-

Posts

1,145 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith_W

-

Hi Christine, to bend your planks, use a steam iron after soaking them. Turn your iron on to maximum, then place your soaked planks under the iron for a few seconds. Then, move you iron away whilst using the edge of the iron to bend the planks. Most people would recommend that you NOT nail the planks to the frame. Rather, you should glue the planks using PVA (white) glue and clamp it until the glue is cured. You can make a simple clamp out of paper clips, like this:

-

Amazingly accurately constructed. You are doing a great job.

- 346 replies

-

- terror

- polar exploration

-

(and 2 more)

Tagged with:

-

Arrrr. She's a fine boat, she is. Well done, Cap'n.

- 625 replies

-

- bounty launch

- model shipways

-

(and 1 more)

Tagged with:

-

Hi Ray, it's time for me to jump in. A few days ago, I thought I would research this frigate as my next build. A search brought me to your log, which I have read every evening before going to bed. You may have noticed from the "likes" you started receiving for posts made a couple of years ago Congratulations on your build, she is a masterpiece and something for all of us to aspire to. And thanks for sharing with us.

- 536 replies

-

- diana

- caldercraft

-

(and 1 more)

Tagged with:

-

3D Printing - Not Just Yet!

Keith_W replied to dvm27's topic in CAD and 3D Modelling/Drafting Plans with Software

Some months ago I started that other thread on 3D Printers. After doing some research and looking at actual 3D printed samples, my conclusion was the same as Pat's. Affordable 3D printers are a waste of time if you are a ship modeller. The resolution is too low, and the parts are too crude to be of any use. At this point in time, it is better to pay someone to make the print for you. -

Thomas, on my Bounty I failed to edge glue the planks. That's why over time, the gaps between the planks appeared. If I were to do it again, I would definitely edge glue the planks and wipe off the excess. As for what's inside, once you build it up and fill her with barrels, stones, etc you won't see the other side of the planking - so don't worry about it. More important to make sure those planks are snug and well glued.

-

GO START YOUR BUILD LOG NOW!!!!!!!!!

-

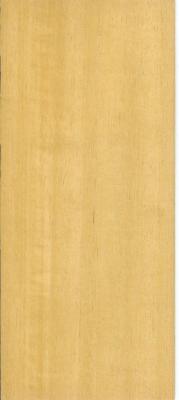

Ramin is a yellow coloured wood, which is medium grained. This is an image I pulled off a Google search, and is a reasonable approximation of what AL typically supplies in their kits: As for 6mm x 5mm x 730mm, time to get your ruler out. That is an almost square dowel. Pull out all the long yellow squarish dowels from your kit and measure them. (EDIT) I should note that 6mm x 5mm x 730mm seems like a very odd shape. If it is for planking, are you sure that the instructions don't say ... 6mm x 0.5mm x 730mm?

-

Izzy, I agree with Jason. I prefer Vallejo. Before this, I used Tamiya and Mr. Hobby. The advantage of Vallejo is that they come in squeeze bottles, meaning that they won't dry out and cause the cap to be stuck to the glass jar (anybody who has ever used Tamiya paints will know this!). They are also really finely ground, and spread very nicely. I squeeze out a tiny bit of paint directly onto the model, or onto a piece of cardboard, depending on how much control I need over the paint.

-

Perhaps I am a little influenced by Chris Watton's comment on the other thread where he says that his new HMS Prince kit is nearly the same size as the old kit, despite the new kit being designed for a larger scale. When I asked him why, his reply was that the older kit was not accurately scaled, along with some other mistakes.

-

Congratulations, Vince. You do know that Chris Watton is working on a new HMS Prince to replace the one Amati removed from the catalogue, don't you. That one seems to be a few years away, but it's on my bucket list.

-

How do you break a laser machine, out of curiosity?

-

Anton, are you human? Your first picture showing the bashed boat and sprayed grey with primer ... is only 2 hours earlier than the painted and finished boat. Paint doesn't dry that quick, let alone painting detail upon detail, and time spent photographing and uploading pics to MSW. In the same amount of time, I have had a relaxing dinner and opened a bottle of wine. I feel so unproductive compared to you!

-

Thanks for the update RMC, she's beautiful. This ship is on my bucket list (I have a very big bucket) but i'm not sure if I should even attempt it given that yours is likely to be the definitive Vanguard build

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.