lower than the Dremel tool. Here is mine so you can see what I'm talking about. I have mine supported by a Dremel drill press workstation which is clamped into the end-vise on my work bench instead of being permanently mounted somewhere.

-

Thank you Alfons. My next build is an AVS, the build log has been opened, but nothing is actually started yet. Went out during lunch and snapped a few pictures, most of them were terribly out of focus and poorly framed because the sunlight makes it impossible to actually see the viewscreen on my old camera, but a few were ok, so I'll put them up as the final photos of the Carmen here. Unfortunately my stucco house backdrop makes the running rigging all but disappear in the photos. Oh well.

- 119 replies

-

- carmen

- constructo

-

(and 2 more)

Tagged with:

-

Spectacular build, I'm amazed that this is your first wooden ship. Your carpentry skills are certainly finding a home with this!

- 79 replies

-

- santa maria

- amati

-

(and 2 more)

Tagged with:

-

Thanks for visiting gentlemen! Alistair, your AVS is simply amazing. Going to be quite the tough act to follow! I notice you suggest replacing the rope (I already have Syren rope for this build) the blocks, and the deck. The blocks in the kit really look quite nice, although my only 'live' point of reference is the blocks from the Carmen kit by Constructo that I just finished. What do you use to determine that the blocks are 'bad' relative to Chuck's? Here are the kit parts - the deadeyes and little round things really look good to me, the blocks are a bit uneven, so maybe worth upgrading. By the 'deck', are you referring to the false deck, or the planking material, and what did you use? I know I've read on some logs that replacing the false deck plywood with basswood is a good investment for fitment reasons, and of course many people seem to upgrade the deck planking to holly or some other material.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

Edit: Adding an index Section 1 - Pre-planking work. Beginning the bulkheads Shimming the bulkheads Cutting the Rabbet Reinforcing the bulkheads Fairing bulkhead tops and placing sub-decks Shimming bulkhead extensions and fairing Stern building issues Stern construction Knights heads and first planks Waterways and transom work Section 2 - First planking and surrounding work. Stern windows and planking Outer bulwark planking Lower planking part 1 Side-bar - Reno trip Lower planking part 2 Lower planking part 3 Lower planking part 4 Section 3 - Wales and inner bulwarks Wales part 1 Wales part 2 and spirketing plank 1 Spirketing plank 2 Inner bulwarks The black strake & inner bulwarks painting Scuppers and inner bulwarks painting Outer bulwarks 2nd planking and more painting Outer bulwarks 2nd planking and Cap Rail Stern cap rail and planking Section 4 - Outer painting and 2nd planking below wales. Bulwark painting Lower planking part 1 Lower planking part 2 Lower planking part 3 Lower planking part 4 Lower planking part 5 Lower planking part 6 Planking time-lapse video Lower planking completion Sweep ports part 1 Sweep ports part 2 Section 5 - Deck & furniture Main hatch and scuttle port Companionway Deck planking begins Remaking the galley hatch Deck planking continued Deck planking complete - tree nailing Planking the poop deck Guns! Rudder Rigging the Cannons - beginning Ships wheel Rigging the Cannons - continued Rigging the Cannons - rope coils Stropping a single block Making the Catheads Elm tree pumps Ladders and Binnacle Swivel gun posts and channels Chain plates & dead-eyes Section 6 - Masts & Standing Rigging Bowsprit sheaves & main mast construction Jib boom & Top mast Gaff, boom & yards Swivel Gun yoke jig Swivel Gun soldering - mount, yoke, handles. Main mast standing rigging begins Shroud Lanyards Mounting the Bowsprit Bobstay & Forestay Naming Day Section 7 - Running Rigging Beginning the running rigging Sidebar - San Diego Festival of Sail trip (link to other thread) Running rigging completed Rope coils Anchor buoys End of the line ------------------------------ Beginning of build log: Just starting up the log with what appears to be the traditional 'unboxing' post. This was actually done on September 6th, but I did not see any point in opening a build log while I was still working on the Carmen, as I'm not going to attempt to do multiple builds at once yet (no room, even if I wanted to). I took inventory using the parts list included, and everything seems to be ship-shape. I will likely not actually begin working on this until the weekend, as I've got an idea for a display stand for the Carmen to take to my office (my not at home office), and now that I'm done building the Carmen, I want to read through the instructions and some build logs for the AVS before I begin. Until then, here are the unboxing photo's.

- 831 replies

-

- Armed Virginia Sloop

- Model Shipways

-

(and 1 more)

Tagged with:

-

I'm sure the suspense between posts was killing you. Heh. For the running rigging without sails, there is no plan in the kit, and not enough blocks to really do it right in a lot of areas (like the bowsprit done like the AVS). I looked at all sorts of different schooner build photos that were done without rigging in the gallery, and just sort of winged it. I posted earlier that I was short 3 single blocks. Well, it turned out that I was actually not short 3, but only 1, and that one was a block that I dropped sometime last week, and I've never been able to find it. The other two were attached to the booms where I actually should have installed double blocks. Woops. I cut off the singles and installed doubles in their place, leaving me only short the 1 block. I sanded down a double block to single thickness, and unless you know which block to inspect up close, there is no way to tell, so success! I also decided that the 'natural' seizing on all of the standing rigging just looked weird to me, so I changed it all to black. After one marathon rigging session, I present to you.. The finished Carmen! I'm obviously not a photographer, nor do I have a 'real' camera. Mixture of flash and no flash without great lighting. I should try to take some better photo's outside at lunch tomorrow if the hurricane doesn't actually decide to hit us.

- 119 replies

-

- carmen

- constructo

-

(and 2 more)

Tagged with:

-

Update for the last couple days. So when I started test fitting the yards it occurred to me that holding the proper angle was going to be really difficult using the rigging, let alone making sure they stayed straight front to rear, so I drilled some holes and added pins. Test fitting, pins worked great, look ma, no glue (or hands)! I didn't care for the "tie a rope between the jaws with square knots" method of yard attachment the kit instructed, so I got some small black glass beads and put them on with thread. I've decided after this that people who do beading for fun must be more insane than people that build little wooden ships. And mounted the yards in preparation for doing the running rigging, since I've decided not to do sails on this build. And, after taking this picture, I started working on the rigging, and completely forgot to take any progress photos. Oh well, next post will show the end of this evenings progress...

- 119 replies

-

- carmen

- constructo

-

(and 2 more)

Tagged with:

-

That's a lot of ropes and knots! Square rig is going to be a big step up in that department. Not sure if I'm looking forward to that given the 'interesting' time I'm having with my little schooner rig. Very nicely done David, she's certainly something you can display proudly.

- 439 replies

-

- victory

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks Keith, that is an interesting setup. Based on the noise it was making while working on this kit, I think my drill is not long for this world however! So I'm looking at the running rigging, and it turns out that my run of having 'extra' parts in this kit has come to an end. I am short 3 single blocks. I do have 3 extra deadeyes and 3 extra double blocks. I may try to sand down a double block and see if it will work as a single.

- 119 replies

-

- carmen

- constructo

-

(and 2 more)

Tagged with:

-

A new build I haven't seen before (well, an older build I suppose, but new to me). I've never seen the Astrolabe before, interesting how the first planking is not extended into the bow and stern filler. Will be interested to see how that works as you complete it. Great job so far, it's looking fine!

-

Went back and looked at your planking on the 3rd page, as I had skipped through that fairly fast when I first started following this log (there are just so many logs and so little time!). Wow, what an amazingly patient and analytical approach, but it turned out great! I'll have to re-read this a few times when I tackle my next project's planking.

-

Thank you for the kind words Testazyk, S.Coleman, and Lawrence. Lawrence, after reading through your Victory build over the last month, I'm fairly stunned that you could get anything at all out of my little Carmen build, but if indeed it helps you in some small way, then that makes me quite happy. Had a terrible 2.5 hour commute home tonight, and have a teleconference with the India group in about 15 minutes (one of many downsides of having part of your team almost exactly 1/2 way around the world, a 12.5 hour time difference), so I doubt I'll make much progress this evening, but I have a few details I would like to get done in preparation for the booms and gaffs to make their permanent home on the ship. I've decided to finish her without sails at this time, as I am just not up to all the stitching lines in the sails right now, and I think she looks great without sails, so the addition of the yards, and some running rigging should make for a nice display I think.

- 119 replies

-

- carmen

- constructo

-

(and 2 more)

Tagged with:

-

Hi Jon. Great looking build, but I have a question regarding the kit selection itself. The Mamoli kit is significantly more expensive than the MS kit, but I have not found a comparison between them. As they are the same scale I am curious as to what the reason is for the much higher cost of the Mamoli kit and wondered if you could shed some light on this. Thanks, and again, great build and log.

- 974 replies

-

- rattlesnake

- mamoli

-

(and 1 more)

Tagged with:

-

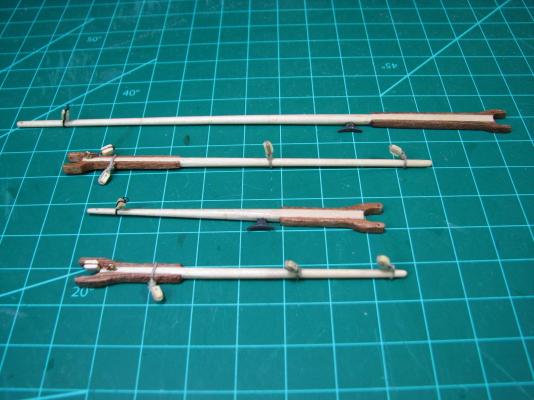

Thanks Russ, I owe it to another member here - I used a method from Bob's (bhermann) Bluenose build log. I marked the dowels at multiple points and transferred the size mechanically to the dowel at that point from the plans using the caliper. I then used sandpaper (for two of them chucked into a drill, and for the two shorter ones, I just sanded by hand while slowly turning the dowel) to sand them down to the marks. I then laid them on the plans directly to compare and finish. In this picture you can see all the bits and pieces, and the main boom has had the taper points transferred, but not yet sanded. This method worked very well for me, but I still want a lathe.

- 119 replies

-

- carmen

- constructo

-

(and 2 more)

Tagged with:

-

Just a bit of progress from this weekend and this evening, as I was working on moving lots of stored stuff (10 years worth of storage room accumulation) in preparation for a new hobby room. I had tapered the gaffs and booms, and glued the jaws?, clamped them, and left them to dry on Saturday. I completed the boom shaping yesterday, and then tonight I shaped the gaffs, and rigged all 4 pieces. These display an interesting 'history' of my block stropping, and I'm leaving them as is just for my own interest. First, the double blocks were stropped with the kit's copper wire to the eyebolts per the instructions. Second, after I got the blackened wire, the single blocks on the booms were stropped with the blackened wire in place of the bare copper. Third, tonight I read about the 'figure eight' rope stropping technique for attaching blocks to yards, and used that technique for the 6 single blocks attached to the gaffs. The rope system is really nice, and fast, and looks pretty good too! Here are the completed pieces before varnishing. And now, complete and drying.

- 119 replies

-

- carmen

- constructo

-

(and 2 more)

Tagged with:

-

Thanks glued. It's only clean because it's my library and office, so I'm trying to keep it from becoming a pile of sawdust while I'm working on turning another room into a dedicated hobby room that isn't filled with bookshelves and computers.

- 119 replies

-

- carmen

- constructo

-

(and 2 more)

Tagged with:

-

Fantastic job, very amazed that this is your first build.

- 76 replies

-

- san juan nepomuceno

- artesania latina

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.