-

Posts

1,145 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith_W

-

It was a long time since I built this kit, but I seem to remember that the frames were very flexible until the lower deck was installed. I suggest you dry fit the lower deck and see if it pulls the frames into alignment. Use it as a guide for further frames. IT IS VERY IMPORTANT that the frames are aligned, all sorts of trouble awaits you further down the build if they are not!

-

1. Is it within my skill level? 2. Do I like the look of the ship? The second point over-rules the first. I am way in too deep with my current build! Forced to obtain skills that I don't have. And if not, I have to repeat making parts until I get it right

-

Vince, it looks as if you have left excess wood and you are planning to shave it off later, after you determine the shape of the transom after you add the banisters? I too, am working on the transom (no pictures, because I have attempted to fabricate the same part five times and failed) - I took the shape of the transom decks off the plans, which will include the final curve of the rear transom piece. You will note that it is curved in one dimension, whereas the transom decks are curved in three dimensions! (Hence the high failure rate, each attempt seems to be off by 1mm or 2). Difficult for me to explain without a diagram, but I am overseas at the moment and do not have ready access to my plans so that I can show you.

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

It actually costs much less to buy it from Chuck. You would have to wind A LOT OF ROPE before it becomes economically feasible. Not to mention, having to shop for thread, learning to use the machine, botching up runs, and making the thread. For some on MSW, it may be worth it. But for me, I would much rather buy.

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

Keith_W replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Don't be so humble, Doris. Your RC really is the definitive RC build. It is a signal to the rest of us at MSW that what our current idea of a "magnificent" build is, is totally inadequate. If you can find me another RC build on MSW, or anywhere in the world, that exceeds yours in terms of detail, the fine-ness of the workmanship, and sheer beauty, I will quite happily name the other person the best RC builder in the world. But I am betting that you won't. So until then, YOU wear the crown, and you should be proud of it.- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

Yes, I know that the technique has been around for a while. That's how Rodin made his bronze busts. But what is new about this is the use of 3D printing and the ability to send CAD files through the net, and receive the finished casting in the mail. In the past you would have to make the casting yourself, make the mold, melt your own metal ... that's just a bit too much work for me

-

I came across this post in another forum. I thought that it would be of interest to MSW'ers, so I am reposting part of his post here: "These logos were custom designed by myself. They were made by shapeways in Solid silver (yep, silver). Cost around $70 each. Shapeways use lost form casting to produce these. They print the design in wax. Form a mould around the wax (probably plaster of paris or something). Then the molton silver is poured onto the wax. The wax dissappears and what you see is left. They even cast with platinum (dont ask what the price for platinum is)." (That's AUD$70, i.e. about USD$50). The company he refers to is this one: http://www.shapeways.com/ This process might be useful to make plaques for our models, and maybe castings for bow and stern decorations. I haven't checked yet, but they may be able to use a cheaper metal if it's "only" for castings. Given that I will be spending 3 years of my life on my current model, I think that about $100 for a nice silver plaque would be worth it!

-

Proxxon Micro MBS 240/E Band Saw Review

Keith_W replied to Blue Ensign's topic in Modeling tools and Workshop Equipment

Thank you Mike. Looks as if that's now on my shopping list. -

Proxxon Micro MBS 240/E Band Saw Review

Keith_W replied to Blue Ensign's topic in Modeling tools and Workshop Equipment

Mike, a question. Are you able to cut metal with this bandsaw? -

Unsticking White Glue

Keith_W replied to shortgrass's topic in Building, Framing, Planking and plating a ships hull and deck

Use Isopropyl Alcohol which you can buy from a hardware store. Use your hobby knife to make some incisions in the glue - that helps the alcohol penetrate and work faster. Keep brushing it on (because it evaporates very quickly), and use your knife to scrape away softened glue to help more alcohol enter the joint. -

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

Keith_W replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Your model room is amazing! You could have a one person exhibition right there!- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

How would you improve your Byrnes tools?

Keith_W replied to Keith_W's topic in Modeling tools and Workshop Equipment

Thank you for getting the thread back on topic, Danny. My intention was for this thread to be feedback for Jim and Donna to improve their tools, or to create new offerings. Not for how individual users could modify their own tools. I probably wasn't very clear about this in my first post. -

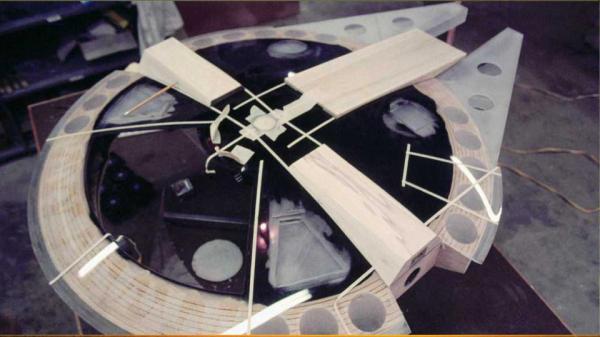

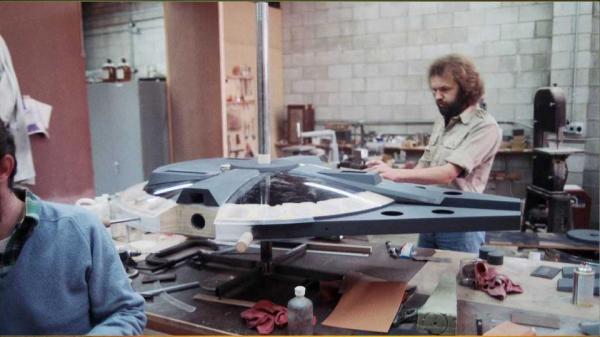

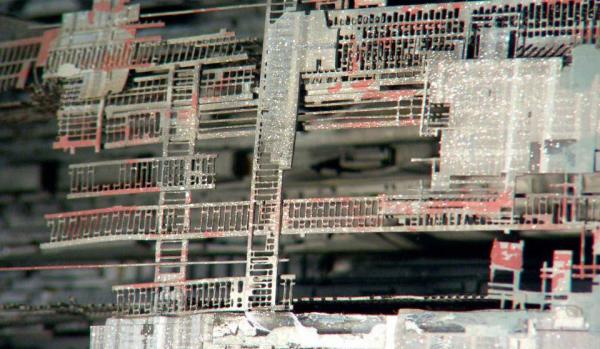

Want to be impressed? Want to be really impressed? Well, head over here: http://slightlywarped.com/detailed-close-ups-of-star-wars-spaceships/ You will see what professional model makers can do. They MUST make their models look realistic, because it's going to appear on film! Here is a sample.

-

How would you improve your Byrnes tools?

Keith_W replied to Keith_W's topic in Modeling tools and Workshop Equipment

Thanks nobotch, but I might point out that the link in the first line of your post links back to this thread. Could you fix this please? -

How would you improve your Byrnes tools?

Keith_W replied to Keith_W's topic in Modeling tools and Workshop Equipment

Thomas, I have the auxillary tilting table but I have only used it ONCE ... to make a test cut. Part of the reason is because it is really annoying to remove the fence and then try not to misplace the screws. I have other ways to cut a bevel which involve much less fuss, but if there is one particular kind of cut that you need, then the tilting table is the best way to do it. -

OK this is NOT a thread to complain about Byrnes tools. If you want to do that, start your own thread! I am a happy and proud owner of all of Jim's tools (with the exception of the Rope Walk), and I have used some of them for more than a year now. My intention is for us as a community to point out areas that we think can be improved, or new tools or accessories we would like to see them stock. Here are a few off the top of my head. Byrnes table saw. - FENCE. Would be good if the fence was easier to remove. From memory, it requires undoing about 6 screws. For that, I have to find the correct sized Allen key and make sure I don't lose the screws after I remove them. - RIVING KNIFE. Most full sized saws have this as standard. Would it be possible to offer this as an accessory? - THIN RIPPING JIG. Would be good to offer this as an accessory. See this thread: http://modelshipworld.com/index.php/topic/10585-thin-ripping-jig-for-the-byrnes-table-saw/ Byrnes draw plate - LARGER HOLES. Please offer another drawplate for sale, this time with larger holes. It would be extremely useful for pulling dowels down to size. I am not suggesting you replace the current drawplate (which is darn near perfect), but offer another drawplate with larger holes. Byrnes Disc Sander - At the moment it is not possible to change sanding grits without destroying the stick-on sandpaper. It would help if the machined disc was interchangeable (and you offer additional metal discs as accessories) so that we can have a selection of grits handy.

-

Hi Don, no need to use a PVC pipe. I filled my bathtub 1/4 with water and simply threw the planks in there for a couple of hours. Usually, I chuck them in the water before going to work, then take them out when I get back - that's 10 hours, but from experience 2-3 hours is all you need. Maybe more if you are trying to bend a stiff, brittle wood like walnut. Then you need a few minutes with the steam iron to get them into shape, then 24 hours to dry in the sun and they are ready. A drop plank is where 3 planks become two, as per this diagram:

-

Beautiful ship, Alex. So good to see her finished. She truly is museum quality.

- 227 replies

-

- cumberland

- 74 gun

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.