-

Posts

3,267 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by KeithAug

-

-

-

Tadheus

lovely work and very realistic.

- tadheus, Gerhardvienna, mtaylor and 1 other

-

4

4

-

Tom,

Yes hand tools only. Power tools were limited to a mini craft drill, a Black and Decker hand drill and a soldering iron. I didn't even have a power sander. I managed to make a lot of the circular parts out of nesting brass tubes - I got a huge bag of offcuts from a local model shop. What little turning I needed to do was done with the black and decker and various files. I bought the frigates props / shafts / rudders but apart from that all the other metalwork was hand made. That said I don't think I would ever want to do without a lathe and mill now. Both were bought 4 years ago and I rely on them a lot.

I did buy planking pre cut - but this was an expensive option and now I cut my own - as illustrated earlier in my build log.

I have now adopted a policy of if If I need a power tool I buy it or make it, life as a result is much easier.

Tom / Jorgen

Thank you for your kind comments.

- mtaylor, thomaslambo, wyz and 1 other

-

4

4

-

Hello Julie welcome back.

Having completed the balsa backing I sanded it level with the deck frames.

I did the first planking working from deck level to keel.

I then fitted and glued the deck in place.

I then fitted the deck edge plank.

I then sanded the 1st planking. The edges of the plywood deck and deck edge plank being sanded as I sanded the hull planking.

I then did the 2nd planking.

The advantage of this sequence is that the second planking comes all the way up to deck level and covers the edges of the plywood and deck edge plank.

I think you could adopt the above sequence and use the first plank to correct your dip by sitting the deck on the plank locally with a bit of shimming on top of the frames to support it.

-

Hi Jorgen

Thanks of the feedback.

You clearly have skill - with practice you will be soon be achieving the quality of work you aspire to.

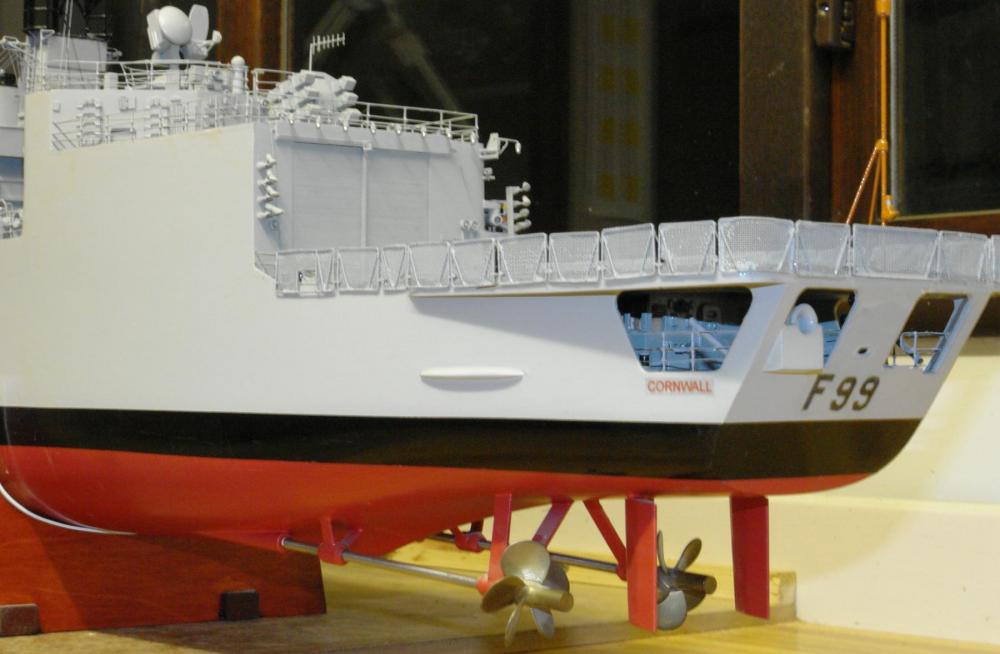

For many years I had relatively simple tools - here are a couple of models I produced with only hand tools and a model makers hand drill.

The tug was my first model - a kit.

The frigate was my second - scratch build

-

Boyd

This is a lovely build and I love your attention to detail and quality of work.

-

-

-

-

-

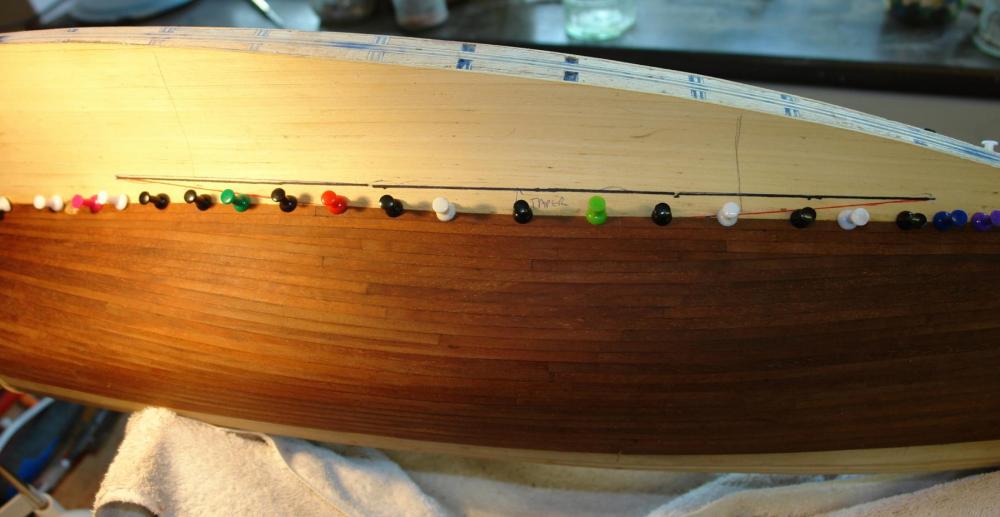

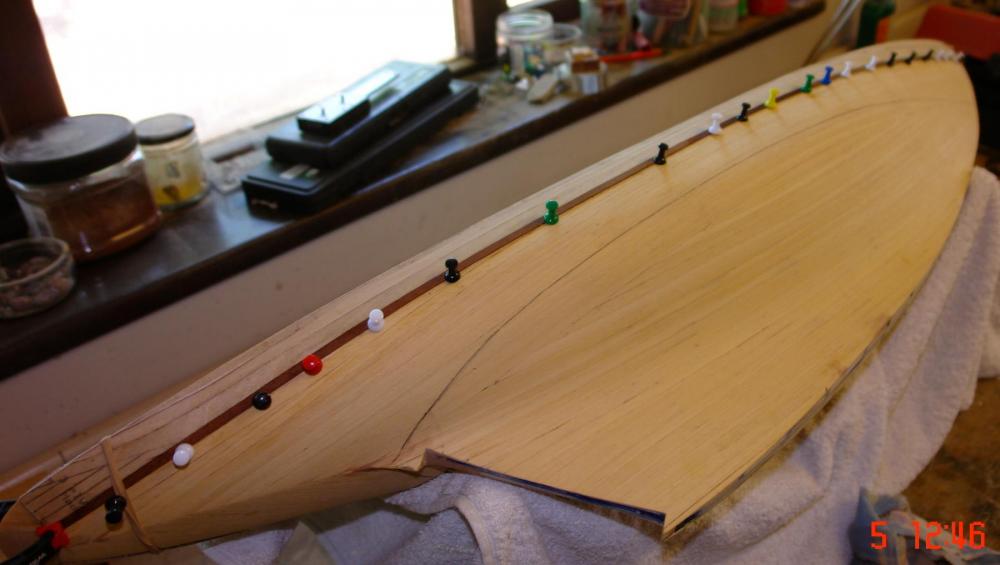

Appart from doing other stuff I have found a bit of time to progress the planking.

On my last post I had started attaching the taper planks.

I progressed the taper planks which started having the desired effect of filling the area of maximum beam while limiting the degree of bending in the stiff direction of the plank. I also planked the end of the keel in front of the rudder position.

You may remember form a previous post I had marked the hull and identified where i would get to if I had pressed on with parallel planking (red line). Also you may recall that i wanted to end up at the black line. The plan worked reasonably well as illustrated by the photographs.

I did have to do a fairly complicated adjustment by letting in a fillet pieces at one position on each side. See 4th plank down on the next photo.

Much of the tricky planking is now done and most of the remaining planks will parallel, supplemented by finely tapered wedges to fill out the rear of keel.

- tadheus, tasmanian, thomaslambo and 8 others

-

11

11

-

So here is my solution to creating uniform shallow taper planks.

I have a home made thickness sander attachment for my milling machine as follows:-

The oak plank up-stand is pivoted about the end towards the front of the photo with coarse adjustment being achieved by the screw adjuster to the right of the oak plank. Fine adjustment down to thousands of an inch is achieved by using the mill table adjustment. It all works very well for sanding parallel planks.

I realised I could use the thickness sander to taper sand by setting the oak plank at the desired angle and sticking the workpiece to the the oak plank using double sided tape. Then by traversing the workpiece past the sanding drum (using the mill table) I was able taper sand the workpiece. I should explain that the final planks were going to be slit from the tapered workpiece using the table saw.

I wanted a taper of about 1/3 of a degree over the 15 inch length of the workpiece - which equates to the narrow end being about 1/2 the thickness of the wide end.

This photo shows the tapered workpiece laid alongside a parallel workpiece.

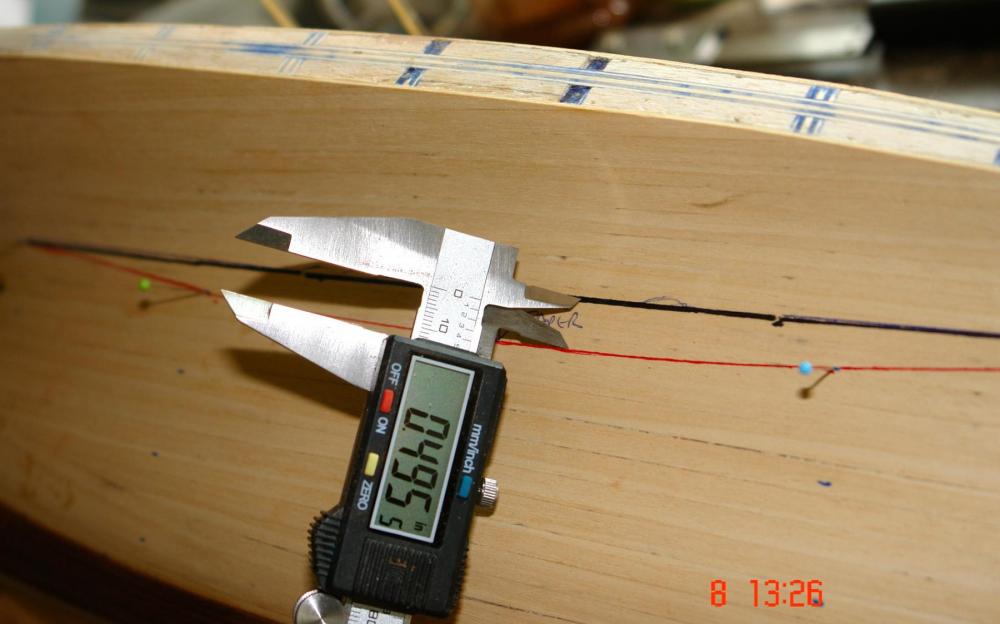

And the dimensions achieved.

The final photos show the tapered planks being attached to the hull.

- aviaamator, Julie Mo, Nirvana and 5 others

-

8

8

-

For interest - here is what the real thing looks like.

Hopefully the model will do the original justice.

- dgbot, Landlubber Mike, Nirvana and 2 others

-

5

5

-

Thank you Mark and John for your supportive comments.

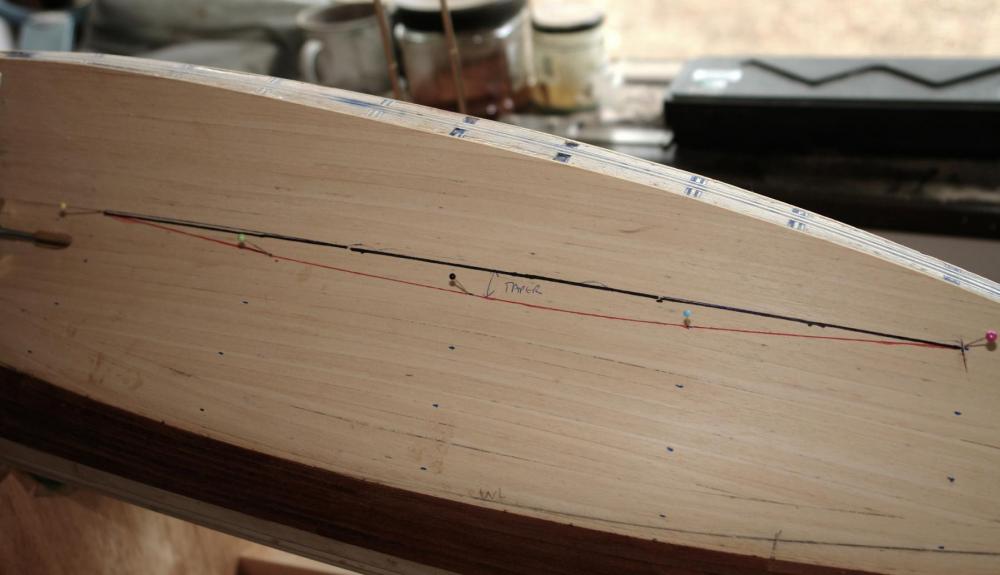

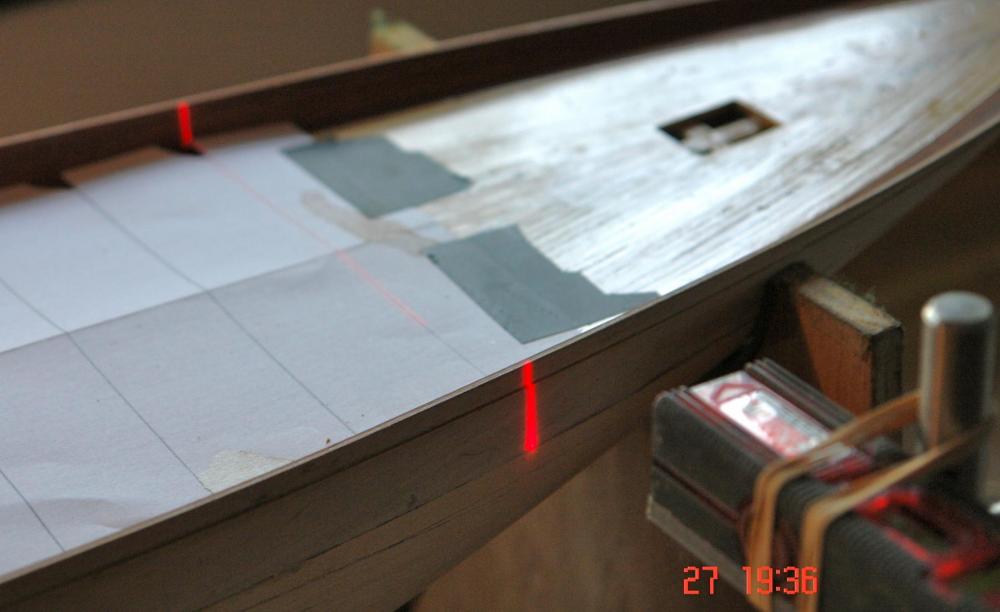

I have been progressed a little with the hull 2nd planking.

I find it is quite easy to over think the planking and I prefer to just get on with it and let the planks tell me when they are finding it difficult to follow one another. In this case this started to occur after the 8th / 9th parallel plank. At this stage I marked off the hull as though I would continue with parallel planks. This produced the red line on the photo. I concluded that planking to the red line (even if it was possible) would produce a quite unrealistic planking effect on the keel so I drew the black line to represent where I wanted the planks to fall.

Measuring the space between the lines gave me an indication of how much "extra" planking width I would have to find at the waist - .495 inch (about 3 plank widths) in this case.

I now need a cunning plan for manufacturing a reasonable number of accurately formed taper planks. I feel a bit of experimenting coming on.

-

-

Before getting too far into the 2nd planking I needed to drill the holes to take the hawse pipes (one on either side of the bow). These are at a compound angle flaring outward and forward as they descend through hull. Three options were available for drilling as follows:-

1, Drill from the deck and exit the drill through the hull.

2, Drill from the hull and exit the drill through the deck.

3, Drill half way from the deck and half way from the hull - meeting in the middle!!!!!

Option 3 would appear to be bonkers however............

Options 1 and 2 have the potential for the exit holes to be out of position - which I thought would look awful. So option 3 it was!

I marked guide lines on the hull at the correct angle and used my hand held drill carefully judging the correct angle. By using a smaller drill than the final hole size and enlarging it with a circular needle file I did manage to make the holes join up. I finished with a 0.16" (4mm reamer to clean up the holes so the hawse pipe would fit snugly.

-

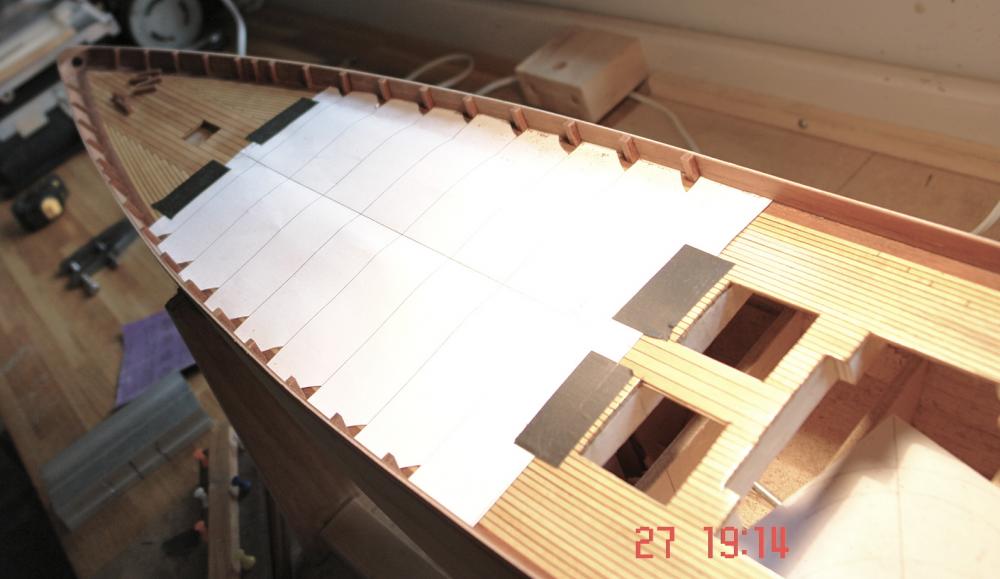

Having completed the ribs I decided to attach the 3rd of the profiled 1/32 inch (actually .036') plywood layers that went to create the profile at the upper edge of the hull.

With this in place it was time to commence the second mahogany planking. This was cut from the old table top mentioned earlier. The planks were .036" x .180" x 15 inch. The first plank went on butting up to the step created by the 3rd plywood layer.

the bulwarks have turned out well and are very solid - testament to the strength of layers of laminated plywood.

3 layers of planking now in place.

so far, so good.

I should probably explain at this stage that the plywood will be painted white while and I am considering leaving the mahogany visible - probably satin poly.

- KORTES, mtaylor, thomaslambo and 6 others

-

9

9

-

I managed to get enough time to complete the ribs. I was struggling a bit to see the laser line until I realised the batteries were about 10 years old. the new ones improved matters greatly.........

With all the ribs attached I used a flexible dowel (zero kerf) pull saw to trim them back to the height of the bulwark.

-

Michael

Sorry my reply wasn't easy for you to understand.

This is the type of blade I use. Sold by www.rdgtools.co.uk.

It is a bit too big for your table saw.

4" HSS SLITTING SAW 0.8mm WIDE / 1" BORE

MAXIMUM UP TO 130 TEETH FOR BETTER CUTTING

SEE OUR OTHER SLITTING SAWS

Be sure to add me to your favourites list!

-

-

Michael

I use a metal cutting slitting saw blade which is 1/32 (.031) inch wide and has zero kerf. This gives me an almost polished finish to the planks and control on thickness of +/- .0015 inch. The blade has 108 teeth and was bought off the web for about £6 (probably originated from China). I don't have a Proxxon saw and I think the problem you are going to encounter is getting a slitting saw bade of 80mm X 10mm bore. I think this sizing is pretty much exclusive to Proxxon (unless someone else know different).

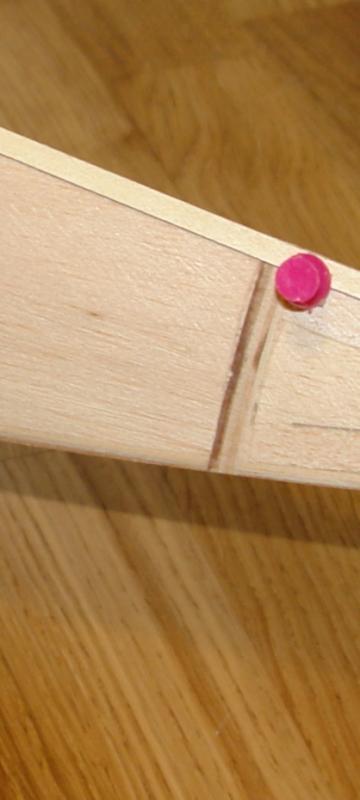

Example of my planks cut with the blade described above :-

-

Hello Francis

I have never found a way around the 2MB limit other than resizing the image in the camera or cropping the image on the computer.

Keep me posted on your progress.

Regards

-

Francis

I should add that their is more than one way to skin a cat and your option of leaving the fore keel frames square and then adding triangular stock is equally valid. If you look at my Altair link below you will see that it adopts the alternative method you suggest.

Regards

-

Hello Francis

I am happy to help but I may need a bit more information to understand your questions.

In terms of the balsa backing what I did was as follows:-

I initially didn't remove the scorched edges of the frames because I wanted to use them as a guide when sanding.

I then sanded the balsa back to the frames. On the fore and aft frames the sanding removes only some of the scorching. This because the curvature of the hull means that the frames themselves have to be flared. The trick is to leave a very thin line of scorching at the high edge of the frame.

See Photo - At this point the sanding of the balsa is complete.

On the middle frames (which have minimal flare) I sanded the backing until the scorching on the frames was lightly removed.

I'm not quite following your point re the sharp V on the keel. The bulb of the keel is a round shape which transitions to a sharp V as you move forward. Anyway I didn't find the need to leave it square and then glue on triangular stock. I just shaded the longitudinal frames to form the sharp V.

To get the planking sharp at the keel I laid the planks with circa 1/4 inch overhang. I then sanded them back from the opposite side of the hull. Making sure that the sanding block was always parallel with the opposite side of the hull, and taking care not to remove more of the already sanded balsa / frames on that side. I then did the opposite when I had planked the other side.

The attached photo shows the frames sanded to a sharp v and the planks being attached with a overhang

I hope that makes sense, but if not get back to me.

I'm happy to answer any other questions.

Are you planning to do a building log - it would help me to understand your questions better and perhaps give some pre warning of issues you might be about to encounter.

Regards.

Altair 1931 by KeithAug - FINISHED - Scale 1:32 - schooner

in - Build logs for subjects built 1901 - Present Day

Posted

I am nearing completion of the hull second planking so a few photos to show progress. By this stage all the remaining planks are parallel so the job is becoming much easier. You can see that I have had to add a couple of wedge pieces to fill out the back of the keel.

I have started looking for fill in jobs while the glue dries on the last plank. Here I have planked the stern.

I have also started doing a bit of rough sanding to get the hull planks smooth.

I also sanded the stem ready to lay up the longitudinal planks from which stem profile is shaped.

Only about 8 planks to go before the hull planking is complete.