-

Posts

10,524 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ccoyle

-

Great idea -- and I love the precision "clamps"!

- 216 replies

-

- masterkorabel

- ships

-

(and 3 more)

Tagged with:

-

If anyone is interested in this kit, Model Expo currently has it on sale for $69.99, which is a good price.

- 117 replies

-

Kit Review Harbor Tug WARATAH 1902 - HMV - 1/250 - CARD

ccoyle replied to ccoyle's topic in REVIEWS: Model kits

I'm not clear on what you are asking for. Did you order the laser-cut detail set but not the actual kit itself? Because the instructions come with the kit. -

Very striking! I enjoyed the sequence of photos showing the yard being hoisted. Cheers!

- 59 replies

-

- Billing Boats

- Le Martegaou

-

(and 1 more)

Tagged with:

-

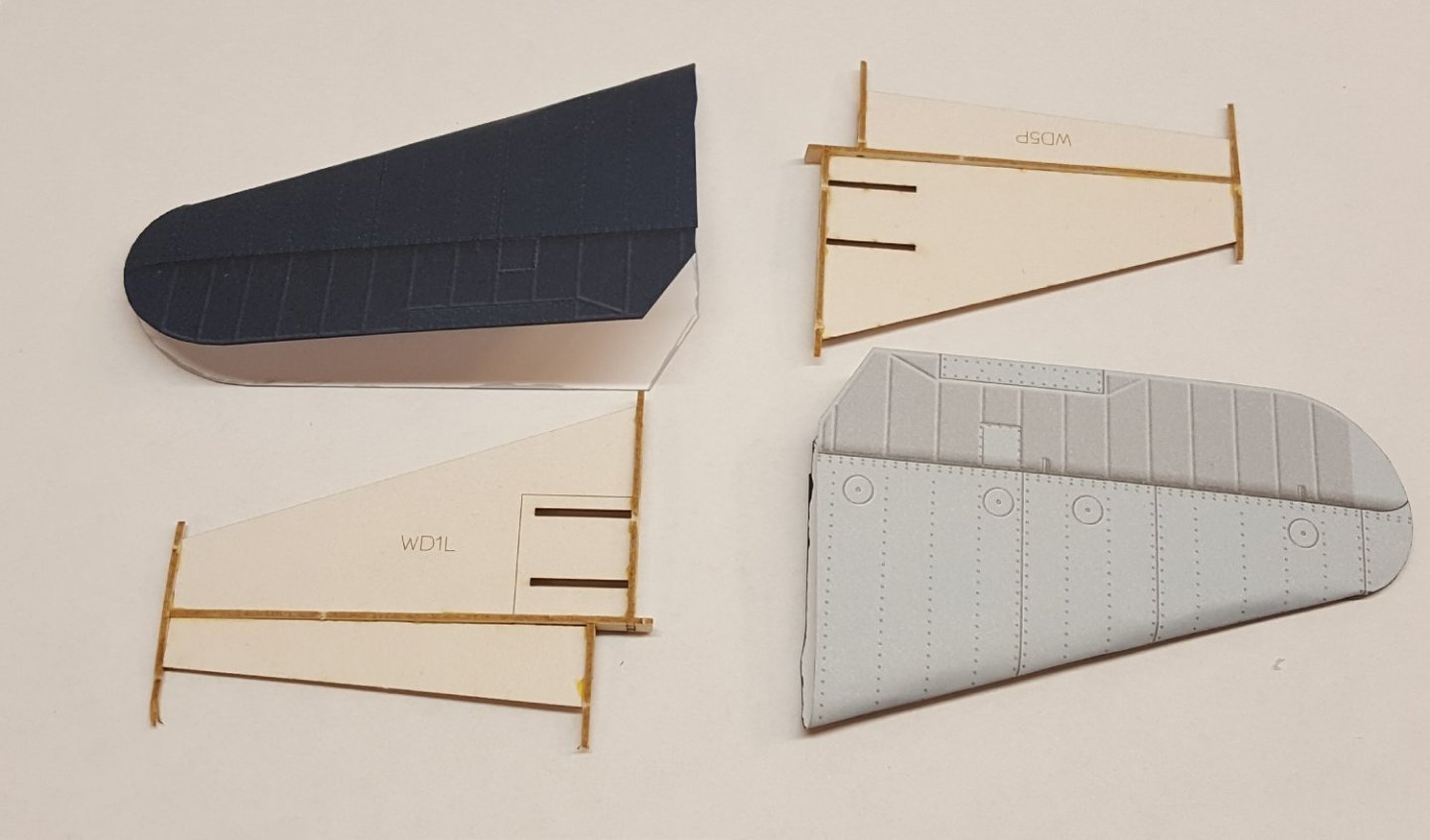

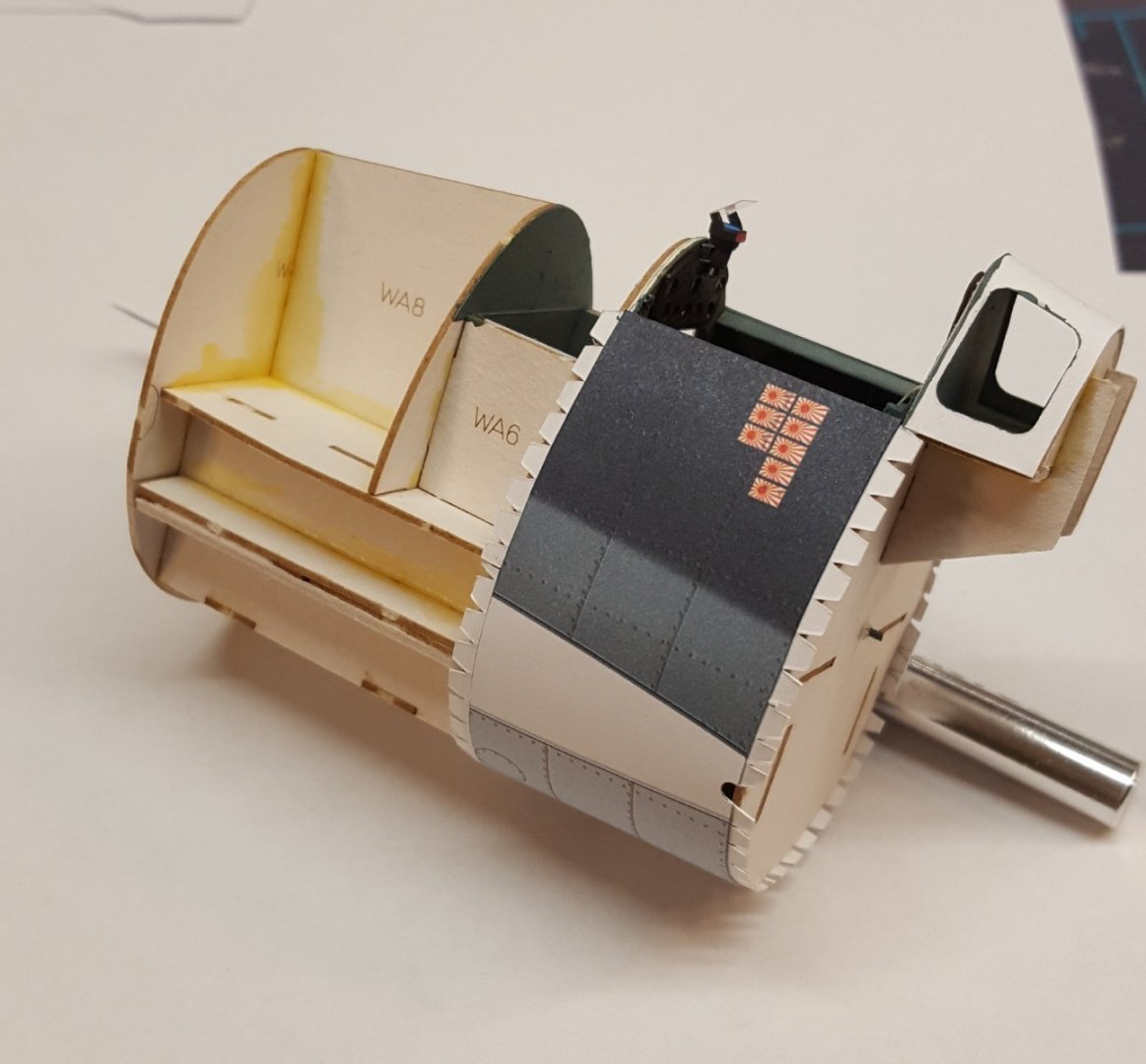

Sub-structure for horizontal stabilizers finished and skins cut out. I won't glue these together until I have the fuselage finished and can then better judge the spatial relationship between frames & skin. And first fuselage skin attached. Fit looks good so far. Dion, I'll have to look into your suggestion.

-

Photo Reference Library

ccoyle replied to JSGerson's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

The most likely reasons are no one has asked for one (or at least very few people have asked), and it would probably entail a not insignificant amount of work for an MSW staff member. On top of those two reasons, sharing photos gleaned from the internet often constitutes some form of IP infringement. -

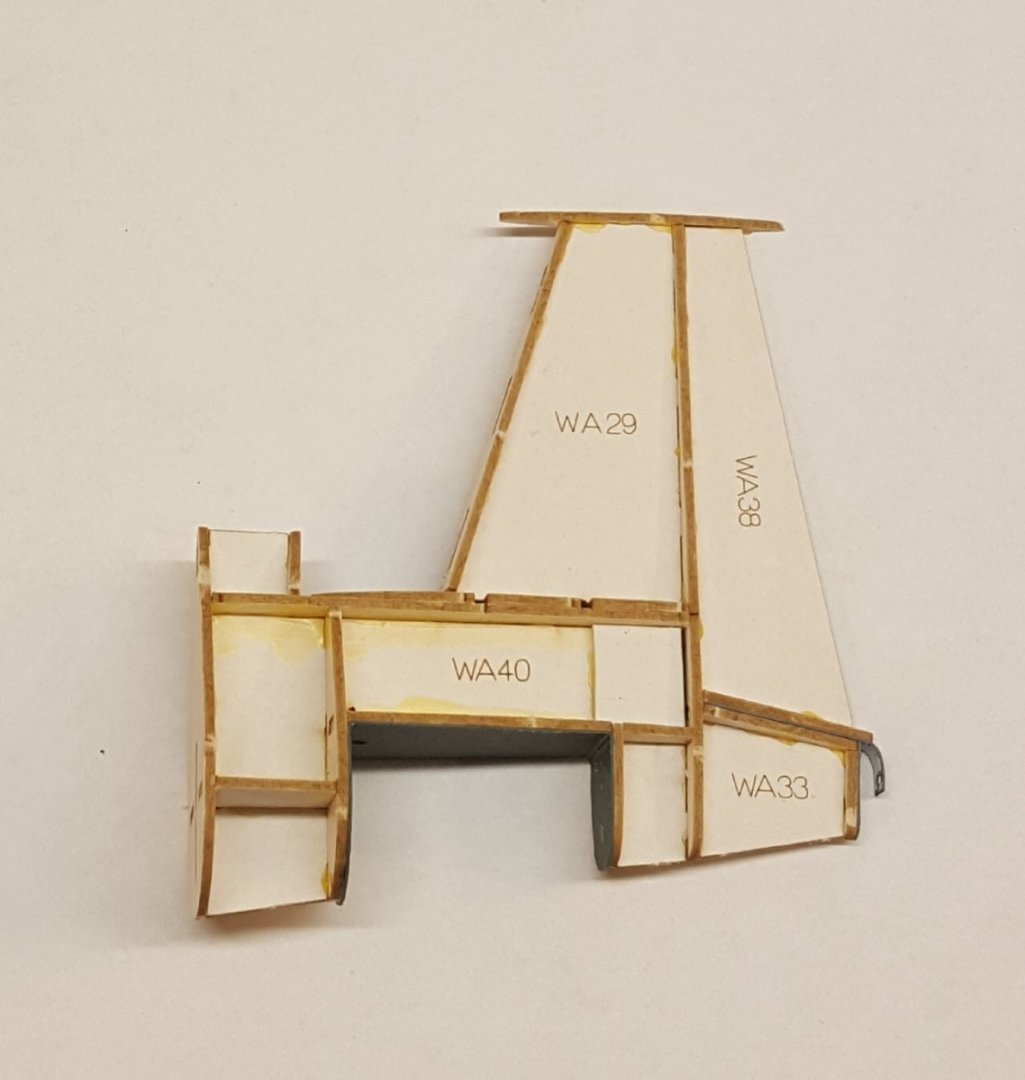

Finished the sub-structure for the empennage. There was quite a bit of confusion with this bit, because first of all I don't read Polish, which meant it took me awhile to catch on to there being different laser-cut parts for the options described back in post #28. I ended up using the wrong main profile former, which subsequently required some minor fixes. Also, the parts numbering system is unlike anything I've seen in any other publisher's kits, which again is very confusing for non-Polish speakers. But who doesn't like a challenge, right? 🙄😆 There's an inner skin that wraps around the tail wheel well, which I have added but didn't get a picture of -- cuz it's not all that interesting. Cheers!

-

Welcome! Great intro!

-

Dude -- we have an entire continent's worth of indigenous workboat types that Chris hasn't touched yet, should he ever get the urge to try something different.

- 16 replies

-

- Ranger

- Vanguard Models

-

(and 2 more)

Tagged with:

-

I realized while working on the sub-structure for the empennage that the kit provides alternative internal parts for making separate control surfaces, so I need to make the decision about those real soon. I'm leaning away from the separate parts at the moment, since this is a presentation model, and separate control surface, despite their 'cool' factor, come at the cost of increased complexity and a greater potential for boogering things. Clean looks are more important on this model than extra detail.

-

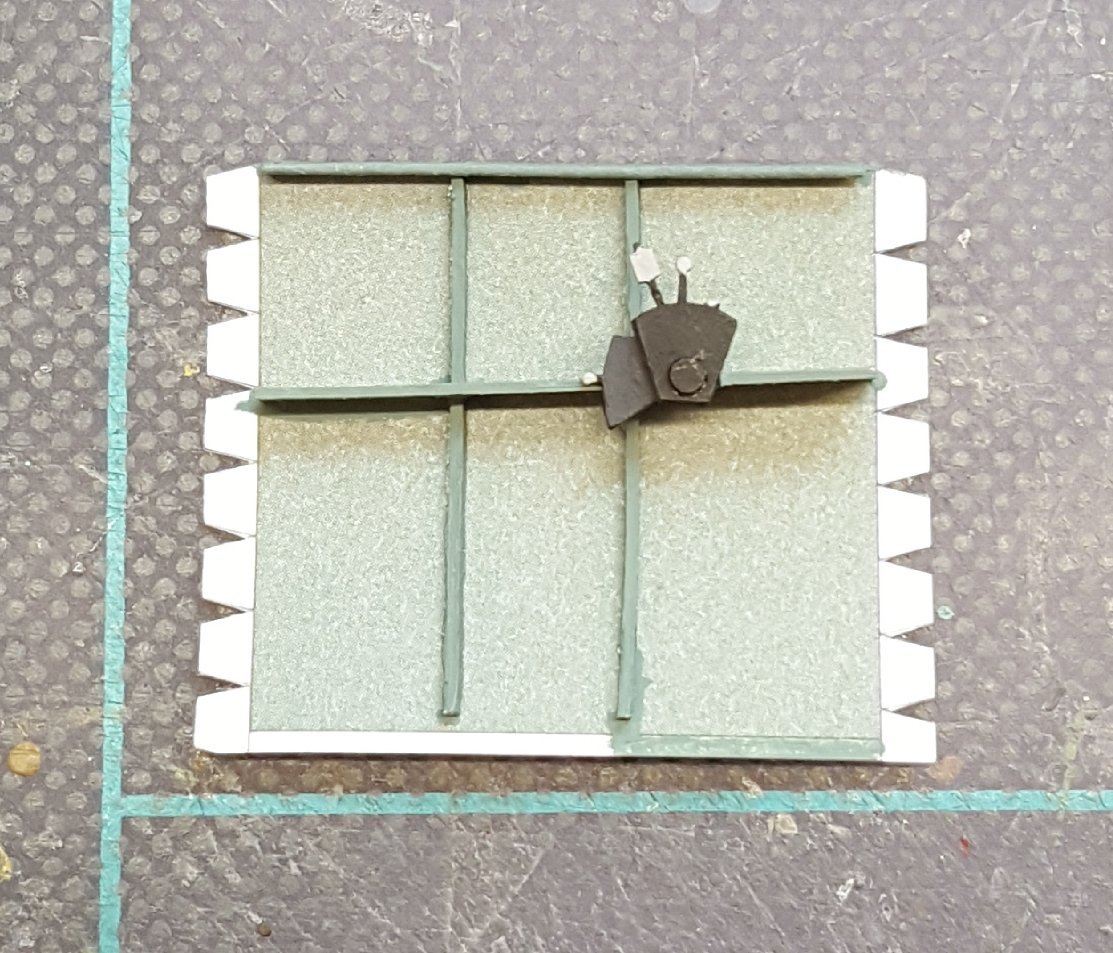

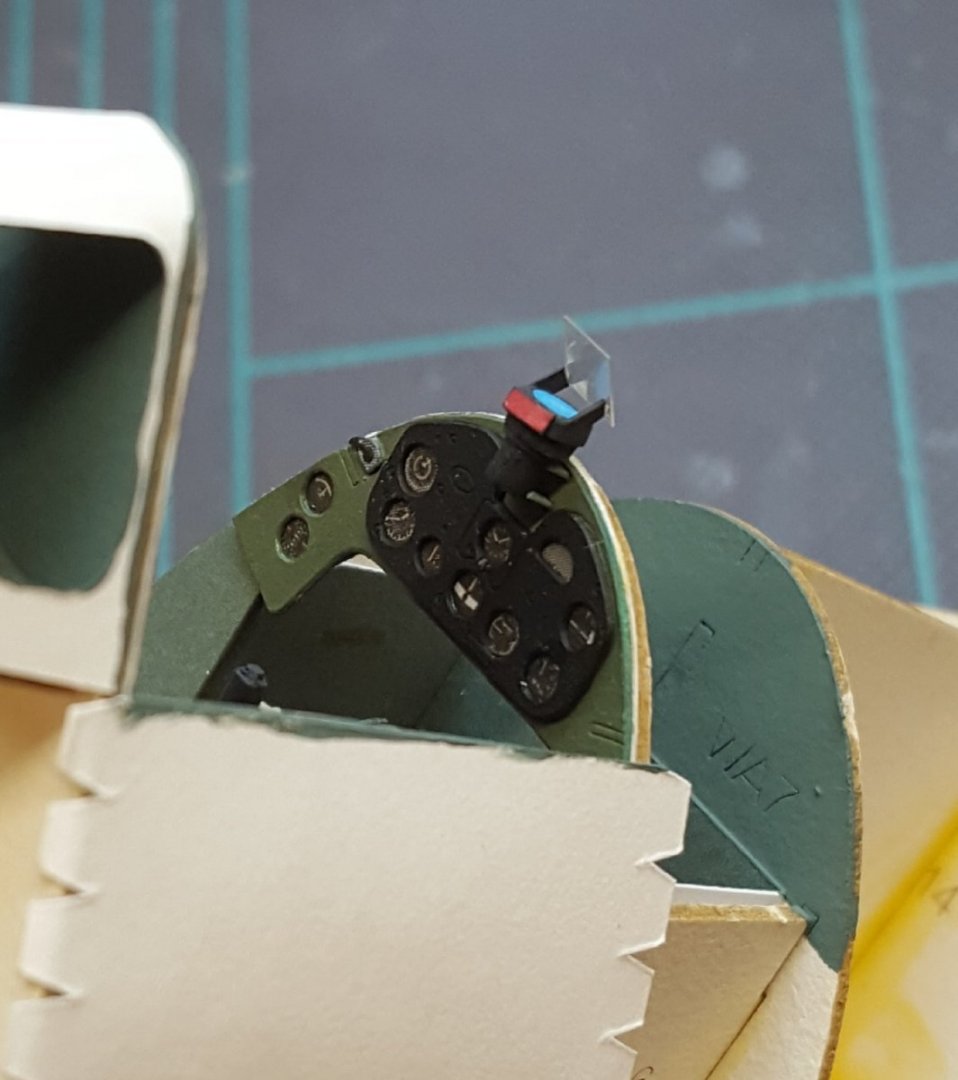

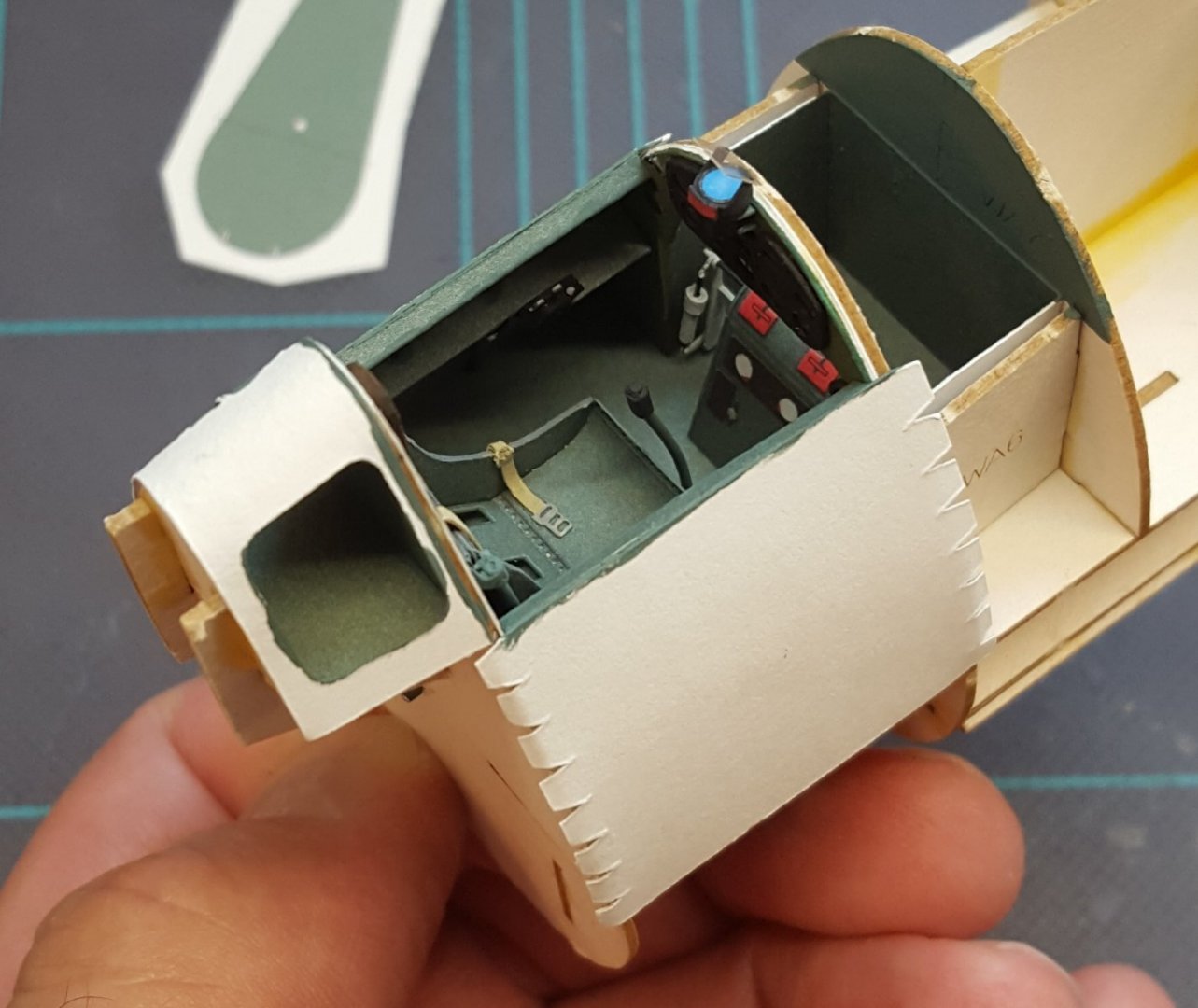

Cockpit is done now. First we have the port-side wall, which I'm fairly certain is way over-simplified, since it has only a single quadrant. Then the reflector sight. Laser-cut parts were provided for this, but -- believe it or not -- they were just too delicate. The sight was easier to make with the original card parts. And finally we have the port wall attached to the fuselage. As is usual with airplane models, much of the hard work done on the cockpit will subsequently evade much notice. Cheers!

-

Totally depends on if you can live with yourself afterwards

-

Welcome aboard, Jim!

-

So, is this a different kit than the 1/72 scale gunboat that was in development back in 2020? I'm just trying to figure out where this kit is in relationship to the other kits in the development pipeline. Would also really like to see some progress reports on those other kits! (hint hint)

- 216 replies

-

- masterkorabel

- ships

-

(and 3 more)

Tagged with:

-

Beautiful job -- congratulations! The case looks great, too. Cheers!

- 157 replies

-

- model shipways

- syren

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.